Precision is a cornerstone of effective grinding, particularly when using a 2×72 grinder. The alignment of the grinder directly influences the quality of the finished product, whether it be a knife, tool, or any other metalwork. When the components of the grinder are not aligned correctly, it can lead to uneven wear on the belts, inconsistent grinding results, and ultimately, a compromised end product.

This is especially critical in applications where tight tolerances are required, as even minor misalignments can result in significant deviations from desired specifications. Moreover, precision in alignment contributes to the longevity of the equipment. A well-aligned 2×72 grinder will experience less strain on its components, reducing the likelihood of mechanical failures and extending the lifespan of both the machine and its consumables.

For professionals and hobbyists alike, investing time in ensuring proper alignment is not just about achieving immediate results; it is also about fostering a sustainable and efficient workflow that minimizes downtime and maximizes productivity.

Key Takeaways

- Precision in 2×72 grinder alignment is crucial for achieving accurate and consistent results in metalworking and knife making.

- When selecting CNC precision tools for your 2×72 grinder, consider factors such as accuracy, durability, and compatibility with your specific grinder model.

- Proper assembly and adjustment of your 2×72 grinder is essential for achieving a perfect fit and ensuring optimal performance.

- Fine-tuning your 2×72 grinder is necessary to achieve optimal performance and to meet the specific requirements of your metalworking or knife making projects.

- Maintaining precision alignment in your 2×72 grinder is key to ensuring consistent and high-quality results in your grinding operations.

Selecting the Right CNC Precision Tools for Your 2×72 Grinder

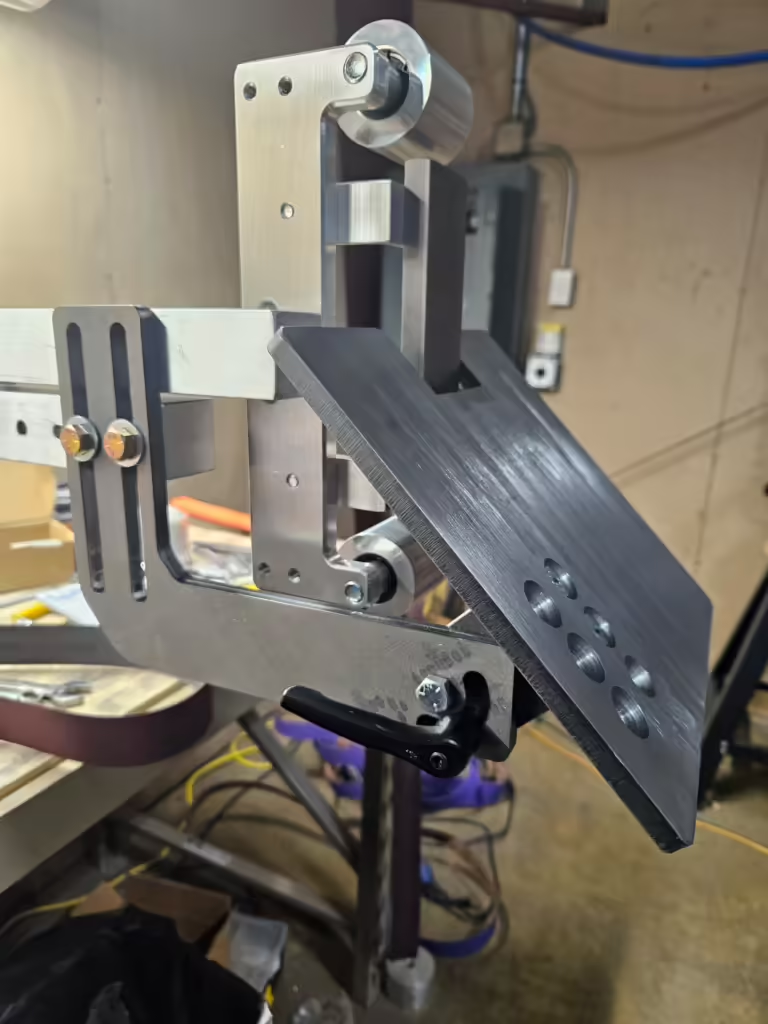

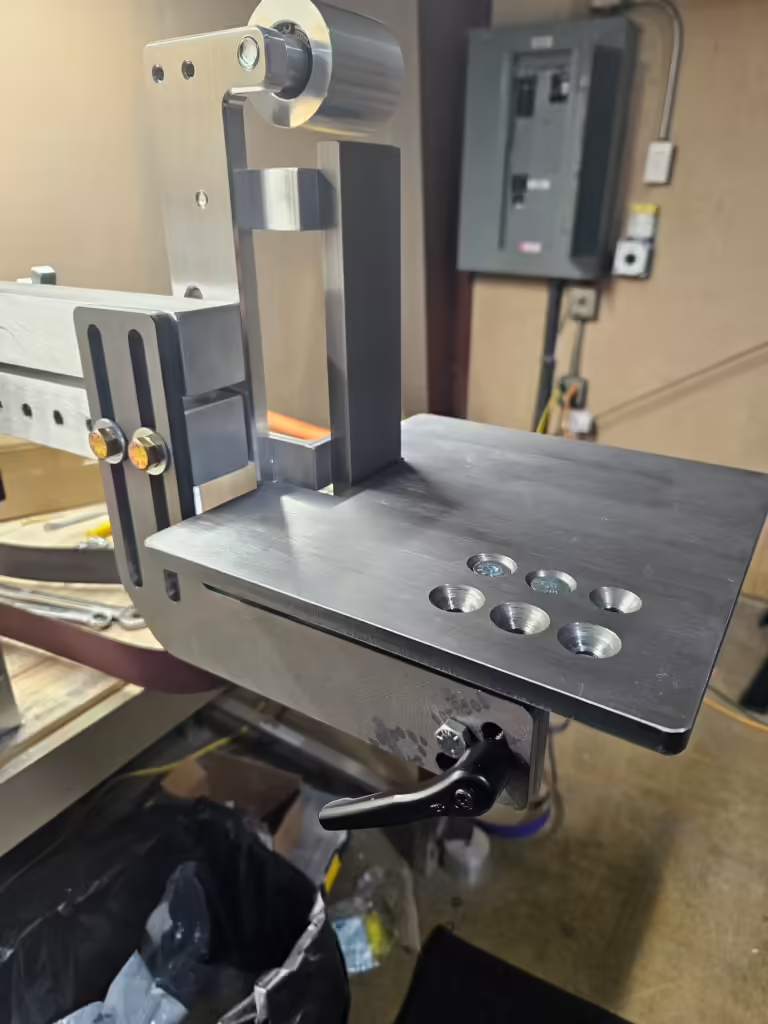

Choosing the appropriate CNC precision tools for your 2×72 grinder is essential for achieving optimal performance. The right tools can enhance the capabilities of your grinder, allowing for more intricate designs and finer finishes. When selecting tools, consider factors such as material compatibility, tool geometry, and the specific grinding tasks you intend to perform.

High-quality CNC tools are designed to withstand the rigors of grinding while providing consistent results. Additionally, it is crucial to ensure that the tools you select are compatible with your specific model of 2×72 grinder. TorusCNC offers a range of precision tools tailored for their grinders, ensuring that users can achieve the best possible outcomes.

By investing in tools that are specifically designed for your equipment, you can enhance both efficiency and effectiveness in your grinding processes. This careful selection process not only improves performance but also contributes to a smoother workflow and better overall results.

Achieving Perfect Fit: Tips for Proper Assembly and Adjustment

Proper assembly and adjustment of your 2×72 grinder are vital for achieving a perfect fit and ensuring optimal performance. Start by carefully following the manufacturer’s instructions during assembly, paying close attention to each component’s placement and orientation. Ensuring that all parts are securely fastened will prevent any unwanted movement during operation, which can lead to misalignment and inconsistent results.

Once assembled, take the time to make necessary adjustments to achieve the desired fit. This may involve fine-tuning the tension on the belts or adjusting the tracking mechanism to ensure that the belt runs true. Regularly checking these adjustments will help maintain precision over time.

It is also beneficial to familiarize yourself with the specific features of your TorusCNC grinder, as understanding its unique capabilities can aid in making more informed adjustments that enhance performance.

Fine-tuning Your 2×72 Grinder for Optimal Performance

| Aspect | Metrics |

|---|---|

| Motor Power | 1.5 – 3 horsepower |

| Belt Speed | 4500 – 6000 feet per minute |

| Tracking Mechanism | Consistent and reliable tracking |

| Platen | Flat and sturdy for precise grinding |

| Tool Rest | Adjustable and stable for accurate sharpening |

Fine-tuning your 2×72 grinder is an ongoing process that can significantly impact its performance. Start by assessing the current setup and identifying areas that may require adjustment. This could include checking belt tension, ensuring proper alignment of the tracking system, or adjusting the angle of the work rest.

Each of these factors plays a crucial role in how effectively your grinder operates. In addition to mechanical adjustments, consider the type of belts you are using. Different materials and grits can yield varying results depending on the task at hand.

Experimenting with different combinations can help you discover what works best for your specific applications. By continuously fine-tuning your setup and being open to experimentation, you can unlock the full potential of your TorusCNC 2×72 grinder and achieve superior results in your grinding projects.

Maintaining Precision Alignment in Your 2×72 Grinder

Maintaining precision alignment in your 2×72 grinder is essential for ensuring consistent performance over time. Regular maintenance checks should be part of your routine to identify any signs of wear or misalignment before they become significant issues. This includes inspecting belts for signs of fraying or uneven wear, as well as checking all mounting points and fasteners for tightness.

Incorporating a systematic approach to maintenance can help prolong the life of your grinder and maintain its precision. Create a schedule for regular inspections and adjustments based on usage frequency. Keeping a log of these maintenance activities can also provide valuable insights into patterns that may indicate when certain components need replacement or further attention.

By prioritizing maintenance, you can ensure that your TorusCNC grinder remains aligned and performs at its best.

Troubleshooting Common Alignment Issues in Your 2×72 Grinder

Even with careful assembly and maintenance, alignment issues can occasionally arise with your 2×72 grinder. Common problems include belt tracking issues, uneven wear on grinding surfaces, or vibrations during operation. Identifying these issues early is crucial to preventing further complications.

If you notice that the belt is not tracking properly, start by checking the alignment of the tracking mechanism and adjusting it as needed. Another common issue is uneven wear on belts or grinding surfaces, which can indicate misalignment or improper tensioning. Regularly inspecting these components will help you catch problems before they escalate.

If vibrations occur during operation, it may be necessary to check for loose components or imbalances in the setup. By systematically troubleshooting these common issues, you can maintain optimal performance and extend the life of your TorusCNC 2×72 grinder.

The Benefits of CNC Precision in Your 2×72 Grinder

The integration of CNC precision technology into your 2×72 grinder offers numerous benefits that enhance both efficiency and quality. One of the most significant advantages is the ability to achieve consistent results across multiple projects. CNC precision allows for repeatable settings that ensure each piece produced meets exact specifications, reducing variability and improving overall quality.

Additionally, CNC technology often enables more complex designs that would be challenging to achieve manually. This opens up new possibilities for creativity and innovation in your work. With tools like those offered by TorusCNC, users can leverage advanced features that streamline processes and enhance productivity.

The combination of precision and versatility makes CNC-equipped grinders an invaluable asset for both professional craftsmen and dedicated hobbyists.

Taking Your Grinding to the Next Level with CNC Precision Technology

Embracing CNC precision technology in your 2×72 grinder can elevate your grinding capabilities to new heights. By utilizing advanced features such as programmable settings and automated adjustments, you can significantly reduce manual labor while increasing accuracy. This technology allows for more intricate designs and higher-quality finishes that were previously difficult to achieve with traditional methods.

Moreover, investing in CNC precision tools from TorusCNC not only enhances your current capabilities but also prepares you for future advancements in grinding technology. As you become more familiar with these tools and their potential applications, you will find new ways to innovate within your craft. Ultimately, taking advantage of CNC precision technology will not only improve your current projects but also inspire new ideas and techniques that push the boundaries of what is possible in metalworking.

FAQs

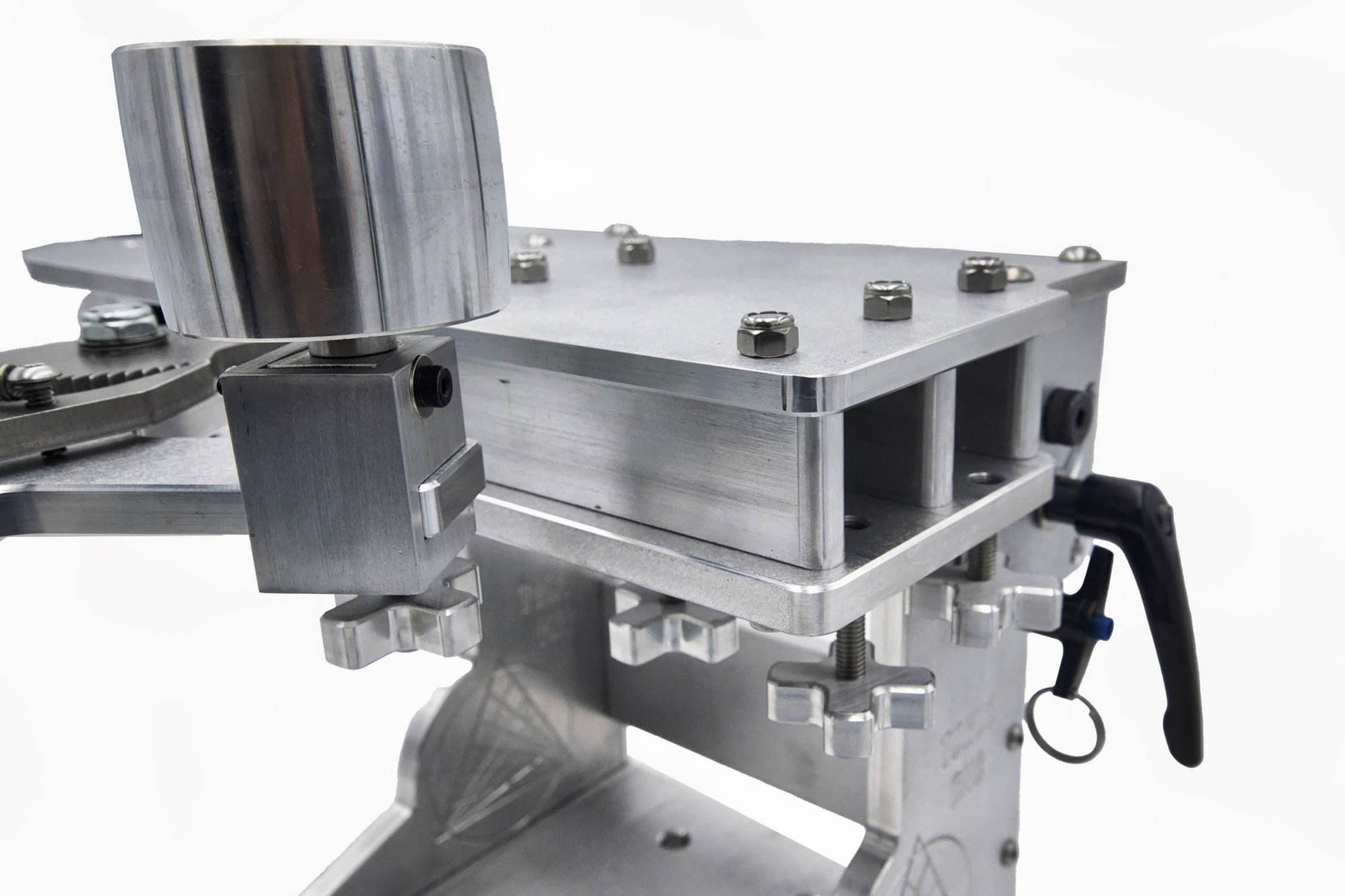

What is CNC precision in the context of a 2×72 grinder?

CNC precision refers to the use of computer numerical control (CNC) technology to ensure precise and accurate measurements, cuts, and alignments in the manufacturing of 2×72 grinders. This technology allows for high levels of accuracy and consistency in the production process.

How does CNC precision ensure a perfect fit in a 2×72 grinder?

CNC precision ensures a perfect fit in a 2×72 grinder by allowing for precise machining of components to exact specifications. This results in parts that fit together seamlessly, reducing the likelihood of misalignments or inconsistencies in the final product.

What are the benefits of using CNC precision in the manufacturing of 2×72 grinders?

The benefits of using CNC precision in the manufacturing of 2×72 grinders include increased accuracy, consistency, and quality of the final product. CNC precision also allows for greater efficiency in the production process, as well as the ability to create complex and intricate designs with ease.

How does CNC precision contribute to alignment in a 2×72 grinder?

CNC precision contributes to alignment in a 2×72 grinder by ensuring that all components are machined to exact specifications, resulting in proper alignment when the grinder is assembled. This helps to prevent issues such as wobbling or uneven grinding, and ensures that the grinder operates smoothly and efficiently.

Can CNC precision be applied to custom 2×72 grinders?

Yes, CNC precision can be applied to custom 2×72 grinders. By using CNC technology, custom grinder manufacturers can ensure that each component is machined to the specific requirements of the customer, resulting in a high-quality, custom grinder with precise fit and alignment.