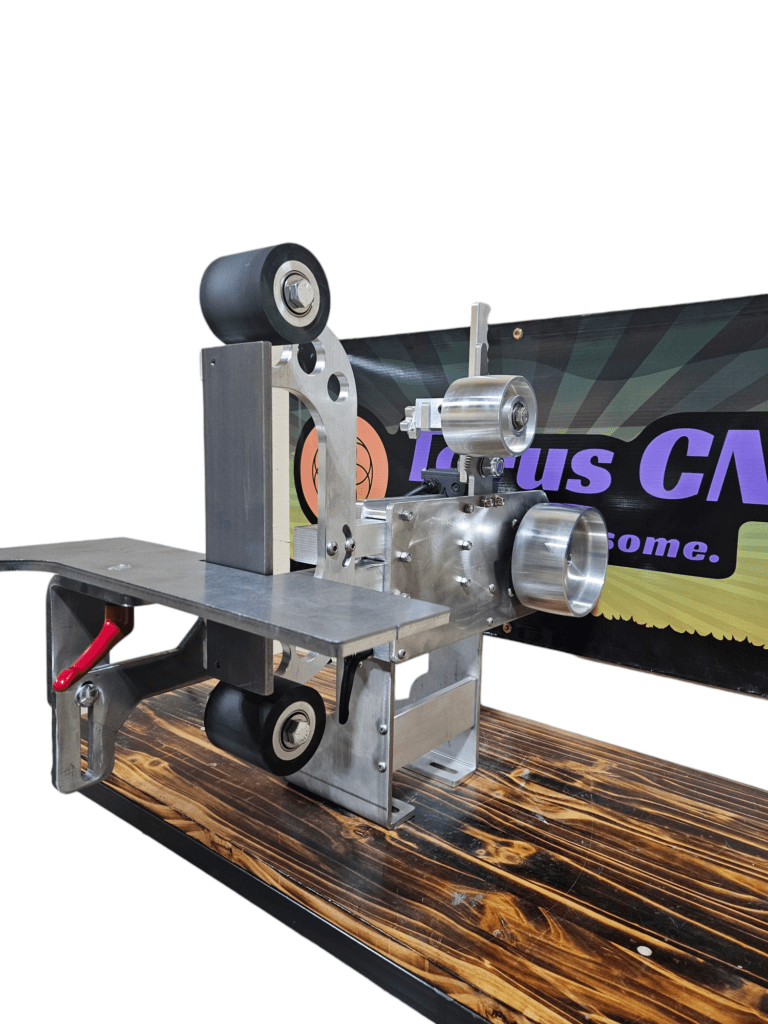

In the world of knife making, the tools and equipment used can significantly influence the quality and efficiency of the final product. One such critical component is the platen length of a belt grinder. The platen serves as a flat surface against which the knife blade is ground, and its length can vary based on the specific needs of the craftsman.

Understanding the nuances of platen length is essential for both novice and experienced knife makers alike, as it can directly impact the grinding process, the quality of the blade, and ultimately, the satisfaction of the maker. Platen length is not merely a technical specification; it embodies a range of considerations that can affect the overall knife-making experience. From the type of knives being produced to the techniques employed during grinding, the choice of platen length can dictate how effectively a maker can achieve their desired results.

As we delve deeper into this topic, we will explore the importance of platen length, its effects on grinding, and how it can be tailored to meet individual needs.

Key Takeaways

- Platen length refers to the size of the flat surface on a grinder where the knife is sharpened or shaped.

- The platen length is crucial for knife makers as it directly impacts the efficiency and precision of the grinding process.

- Longer platen length allows for better control and accuracy in grinding, resulting in smoother and more consistent knife edges.

- However, longer platen length may also require more space and investment, making it less practical for some knife makers.

- When choosing platen length, knife makers should consider the types of knives they work with, their workspace limitations, and their specific knife making needs.

Importance of Platen Length for Knife Makers

The significance of platen length in knife making cannot be overstated. A well-chosen platen length allows for greater control over the grinding process, enabling makers to achieve precise angles and finishes on their blades. This precision is particularly crucial when working with high-quality materials that require careful handling to avoid damage or imperfections.

A platen that is too short may limit the maker’s ability to grind larger blades effectively, while one that is excessively long may introduce challenges in maneuverability and control. Moreover, platen length plays a vital role in determining the overall efficiency of the grinding process. A longer platen can provide a more stable surface for grinding, allowing for smoother transitions and more consistent results.

This stability can be especially beneficial when working on intricate designs or when trying to maintain uniformity across multiple blades. In essence, understanding and selecting the appropriate platen length is fundamental to achieving both quality craftsmanship and operational efficiency in knife making.

How Platen Length Affects the Grinding Process

The grinding process is inherently influenced by the dimensions of the platen. A longer platen offers a larger surface area for contact with the blade, which can facilitate more even grinding across its length. This characteristic is particularly advantageous when working with longer knives or when attempting to achieve specific bevels and edge geometries.

The extended surface area allows for better heat dissipation during grinding, reducing the risk of overheating and warping the blade material. Conversely, a shorter platen may limit the grinding area, necessitating more passes over the surface to achieve the desired results. This can lead to increased wear on both the belt and the blade, as well as a greater likelihood of inconsistencies in the grind.

Additionally, shorter platens may require more frequent adjustments and repositioning of the blade, which can disrupt workflow and lead to inefficiencies. Therefore, understanding how platen length affects these dynamics is crucial for optimizing the grinding process.

Advantages of Longer Platen Length for Knife Makers

One of the primary advantages of a longer platen length is its ability to accommodate a wider variety of blade sizes and shapes. For knife makers who specialize in producing larger blades or those with unique profiles, a longer platen provides the necessary support to achieve consistent results across different projects. This versatility allows for greater creativity and experimentation in design, as makers are not constrained by the limitations of their equipment.

Additionally, longer platens contribute to improved stability during grinding. The increased surface area helps to distribute pressure more evenly across the blade, reducing the likelihood of uneven wear or damage. This stability is particularly beneficial when working with harder materials that require more aggressive grinding techniques.

Furthermore, a longer platen can enhance the overall finish of the blade by allowing for smoother transitions between grits, resulting in a polished appearance that reflects the skill and dedication of the maker.

Disadvantages of Longer Platen Length for Knife Makers

While there are numerous advantages to using a longer platen length, there are also potential drawbacks that knife makers should consider. One significant disadvantage is that longer platens can be more cumbersome to maneuver, particularly for intricate or detailed work. The added length may make it challenging to control the angle and pressure applied during grinding, which could lead to inconsistencies in the final product.

Moreover, longer platens may require more space in a workshop setting. For makers with limited workspace, accommodating a larger grinder with an extended platen could pose logistical challenges. This spatial consideration is essential when designing a workshop layout, as it can impact workflow efficiency and accessibility to tools and materials.

Therefore, while longer platens offer certain benefits, they also necessitate careful consideration regarding their practical implications in a knife-making environment.

Considerations When Choosing Platen Length

When selecting an appropriate platen length for knife making, several factors come into play. First and foremost is the type of knives being produced. Makers who focus on larger blades may benefit from a longer platen that can accommodate their designs, while those specializing in smaller or more intricate knives might find shorter platens more manageable.

Understanding one’s specific needs and preferences is crucial in making an informed decision. Another important consideration is the maker’s level of experience and comfort with different grinding techniques. Novice knife makers may prefer shorter platens that allow for greater control and ease of use as they develop their skills.

In contrast, experienced makers may opt for longer platens that enable them to push their creative boundaries and experiment with various designs. Ultimately, choosing the right platen length involves balancing personal preferences with practical considerations related to workspace and intended projects.

How Platen Length Impacts Different Types of Knives

The impact of platen length varies significantly depending on the type of knives being crafted. For instance, when making chef’s knives or utility knives that require precise edge geometry, a longer platen can facilitate smoother transitions between grits and help achieve a refined finish. The stability provided by an extended surface area allows for consistent pressure application, which is essential for maintaining sharpness and durability.

On the other hand, when crafting smaller knives such as pocket knives or specialized tools, shorter platens may be more advantageous. These types of knives often require intricate detailing and fine control during grinding, which can be more easily achieved with a shorter surface area. The ability to maneuver quickly and precisely around curves or complex shapes becomes paramount in these cases.

Thus, understanding how platen length interacts with different knife types is essential for optimizing both design and functionality.

Customizing Platen Length for Specific Knife Making Needs

Customization plays a vital role in achieving optimal results in knife making, and this extends to platen length as well. Many knife makers choose to modify their equipment to suit their specific needs better. This could involve adjusting existing platens or even fabricating custom platens tailored to particular projects or techniques.

Such modifications allow makers to fine-tune their grinding processes and achieve results that align closely with their artistic vision. Customizing platen length also opens up opportunities for innovation in design. By experimenting with different lengths, makers can discover new techniques that enhance their workflow or improve blade performance.

This adaptability fosters creativity within the craft, encouraging makers to push boundaries and explore new possibilities in their work.

The Relationship Between Platen Length and Workspace

The relationship between platen length and workspace cannot be overlooked in knife making. A well-organized workshop is essential for maximizing efficiency and productivity, and this includes considering how equipment size impacts available space. Longer platens may require additional room for maneuvering during grinding sessions, which could necessitate adjustments in workshop layout or tool placement.

Furthermore, workspace ergonomics play a crucial role in ensuring comfort during long hours of crafting knives. A longer platen might lead to awkward body positioning if not properly integrated into the workspace design. Therefore, it’s essential for knife makers to assess their available space carefully and consider how platen length will fit into their overall workflow before making a purchase or modification.

Tips for Maximizing the Benefits of Platen Length

To fully leverage the advantages offered by platen length in knife making, several strategies can be employed. First, it’s important to maintain proper belt tension and alignment on your grinder; this ensures that you are getting consistent contact across the entire surface area of your platen. Regular maintenance checks will help prevent issues that could arise from uneven wear or misalignment.

Additionally, experimenting with different grinding techniques can help maximize efficiency based on your chosen platen length. For instance, using varying angles or pressure settings can yield different results depending on whether you are working with a longer or shorter platen. Keeping detailed notes on your processes will allow you to refine your approach over time and discover what works best for your specific needs.

Finding the Right Platen Length for Your Knife Making Needs

In conclusion, selecting the right platen length is a critical decision that can significantly influence both the quality of craftsmanship and overall efficiency in knife making. By understanding how platen length affects various aspects of the grinding process—from stability and control to workspace considerations—makers can make informed choices that align with their specific needs and preferences. Ultimately, whether opting for a longer or shorter platen depends on individual factors such as knife type, experience level, and workspace constraints.

By carefully evaluating these elements and considering customization options where necessary, knife makers can optimize their equipment for superior results in their craft. Finding that perfect balance will not only enhance productivity but also elevate the artistry inherent in creating exceptional knives.

FAQs

What is platen length?

Platen length refers to the length of the flat surface on a belt grinder where the knife maker grinds and shapes the blade.

Why is platen length important for knife makers?

Platen length is important for knife makers because it determines the amount of surface area available for grinding and shaping the blade. A longer platen allows for more efficient and precise grinding, especially for longer blades.

Does platen length matter for knife makers?

Yes, platen length does matter for knife makers, especially for those working on longer blades. A longer platen provides more support and stability when grinding and shaping the blade, resulting in better precision and control.

What are the advantages of a longer platen for knife makers?

A longer platen allows for better support and stability when grinding longer blades, resulting in more precise and controlled shaping. It also allows for more efficient grinding, reducing the need for multiple passes.

Are there any disadvantages to a longer platen for knife makers?

One potential disadvantage of a longer platen is that it may take up more space in the workshop. Additionally, a longer platen may require a more powerful motor to maintain consistent speed and power throughout the grinding process.