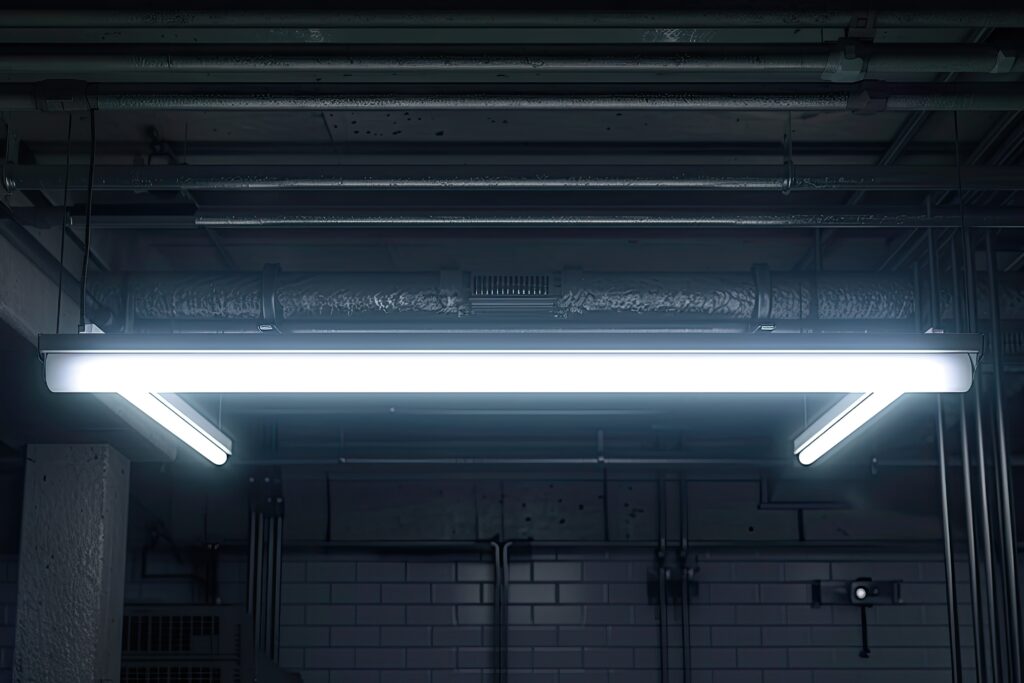

In the world of machining and metalworking, precision is paramount. Grinders, whether used in industrial settings or home workshops, require optimal visibility to ensure accuracy and safety. This is where LED task lighting comes into play.

LED lights have revolutionized the way we illuminate workspaces, providing bright, energy-efficient lighting that enhances visibility without generating excessive heat. As grinders are often used in environments where shadows can obscure fine details, integrating LED task lighting can significantly improve the overall grinding experience. The introduction of LED task lighting to grinders is not merely a matter of convenience; it is a strategic enhancement that can lead to better outcomes in terms of both quality and safety.

With the right lighting, operators can see their workpieces more clearly, allowing for more precise adjustments and reducing the risk of errors. This article will explore the myriad benefits of adding LED task lighting to grinders, the various options available, installation tips, and much more.

Key Takeaways

- LED task lighting can improve precision and accuracy in grinding processes

- Adding LED task lighting to your grinder can enhance safety and reduce the risk of accidents

- There are different types of LED task lighting options available for grinders, including flexible arm lights and magnetic base lights

- Installing LED task lighting on your grinder is a straightforward process that can be done with basic tools

- When choosing LED task lighting for your grinder, consider factors such as brightness, durability, and energy efficiency

Benefits of Adding LED Task Lighting to Your Grinder

One of the most significant advantages of incorporating LED task lighting into your grinder setup is the enhanced visibility it provides. Traditional lighting solutions often cast shadows or create uneven illumination, making it difficult to see intricate details on the workpiece. In contrast, LED lights offer a bright, focused beam that illuminates the grinding area uniformly.

This clarity allows operators to detect imperfections or inconsistencies in their work, leading to higher-quality results. Moreover, LED lights are known for their energy efficiency and longevity. Unlike incandescent bulbs that consume more power and have shorter lifespans, LEDs use significantly less energy and can last for tens of thousands of hours.

This not only reduces electricity costs but also minimizes the frequency of bulb replacements, making them a cost-effective solution in the long run. Additionally, LEDs emit very little heat, which is particularly beneficial in grinding applications where excessive heat can affect both the operator’s comfort and the integrity of the materials being worked on.

Different Types of LED Task Lighting Options Available

When it comes to selecting LED task lighting for grinders, there are several options to consider. One popular choice is flexible LED strip lights, which can be easily mounted along the edges of the grinder or workbench. These strips provide a continuous line of light and can be cut to fit specific lengths, making them highly customizable for different setups.

Their flexibility allows them to be positioned in a way that minimizes shadows and maximizes illumination. Another option is LED work lights that come with adjustable arms or magnetic bases. These lights can be positioned precisely where they are needed most, providing targeted illumination on the grinding surface.

Some models even feature dimming capabilities, allowing users to adjust the brightness according to their specific needs. Additionally, portable LED task lights can be beneficial for those who require mobility in their workspace, as they can be easily moved around as needed.

How to Install LED Task Lighting on Your Grinder

Installing LED task lighting on your grinder is a straightforward process that can typically be completed with minimal tools. First, assess your workspace to determine the best location for the lights. Ideally, you want to position them in a way that eliminates shadows while providing direct illumination on the grinding area.

Once you have identified the optimal placement, clean the surface where the lights will be mounted to ensure proper adhesion. For strip lights, most come with an adhesive backing that allows for easy installation. Simply peel off the protective layer and stick the strip in place.

For adjustable work lights or those with magnetic bases, ensure that they are securely attached and positioned correctly. If your lights require wiring, follow the manufacturer’s instructions carefully to connect them safely to a power source. Always prioritize safety during installation by ensuring that all electrical connections are secure and insulated.

Tips for Choosing the Right LED Task Lighting for Your Grinder

Selecting the right LED task lighting for your grinder involves considering several factors to ensure optimal performance. First and foremost, assess the brightness level required for your specific tasks. Measured in lumens, brighter lights are generally better for detailed work, while softer lighting may suffice for general tasks.

Look for lights that offer adjustable brightness settings for added versatility. Another important consideration is color temperature, which affects how colors appear under different lighting conditions. A cooler color temperature (around 5000K to 6500K) mimics daylight and is ideal for precision work as it enhances visibility and reduces eye strain.

Additionally, consider the durability of the lighting fixtures; they should be robust enough to withstand the rigors of a workshop environment where dust and debris are common.

Maintenance and Care for LED Task Lighting on Grinders

Maintaining LED task lighting is relatively simple but essential for ensuring longevity and optimal performance. Regularly inspect the lights for any signs of damage or wear, such as frayed wires or cracked fixtures. Keeping the lights clean is also crucial; dust and grime can accumulate over time and diminish brightness.

Use a soft cloth or a gentle cleaning solution to wipe down the surfaces without damaging any components. If your LED lights are equipped with adjustable features or moving parts, ensure that these mechanisms are functioning smoothly. Lubricate any joints or hinges as necessary to prevent stiffness or breakage.

Additionally, check electrical connections periodically to ensure they remain secure and free from corrosion.

Safety Considerations When Using LED Task Lighting on Grinders

While LED task lighting enhances visibility and safety in grinding operations, it is essential to adhere to safety protocols when using these lights. First and foremost, ensure that all electrical components are properly installed and insulated to prevent short circuits or electrical shocks. Use lights that are rated for industrial use if your grinder operates in a demanding environment.

Furthermore, be mindful of glare when positioning your lights. Excessive glare can lead to eye strain and hinder visibility rather than improve it. Adjusting the angle of the lights or using diffusers can help mitigate this issue.

Lastly, always wear appropriate personal protective equipment (PPE) when operating grinders, regardless of lighting conditions.

How LED Task Lighting Can Improve Precision and Accuracy in Grinding

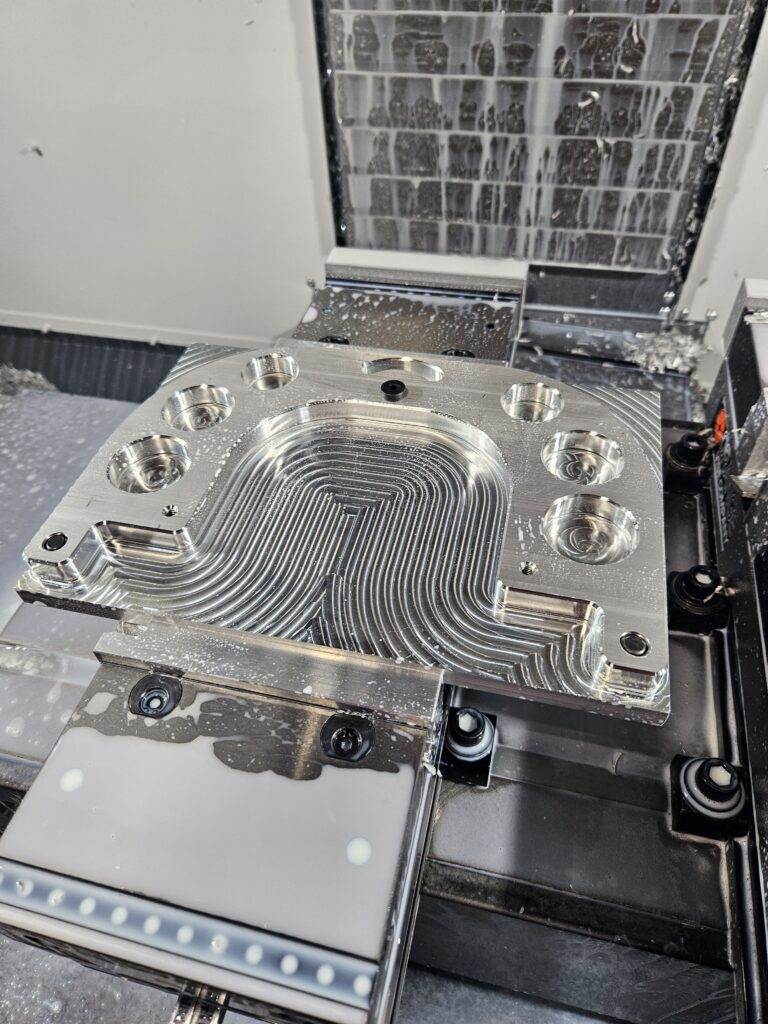

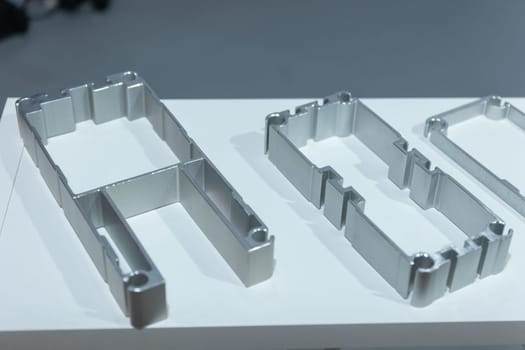

The impact of proper lighting on precision work cannot be overstated. In grinding applications, even minor misalignments can lead to significant errors in finished products. By integrating LED task lighting into your grinder setup, operators gain enhanced visibility that allows them to make more accurate adjustments during the grinding process.

This increased clarity helps in identifying defects or inconsistencies early on, reducing waste and improving overall quality. Moreover, well-placed LED lighting can help operators maintain consistent pressure and angles while grinding, further enhancing precision. The ability to see clearly what they are working on allows operators to focus on technique rather than struggling with inadequate lighting conditions.

As a result, businesses can achieve higher standards of craftsmanship and reduce rework costs associated with poorly executed grinding tasks.

Case Studies: Success Stories of Upgrading Grinders with LED Task Lighting

Numerous businesses have reported significant improvements after upgrading their grinders with LED task lighting. For instance, a small machine shop specializing in custom parts found that after installing LED strip lights above their grinding stations, their production efficiency increased by 20%. Operators were able to see details more clearly, leading to fewer mistakes and faster turnaround times on projects.

Another case involved a larger manufacturing facility that integrated adjustable LED work lights into their grinding areas. The flexibility of these lights allowed operators to position them according to their specific needs throughout different tasks. As a result, they reported a marked decrease in operator fatigue due to reduced eye strain and improved overall working conditions.

Cost Considerations for Adding LED Task Lighting to Your Grinder

When considering the addition of LED task lighting to your grinder setup, it’s essential to evaluate both initial costs and long-term savings. The upfront investment in quality LED fixtures may seem higher than traditional lighting options; however, this cost is often offset by energy savings over time due to LEDs’ lower power consumption and longer lifespan. Additionally, consider potential productivity gains from improved visibility and reduced errors in grinding operations.

The ability to produce higher-quality work with fewer mistakes can lead to increased profitability in the long run. Therefore, while there may be an initial expenditure involved in upgrading your lighting system, the return on investment can be substantial when factoring in enhanced efficiency and reduced operational costs.

Future Trends in LED Task Lighting for Grinders

As technology continues to evolve, so too does the landscape of LED task lighting solutions for grinders. One emerging trend is the integration of smart technology into lighting systems. Smart LEDs can be controlled via mobile apps or voice commands, allowing operators to adjust brightness levels or color temperatures seamlessly without leaving their workstation.

Another trend is the development of more compact and versatile lighting solutions that incorporate advanced optics for better light distribution without increasing size or complexity. These innovations aim to provide even greater flexibility in positioning while maintaining high levels of illumination quality. In conclusion, integrating LED task lighting into grinder setups offers numerous benefits ranging from improved visibility and precision to enhanced safety and efficiency.

As technology advances, these solutions will continue to evolve, providing even more opportunities for operators to optimize their grinding processes effectively.

FAQs

What is LED task lighting?

LED task lighting is a type of lighting that is designed to provide focused and bright illumination for specific tasks, such as working on a grinder. It is energy-efficient and long-lasting, making it a popular choice for workspaces.

Why should I install LED task lighting on my grinder?

Installing LED task lighting on your grinder can improve visibility and safety while working. It can help you see the workpiece more clearly and reduce the risk of accidents or mistakes.

How do I install LED task lighting on my grinder?

To install LED task lighting on your grinder, you will need to purchase a suitable LED light fixture and mounting hardware. Follow the manufacturer’s instructions for installation, and ensure that the lighting is securely attached to the grinder.

What are the benefits of using LED task lighting on a grinder?

LED task lighting offers several benefits, including energy efficiency, long lifespan, and bright, focused illumination. It can also improve productivity and reduce eye strain while working on the grinder.

Are there any safety considerations when installing LED task lighting on a grinder?

When installing LED task lighting on a grinder, it is important to ensure that the lighting is securely mounted and does not interfere with the operation of the grinder. Additionally, be sure to follow all safety guidelines and recommendations provided by the manufacturer.