Introduction

Overview of Knife Making

Knife making is both an art and a science, steeped in tradition and crafted with precision. From selecting the right steel to achieving a sharp edge, the entire process of knife making involves meticulous attention to detail. Aspiring knife makers often start their journeys by understanding various techniques and tools, with the 2×72 grinder being one of the most pivotal. This tool helps in shaping and sharpening blades with unparalleled efficiency. Some fundamental aspects of knife making include:

- Steel Selection: Choosing the right type of steel is crucial for durability and performance.

- Heat Treatment: This process enhances the material properties, enabling the blade to hold its edge.

- Blade Design: Aesthetic and functional design choices contribute to the effectiveness of the knife.

Significance of Efficiency in the Process

Efficiency plays a critical role in knife making. As with many crafts, time is an essential factor. An efficient process not only reduces production time but also allows makers to optimize their skills. Some of the key reasons for prioritizing efficiency include:

- Consistent Quality: Streamlined processes help maintain high quality across multiple knives.

- Cost Effectiveness: Reducing time spent on each project translates to lower production costs.

- Skill Development: Efficient techniques enable makers to focus on honing their craftsmanship rather than struggling with tools and methods.

In summary, a harmonious blend of traditional methods and modern efficiency techniques can significantly elevate the knife-making experience.

Understanding the 2×72 Grinder

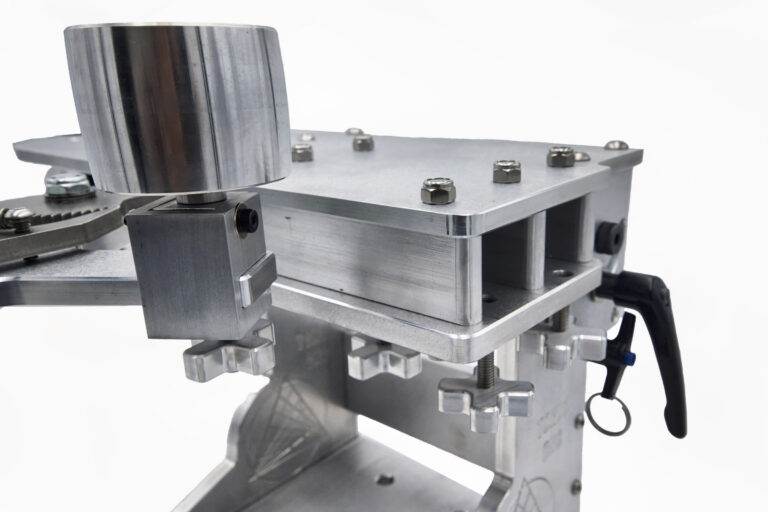

Features and Specifications

The 2×72 grinder has become a staple in the knife-making community due to its robust design and versatility. It predominantly features a 2-inch wide and 72-inch long abrasive belt, allowing for varied grit selections to cater to different stages of knife crafting. Here are some key specifications and features:

- Powerful Motor: Typically ranging from 1 to 3 horsepower, enabling smoother operation and reduced strain on the machine.

- Adjustable Tracking: Allows users to easily adjust the belt alignment for consistent grinding and shaping.

- Multiple Speed Options: Many models offer variable speed control, offering greater flexibility in grinding and polishing.

- Interchangeable Attachments: Compatibility with different tools such as platen, wheels, and work rests enhances versatility.

Benefits for Knife Making Projects

The advantages of using a 2×72 grinder for knife making projects cannot be overstated. The precision and adaptability of this tool can significantly improve the output quality. Some notable benefits include:

- Enhanced Precision: The long belt allows for control over finer details, resulting in clean grinds and polished finishes.

- Time Efficiency: The powerful motor and large surface area reduce time spent on each knife, making it ideal for batch production.

- Reduced Physical Strain: The ergonomic design minimizes fatigue, allowing makers to work longer without discomfort.

- Cost Efficiency: With reduced production time and waste, the 2×72 grinder ultimately lowers costs for both hobbyists and professionals.

In essence, understanding the features and benefits of the 2×72 grinder can elevate one’s knife-making process, making it an invaluable tool in any maker’s workshop.

Advantages of Using a 2×72 Grinder

Precision and Consistency

One of the standout advantages of the 2×72 grinder is its ability to provide unmatched precision and consistency in knife making. For craftspeople, achieving the right grind on a blade is essential not only for aesthetics but also for functionality. The long belt allows for smooth, controlled movements, enabling intricate designs and even edge geometries. Consider the following benefits:

- Controlled Grinding Angles: With the right technique, knife makers can easily maintain consistent angles, crucial for creating sharp, effective blades.

- Uniform Finishing: The consistent surface provided by the 2×72 grinder minimizes imperfections, ensuring each blade meets high standards.

- Repeatable Results: Once a desired technique is mastered, replicating it becomes simpler, saving time and effort in recurring projects.

Time-Saving Capabilities

In today’s fast-paced environment, time is of the essence, and the 2×72 grinder excels in this regard. By streamlining various stages of the knife-making process, it allows artisans to maximize productivity. Some notable time-saving aspects include:

- Fast Material Removal: The powerful motor and wide belt design efficiently remove substantial material quickly, reducing overall shaping time.

- Quick Belt Changes: Transitioning between various grits is rapid and straightforward, enabling swift shifts during the crafting process.

- Batch Processing: Multiple blades can be worked on simultaneously, as the grinder can accommodate different angles and profiles, leading to faster project completion.

In conclusion, the precision and time-saving capabilities of the 2×72 grinder not only enhance the quality of knife making but also make it a preferred choice among both beginners and seasoned professionals.

Techniques for Maximizing Efficiency

Proper Blade Grinding

Mastering proper blade grinding techniques is essential for maximizing the efficiency of a 2×72 grinder. When knife makers consistently utilize effective grinding methods, they significantly enhance both productivity and blade performance. Here are some key pointers for successful grinding:

- Angle Consistency: Maintaining a consistent angle throughout the grinding process is crucial. Whether using a fixed jig or freehand techniques, practice makes perfect.

- Leverage Belt Speed: Adjust the grinder’s speed to suit the material and desired outcome. Slower speeds are suitable for finer grits, while faster speeds can expedite material removal during initial shaping.

- Monitor Belt Wear: Regularly check the condition of the grinding belt. A worn belt can compromise your work’s precision and safety; replace it as needed to maintain optimal performance.

Utilizing Different Attachments

To further enhance efficiency, utilizing various attachments with the 2×72 grinder can make a notable difference. These attachments help adapt the grinder for multiple tasks, broadening its functionality. Consider these powerful options:

- Platen Attachments: These are essential for flat grinding and provide a solid surface for achieving precise edges.

- Contact Wheels: They can help with hollow grinding, offering a rounded surface for shaping blades and enhancing comfort.

- Work Tables and Rests: Using these supports enables better control and reduces fatigue during extended grinding sessions.

By adopting these techniques and utilizing the right attachments, knife makers can significantly improve their efficiency while producing high-quality blades. Each step not only maximizes productivity but also enhances the overall crafting experience.

Safety Measures when Using a 2×72 Grinder

Personal Protective Equipment

When it comes to using a 2×72 grinder, prioritizing safety is paramount. The speed and power of this machine can generate significant heat and debris, making personal protective equipment (PPE) essential. Here are some crucial items every knife maker should consider:

- Safety Goggles: Protecting the eyes from flying debris and sparks is critical. Opt for goggles that provide a snug fit and maximum visibility.

- Dust Mask/Respirator: Grinding produces fine dust that can be harmful when inhaled. A quality dust mask or respirator can safeguard respiratory health.

- Hearing Protection: Continuous exposure to the noise of a grinder can lead to hearing loss. Use earmuffs or earplugs designed for high-decibel environments.

- Gloves and Aprons: While gloves provide hand protection, be cautious of long sleeves and gloves that can get caught in the machinery. Instead, opt for a durable leather or canvas apron.

Maintenance and Care Tips

Proper maintenance of the 2×72 grinder not only extends its life but also ensures a safer working environment. Here are some essential care tips:

- Regular Inspections: Frequently check belts, wheels, and other components for wear and tear. Replace any parts showing signs of damage promptly.

- Clean Work Area: Maintain a clean workspace to prevent accidents. Sweep up metal shavings and debris regularly.

- Lubrication: Ensure all moving parts are well-lubricated to minimize friction, reducing wear and preventing overheating.

- Emergency Shutdown: Make sure you know how to shut down the grinder quickly in case of an emergency.

By observing these safety measures and taking proper care of the equipment, knife makers can create a secure and efficient workspace, allowing them to focus on their craft.

Comparison with Other Grinding Tools

Efficiency Comparison

When assessing the efficiency of the 2×72 grinder against other grinding tools, it becomes evident that its design offers distinct advantages. Other popular alternatives—such as bench grinders and angle grinders—provide valuable capabilities, but they often lack the finesse of a 2×72. Here are some key efficiency points to consider:

- Material Removal: The 2×72 grinder’s broad, continuous belt allows for rapid material removal without overheating, unlike bench grinders that create localized heat, leading to potential blade warping.

- Versatility: This grinder accommodates various attachments and belts, making it suitable for different tasks, from profiling to polishing, which other tools may not perform as well.

- Control: The length and speed of the belt provide better control over grinding angles, resulting in precise and consistent finishes.

Cost Comparison

When it comes to cost, the 2×72 grinder is often seen as an investment, but its value becomes clear when compared to other options:

- Initial Investment: The upfront cost of a 2×72 grinder may be higher than bench and angle grinders. However, it offers a greater range of capabilities, making it a versatile tool for knife making.

- Longevity: With proper maintenance, a quality 2×72 grinder can last for years, reducing the need for frequent replacements that other, less durable tools may require.

- Efficiency Gains: The time saved through greater efficiency can offset the initial cost, making the 2×72 grinder a cost-effective choice for both hobbyists and professionals.

In summary, while the initial investment in a 2×72 grinder may be higher, its efficiency and longevity often make it the preferred choice for serious knife makers.

Real-Life Applications in Knife Making

Case Studies

Real-life applications of the 2×72 grinder can be observed in various knife-making projects that showcase its versatility and impact on craftsmanship. For instance, a case study involving a small workshop revealed that transitioning to a 2×72 grinder significantly reduced the production time for custom knives. The maker reported:

- Improved Material Removal: By utilizing the wide belt, they could shape blades more rapidly, reducing initial grinding time by almost 30%.

- Enhanced Quality Control: Consistent grinds led to fewer errors, resulting in a higher-quality product. The owner noted a 25% increase in customer satisfaction due to better finishes.

- Versatile Uses: The same grinder was employed for both profiling and polishing knives, showcasing its adaptability for various processes.

Testimonials from Experts

Experts in the knife-making field consistently advocate for the 2×72 grinder as a game-changing tool. A respected knife maker highlighted:

- Precision: “The 2×72 grinder allows me to achieve consistent angles with ease. It’s become an integral part of my workflow.”

- Efficiency: Another mentioned, “I can go from raw steel to a finished knife in a fraction of the time compared to my previous setups.”

- Adaptability: Many professionals express how the wide range of attachments and belt options enable them to experiment with designs and techniques, making this tool an invaluable asset.

These case studies and expert testimonials illustrate how the 2×72 grinder not only enhances efficiency but also improves the quality of the final product, solidifying its place in modern knife making.

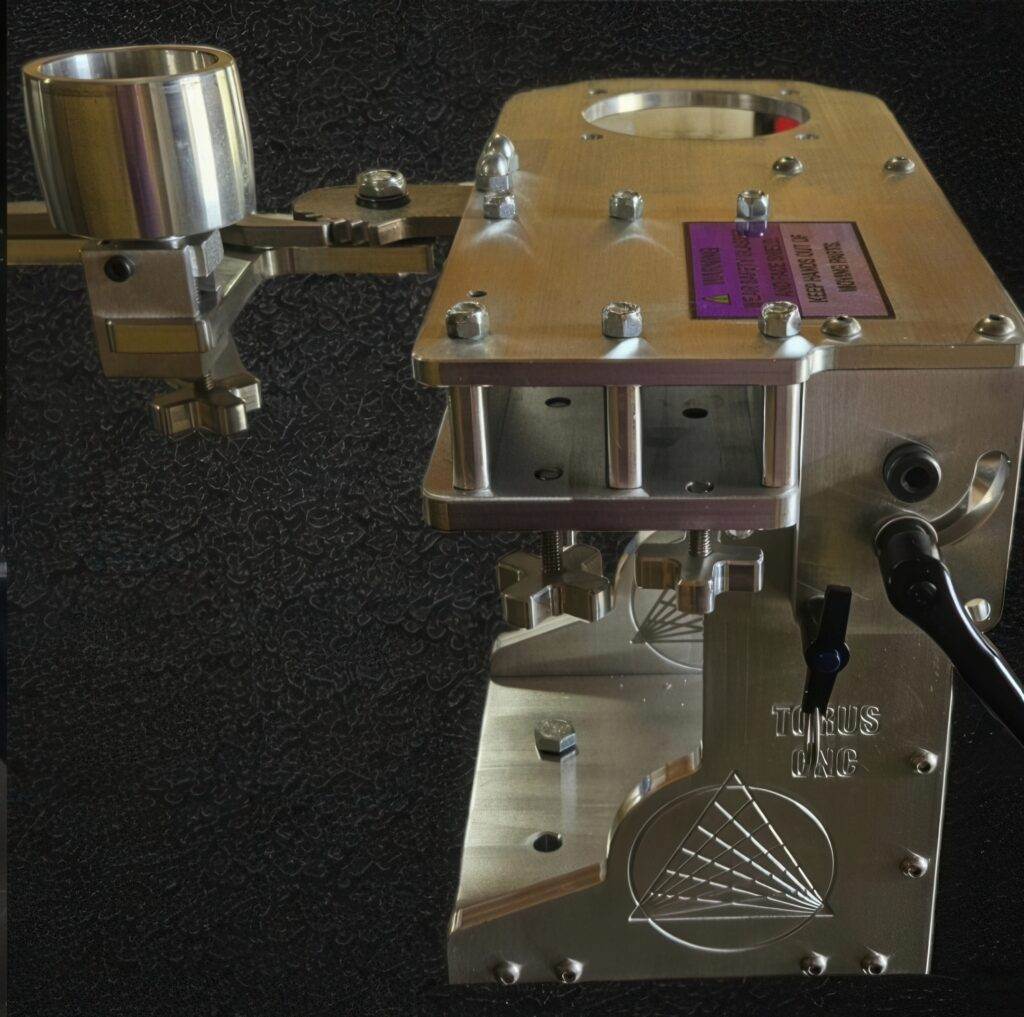

Innovations in 2×72 Grinder Technology

Latest Features

As technology continues to evolve, so does the 2×72 grinder, reflecting innovations that enhance functionality and user experience. Recent models boast several cutting-edge features that set them apart:

- Variable Speed Controls: Newer grinders now offer advanced variable speed settings, enabling users to fine-tune their approach depending on the material and application, providing greater control over the grinding process.

- Digital Displays: Some grinders feature digital interfaces that monitor belt speeds, allowing for precise adjustments and improved consistency.

- Tool-Free Belt Changes: Innovations have led to designs that allow users to change belts quickly and easily without the need for tools, streamlining the workflow significantly.

- Integrated Dust Collection: Enhanced dust management systems not only keep the workspace cleaner but also contribute to improved health safety by reducing inhalation hazards associated with fine dust.

Future Trends

Looking ahead, the future of 2×72 grinders signals exciting possibilities for both professionals and hobbyists. Potential trends include:

- Smart Technology Integration: We may see more grinders equipped with smart features that monitor performance and suggest optimal settings based on the user’s previous projects, further enhancing efficiency.

- Sustainable Materials: The market might shift toward using eco-friendly components and manufacturing processes, catering to the growing demand for sustainability.

- Customization Options: Future models could offer increased customization, allowing users to select specific features that best fit their unique knife-making style.

In conclusion, the constant innovations in 2×72 grinder technology not only empower knife makers to enhance their craft but also pave the way for the next generation of tools in this age-old trade, ensuring it remains relevant and efficient for years to come.

Tips for Choosing the Right 2×72 Grinder

Considerations for Beginners

For those just starting in knife making, selecting the right 2×72 grinder can feel overwhelming. However, focusing on a few key considerations can simplify the process:

- Budget: Determine a budget that suits your level of commitment. Entry-level grinders can range widely in price, so it’s essential to balance quality and affordability.

- Basic Features: Look for a model that offers essential features such as variable speed control and adjustable tracking. These functionalities are crucial for achieving different grinds as you learn.

- Ease of Use: Beginners should seek grinders known for user-friendly designs. A straightforward setup will encourage experimentation and help build confidence early on.

By starting with a reliable and functional machine, newcomers can focus on honing their skills without the frustration of overly complicated equipment.

Advanced Features for Professionals

For seasoned knife makers, investing in a high-quality 2×72 grinder can greatly enhance efficiency and output quality. When considering advanced features, focus on:

- Higher Horsepower Motors: A more powerful motor can handle tougher materials and provide smoother operation, especially for extensive production runs.

- Enhanced Attachments and Accessories: Look for models that offer a variety of attachments, such as contact wheels for hollow grinding or specialized platens for flat grinding.

- Precision Tracking Systems: Advanced grinders feature tracking mechanisms for maintaining perfect belt alignment, ensuring consistent results with every project.

- Customizable Components: Select a grinder that allows for custom configurations and upgrades, ensuring you can adapt the machine to new techniques and evolving needs.

By considering these factors, both beginners and experienced knife makers can find a 2×72 grinder that meets their unique requirements, ultimately enhancing their crafting experience.