In the realm of manufacturing, the ability to switch grinding methods efficiently is paramount. As industries evolve and customer demands shift, manufacturers must adapt their processes to maintain competitiveness. Efficiently transitioning between different grinding techniques not only enhances productivity but also ensures that quality standards are met consistently.

The grinding process is often a critical step in the production line, and any delays or inefficiencies can lead to significant downtime, increased costs, and ultimately, a loss of market share. Moreover, the importance of efficient grinding method switching extends beyond mere operational efficiency. It also plays a crucial role in resource management.

By optimizing the grinding process, manufacturers can reduce waste, conserve energy, and minimize the use of raw materials. This not only contributes to a more sustainable production model but also aligns with the growing emphasis on environmental responsibility within the industry. Therefore, understanding and implementing efficient switching methods is not just a matter of operational necessity; it is a strategic imperative for modern manufacturing.

Key Takeaways

- Efficiently switching grinding methods is important for maximizing productivity and achieving optimal results in manufacturing processes.

- Common challenges in switching grinding methods include time-consuming setups, tool changes, and operator training.

- Universal mounting systems can facilitate seamless transitions between different grinding methods, reducing downtime and increasing efficiency.

- Quick-change tooling can save time and effort by allowing for rapid switches between different grinding tools and abrasives.

- Adaptive control technology can help ensure smooth transitions between grinding methods, improving accuracy and consistency in the manufacturing process.

Identifying Common Challenges in Switching Grinding Methods

Despite the clear benefits of efficient grinding method switching, several challenges can impede this process. One of the most significant hurdles is the complexity of different grinding techniques. Each method may require specific tools, settings, and parameters, making it difficult for operators to transition smoothly from one to another.

This complexity can lead to increased training time and a steeper learning curve for new operators, ultimately affecting productivity. Another common challenge is the potential for equipment compatibility issues. Not all machines are designed to accommodate various grinding methods seamlessly.

This can result in additional costs for retrofitting existing equipment or investing in new machinery altogether. Furthermore, the need for precise calibration when switching methods can lead to downtime, as operators must ensure that each setup meets the required specifications. Addressing these challenges is essential for manufacturers looking to enhance their grinding operations and maintain a competitive edge.

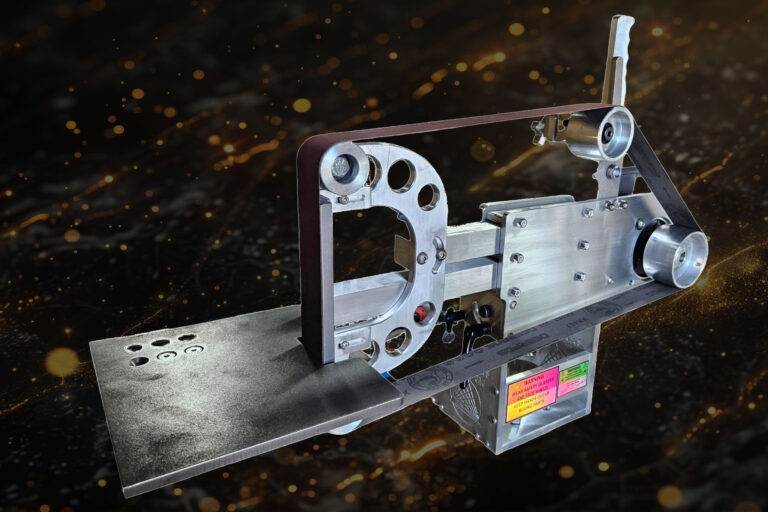

Utilizing Universal Mounting Systems for Seamless Transitions

One effective solution to the challenges of switching grinding methods is the implementation of universal mounting systems. These systems are designed to accommodate a wide range of tools and attachments, allowing operators to switch between different grinding methods with minimal effort. By standardizing the mounting process, manufacturers can significantly reduce the time spent on setup and calibration, leading to smoother transitions and increased productivity.

Universal mounting systems also enhance flexibility in production. With the ability to quickly adapt to various grinding techniques, manufacturers can respond more effectively to changing customer demands or production requirements. This adaptability not only streamlines operations but also fosters innovation, as teams can experiment with different methods without the fear of lengthy downtimes or complex setups.

Ultimately, investing in universal mounting systems can be a game-changer for manufacturers seeking to optimize their grinding processes.

Implementing Quick-Change Tooling for Time-Saving Switches

Quick-change tooling is another innovative approach that can facilitate efficient switching between grinding methods. This technology allows operators to replace tools rapidly without the need for extensive adjustments or recalibrations. By minimizing the time required for tool changes, manufacturers can significantly reduce downtime and enhance overall productivity.

The benefits of quick-change tooling extend beyond mere time savings. This system also promotes consistency in production quality, as operators can maintain tighter control over tool performance and wear. Additionally, quick-change tooling can lead to reduced labor costs, as fewer personnel are needed to manage tool changes and setups.

As manufacturers strive for greater efficiency and cost-effectiveness, implementing quick-change tooling becomes an essential strategy in optimizing grinding operations.

Leveraging Adaptive Control Technology for Smooth Transitions

Adaptive control technology represents a significant advancement in the field of grinding operations. By utilizing real-time data and feedback mechanisms, this technology enables machines to adjust their parameters automatically during the grinding process. This adaptability allows for smoother transitions between different grinding methods, as machines can recalibrate themselves based on the specific requirements of each technique.

The integration of adaptive control technology not only enhances efficiency but also improves product quality. By continuously monitoring performance metrics, manufacturers can identify potential issues before they escalate into significant problems. This proactive approach minimizes waste and ensures that each grinding method is executed with precision.

As industries continue to embrace automation and smart manufacturing practices, leveraging adaptive control technology will be crucial for maintaining competitive advantage.

Training Operators for Efficient Grinding Method Switches

While technology plays a vital role in facilitating efficient grinding method switches, the human element cannot be overlooked. Proper training for operators is essential to ensure that they are equipped with the skills and knowledge necessary to navigate different grinding techniques effectively. A well-trained workforce can make informed decisions during transitions, minimizing errors and maximizing productivity.

Training programs should focus on both theoretical knowledge and practical skills. Operators need to understand the nuances of each grinding method, including its specific requirements and potential challenges. Additionally, hands-on training with equipment and tools will help build confidence and competence among operators.

By investing in comprehensive training initiatives, manufacturers can empower their workforce to handle transitions smoothly and efficiently.

Incorporating Automated Tool Change Systems for Streamlined Operations

Automated tool change systems are revolutionizing the way manufacturers approach grinding operations. These systems allow for rapid tool changes without manual intervention, significantly reducing downtime associated with switching methods. By automating this process, manufacturers can achieve higher levels of efficiency and consistency in their production lines.

The implementation of automated tool change systems also enhances safety in the workplace. With fewer manual tool changes required, the risk of accidents or injuries associated with handling sharp tools is minimized. Furthermore, these systems can be integrated with existing machinery, allowing manufacturers to upgrade their operations without a complete overhaul of their equipment.

As automation continues to shape the future of manufacturing, incorporating automated tool change systems will be essential for staying competitive.

Investing in Multi-Process Grinding Machines for Versatility

Multi-process grinding machines offer a versatile solution for manufacturers looking to streamline their operations. These machines are designed to perform various grinding techniques within a single unit, eliminating the need for multiple setups and reducing transition times significantly. By investing in multi-process machines, manufacturers can enhance their flexibility and responsiveness to changing production demands.

The versatility of multi-process grinding machines also contributes to improved resource management. With the ability to handle different grinding methods in one machine, manufacturers can reduce their footprint and minimize energy consumption associated with operating multiple machines. This not only leads to cost savings but also aligns with sustainability goals by reducing waste and energy usage.

As manufacturers seek ways to optimize their operations, multi-process grinding machines represent a forward-thinking investment.

Exploring Hybrid Grinding Solutions for Flexibility

Hybrid grinding solutions combine traditional grinding methods with advanced technologies such as laser or electrical discharge machining (EDM). This innovative approach allows manufacturers to leverage the strengths of multiple techniques within a single process, enhancing flexibility and efficiency in production. By exploring hybrid solutions, manufacturers can address complex machining challenges that may be difficult to achieve with conventional methods alone.

The integration of hybrid grinding solutions also opens up new possibilities for product design and development. Manufacturers can experiment with different materials and geometries without being constrained by the limitations of traditional grinding methods. This flexibility fosters innovation and enables companies to stay ahead of market trends by offering unique products that meet evolving customer needs.

Optimizing Workflow Planning for Minimizing Angle Resets

Effective workflow planning is crucial for minimizing angle resets during grinding method switches. By carefully mapping out production processes and identifying potential bottlenecks, manufacturers can streamline operations and reduce unnecessary delays associated with angle adjustments. A well-structured workflow not only enhances efficiency but also contributes to improved product quality by ensuring that each step in the process is executed seamlessly.

In addition to optimizing workflow planning, manufacturers should consider implementing standardized procedures for angle resets. By establishing clear guidelines and best practices for adjusting angles during transitions, operators can minimize variability and maintain consistency across different grinding methods. This approach not only saves time but also enhances overall productivity by reducing the likelihood of errors during setup.

Evaluating the Cost and Time Savings of Efficient Grinding Method Switching

Ultimately, evaluating the cost and time savings associated with efficient grinding method switching is essential for justifying investments in new technologies and processes. Manufacturers should conduct thorough analyses to quantify the benefits of implementing strategies such as universal mounting systems, quick-change tooling, and automated tool change systems. By measuring key performance indicators such as downtime reduction, labor savings, and improved product quality, companies can gain valuable insights into the return on investment associated with these initiatives.

Furthermore, understanding the long-term implications of efficient grinding method switching is crucial for strategic planning. As industries continue to evolve and customer demands shift, manufacturers must remain agile and adaptable in their operations. By prioritizing efficiency in their grinding processes, companies can position themselves for sustained success in an increasingly competitive landscape.

In conclusion, efficiently switching grinding methods is a multifaceted challenge that requires a comprehensive approach encompassing technology, training, workflow optimization, and strategic investments. By addressing common challenges and leveraging innovative solutions such as universal mounting systems, quick-change tooling, adaptive control technology, automated tool change systems, multi-process machines, hybrid solutions, and effective training programs, manufacturers can enhance their operational efficiency while maintaining high-quality standards. Ultimately, this commitment to efficiency will not only drive productivity but also position companies for long-term success in an ever-evolving manufacturing landscape.

FAQs

What is flat grinding and wheel grinding?

Flat grinding is a type of surface grinding where the grinding wheel is in a flat orientation, while wheel grinding involves using a grinding wheel that is mounted on a spindle.

What are the advantages of being able to switch between flat and wheel grinding without resetting angles?

The ability to switch between flat and wheel grinding without resetting angles saves time and effort, as it eliminates the need to recalibrate the grinding equipment for different types of grinding.

How does the ability to switch between flat and wheel grinding without resetting angles benefit the grinding process?

This capability allows for greater flexibility in the grinding process, as it enables operators to quickly transition between different grinding methods based on the specific requirements of the workpiece.

What types of industries or applications can benefit from the ability to switch between flat and wheel grinding without resetting angles?

This capability is beneficial for a wide range of industries and applications that require precision grinding, such as automotive, aerospace, tool and die making, and general metalworking.

Are there any limitations or considerations to keep in mind when switching between flat and wheel grinding without resetting angles?

Operators should ensure that the grinding equipment is capable of accommodating both flat and wheel grinding methods, and that the transition between the two methods does not compromise the quality or accuracy of the grinding process.