Introduction

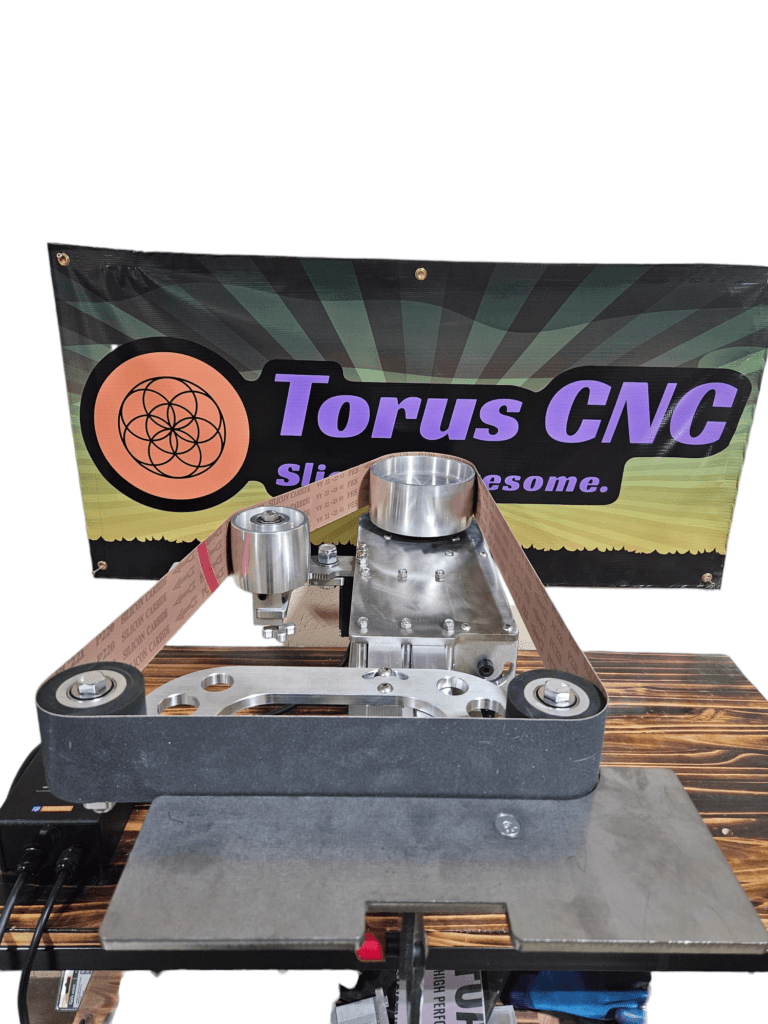

Overview of 2×72 Grinder

When it comes to craftsmanship in knife making, the tools of the trade play a pivotal role in achieving precision and quality. Among these, the 2×72 grinder stands out as a major asset. Designed for versatility and efficiency, a 2×72 grinder features an expansive 2-inch by 72-inch belt. This size allows for a range of grinding options, making it suitable for both beginners and seasoned professionals. The length of the belt provides a greater surface area for grinding, which helps in achieving various tasks, from smoothing out rough edges to perfecting intricate bevels. Due to its size, the grinder can quickly remove material without sacrificing control over the finishing process. Additionally, the adjustable speed and interchangeable belts make it highly adaptable for different projects, whether they involve shaping stainless steel or crafting a beautiful Damascus blade. Some key features of the 2×72 grinder include:

- Strong Motor: Capable of delivering consistent power for long periods.

- Ease of Use: User-friendly design that minimizes the learning curve.

- Durability: Built to endure the rigors of constant use in a workshop setting.

Importance of Grinder in Knife Making

In knife making, the importance of a high-quality grinder like the 2×72 cannot be overstated. It is not merely about removing metal; it’s about bringing a vision to life through precision and artistry. A well-functioning grinder will significantly affect the quality of the finished product. Here’s why a grinder is essential in the knife-making process:

- Achieving Precision: A grinder allows for accurate shaping of both the blade and the handle. This precision is key to the knife’s performance.

- Efficient Material Removal: The robust design of a 2×72 grinder facilitates the quick removal of material, allowing makers to move through the initial shaping stages faster.

- Smoothing Surfaces: After the basic shape is formed, a grinder helps in refining the surface, crucial for aesthetics and usability.

- Versatile Applications: Beyond knife-making, a 2×72 grinder is invaluable in other metalworking projects, showcasing its versatility and cost-effectiveness.

In conclusion, the 2×72 grinder is not just a tool; it is a knife maker’s best ally, providing the means to transform raw material into functional art. Whether you are a novice eager to learn or an expert honing your craft, investing in a quality grinder will surely enhance your knife-making journey.

Precision Grinding

Consistent Blade Shapes

Precision grinding is a hallmark of quality knife making, and one of the most significant advantages of using a 2×72 grinder is the ability to achieve consistent blade shapes. Every knife maker desires blades that reflect symmetrical aesthetics and functional excellence. The 2×72 grinder excels in this area, allowing craftspeople to replicate designs accurately and efficiently. To illustrate, consider a knife designed for utility—having a consistent blade shape ensures that it performs tasks effectively across different uses, from slicing to prying. With the 2×72 grinder, makers can easily adjust the belt tension and angle of the grind, enabling them to craft blades that showcase uniformity and smooth contours. Key aspects that contribute to achieving consistent blade shapes include:

- Belt Variety: The availability of multiple belt grits and types allows makers to tailor their approach based on the desired finish and design.

- Controlled Speed: Many 2×72 grinders allow for variable speeds; slower speeds can provide finely tuned grinding, while faster speeds help with initial shaping.

- Setup Memorization: Once a setup for a specific blade design is established, it can be replicated, ensuring that future products maintain the same high standards.

Using a grinder with these attributes means that even the most complex designs can be tackled efficiently, leading to massive time savings without compromising quality.

Accurate Bevel Angles

Another critical aspect of precision grinding in knife making is the accuracy of bevel angles. The bevel determines not only the knife’s aesthetic appeal but also its performance characteristics. A finely ground bevel enhances the cutting edge, making it sharper and more functional. Achieving accurate bevel angles is crucial for several reasons:

- Performance: A knife with the correct bevel angle will cut more efficiently and offer better control, leading to a superior user experience.

- Durability: Proper angles help in wearing down the blade evenly, prolonging its lifespan and maintaining its performance.

- Sharpness: The steepness of the bevel impacts how sharp the knife can be honed. A well-ground bevel allows for easier and more consistent sharpening.

With a 2×72 grinder, adjusting and maintaining these bevel angles becomes a straightforward task. Craftspeople can utilize jigs or guides to lock in their settings, ensuring accuracy with each new blade. Here are some tips for achieving precise bevel angles:

- Use Angle Jigs: These tools can help maintain consistent angles, especially for those new to knife making.

- Gradual Material Removal: Taking the time to work gradually helps maintain control over the edge and angles.

- Visual Marking: Some makers prefer to mark the desired angle on the steel before grinding to have a visual reference point.

In conclusion, precision grinding with a 2×72 grinder is vital in achieving both consistent blade shapes and accurate bevel angles. Mastering these elements not only enhances the quality of the knives but also elevates the overall craftsmanship involved in the art of knife making.

Time Efficiency

Faster Material Removal

Time efficiency plays a crucial role in the knife-making process, and one of the standout benefits of the 2×72 grinder is its ability to facilitate faster material removal. Unlike traditional grinding methods that can be labor-intensive and time-consuming, the 2×72 grinder allows craftsmen to slice through material quickly and effectively. With a powerful motor and a larger belt size, the 2×72 grinder removes significant amounts of metal in a fraction of the time. This efficient material removal is especially vital during the initial stages of crafting a blade. For instance, rough-shaping a blade might typically take several hours with inferior equipment, but with a 2×72 grinder, this task may be completed in as little as half the time. When considering faster material removal, keep these points in mind:

- Enhanced Power: The robust motor can tackle tough materials with ease, allowing for smooth transitions across different metal types.

- Wide Belt Surface: The larger surface area of the belt ensures more efficient grinding, eliminating the need for multiple passes over the same area.

- Variable Speeds: Being able to adjust the speed affects how aggressively you can grind material, allowing you to optimize the process according to preference and blade requirements.

Using the 2×72 grinder, artisans can focus more time on intricate details and finishing touches rather than laboriously shaping the base form of their blades.

Streamlined Grinding Process

Coupled with faster material removal, the 2×72 grinder also streamlines the overall grinding process. This tool integrates multiple functions—shaping, profiling, and finishing—into one apparatus, creating a fluid workflow that enhances productivity. A streamlined process reduces the time spent switching between different tools and set-ups, making the craft not only quicker but also much more enjoyable. Craftspeople can transition seamlessly from one grinding station to another while ensuring they maintain control and precision. Here are some elements that contribute to a streamlined grinding process:

- Belt Switching: Changing belts on a 2×72 grinder is quick and hassle-free. Having multiple belts easily available means the craftsman can conveniently shift from rough grinding to finer finishes without interrupting the workflow.

- Angle Adjustment: The ability to adjust angles quickly allows for rapid changes in operations—making it easier to handle different designs or intricate tasks without wasting time on recalibrating setups.

- Integrated Workspace: Many 2×72 grinders can be fitted with accessories like work tables and safety guards, enhancing workspace efficiency and safety during operation.

Ultimately, the efficiency of the 2×72 grinder means that knife making evolves from being a lengthy ordeal into a streamlined, enjoyable craft. This approach not only maximizes output but also allows artisans to create high-quality knives with less frustration and more inventive spirit. In the fast-paced world of craftsmanship, the time saved is often reflected in the quality and quantity of the final pieces, enabling artisans to meet demands effectively while focusing on their craft.

Versatility

Various Grinding Options

Versatility is a hallmark of the 2×72 grinder, making it an indispensable tool for knife makers who require flexibility in their craft. One of the most attractive features of this grinder is its ability to accommodate a wide variety of grinding options. Whether crafting a chef’s knife, a hunting blade, or a custom utility tool, the 2×72 grinder can tackle various tasks with finesse. With the capacity to use different belt types, grits, and attachments, users can switch between operations such as rough shaping, bevel grinding, and even polishing with relative ease. Here are some of the grinding options available to users of the 2×72 grinder:

- Belt Grit Variety: The choice of grits—from coarse to fine—allows for tailoring the grinding process to specific needs. Coarse belts quickly remove metal, while finer belts enhance the finish. Utilizing a progression from coarse to fine ensures a smooth and polished blade.

- Flat and Contour Grinding: The flat platen attachment helps in creating flat surfaces, while the contact wheel enables makers to shape curved edges, offering flexibility in design.

- Specialized Attachments: Accessories such as platen systems, slack belts, and tilting tables can be integrated to expand the capabilities of the grinder, allowing for creativity and innovation in design.

All of these options contribute to a more dynamic workflow, enabling makers to experiment with different styles and techniques without requiring multiple machines or tools.

Compatible with Different Materials

In addition to its various grinding options, the 2×72 grinder shines in its compatibility with different materials. Not just limited to steels, a skilled knife maker can utilize this versatile tool for working with a range of materials, enhancing the potential repertoire of their craft. Some materials suitable for grinding on a 2×72 grinder include:

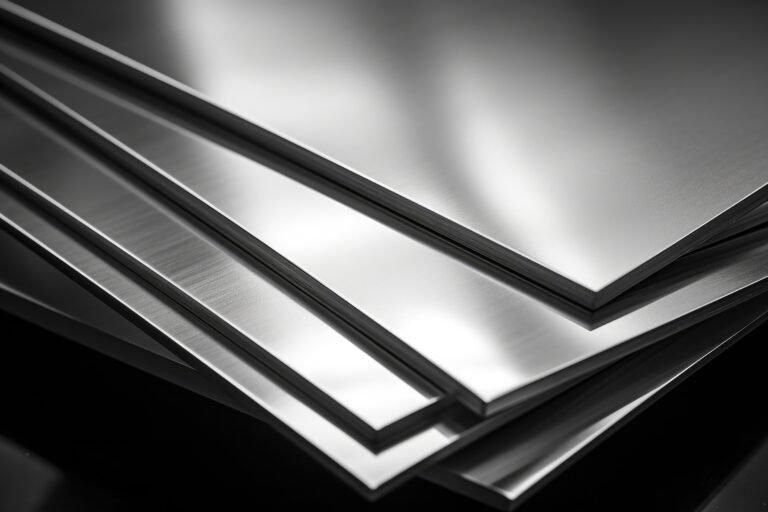

- Stainless Steel: Known for its durability and resistance to corrosion, stainless steel can be shaped efficiently, making it popular for kitchen knives.

- Carbon Steel: This type of steel offers excellent edge retention, and the grinding process can reveal intricate designs in the material.

- Titanium: With its unique properties and weight, titanium is gaining traction in the custom knife-making scene. The 2×72 grinder’s power enables efficient grinding of this challenging material.

- Wood and Composites: When outfitting a grinder with the appropriate attachments, wood and synthetic materials can also be shaped and finished, allowing for the crafting of custom handles to complement high-performance blades.

The adaptability of the 2×72 grinder not only caters to various materials but also empowers artisans to pursue diverse projects within their craft. In summary, the versatility of the 2×72 grinder extends far beyond mere functionality; it encompasses a wide array of grinding options and material compatibility that fosters creativity and innovation. For both novice and experienced knife makers, this adaptability is essential in exploring the full potential of their craft, resulting in unique, high-quality creations that stand out in any collection.

Cost-Effective Solution

Long-Term Savings

When investing in tools for knife making, cost-effectiveness becomes a primary concern for artisans at all skill levels. The 2×72 grinder stands out as a smart investment, offering long-term savings that can positively impact a knife maker’s bottom line. While the initial purchase price may seem daunting, the value it brings over time far outweighs the initial expenditure. The reasons that make the 2×72 grinder a cost-effective solution include:

- Reduced Time Costs: The efficiency of the 2×72 grinder means that jobs can be completed significantly faster compared to traditional methods. Time saved on each project translates to more projects completed within a specific timeframe, thus boosting potential earnings.

- Versatile Applications: As previously mentioned, the grinder’s ability to handle various grinding tasks and materials eliminates the need for multiple machines. By consolidating various grinding tasks into one tool, the maker saves on additional equipment costs.

- High-Quality Output: Well-crafted knives lead to satisfied customers who are willing to pay a premium for quality products. Investing in a high-performing grinder enhances the overall quality of the craftsmanship, translating to improved sales.

- Increased Production: The ability to produce more knives in less time secures enhanced revenue streams, which stabilizes finances. More output generally equates to a stronger reputation and repeat business.

Overall, the 2×72 grinder presents a solid case for long-term savings, confirming that the upfront costs can indeed yield significant benefits over time.

Minimal Maintenance Requirements

Another reason why the 2×72 grinder is a cost-effective tool is due to its minimal maintenance requirements. For any craftsman, the last thing they want is to be bogged down with equipment issues that can disrupt their workflow and lead to additional expenses. Fortunately, the design and build of the 2×72 grinder prioritize durability and ease of use. Consider the following aspects related to minimal maintenance:

- Durable Construction: The robust materials used in manufacturing 2×72 grinders mean they are built to last, withstanding extensive use without breaking down frequently.

- Easy Belt Replacement: Changing belts is a straightforward process that requires no specialized skills, allowing the maker to get back to work quickly and without extra costs.

- Fewer Components to Manage: Compared to more complex machines, the simplicity of the 2×72 grinder’s design means there are fewer parts to wear out or break down, further reducing maintenance concerns.

- Self-Servicing: Many common maintenance tasks can be performed by the user themselves, such as keeping the belts clean and replacing them as needed. This self-sufficiency can save on labor costs associated with repairs and servicing.

In conclusion, the 2×72 grinder is not just an investment in a tool; it represents a long-term cost-effective solution for knife makers. From the savings incurred through improved efficiency and reduced project turnaround times to the low maintenance needs that keep operational costs down, this grinder positions itself as an invaluable asset. By choosing a 2×72 grinder, artisans are not just buying a tool; they are securing a reliable partner in their journey toward crafting exceptional knives.