In the realm of modern manufacturing and design, the integration of quick detachable work rests has emerged as a pivotal element. These components not only enhance the functionality of machinery but also reflect a commitment to innovation and efficiency. The ability to swiftly attach and detach work rests allows for greater flexibility in production processes, enabling manufacturers to adapt to varying project requirements without significant downtime.

This adaptability is crucial in an industry that demands rapid responses to changing market conditions and customer needs. Moreover, the design of quick detachable work rests embodies a forward-thinking approach that prioritizes user experience. By facilitating easy adjustments and modifications, these work rests contribute to a more streamlined workflow.

Designers and engineers are increasingly recognizing that the incorporation of such features can lead to improved productivity and reduced operational costs. As industries continue to evolve, the importance of innovative design elements like quick detachable work rests cannot be overstated; they are essential for maintaining competitiveness in a fast-paced market.

Key Takeaways

- Quick detachable work rests are important in innovative design as they allow for flexibility and adaptability in manufacturing processes.

- The advantages of quick detachable work rests in industrial applications include increased productivity, reduced downtime, and improved safety.

- Quick detachable work rests improve efficiency in manufacturing processes by allowing for quick adjustments and changes to accommodate different workpieces.

- Quick detachable work rests play a crucial role in ensuring safety in work environments by providing stable support for workpieces and reducing the risk of accidents.

- Different types of quick detachable work rests have specific applications, such as adjustable work rests for versatile use and magnetic work rests for easy installation and removal.

Advantages of Quick Detachable Work Rests in Industrial Applications

The advantages of quick detachable work rests in industrial applications are manifold. One of the most significant benefits is the reduction in setup time. Traditional work rests often require extensive adjustments and manual labor to change configurations, which can lead to delays in production schedules.

In contrast, quick detachable work rests allow operators to switch between different setups with minimal effort, thereby enhancing overall productivity. This efficiency is particularly valuable in environments where time is of the essence, such as assembly lines or custom manufacturing settings. Additionally, quick detachable work rests contribute to improved versatility in industrial applications.

They can be easily modified or replaced to accommodate various tasks or materials, making them suitable for a wide range of operations. This adaptability not only maximizes the utility of machinery but also minimizes the need for multiple specialized tools. As a result, businesses can optimize their resources and reduce costs associated with maintaining an extensive inventory of equipment.

How Quick Detachable Work Rests Improve Efficiency in Manufacturing Processes

Efficiency is a cornerstone of successful manufacturing processes, and quick detachable work rests play a crucial role in enhancing this efficiency. By allowing for rapid changes in setup, these work rests enable manufacturers to respond swiftly to production demands. For instance, when a new product line is introduced or when adjustments are needed for different materials, operators can quickly detach and reattach work rests without extensive downtime.

This agility not only keeps production flowing smoothly but also helps meet tight deadlines and customer expectations. Furthermore, the ease of use associated with quick detachable work rests reduces the likelihood of errors during setup. When operators can swiftly make adjustments without complicated procedures, the chances of misalignment or incorrect configurations diminish significantly.

This accuracy translates into higher quality outputs and less waste, as products are manufactured right the first time. In an industry where precision is paramount, the role of quick detachable work rests in improving efficiency cannot be overlooked.

The Role of Quick Detachable Work Rests in Ensuring Safety in Work Environments

Safety is a critical consideration in any industrial setting, and quick detachable work rests contribute significantly to creating safer work environments. By facilitating easy adjustments and modifications, these components reduce the need for operators to engage in potentially hazardous manual handling practices. When work rests can be quickly detached and reattached without excessive force or awkward movements, the risk of workplace injuries decreases substantially.

Moreover, quick detachable work rests often incorporate safety features that further enhance their usability. For example, many designs include locking mechanisms that ensure stability during operation, preventing accidental disengagement while machinery is in use. This added layer of safety not only protects workers but also safeguards equipment from damage caused by improper setups.

In an era where workplace safety regulations are increasingly stringent, the implementation of quick detachable work rests aligns with best practices for maintaining a secure working environment.

Different Types of Quick Detachable Work Rests and Their Applications

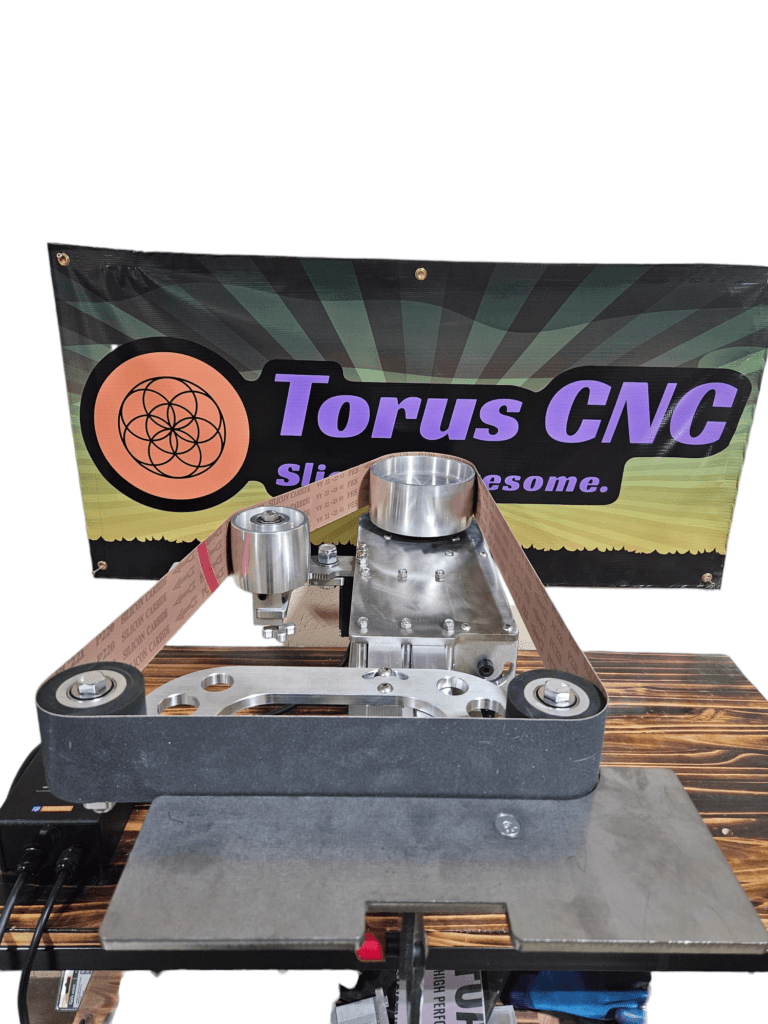

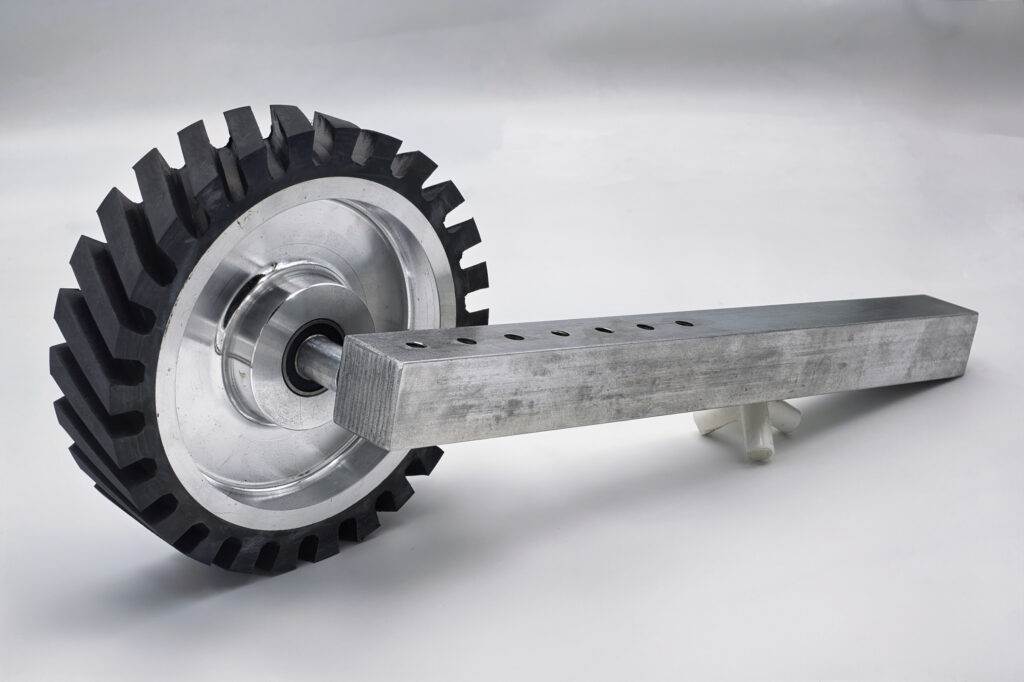

The diversity of quick detachable work rests available on the market today caters to a wide array of applications across various industries. One common type is the adjustable work rest, which allows operators to modify the height and angle according to specific tasks. This flexibility makes it ideal for operations that require precision and adaptability, such as machining or assembly processes.

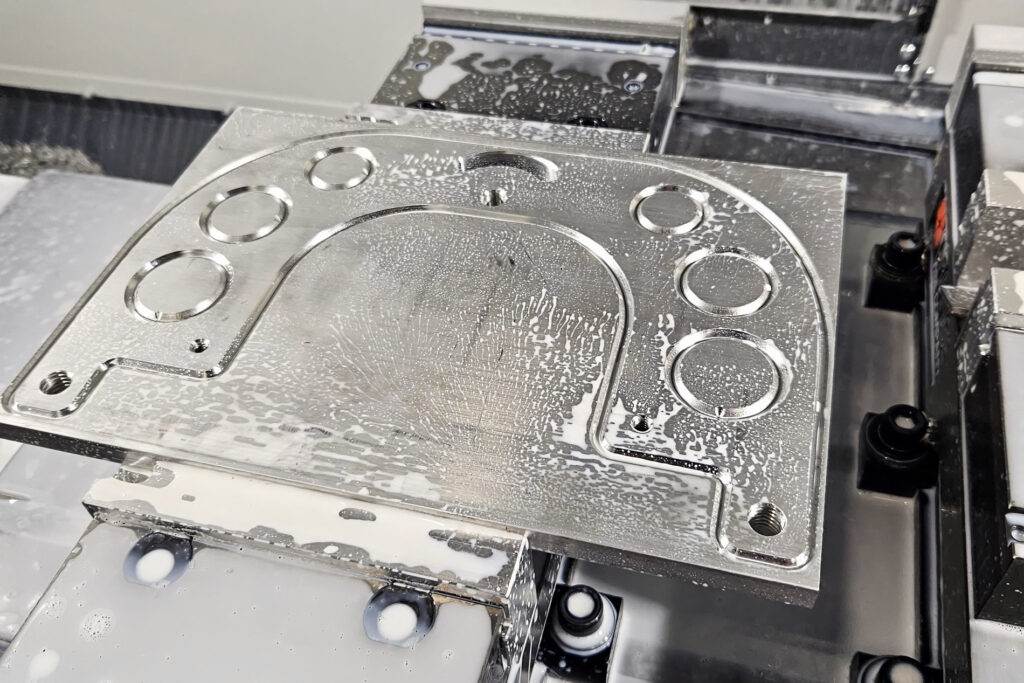

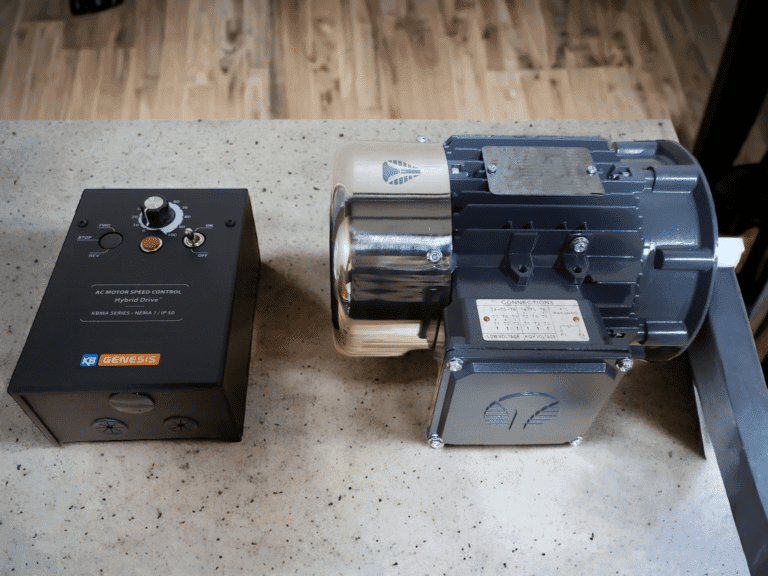

Another popular variant is the modular work rest, which can be customized with interchangeable components to suit different manufacturing needs. These modular systems enable businesses to tailor their setups based on project requirements, enhancing both efficiency and versatility. Additionally, specialized quick detachable work rests designed for specific machinery—such as CNC machines or lathes—offer targeted solutions that optimize performance while ensuring compatibility with existing equipment.

Design Considerations for Quick Detachable Work Rests

When designing quick detachable work rests, several key considerations must be taken into account to ensure optimal performance and usability. First and foremost is the ease of attachment and detachment; a well-designed work rest should allow operators to make adjustments quickly without requiring excessive force or complicated procedures. This user-friendly approach not only enhances efficiency but also encourages consistent use among operators.

Another critical factor is durability. Quick detachable work rests must withstand the rigors of industrial environments, including exposure to heavy loads, vibrations, and potential impacts. Selecting high-quality materials and robust construction techniques is essential for ensuring longevity and reliability.

Additionally, designers should consider incorporating features that facilitate maintenance and cleaning, as this contributes to the overall lifespan and functionality of the work rest.

The Impact of Quick Detachable Work Rests on Ergonomics and Worker Comfort

Ergonomics plays a vital role in worker comfort and productivity, and quick detachable work rests can significantly enhance ergonomic practices within manufacturing environments. By allowing operators to adjust the height and angle of work rests easily, these components help maintain proper posture during tasks. This adaptability reduces strain on the body, minimizing the risk of musculoskeletal disorders that can arise from prolonged periods of awkward positioning.

Furthermore, quick detachable work rests can be designed with ergonomic features such as padded surfaces or contours that support natural hand positions during operation. By prioritizing worker comfort through thoughtful design, businesses can foster a more positive workplace atmosphere while simultaneously boosting productivity levels. Ultimately, investing in ergonomic solutions like quick detachable work rests reflects a commitment to employee well-being and operational excellence.

Case Studies of Successful Implementation of Quick Detachable Work Rests

Numerous case studies illustrate the successful implementation of quick detachable work rests across various industries. In one notable example, a leading automotive manufacturer integrated quick detachable work rests into their assembly line processes. By doing so, they were able to reduce setup times by over 30%, allowing for faster production cycles without compromising quality.

The flexibility provided by these work rests enabled teams to adapt quickly to changing product specifications while maintaining high standards. Another case study highlights a furniture manufacturing company that adopted modular quick detachable work rests in their production facility. This transition allowed them to customize their setups based on different product lines, resulting in increased efficiency and reduced material waste.

The ability to swiftly switch between configurations not only streamlined operations but also empowered workers by giving them greater control over their tasks.

Future Trends and Innovations in Quick Detachable Work Rests

As technology continues to advance, future trends in quick detachable work rests are likely to focus on enhanced automation and smart features. The integration of sensors and IoT technology could enable real-time monitoring of work rest performance, providing valuable data for optimizing manufacturing processes. Such innovations would allow operators to make informed decisions about adjustments based on actual usage patterns rather than relying solely on manual observations.

Additionally, advancements in materials science may lead to the development of lighter yet more durable materials for constructing quick detachable work rests. This evolution would further enhance usability while maintaining strength and stability under heavy loads. As industries strive for greater efficiency and sustainability, these innovations will play a crucial role in shaping the future landscape of manufacturing.

Key Factors to Consider When Choosing Quick Detachable Work Rests for a Specific Application

Selecting the right quick detachable work rest for a specific application involves careful consideration of several key factors. First and foremost is compatibility with existing machinery; ensuring that the chosen work rest integrates seamlessly with current equipment is essential for maximizing efficiency. Additionally, evaluating the weight capacity and stability requirements based on anticipated workloads will help determine the most suitable design.

Another important aspect is the ease of use; operators should be able to attach and detach the work rest without extensive training or complicated procedures. Furthermore, considering the specific tasks being performed will guide decisions regarding adjustability features and ergonomic considerations. By taking these factors into account, businesses can make informed choices that align with their operational goals.

The Role of Quick Detachable Work Rests in Promoting Sustainable and Green Manufacturing Practices

In an era where sustainability is paramount, quick detachable work rests can contribute significantly to green manufacturing practices. By enabling efficient setups and reducing material waste through precise adjustments, these components align with eco-friendly initiatives aimed at minimizing environmental impact. The ability to quickly adapt machinery for different tasks also means that fewer resources are consumed in producing specialized equipment.

Moreover, investing in durable quick detachable work rests reduces the need for frequent replacements, further supporting sustainability efforts by decreasing waste generation over time. As manufacturers increasingly prioritize environmentally responsible practices, incorporating innovative solutions like quick detachable work rests will play a vital role in achieving their sustainability objectives while maintaining operational efficiency.

FAQs

What are quick detachable work rests?

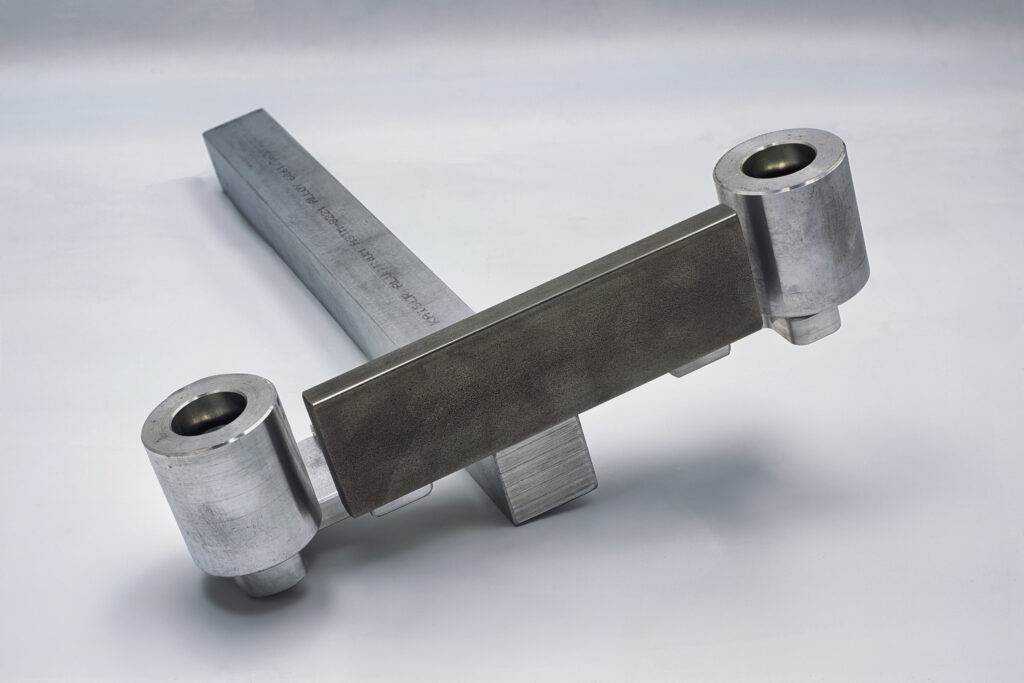

Quick detachable work rests are devices used in machining and metalworking to support and guide the workpiece during the machining process. They are designed to be easily attached and removed from the machine, allowing for quick setup and changeover between different workpieces.

What are the design inspirations for quick detachable work rests?

The design inspirations for quick detachable work rests can come from various sources, including ergonomic considerations, ease of use, durability, and compatibility with different types of machines. Additionally, designers may draw inspiration from existing work rest designs and seek to improve upon them by addressing common issues and limitations.

What are the key considerations in designing quick detachable work rests?

Key considerations in designing quick detachable work rests include the material and construction of the work rest, the method of attachment to the machine, the adjustability and flexibility of the work rest, and the overall ease of use for the operator. Designers must also consider the specific requirements of the machining process and the types of workpieces that will be supported.

How do quick detachable work rests improve efficiency in machining processes?

Quick detachable work rests improve efficiency in machining processes by reducing setup time and allowing for rapid changeover between different workpieces. This can lead to increased productivity and reduced downtime, ultimately improving the overall efficiency of the machining operation.