In the world of manufacturing and machining, efficiency is paramount. One of the critical aspects that can significantly impact productivity is the process of changing belts in machinery. Whether in a CNC machine or a traditional lathe, the time taken to switch belts can lead to substantial downtime, affecting overall output and profitability.

Efficient belt changes not only minimize idle time but also enhance the workflow, allowing operators to focus on their tasks without unnecessary interruptions. The ability to quickly and effectively change belts can be the difference between meeting production deadlines and falling behind schedule. Moreover, efficient belt changes contribute to the longevity of machinery.

Frequent and prolonged downtime can lead to wear and tear on components, increasing maintenance costs and reducing the lifespan of the equipment. By streamlining the belt change process, manufacturers can ensure that their machines operate at optimal performance levels. This not only saves time but also reduces the risk of mechanical failures that can arise from improper handling during belt changes.

Therefore, investing in methods and tools that facilitate efficient belt changes is essential for any operation aiming for excellence in production.

Key Takeaways

- Efficient belt changes are crucial for maintaining productivity and minimizing downtime in industrial operations.

- Spacer sleeves play a key role in lathe operations by ensuring precise alignment and spacing of components.

- Lathe-turned spacer sleeves offer advantages such as improved accuracy, durability, and reduced maintenance for belt changes.

- Streamlining belt changes with lathe-turned spacer sleeves involves a systematic approach for optimal results.

- The choice of material for lathe-turned spacer sleeves is important for ensuring compatibility with specific operational requirements.

Understanding the Role of Spacer Sleeves in Lathe Operations

Spacer sleeves play a crucial role in lathe operations, particularly when it comes to ensuring proper alignment and spacing between components. These cylindrical devices are designed to fill gaps and maintain the correct distance between parts, which is vital for achieving precision in machining tasks. In the context of belt changes, spacer sleeves can help facilitate smoother transitions and adjustments, ensuring that belts fit snugly and operate efficiently without slippage or misalignment.

The importance of spacer sleeves extends beyond mere functionality; they also contribute to the overall safety of lathe operations. Properly installed spacer sleeves can prevent components from coming loose during operation, reducing the risk of accidents or equipment damage. Additionally, they help maintain consistent tension on belts, which is essential for optimal performance.

Understanding how spacer sleeves work and their significance in lathe operations is fundamental for anyone involved in machining processes.

Advantages of Lathe-Turned Spacer Sleeves for Belt Changes

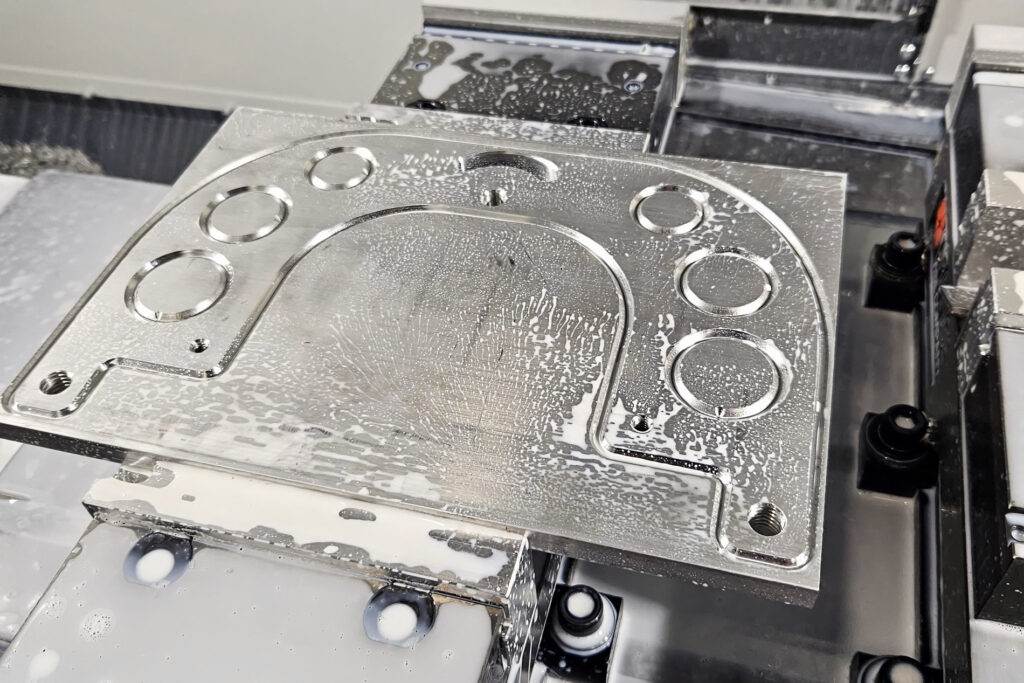

Lathe-turned spacer sleeves offer several advantages over standard spacer options, particularly when it comes to belt changes. One of the primary benefits is their precision. Lathe-turned components are manufactured with high accuracy, ensuring that they fit perfectly within the machinery.

This precision minimizes the risk of misalignment during belt changes, which can lead to operational inefficiencies and increased wear on belts and pulleys. Another significant advantage is customization. Lathe-turned spacer sleeves can be tailored to meet specific requirements, including size, material, and design features.

This level of customization allows manufacturers to create solutions that are perfectly suited to their unique machinery and operational needs. Furthermore, lathe-turned spacer sleeves are often made from durable materials that can withstand the rigors of machining environments, ensuring longevity and reliability during belt changes.

Step-by-Step Guide to Streamlining Belt Changes with Lathe-Turned Spacer Sleeves

To effectively streamline belt changes using lathe-turned spacer sleeves, a systematic approach is essential. The first step involves assessing the current setup and identifying areas where improvements can be made. This includes evaluating the existing spacer sleeves and determining if they meet the necessary specifications for optimal performance.

Once this assessment is complete, operators can proceed to select or design lathe-turned spacer sleeves that align with their requirements. The next step is to implement a standardized procedure for changing belts that incorporates the use of these spacer sleeves. This may involve training staff on the correct installation techniques and ensuring that all necessary tools are readily available.

By establishing a clear protocol for belt changes, manufacturers can reduce variability in the process, leading to faster and more efficient operations. Regular reviews of this procedure can also help identify further opportunities for improvement.

Choosing the Right Material for Lathe-Turned Spacer Sleeves

Selecting the appropriate material for lathe-turned spacer sleeves is critical for ensuring their effectiveness in belt change operations. Common materials include aluminum, steel, and various plastics, each offering distinct advantages depending on the application. For instance, aluminum is lightweight yet strong, making it an excellent choice for applications where weight reduction is a priority.

On the other hand, steel provides superior durability and resistance to wear, making it suitable for high-stress environments. Additionally, considerations such as temperature resistance, corrosion resistance, and cost should also influence material selection. For example, if the lathe operates in a humid environment or involves exposure to chemicals, materials with high corrosion resistance may be necessary.

Ultimately, choosing the right material involves balancing performance requirements with budget constraints while ensuring that the selected material aligns with the specific demands of the machining process.

Customization Options for Lathe-Turned Spacer Sleeves

Customization is one of the standout features of lathe-turned spacer sleeves, allowing manufacturers to create components that perfectly fit their operational needs. Customization options can include variations in diameter, length, wall thickness, and even specific design features such as grooves or notches that enhance functionality. This level of tailoring ensures that each spacer sleeve serves its intended purpose effectively while integrating seamlessly into existing machinery.

Moreover, customization extends beyond physical dimensions; it can also encompass material choices and surface finishes. For instance, a manufacturer may opt for a specific coating on a spacer sleeve to enhance its wear resistance or reduce friction during operation. By leveraging customization options, manufacturers can optimize their lathe operations and improve overall efficiency during belt changes.

Tips for Proper Maintenance of Lathe-Turned Spacer Sleeves

Maintaining lathe-turned spacer sleeves is essential for ensuring their longevity and effectiveness in belt change operations. Regular inspections should be conducted to check for signs of wear or damage, such as cracks or deformation. Any compromised spacer sleeves should be replaced immediately to prevent operational issues during belt changes.

Additionally, cleaning these components regularly can help remove debris or contaminants that may affect their performance. Lubrication is another critical aspect of maintenance. While spacer sleeves themselves may not require lubrication, ensuring that surrounding components are well-lubricated can enhance overall performance during belt changes.

Operators should also keep an eye on alignment and fit; any misalignment can lead to increased wear on both the spacer sleeves and belts themselves. By adhering to these maintenance tips, manufacturers can ensure that their lathe-turned spacer sleeves continue to perform optimally over time.

Common Mistakes to Avoid When Using Lathe-Turned Spacer Sleeves

While lathe-turned spacer sleeves offer numerous benefits for streamlining belt changes, there are common mistakes that operators should avoid to maximize their effectiveness. One prevalent error is neglecting proper installation techniques. Incorrectly installed spacer sleeves can lead to misalignment issues that compromise both safety and performance during operation.

It’s crucial for operators to follow established guidelines for installation to ensure that each component functions as intended. Another mistake involves overlooking regular maintenance checks. Failing to inspect spacer sleeves regularly can result in undetected wear or damage that may lead to operational failures during critical moments.

Additionally, operators should avoid using generic or ill-fitting spacer sleeves as substitutes for custom lathe-turned options; this can lead to inefficiencies and increased wear on machinery components. By being aware of these common pitfalls, manufacturers can enhance their operations and ensure smoother belt change processes.

Case Studies: Successful Implementation of Lathe-Turned Spacer Sleeves for Belt Changes

Examining case studies where lathe-turned spacer sleeves have been successfully implemented provides valuable insights into their effectiveness in streamlining belt changes. In one instance, a manufacturing facility specializing in automotive parts faced significant downtime due to inefficient belt change processes. By integrating custom lathe-turned spacer sleeves into their operations, they were able to reduce belt change times by nearly 50%.

This improvement not only boosted productivity but also enhanced overall machine reliability. Another case study involved a woodworking shop that struggled with frequent misalignment issues during belt changes on their lathes. After switching to precision-engineered lathe-turned spacer sleeves designed specifically for their equipment, they reported a marked decrease in alignment-related problems.

This transition not only improved efficiency but also reduced material waste caused by misaligned cuts. These examples illustrate how investing in quality lathe-turned spacer sleeves can lead to significant operational improvements.

Comparing Lathe-Turned Spacer Sleeves with Other Belt Change Methods

When evaluating different methods for facilitating belt changes in machinery, lathe-turned spacer sleeves stand out due to their precision and customization capabilities. Compared to standard off-the-shelf spacers or shims, lathe-turned options offer superior fitment tailored specifically for individual machines. This precision minimizes misalignment risks and enhances overall efficiency during belt changes.

In contrast, other methods such as using adjustable tensioners or generic spacers may provide temporary solutions but often lack the long-term reliability offered by lathe-turned components. While adjustable tensioners can allow for some flexibility in spacing, they may not provide the same level of stability as custom-engineered spacer sleeves designed for specific applications. Ultimately, choosing lathe-turned spacer sleeves represents a proactive approach toward optimizing belt change processes.

Future Innovations in Lathe-Turned Spacer Sleeves for Streamlining Belt Changes

As technology continues to advance within manufacturing sectors, future innovations in lathe-turned spacer sleeves are likely to emerge that further streamline belt change processes. One potential area of development involves integrating smart technology into spacer sleeve designs—such as sensors that monitor wear levels or alignment status—allowing operators to receive real-time feedback on component performance. Additionally, advancements in materials science may lead to new composite materials that offer enhanced durability while remaining lightweight—further improving efficiency during belt changes without compromising strength or reliability.

As manufacturers continue seeking ways to optimize operations and reduce downtime associated with belt changes, innovations in lathe-turned spacer sleeves will undoubtedly play a pivotal role in shaping future machining practices. In conclusion, efficient belt changes are vital for maintaining productivity in manufacturing environments, and lathe-turned spacer sleeves offer a range of benefits that enhance this process significantly. From precision engineering to customization options and ongoing maintenance practices, understanding how these components function within lathe operations is essential for any manufacturer aiming for excellence in production efficiency.

FAQs

What are lathe-turned spacer sleeves?

Lathe-turned spacer sleeves are cylindrical components that are manufactured using a lathe machine. They are designed to fit over a shaft or spindle to create a precise spacing or alignment between components.

What are the benefits of using lathe-turned spacer sleeves for quick belt changes?

Using lathe-turned spacer sleeves for quick belt changes allows for easy and efficient adjustment of belt tension and alignment. They provide a precise and reliable way to maintain proper spacing between pulleys, reducing the time and effort required for belt changes.

How are lathe-turned spacer sleeves used for quick belt changes?

Lathe-turned spacer sleeves are installed between the pulleys and the bearings or other components to create the necessary spacing for the belts. They can be easily adjusted or replaced as needed to accommodate different belt sizes or configurations.

What materials are lathe-turned spacer sleeves typically made from?

Lathe-turned spacer sleeves can be made from a variety of materials, including steel, aluminum, brass, and other metals. The choice of material depends on the specific application and the required strength, durability, and corrosion resistance.

What industries commonly use lathe-turned spacer sleeves for quick belt changes?

Lathe-turned spacer sleeves are commonly used in industries such as manufacturing, automotive, agriculture, and industrial machinery, where belt-driven systems are prevalent. They are also used in woodworking, metalworking, and other applications where precise belt tension and alignment are critical.