Importance of 2×72 Belt Grinders

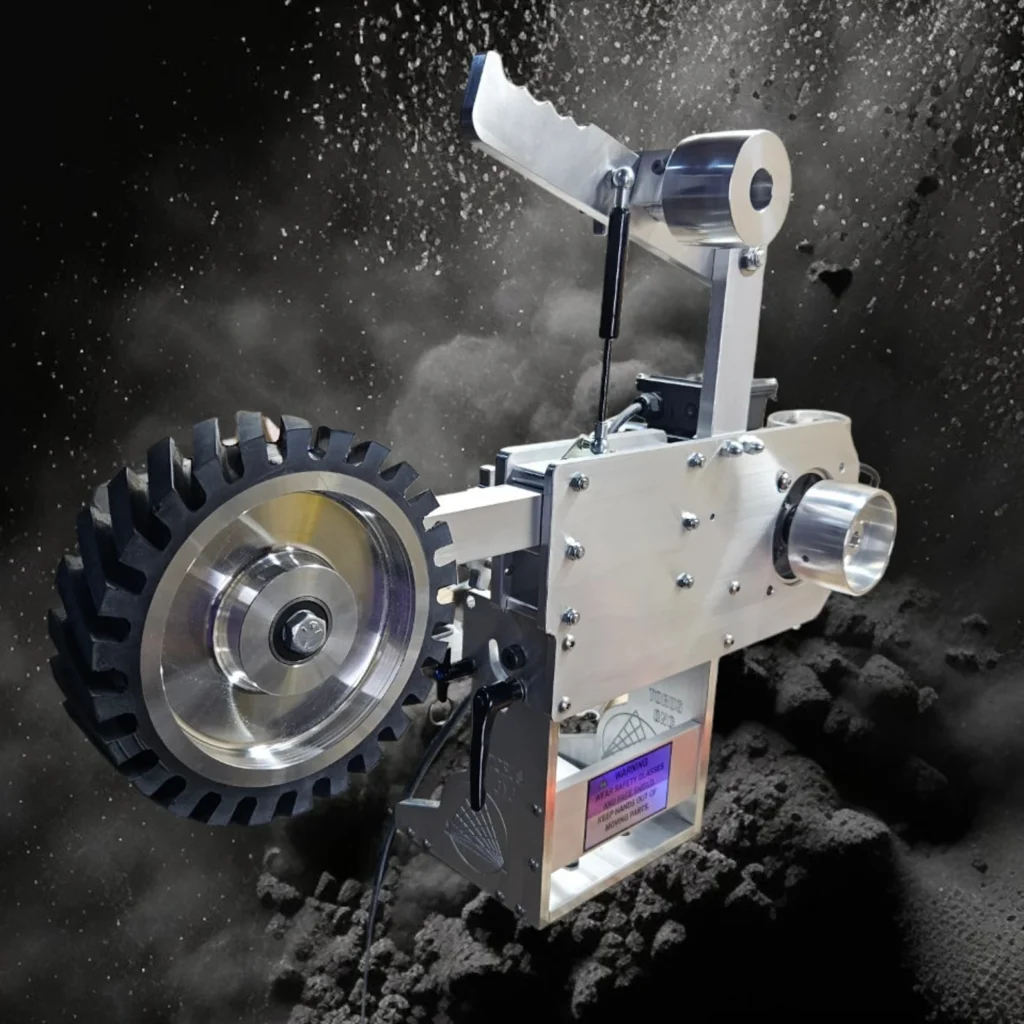

The world of grinding and shaping metal has evolved significantly, but the 2×72 belt grinder still stands out as an essential tool for many professionals and hobbyists. Whether you’re crafting custom knives, fitting metal components, or working on intricate designs, the 2×72 belt grinder takes center stage due to its impeccable functionality and versatility. One of the key reasons for its importance is the efficiency it offers. These machines boast speed and precision, allowing users to achieve incredible results in less time. Moreover, the adaptability of 2×72 belt grinders makes them suitable for various applications, from heavy stock removal to delicate finishing work. Here are several reasons why 2×72 belt grinders are indispensable:

- Versatile Grinding Options: They can accommodate different belts to suit various tasks, whether you require coarse grinding or a fine polish.

- Cost-Effectiveness: Investing in a quality 2×72 belt grinder can lead to significant long-term savings, minimizing the need for multiple tools.

- Customization: Users can tailor their projects to perfection, ensuring that each job is met with precise finishes.

- Safety Features: Many models come equipped with advanced guarding systems, promoting safe operation.

Overall, the 2×72 belt grinder plays a pivotal role in enhancing productivity and craftsmanship, making it a fundamental piece of equipment in any metalworking shop.

Efficiency of 2×72 Belt Grinders

Speed and Precision

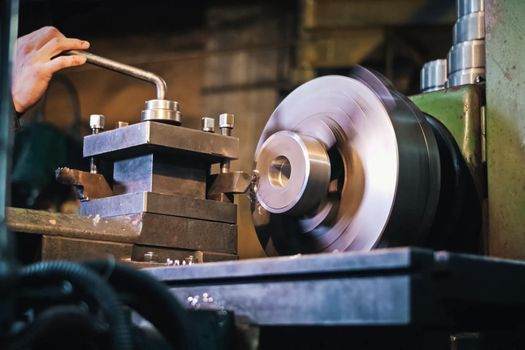

Transitioning from the undeniable importance of 2×72 belt grinders, their efficiency stands out as a crucial aspect that elevates the experience of any user. The remarkable speed and precision these machines deliver set them apart from other grinding tools available on the market. When it comes to speed, the 2×72 belt grinder is designed to tackle demanding tasks without sacrificing quality. Users can achieve swift material removal, which is especially beneficial when working on larger projects that require extensive grinding. A well-tuned machine can operate at varying belt speeds, allowing for adaptability depending on the specific application. Here are some highlights:

- Rapid Material Removal: The powerful motor can swiftly remove layers of metal, greatly reducing the time needed for shaping.

- Adjustable Speed Settings: Many models feature variable speed controls, enabling users to optimize performance based on the task—whether it’s rough grinding or fine finishing.

Precision is equally important in metalworking, and the 2×72 belt grinder delivers reliable results. The flat platen allows for consistent pressure and alignment, minimizing the chances of mistakes. Whether crafting intricate details on a knife blade or smoothing out an irregular surface, this tool ensures every cut is precise. Ultimately, the combination of speed and precision makes the 2×72 belt grinder indispensable for anyone serious about their trade, allowing for a seamless blend of efficiency and craftsmanship.

Versatility of 2×72 Belt Grinders

Various Grinding Options

Building on the remarkable efficiency brought by 2×72 belt grinders, their versatility further enhances their appeal to metalworkers and artisans alike. These machines are not just one-dimensional; they offer a wide array of grinding options that cater to various needs and preferences. One of the most impressive features of the 2×72 belt grinder is its capability to accommodate different types of belts. This flexibility means that users can switch between belts tailored for specific tasks, allowing for a seamless transition from rough shaping to finer finishing. Here’s a closer look at the different grinding options available:

- Grit Variety: Users can choose belts with varying grit sizes—coarse belts for aggressive material removal and finer belts for polishing and finishing.

- Specialized Belts: From ceramic to zirconia, the options are vast, allowing for specific applications like steel cutting or deburring.

- Attachment Options: Many models offer additional attachments, such as a contact wheel or flat platen, expanding the range of tasks one can perform.

This versatility is particularly beneficial for custom work, such as knife making. A craftsman can begin with a coarse grit to shape the blade, followed by medium and fine grits to refine the edge. The ability to achieve high-quality results in a single machine streamlines the workflow and enhances productivity. In essence, the 2×72 belt grinder transcends basic grinding, making it an indispensable tool across multiple trades and crafts, ensuring users can tackle diverse projects efficiently.

Cost-Effectiveness of 2×72 Belt Grinders

Long-Term Savings

Transitioning from the impressive versatility of 2×72 belt grinders, it is essential to discuss their cost-effectiveness, particularly focusing on the long-term savings they offer to users. While the initial investment may seem substantial, the value delivered over time makes it a smart choice for both hobbyists and professionals. Investing in a 2×72 belt grinder can lead to significant savings in various ways:

- Durable Materials: Built from high-quality components, these grinders are designed to last. By reducing the need for frequent replacements, users save on overall costs in the long run.

- Efficiency in Time: With high speed and precision, tasks that previously took hours can often be completed in minutes. This efficiency translates into more projects and potentially increased income for professionals.

- Versatile Usage: As discussed previously, their adaptability means you won’t need to purchase multiple machines for different tasks. A single investment covers a range of grinding, shaping, and finishing needs.

- Reduced Material Waste: Fine-tuning a project with a 2×72 grinder results in less scrap material, which means users save money by optimizing their use of resources.

In the grand scheme, the true cost savings from a 2×72 belt grinder come not from the purchase price, but from its longevity, efficiency, and multifunctionality. This makes it an essential tool for anyone looking to enhance their metalworking capabilities sustainably.

Customization with 2×72 Belt Grinders

Tailored Blade Finishes

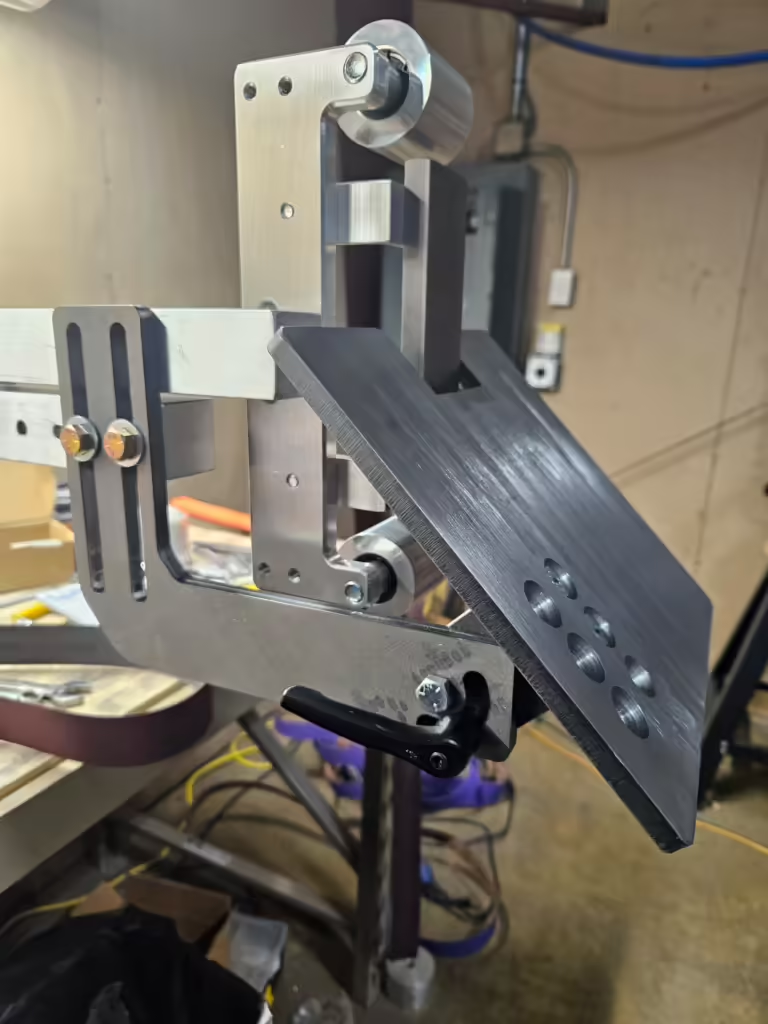

Following the exploration of cost-effectiveness, it’s crucial to highlight another standout feature of the 2×72 belt grinder: its ability to facilitate customized blade finishes. This versatility allows craftsmen to achieve a level of personalization that enhances their work and holds special value for any project. When it comes to crafting blades, achieving the perfect finish is essential, not just for aesthetics, but also for functionality. The 2×72 belt grinder shines in this area, offering several advantages:

- Multiple Belt Options: The ability to easily swap out belts of varying grit helps users transition from rough shaping to a polished finish seamlessly. From low-grit belts for significant material removal to high-grit belts for that razor-sharp edge, the customization options are extensive.

- Adjustable Angles and Techniques: Many grinders come equipped with adjustable work tables and attachments, allowing users to create bevels or contours that suit their design needs.

- Consistent Results: The flat platen or contact wheel provides even pressure, which helps maintain uniformity across the blade.

This level of customization is crucial for those creating specialized knives or tools. Whether a craftsman desires a high-gloss finish or a unique texture, the 2×72 belt grinder provides the tools required to fulfill those creative visions. In essence, the ability to tailor blade finishes with precision not only enhances the quality of the work but also enables artisans to express their unique styles and preferences, solidifying the 2×72 as an essential tool in any workshop.

Safety Features of 2×72 Belt Grinders

Guarding Systems

As we continue to examine the impressive features of 2×72 belt grinders, it’s vital to turn our attention to safety, especially the innovative guarding systems that enhance user protection. While these machines provide incredible versatility and efficiency, safety should always be a priority in any workshop environment. Modern 2×72 belt grinders incorporate several safety features designed to minimize risk during operation. Here’s how these guarding systems play a crucial role:

- Belt Guarding: Covers ensure that the grinding belt is contained, protecting users from unintentional contact with moving parts. This reduces the risk of injury, particularly when the grinder is in use.

- Emergency Stop Button: Most models come equipped with an easily accessible emergency stop button, allowing users to halt operations quickly if a situation arises.

- Adjustable Shields: Some grinders feature adjustable shields that can be positioned according to the user’s preference, providing additional protection from sparks and debris generated during grinding.

- Well-Designed Work Areas: A spacious and clearly defined work area can prevent accidents. Many high-quality models include features that promote a clean and organized workspace, reducing clutter and potential hazards.

By integrating these critical safety features, 2×72 belt grinders not only enhance user experience but also foster a safe working environment. Adhering to these precautions allows craftsmen to focus on their artistry with peace of mind, knowing they are wellprotected while they create.

Durability and Reliability of 2×72 Belt Grinders

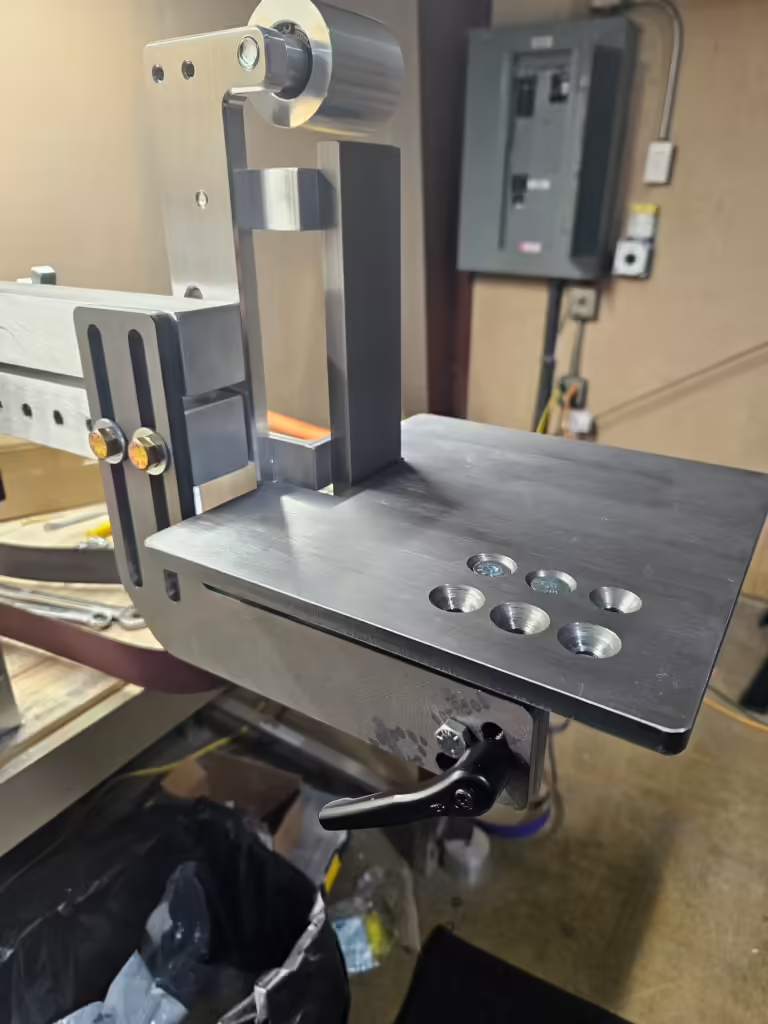

Quality Construction Materials

Continuing our exploration of 2×72 belt grinders, it becomes evident that their durability and reliability are among the most appealing features, thanks primarily to the high-quality construction materials used in their design. This focus on robust materials not only enhances the lifespan of the grinder but also ensures it can withstand the rigors of daily use. When selecting a 2×72 belt grinder, here’s how quality construction materials contribute to its performance:

- Heavy-Duty Frames: Many models feature all-steel construction, which provides a sturdy base that minimizes vibrations. This stability not only leads to better precision while grinding but also contributes to the overall longevity of the machine.

- High-Quality Motors: A reliable motor is vital for consistency in performance. High-performance motors can endure extended use without overheating, ensuring smooth operation throughout various tasks.

- Wear-Resistant Parts: Key components, including pulleys and bearings, are often made from wear-resistant materials to decrease maintenance needs and extend the equipment’s lifespan.

- Easy Maintenance Features: Some grinders are designed with maintenance in mind, making it easy to replace worn parts to keep the machine running smoothly.

By investing in a 2×72 belt grinder constructed with these quality materials, users can enjoy a reliable tool that stands the test of time. This not only fosters trust in the equipment but also reinforces confidence in achieving consistent, high-quality results across various projects, ensuring durability in every aspect of performance.

Maintenance Tips for 2×72 Belt Grinders

Cleaning and Adjustments

Shifting focus from the durability and reliability of 2×72 belt grinders, we arrive at an essential aspect of keeping these powerful machines in top condition: regular maintenance. Proper cleaning and adjustments not only ensure optimal performance but also extend the life of your grinder, allowing you to continue producing quality work for years to come. Here are some effective maintenance tips that every user should consider:

- Regular Cleaning: After each use, take a moment to clean the grinder. Dust and metal shavings can accumulate, affecting performance. A simple brush or compressed air can help clear debris from the machine’s surfaces, including the belt and platen.

- Check the Belts: Inspect belts for signs of wear or damage. Frayed or worn belts should be replaced immediately to maintain performance and quality.

- Align the Tracking: Misalignment can lead to uneven wear on the belts and even compromise safety. Regularly check and adjust the tracking system to ensure the belt runs straight and true.

- Lubricate Moving Parts: Keeping moving parts adequately lubricated ensures smooth operation. Use manufacturer-recommended lubricants on bearings and pulleys to minimize friction.

- Tighten Loose Bolts: Periodically check for loose bolts and fasteners. Tightening any loose components can prevent wear and tear on the grinder.

By adhering to these cleaning and adjustment practices, users can maintain the 2×72 belt grinder in prime condition. Taking the time for maintenance not only safeguards your investment but also enhances your overall grinding experience, allowing for precision and consistency in every project.

Popular 2×72 Belt Grinder Brands

Comparison of Leading Models

With maintenance practices in place, it’s time to explore some of the most popular brands on the market and compare their leading models. Choosing the right 2×72 belt grinder can greatly impact your workflow and the quality of your projects, making it essential to know what each brand offers. Here’s a breakdown of some of the top names in 2×72 belt grinders and their standout features:

- Bader:

- Model: Bader BIII

- Key Features: Known for its sturdy design and robust performance. It offers versatile belt speeds and adjustable angles, making it suitable for various grinding tasks.

- Grizzly:

- Model: Grizzly G1015

- Key Features: This model shines with its powerful motor and capacity for numerous attachments. It’s a great option for both hobbyists and professionals.

- KM (KnifeMaker):

- Model: KM 2×72

- Key Features: Specifically designed for knife-making, this grinder is highly adaptable with multiple options for customization. It’s celebrated for its fine craftsmanship and reliable performance.

- Hollymatic:

- Model: Hollymatic 2×72 Belt Grinder

- Key Features: Ideal for industrial use, it boasts heavy-duty components and exceptional durability, making it suitable for high-demand environments.

When making your decision, consider factors like project requirements, available attachments, and specific features that might enhance your work. Each of these brands has established a reputation for reliability and performance, ensuring that no matter which model you choose, you’ll have a quality tool at your disposal. By comparing these leading models, users can select the 2×72 belt grinder that aligns perfectly with their crafting needs and ensures efficient workflow.