Sharpening large cleavers is a critical aspect of maintaining their functionality and longevity. A well-sharpened cleaver not only enhances the efficiency of cutting through tough meats and vegetables but also ensures safety during food preparation. Dull blades can lead to accidents, as they require more force to cut, increasing the risk of slipping and causing injury.

Therefore, understanding the importance of regular sharpening is essential for anyone who frequently uses these versatile kitchen tools. Moreover, the performance of a cleaver is directly linked to its sharpness. A sharp cleaver allows for precision in cutting, which is particularly important in culinary settings where presentation matters.

The ability to make clean cuts can significantly affect the texture and appearance of food, impacting both cooking times and the final dish’s quality. Thus, sharpening large cleavers should be viewed not just as a maintenance task but as an integral part of culinary practice that enhances both safety and performance.

Key Takeaways

- Sharpening large cleavers is important for maintaining their cutting efficiency and safety

- Choosing the right work rest is crucial for stability and precision when sharpening large cleavers

- Setting up the extended work rest involves securing it firmly and adjusting it to the desired angle

- Safety precautions include wearing protective gear and ensuring the cleaver is properly secured during sharpening

- Following a step-by-step guide is essential for achieving the best results when sharpening large cleavers with an extended work rest

Choosing the Right Work Rest for Sharpening Large Cleavers

Selecting the appropriate work rest is crucial when sharpening large cleavers, as it provides stability and support during the sharpening process. A work rest designed specifically for large blades will accommodate their size and weight, allowing for a more controlled sharpening experience. When choosing a work rest, consider factors such as adjustability, material quality, and compatibility with your sharpening equipment.

A sturdy work rest will help maintain the correct angle while sharpening, which is vital for achieving a sharp edge. Additionally, the design of the work rest can influence the overall sharpening process. Some work rests come with features that allow for easy angle adjustments, which can be beneficial for different types of cleavers or personal preferences.

A well-designed work rest not only enhances precision but also reduces fatigue during the sharpening process, making it easier to achieve consistent results. Therefore, investing time in selecting the right work rest is essential for anyone serious about maintaining their large cleavers.

Setting Up the Extended Work Rest for Sharpening Large Cleavers

Setting up an extended work rest for sharpening large cleavers involves several steps to ensure optimal performance. First, it is essential to secure the work rest firmly to your sharpening machine or bench. This stability is crucial as it prevents any movement during the sharpening process, which could lead to uneven edges or accidents.

Once secured, adjust the height and angle of the work rest to match the specific requirements of your cleaver. The goal is to create a comfortable working position that allows for precise control over the blade. After adjusting the work rest, it’s important to check that it aligns correctly with the sharpening stone or belt.

Misalignment can result in ineffective sharpening and may even damage the blade. Take a moment to test the setup by running the cleaver along the sharpening surface without applying pressure. This preliminary check will help you identify any adjustments needed before you begin sharpening in earnest.

A well-set-up extended work rest can significantly enhance your sharpening experience, leading to better results and a more enjoyable process.

Safety Precautions When Sharpening Large Cleavers with Extended Work Rest

Safety should always be a top priority when sharpening large cleavers, especially when using an extended work rest. One of the first precautions is to wear appropriate personal protective equipment (PPE), such as cut-resistant gloves and safety goggles. These items can protect against accidental slips or debris that may fly off during the sharpening process.

Additionally, ensure that your workspace is clean and free from clutter to minimize distractions and potential hazards. Another important safety measure is to maintain a firm grip on the cleaver while sharpening. This control helps prevent slips that could lead to injuries.

It’s also advisable to keep your hands away from the blade’s path and to use a steady, even pressure when moving the cleaver across the sharpening surface. Familiarizing yourself with the equipment and practicing safe techniques will not only protect you but also enhance your confidence in handling large cleavers during sharpening.

Step-by-Step Guide to Sharpening Large Cleavers with Extended Work Rest

Sharpening large cleavers with an extended work rest can be broken down into a systematic process that ensures effective results. Begin by securing your cleaver in a comfortable position on the work rest, ensuring that it is stable and aligned with your sharpening tool. Next, select an appropriate grit for your sharpening medium; starting with a coarser grit can help reshape any dull edges before moving on to finer grits for polishing.

Once you have your setup ready, begin by applying light pressure as you move the cleaver across the sharpening surface at a consistent angle. It’s essential to maintain this angle throughout the process to achieve an even edge. After several passes on one side, flip the cleaver over and repeat the process on the other side.

Regularly check the sharpness by carefully testing the edge on a piece of paper or another soft material. This step-by-step approach not only ensures thorough sharpening but also allows you to monitor progress effectively.

Tips for Maintaining the Sharpness of Large Cleavers After Sharpening

Once you have sharpened your large cleaver, maintaining its sharpness becomes paramount for continued performance. One effective tip is to regularly hone the blade using a honing steel or ceramic rod after each use. This practice realigns any microscopic teeth on the edge that may have bent during cutting, helping to maintain sharpness without requiring full sharpening sessions frequently.

Additionally, proper storage plays a significant role in preserving a cleaver’s sharpness. Store your cleaver in a protective sheath or magnetic strip rather than tossing it into a drawer where it may come into contact with other utensils. This precaution prevents nicks and dulling caused by friction against other objects.

Regular cleaning after use is also essential; avoid soaking your cleaver in water or placing it in a dishwasher, as these practices can damage both the blade and handle over time.

Common Mistakes to Avoid When Sharpening Large Cleavers with Extended Work Rest

When sharpening large cleavers with an extended work rest, several common mistakes can hinder effectiveness and safety. One frequent error is neglecting to maintain a consistent angle throughout the sharpening process. Variations in angle can lead to uneven edges and may require additional time spent correcting mistakes later on.

To avoid this, take time to practice maintaining your chosen angle before starting on your cleaver. Another mistake is applying excessive pressure while sharpening. Many users believe that pressing harder will yield better results; however, this can lead to overheating and damage to both the blade and sharpening medium.

Instead, focus on using light, even pressure and allowing the sharpening tool to do its job effectively. By being mindful of these common pitfalls, you can enhance your sharpening technique and achieve better results with your large cleavers.

Comparing Different Sharpening Techniques for Large Cleavers

There are various techniques available for sharpening large cleavers, each with its own advantages and disadvantages. Traditional methods such as whetstones offer precise control over angles and allow for fine-tuning of edges but require more skill and practice to master effectively. On the other hand, electric sharpeners provide convenience and speed but may lack the finesse needed for achieving optimal sharpness on larger blades.

Another popular technique involves using guided systems that help maintain consistent angles throughout the sharpening process. These systems can be particularly beneficial for beginners or those who may struggle with freehand techniques. Ultimately, choosing a method depends on personal preference, skill level, and how often one uses their cleavers.

Understanding these differences can help users select the best approach for their needs.

Benefits of Using an Extended Work Rest for Sharpening Large Cleavers

Utilizing an extended work rest when sharpening large cleavers offers numerous benefits that enhance both safety and efficiency. One significant advantage is improved stability during the sharpening process; an extended work rest provides a solid platform that minimizes movement and allows for greater control over blade angles. This stability is particularly important when working with larger blades that require more precision.

Additionally, an extended work rest can reduce fatigue during long sharpening sessions by allowing users to maintain a comfortable posture while working. This ergonomic benefit not only enhances user experience but also contributes to better results by enabling more consistent pressure application throughout the sharpening process. Overall, incorporating an extended work rest into your sharpening routine can lead to superior outcomes and a more enjoyable experience.

Troubleshooting Common Issues When Sharpening Large Cleavers with Extended Work Rest

Even with careful preparation and technique, issues may arise when sharpening large cleavers using an extended work rest. One common problem is uneven edges resulting from inconsistent pressure or angle during sharpening. If you notice this issue, take a step back and reassess your technique; ensure that you are maintaining a steady angle and applying even pressure across the entire length of the blade.

Another issue could be overheating of the blade due to excessive friction against the sharpening medium. If you find that your blade is becoming too hot to touch, pause your sharpening session and allow it to cool down before continuing. You may also want to consider using a coarser grit initially or adjusting your technique to reduce friction buildup.

By being aware of these potential problems and knowing how to address them, you can improve your overall sharpening experience.

Exploring Advanced Techniques for Sharpening Large Cleavers with Extended Work Rest

For those looking to elevate their sharpening skills further, exploring advanced techniques can yield impressive results when working with large cleavers. One such technique involves utilizing different grits in succession—starting with a coarse grit for reshaping followed by medium and fine grits for polishing—ensuring a razor-sharp edge that lasts longer between sharpenings. Another advanced method includes using specialized jigs or guides that allow for precise angle adjustments tailored specifically for different types of cleavers or cutting tasks.

These tools can help achieve professional-level sharpness without requiring extensive experience or skill in freehand sharpening techniques. By incorporating these advanced strategies into your routine, you can significantly enhance both your proficiency and confidence in maintaining large cleavers effectively over time.

FAQs

What is a large cleaver?

A large cleaver is a type of knife with a broad, rectangular blade that is used for chopping and slicing large pieces of meat and vegetables.

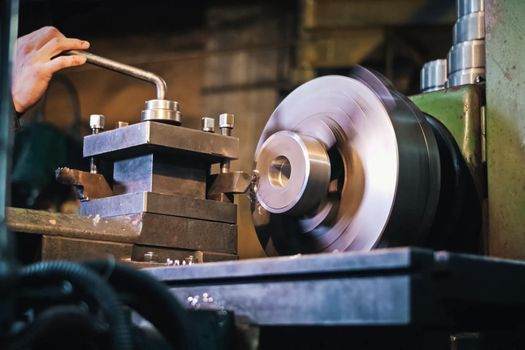

What is grinding?

Grinding is a process of using an abrasive wheel to shape and sharpen a metal object, such as a knife blade.

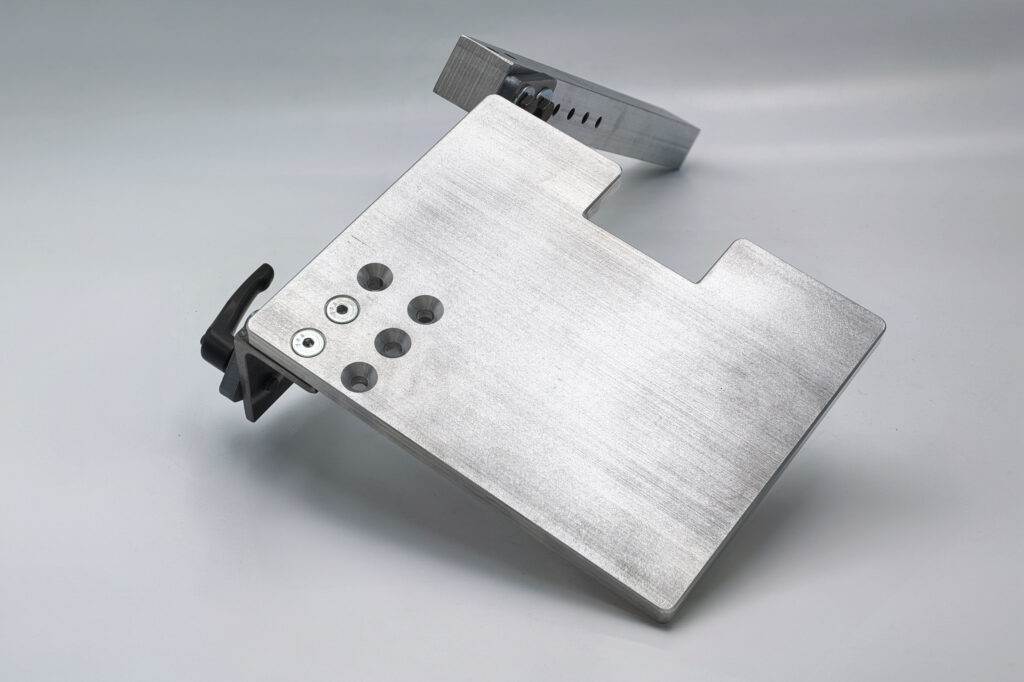

What is an extended work rest?

An extended work rest is a tool used in grinding to support and stabilize the knife blade during the sharpening process.

Why is it important to use an extended work rest when grinding large cleavers?

Using an extended work rest helps to ensure that the large cleaver is properly supported and stabilized during the grinding process, which can improve the accuracy and consistency of the sharpening.

What are the benefits of grinding large cleavers on an extended work rest?

Grinding large cleavers on an extended work rest can help to achieve a more precise and uniform edge, as well as reduce the risk of injury by providing better stability and control during the sharpening process.