In the realm of manufacturing and machining, the choice of materials for tool arms and attachments plays a pivotal role in determining the overall performance and efficiency of operations. Steel tool arms have long been favored for their strength and durability, while aluminum attachments are increasingly gaining traction due to their lightweight properties and versatility. Understanding the characteristics of these materials is essential for professionals seeking to optimize their equipment for specific tasks.

This article delves into the comparative analysis of steel tool arms and aluminum attachments, exploring various factors that influence their effectiveness in different applications. The decision between steel and aluminum is not merely a matter of preference; it involves a careful consideration of the specific requirements of the task at hand. Steel, known for its robustness, is often the go-to choice for heavy-duty applications where strength is paramount.

On the other hand, aluminum offers unique advantages in terms of weight and adaptability, making it suitable for a range of lighter applications. As industries evolve and demand for efficiency increases, understanding the nuances of these materials becomes crucial for making informed decisions.

Key Takeaways

- Steel tool arms offer superior strength and durability compared to aluminum attachments

- Aluminum attachments are lighter and more maneuverable, making them suitable for certain applications

- Steel tool arms are more cost-effective in the long run due to their durability and longevity

- Both steel and aluminum have different levels of corrosion resistance, impacting their longevity

- Consider the specific application and machinery compatibility when choosing between steel and aluminum attachments

Strength and Durability Comparison

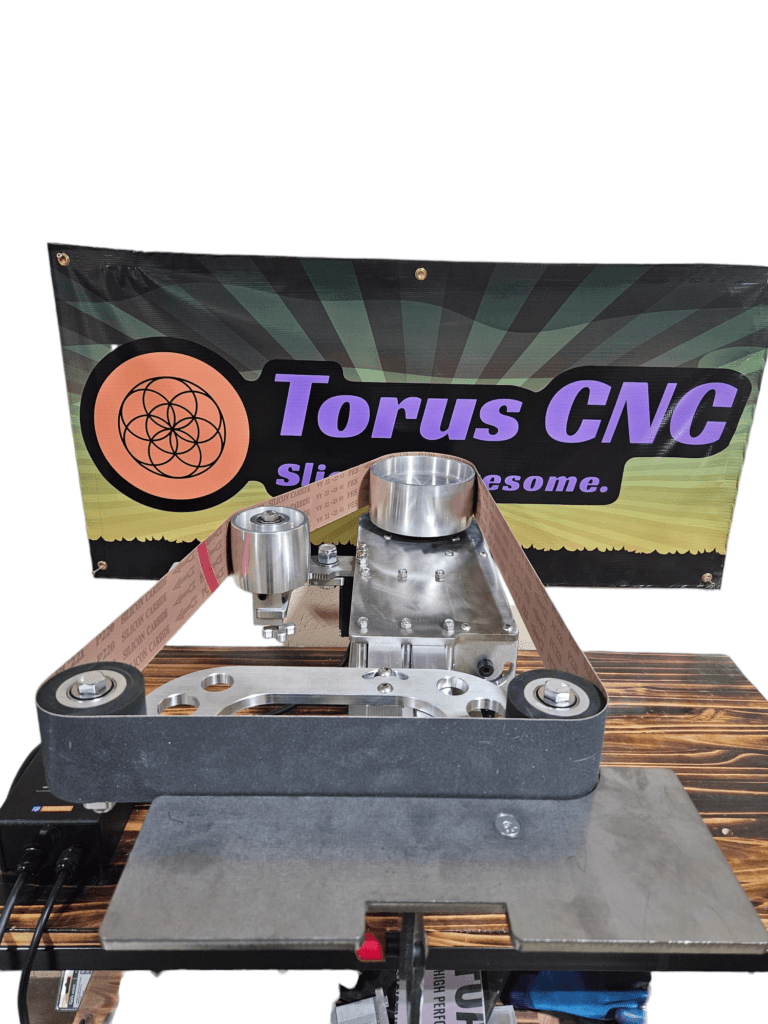

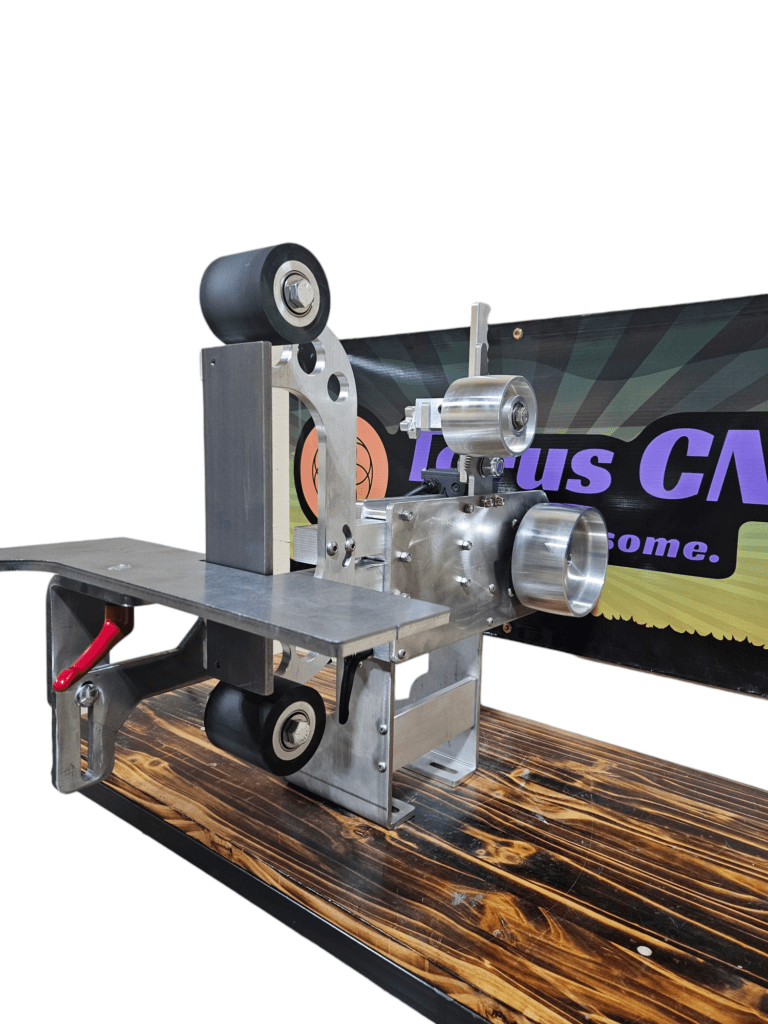

When evaluating steel tool arms against aluminum attachments, strength and durability emerge as critical factors. Steel is renowned for its exceptional tensile strength, which allows it to withstand significant loads without deforming or breaking. This characteristic makes steel an ideal choice for applications that involve heavy machining or high-stress environments.

The inherent toughness of steel ensures that tool arms can endure rigorous use over extended periods, reducing the likelihood of failure and downtime. Conversely, while aluminum is not as strong as steel, advancements in alloy technology have led to the development of high-strength aluminum materials that can perform admirably in various applications. These alloys provide a balance between weight and strength, making them suitable for tasks where reducing mass is essential without compromising performance.

However, it is important to note that aluminum may not be the best choice for extremely heavy-duty applications where maximum strength is required. Therefore, understanding the specific demands of each application is vital when selecting between steel and aluminum.

Weight and Maneuverability Considerations

One of the most significant advantages of aluminum attachments is their lightweight nature. This characteristic greatly enhances maneuverability, allowing operators to handle tools with greater ease and precision. In environments where speed and agility are crucial, such as in assembly lines or intricate machining tasks, the reduced weight of aluminum can lead to improved productivity.

Operators can work more efficiently without the fatigue associated with handling heavier steel components. In contrast, while steel tool arms may offer superior strength, their weight can be a disadvantage in certain scenarios. Heavier components can lead to increased strain on machinery and operators alike, potentially slowing down operations.

However, in applications where stability and rigidity are paramount, the added weight of steel can provide benefits that outweigh its drawbacks. Ultimately, the choice between steel and aluminum should consider the specific operational context, balancing the need for strength with the advantages of maneuverability.

Cost and Affordability Analysis

Cost is a significant factor influencing material selection in manufacturing processes. Generally speaking, steel tends to be more affordable than aluminum on a per-pound basis. This cost-effectiveness makes steel an attractive option for businesses looking to minimize expenses while maintaining quality.

Additionally, the longevity and durability of steel can lead to lower replacement costs over time, further enhancing its appeal from a financial perspective. On the other hand, aluminum’s higher initial cost can be justified by its lightweight properties and potential for increased efficiency in certain applications. For businesses that prioritize speed and agility, investing in aluminum attachments may yield long-term savings through enhanced productivity.

It is essential for companies to conduct a thorough cost-benefit analysis when deciding between these materials, taking into account not only the initial purchase price but also the potential impact on operational efficiency and maintenance costs.

Corrosion Resistance and Longevity

Corrosion resistance is another critical aspect to consider when comparing steel tool arms with aluminum attachments. Steel is susceptible to rust and corrosion when exposed to moisture or harsh environments unless it undergoes protective treatments such as galvanization or coating. This vulnerability can lead to increased maintenance requirements and reduced longevity if not properly managed.

Aluminum, on the other hand, naturally forms a protective oxide layer that enhances its resistance to corrosion. This characteristic makes aluminum an excellent choice for applications in humid or corrosive environments where steel might fail prematurely. The longevity of aluminum components can significantly reduce maintenance efforts and replacement costs over time.

However, it is essential to consider that while aluminum resists corrosion well, it may still be subject to wear under certain conditions, necessitating regular inspections to ensure optimal performance.

Flexibility and Adaptability for Different Applications

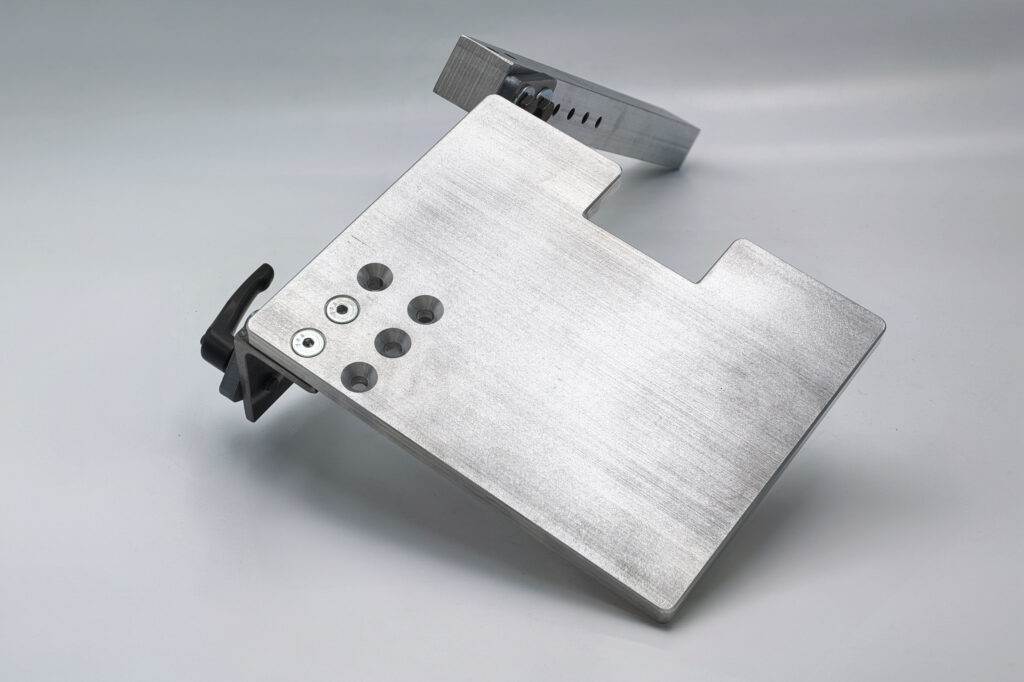

The flexibility and adaptability of materials play a crucial role in their effectiveness across various applications. Aluminum attachments are often favored for their versatility; they can be easily machined or modified to suit specific needs without compromising structural integrity. This adaptability allows manufacturers to customize tools quickly, responding to changing demands in production processes.

Steel tool arms, while less flexible in terms of modification due to their weight and strength characteristics, excel in applications requiring stability and precision. Their robust nature makes them ideal for heavy-duty tasks where reliability is non-negotiable. However, advancements in manufacturing techniques have also allowed for greater customization options with steel components, enabling manufacturers to create tailored solutions that meet specific operational requirements.

Impact on Performance and Efficiency

The choice between steel tool arms and aluminum attachments can significantly impact overall performance and efficiency in manufacturing processes. Steel’s strength allows for high precision in machining tasks, ensuring that tools maintain their shape under stress. This precision translates into better quality products and reduced waste during production.

Aluminum’s lightweight nature contributes to faster operation speeds, which can enhance overall efficiency in certain applications. The ability to maneuver quickly can lead to shorter cycle times and increased output without sacrificing quality. However, it is essential to recognize that performance is not solely determined by material choice; factors such as design, tooling methods, and operator skill also play critical roles in achieving optimal results.

Environmental Impact and Sustainability

As industries increasingly prioritize sustainability, the environmental impact of material choices has come under scrutiny. Steel production is energy-intensive and often involves significant carbon emissions; however, it is highly recyclable, which can mitigate some environmental concerns associated with its production. The longevity of steel components also means they may not need to be replaced as frequently as other materials, potentially reducing waste over time.

Aluminum also boasts strong recyclability credentials; recycled aluminum requires only a fraction of the energy needed for primary production. This characteristic makes aluminum an attractive option for environmentally conscious manufacturers seeking to minimize their carbon footprint. Additionally, the lightweight nature of aluminum can contribute to energy savings during transportation and handling processes.

Ultimately, both materials have their environmental pros and cons, necessitating careful consideration based on specific operational practices.

Maintenance and Upkeep Requirements

Maintenance requirements vary significantly between steel tool arms and aluminum attachments, influencing long-term operational costs. Steel components often require regular inspections for signs of rust or corrosion, especially if they are used in environments prone to moisture exposure. Protective coatings can extend their lifespan but may require periodic reapplication to maintain effectiveness.

Aluminum attachments generally demand less maintenance due to their inherent corrosion resistance; however, they are not immune to wear over time. Regular checks for signs of fatigue or damage are essential to ensure optimal performance. Understanding these maintenance needs is crucial for manufacturers aiming to minimize downtime and maximize productivity through effective upkeep strategies.

Compatibility with Different Machinery and Equipment

Compatibility with existing machinery and equipment is another vital consideration when choosing between steel tool arms and aluminum attachments. Steel components are often designed with specific machinery in mind, ensuring seamless integration into established systems. Their robust nature allows them to withstand the rigors of heavy machinery without compromising performance.

Aluminum attachments offer flexibility in compatibility due to their lightweight properties; they can often be adapted for use with various machines without extensive modifications. This adaptability makes them appealing for businesses looking to upgrade or modify existing equipment without incurring significant costs or downtime. Ultimately, understanding compatibility requirements is essential for ensuring smooth operations across different manufacturing setups.

Making the Best Choice for Your Needs

In conclusion, the decision between steel tool arms and aluminum attachments hinges on a multitude of factors that must be carefully weighed against specific operational needs. Steel offers unparalleled strength and durability but comes with considerations regarding weight and maintenance requirements. Conversely, aluminum provides advantages in terms of maneuverability and corrosion resistance but may not always match steel’s robustness in heavy-duty applications.

Ultimately, manufacturers must assess their unique requirements—considering aspects such as cost, performance expectations, environmental impact, and compatibility with existing systems—to make an informed choice that aligns with their operational goals. By understanding the strengths and limitations of both materials, businesses can optimize their equipment selection for enhanced efficiency and productivity in an ever-evolving industrial landscape.

FAQs

What are steel tool arms and aluminum attachments?

Steel tool arms and aluminum attachments are components used in various machinery and equipment, such as construction machinery, agricultural equipment, and industrial machinery. Steel tool arms are typically used to provide support and stability for attachments, while aluminum attachments are used for various functions such as digging, lifting, and carrying.

What are the differences between steel tool arms and aluminum attachments?

The main difference between steel tool arms and aluminum attachments lies in their material composition. Steel tool arms are made of steel, which is known for its strength and durability, while aluminum attachments are made of aluminum, which is lightweight and corrosion-resistant.

Which is better for attachments, steel tool arms or aluminum?

The choice between steel tool arms and aluminum attachments depends on the specific application and requirements. Steel tool arms are better suited for heavy-duty applications that require strength and durability, while aluminum attachments are more suitable for applications that require lightweight and corrosion-resistant components.

What are the advantages of steel tool arms?

Steel tool arms offer several advantages, including high strength, durability, and resistance to wear and tear. They are also capable of handling heavy loads and providing stability for attachments in demanding applications.

What are the advantages of aluminum attachments?

Aluminum attachments offer advantages such as lightweight construction, corrosion resistance, and ease of handling. They are ideal for applications where weight is a concern and where resistance to corrosion is important, such as in outdoor or marine environments.

What are the limitations of steel tool arms and aluminum attachments?

The main limitation of steel tool arms is their weight, which can be a disadvantage in applications where weight is a critical factor. On the other hand, the main limitation of aluminum attachments is their lower strength compared to steel, which may limit their use in heavy-duty applications.