Vibration in a 2×72 grinder can stem from a variety of sources, each contributing to an overall reduction in performance and an increase in noise levels. One of the primary causes is the imbalance of the grinding wheels. If the wheels are not perfectly aligned or if they have uneven wear, they can create significant vibrations during operation.

This imbalance can lead to not only a noisy experience but also a decrease in the quality of the grind, as the uneven surface can affect the material being worked on. Additionally, loose components within the grinder itself can exacerbate these vibrations, leading to a compounding effect that can make the machine difficult to control. Another significant factor contributing to vibration is the quality and condition of the belts used in the grinder.

Worn or damaged belts can lead to inconsistent tension and alignment, which can further amplify vibratio

ns. Furthermore, the surface on which the grinder is placed plays a crucial role; an unstable or uneven surface can lead to additional shaking and noise. Understanding these causes is essential for anyone looking to optimize their 2×72 grinder’s performance and minimize unwanted vibrations.

Key Takeaways

- Understanding the causes of vibration in the 2×72 grinder is crucial for effective reduction strategies.

- Choosing the right materials for vibration reduction, such as rubber isolation pads, can significantly minimize noise and shake.

- Maintaining proper belt tension is essential for a quieter operation and to prevent excessive vibration.

- Balancing the wheels of the grinder is important for smoother performance and to reduce vibration.

- Installing anti-vibration mounts can effectively minimize shake and contribute to a quieter workspace.

Choosing the Right Materials for Vibration Reduction

Selecting appropriate materials for vibration reduction is critical in enhancing the performance of a 2×72 grinder. One effective approach is to use high-density rubber or foam materials that can absorb vibrations effectively. These materials are designed to dampen sound and reduce the transmission of vibrations from the grinder to its base and surrounding environment.

When choosing these materials, it is essential to consider their density and elasticity, as these factors will determine how well they can absorb and dissipate energy. In addition to rubber and foam, incorporating mass-loaded vinyl or specialized vibration-dampening mats can further enhance vibration reduction. These materials are engineered specifically for soundproofing and vibration isolation, making them ideal for use in workshops where noise levels need to be controlled.

By strategically placing these materials under the grinder or around its base, users can create a more stable and quieter working environment, ultimately leading to improved performance and comfort during operation.

Maintaining Proper Belt Tension for a Quieter Operation

Proper belt tension is crucial for ensuring that a 2×72 grinder operates smoothly and quietly. When belts are too loose, they can slip, causing vibrations that not only affect performance but also lead to premature wear on both the belts and the grinder itself. Conversely, if the belts are too tight, they can create excessive strain on the motor and other components, leading to further complications.

Regularly checking and adjusting belt tension is essential for maintaining optimal performance and minimizing noise. To achieve the right tension, it is advisable to follow manufacturer guidelines regarding belt installation and adjustment. This often involves using a tension gauge or simply applying pressure by hand to ensure that the belt has adequate tension without being overly tight.

Additionally, keeping an eye on belt wear and replacing them when necessary will help maintain a quieter operation. A well-tensioned belt not only reduces vibrations but also enhances the overall efficiency of the grinding process.

Balancing the Wheels for Smoother Performance

Balancing the wheels of a 2×72 grinder is another critical step in reducing vibrations and ensuring smooth operation. Unbalanced wheels can lead to significant shaking during use, which not only affects the quality of work but can also pose safety risks. To achieve proper balance, it is essential to inspect each wheel for any signs of wear or damage that could contribute to imbalance.

If any irregularities are found, it may be necessary to replace or repair the wheels before proceeding. Once any issues have been addressed, balancing can be achieved by using specialized balancing tools or weights designed for this purpose. These tools allow users to identify heavy spots on the wheel and make adjustments accordingly.

By ensuring that both wheels are balanced, users can significantly reduce vibrations during operation, leading to a smoother grinding experience and improved results.

Installing Rubber Isolation Pads for Noise Reduction

Rubber isolation pads are an effective solution for reducing noise generated by a 2×72 grinder during operation. These pads work by absorbing vibrations before they can transfer to the surface on which the grinder is mounted. By installing these pads between the grinder’s base and its mounting surface, users can create a barrier that minimizes noise transmission and enhances overall stability.

When selecting rubber isolation pads, it is important to consider their thickness and density, as these factors will influence their effectiveness in dampening sound. Additionally, ensuring that the pads are properly installed and maintained will maximize their benefits. Over time, wear and tear may necessitate replacement; therefore, regular inspections should be part of routine maintenance to ensure continued noise reduction.

Using Anti-Vibration Mounts to Minimize Shake

Incorporating anti-vibration mounts into a 2×72 grinder setup can significantly minimize shake and enhance operational stability. These mounts are designed specifically to absorb vibrations generated by machinery, preventing them from transferring to the work surface or surrounding environment. By isolating the grinder from its mounting surface, anti-vibration mounts help create a more stable platform for grinding tasks.

When selecting anti-vibration mounts, it is essential to choose ones that are compatible with the weight and design of the grinder. Proper installation is also crucial; mounts should be securely fastened to both the grinder and its base to ensure maximum effectiveness. By utilizing these mounts, users can enjoy a quieter workspace while also prolonging the life of their equipment through reduced wear and tear.

Adjusting the Grinder’s Speed for Reduced Vibration

Adjusting the speed of a 2×72 grinder can play a significant role in reducing vibrations during operation. Different materials require different speeds for optimal grinding performance; however, running the grinder at excessively high speeds can lead to increased vibrations and noise levels. By finding a balance between speed and material type, users can minimize unwanted vibrations while still achieving effective results.

To determine the optimal speed for specific tasks, it may be beneficial to conduct tests with various materials at different speeds. This experimentation allows users to identify settings that yield smooth operation without excessive vibration. Additionally, many modern grinders come equipped with variable speed controls that enable users to make adjustments easily based on their specific needs.

Incorporating Dampening Techniques for a Quieter Workspace

Creating a quieter workspace involves incorporating various dampening techniques alongside equipment modifications. One effective method is to use sound-absorbing panels or curtains around the grinding area. These materials help trap sound waves, reducing overall noise levels in the workshop environment.

Additionally, placing carpets or mats on the floor can further absorb sound and vibrations generated by machinery. Another technique involves organizing tools and equipment in a way that minimizes clutter around the grinder. A tidy workspace not only enhances safety but also reduces potential sources of noise caused by tools rattling against one another or vibrating against surfaces.

By implementing these dampening techniques alongside equipment adjustments, users can create a more pleasant working environment conducive to productivity.

Implementing Proper Tool Rest and Work Support for Stability

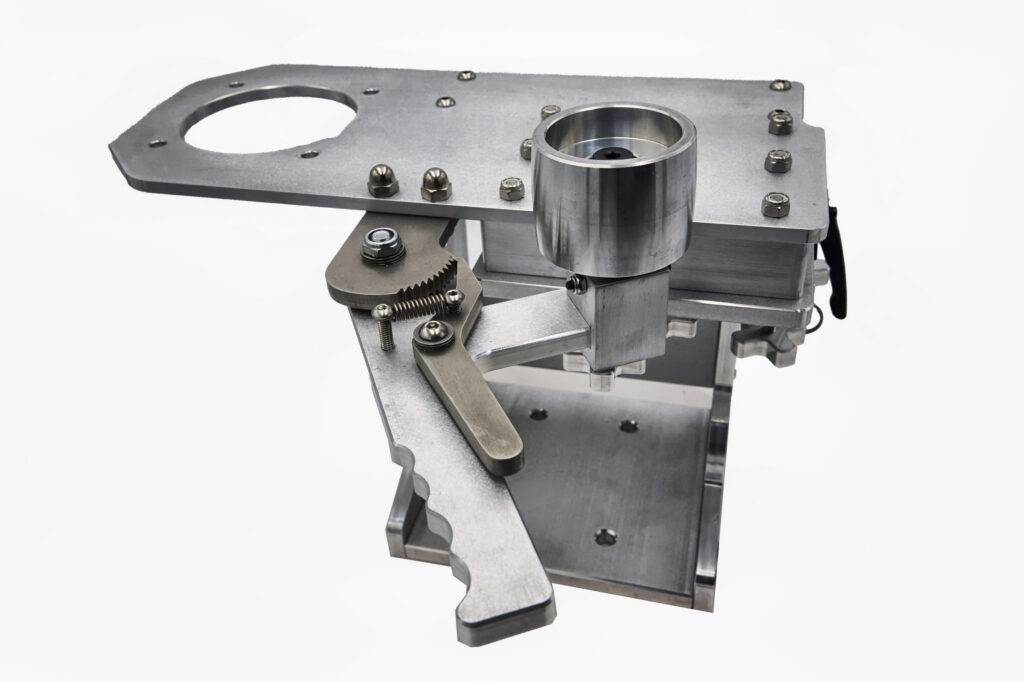

A stable tool rest and work support system are essential components in minimizing vibrations during grinding operations with a 2×72 grinder. An unstable tool rest can lead to excessive movement while grinding, resulting in increased vibrations that affect both performance and safety. Ensuring that tool rests are securely mounted and properly aligned will provide greater stability during use.

Additionally, using adjustable work supports allows users to customize their setup based on specific tasks or materials being worked on. This adaptability not only enhances stability but also improves overall efficiency by allowing for precise control during grinding operations. By prioritizing stability through proper tool rest and work support implementation, users can significantly reduce vibrations while achieving better results.

Regular Maintenance to Prevent Vibration Build-Up

Regular maintenance is crucial in preventing vibration build-up in a 2×72 grinder over time. Routine inspections should include checking for loose components, worn belts, and unbalanced wheels—all of which can contribute to increased vibrations if left unaddressed. Establishing a maintenance schedule ensures that potential issues are identified early on before they escalate into more significant problems.

In addition to visual inspections, cleaning components regularly helps prevent debris accumulation that could interfere with smooth operation. Lubricating moving parts as recommended by manufacturers also contributes to reducing friction and wear, further minimizing vibrations during use. By committing to regular maintenance practices, users can prolong their equipment’s lifespan while maintaining optimal performance levels.

Seeking Professional Help for Persistent Vibration Issues

If persistent vibration issues continue despite implementing various solutions, seeking professional help may be necessary. Experienced technicians possess specialized knowledge about machinery dynamics and can diagnose underlying problems that may not be immediately apparent to users. They can provide insights into potential mechanical failures or misalignments that could be contributing to excessive vibrations.

Consulting with professionals also allows users access to advanced tools and techniques for addressing vibration issues effectively. Whether through repairs or upgrades, expert assistance can lead to long-term solutions that enhance both performance and safety in grinding operations. Ultimately, investing in professional help when needed ensures that users maintain optimal functionality while minimizing disruptions caused by vibration-related challenges.

FAQs

What is a 2×72 grinder?

A 2×72 grinder is a type of belt grinder commonly used in metalworking and knife making. It consists of a motor-driven abrasive belt that is used for grinding, shaping, and polishing metal.

Why does a 2×72 grinder produce vibration and noise?

Vibration and noise in a 2×72 grinder can be caused by various factors such as unbalanced wheels, misalignment of components, worn out parts, or improper installation.

How can I reduce vibration on a 2×72 grinder?

To reduce vibration on a 2×72 grinder, you can try balancing the wheels, checking for misalignment, replacing worn out parts, and ensuring proper installation of all components. Additionally, using vibration-dampening materials and adding rubber feet to the grinder can also help reduce vibration.

What are some tips for quieting a noisy 2×72 grinder?

To quiet a noisy 2×72 grinder, you can try lubricating moving parts, tightening loose components, replacing worn out bearings, and using sound-dampening materials such as rubber or foam. Additionally, adjusting the tension of the abrasive belt and ensuring proper alignment of all components can also help reduce noise.