Chef knife blanks serve as the foundation for crafting high-quality kitchen knives, providing artisans with the essential starting point for their creations. These blanks are typically made from high-carbon stainless steel or other durable materials, designed to withstand the rigors of daily culinary tasks. The process of transforming a blank into a finished knife involves several stages, including profiling, heat treatment, and final sharpening.

Profiling is particularly crucial, as it shapes the blade’s edge and overall form, setting the stage for the knife’s performance and aesthetic appeal. The art of knife making has gained significant popularity in recent years, with many enthusiasts and professionals alike seeking to create custom blades tailored to their specific needs. Understanding the intricacies of working with chef knife blanks is essential for anyone looking to delve into this craft.

From selecting the right materials to employing the appropriate tools and techniques, each step plays a vital role in achieving a high-quality finished product. Among these tools, abrasive belts, particularly 36-grit ceramic belts, are indispensable for efficient profiling.

Key Takeaways

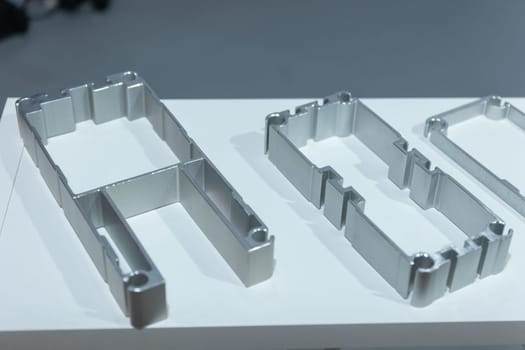

- Chef knife blanks are the foundation for creating custom chef knives and come in various shapes and sizes.

- Efficient profiling is crucial for achieving the desired shape and edge geometry of the chef knife blanks.

- 36-grit ceramic belts are highly effective for material removal and shaping of chef knife blanks.

- Using 36-grit ceramic belts results in faster stock removal, reduced heat buildup, and longer belt life.

- Safety precautions, such as wearing eye protection and using a dust collection system, are essential when using 36-grit ceramic belts.

Importance of Efficient Profiling

Efficient profiling is a critical step in the knife-making process that directly impacts the final product’s performance and usability. Profiling involves shaping the blade to achieve the desired geometry, which includes the thickness, taper, and curvature of the edge. A well-executed profile not only enhances the knife’s cutting ability but also contributes to its balance and comfort during use.

When profiling is done efficiently, it minimizes material waste and reduces the time spent on subsequent steps, such as grinding and polishing. Moreover, efficient profiling allows for greater precision in achieving the desired blade characteristics. A properly profiled knife will have a consistent edge geometry that facilitates smooth cutting and slicing.

This consistency is essential for professional chefs who rely on their tools for precision in food preparation. Additionally, an efficient profiling process can lead to improved overall aesthetics, as the blade’s shape and finish will be more uniform and visually appealing.

/

Understanding 36-Grit Ceramic Belts

36-grit ceramic belts are a popular choice among knife makers for their aggressive cutting capabilities and durability. The grit number indicates the size of the abrasive particles on the belt; in this case, 36-grit refers to relatively coarse particles that can quickly remove material from the surface of the knife blank. Ceramic abrasives are known for their hardness and longevity, making them ideal for heavy-duty applications like profiling chef knife blanks.

These belts are designed to withstand high temperatures generated during the grinding process, which is particularly important when working with high-carbon steels that can lose their temper if overheated. The unique properties of ceramic abrasives allow them to maintain their cutting efficiency even under intense conditions, making them a reliable choice for both amateur and professional knife makers. Understanding how to effectively use 36-grit ceramic belts can significantly enhance the profiling process, leading to better results in less time.

Advantages of Using 36-Grit Ceramic Belts

The advantages of using 36-grit ceramic belts in the profiling of chef knife blanks are manifold. One of the primary benefits is their exceptional cutting speed. The coarse grit allows for rapid material removal, enabling knife makers to shape their blades quickly without sacrificing quality.

This efficiency is particularly beneficial when working with thicker or harder materials that require more aggressive grinding. Another significant advantage is the durability of ceramic belts. Unlike other abrasive materials that may wear down quickly, ceramic belts maintain their cutting performance over extended periods of use.

This longevity translates to fewer belt changes during the profiling process, saving both time and money for knife makers. Additionally, ceramic belts produce a consistent finish on the blade surface, which is crucial for achieving a professional look in the final product.

Steps for Efficient Profiling of Chef Knife Blanks

To achieve efficient profiling of chef knife blanks using 36-grit ceramic belts, several steps should be followed meticulously. First, it is essential to secure the blank firmly in place to prevent any movement during the grinding process. This can be accomplished using a workbench vise or clamps designed specifically for knife making.

Ensuring stability will allow for more controlled and precise grinding. Next, begin by establishing the initial profile of the blade. This involves determining the desired shape and angle of the edge before applying the belt to the blank.

It is advisable to start with light pressure and gradually increase it as needed while maintaining a consistent motion along the blade’s length. This technique helps prevent overheating and ensures an even removal of material. Regularly checking progress will allow for adjustments to be made as necessary, ensuring that the final profile meets expectations.

Safety Precautions when Using 36-Grit Ceramic Belts

Safety should always be a top priority when working with abrasive materials like 36-grit ceramic belts. The high-speed operation of belt grinders can pose various risks, including flying debris and potential injuries from accidental contact with moving parts. To mitigate these risks, it is crucial to wear appropriate personal protective equipment (PPE), including safety goggles, gloves, and a dust mask or respirator.

Additionally, maintaining a clean workspace is essential for safety. Keeping tools organized and free from clutter reduces the likelihood of accidents occurring during the profiling process. It is also advisable to ensure that all equipment is in good working condition before use; any damaged or worn components should be replaced immediately to prevent malfunctions that could lead to injury.

Tips for Achieving Precision with 36-Grit Ceramic Belts

Achieving precision when profiling chef knife blanks with 36-grit ceramic belts requires attention to detail and practice. One effective tip is to develop a consistent technique when applying pressure and moving the blank against the belt. This consistency will help maintain an even profile across the entire blade length.

It may be beneficial to practice on scrap pieces before working on actual knife blanks to refine this technique. Another important aspect is monitoring heat buildup during grinding. Excessive heat can compromise the integrity of the steel and affect its performance characteristics.

To prevent overheating, take breaks during prolonged grinding sessions and allow both the belt and blank to cool down as needed. Using a coolant or lubricant can also help dissipate heat while improving cutting efficiency.

Common Mistakes to Avoid when Profiling Chef Knife Blanks

When profiling chef knife blanks, several common mistakes can hinder progress and affect the quality of the final product. One frequent error is applying too much pressure while grinding, which can lead to uneven profiles or overheating of the blade material. It is essential to find a balance between pressure and speed to achieve optimal results without compromising the integrity of the blank.

Another mistake is neglecting to check progress regularly during profiling. Failing to monitor how much material has been removed can result in over-grinding or an imprecise edge geometry. Taking periodic breaks to assess progress allows for adjustments to be made before reaching a point of no return.

Additionally, not securing the blank properly can lead to unwanted movement during grinding, resulting in inaccuracies in shaping.

Maintenance and Care for 36-Grit Ceramic Belts

Proper maintenance and care for 36-grit ceramic belts are crucial for ensuring their longevity and performance. After each use, it is advisable to clean the belts thoroughly to remove any debris or metal shavings that may have accumulated during grinding. This cleaning process helps maintain cutting efficiency and prevents clogging that can diminish performance over time.

Storing ceramic belts in a cool, dry place away from direct sunlight will also extend their lifespan. Exposure to moisture or extreme temperatures can affect their adhesive properties and overall effectiveness. Regularly inspecting belts for signs of wear or damage will allow for timely replacements before they become ineffective during use.

Comparing 36-Grit Ceramic Belts with Other Abrasive Options

When considering abrasive options for profiling chef knife blanks, 36-grit ceramic belts stand out due to their unique properties compared to other materials like aluminum oxide or zirconia belts. While aluminum oxide belts are often more affordable, they tend to wear out more quickly under heavy use and may not provide the same level of cutting efficiency as ceramic belts. Zirconia belts offer a middle ground between aluminum oxide and ceramic options; however, they still do not match the durability and aggressiveness of 36-grit ceramic belts when it comes to profiling hard materials like high-carbon steel.

Ultimately, choosing 36-grit ceramic belts can lead to better results in terms of speed, precision, and overall quality when shaping chef knife blanks.

Conclusion and Final Thoughts on Efficient Profiling of Chef Knife Blanks

In conclusion, efficient profiling of chef knife blanks is an essential aspect of knife making that significantly influences both functionality and aesthetics. Utilizing 36-grit ceramic belts offers numerous advantages, including rapid material removal and exceptional durability, making them an ideal choice for this task. By following proper techniques and safety precautions while avoiding common pitfalls, artisans can achieve precise profiles that enhance their finished products.

As interest in custom knife making continues to grow, understanding how to effectively work with chef knife blanks becomes increasingly important for both hobbyists and professionals alike. With practice and attention to detail, anyone can master the art of profiling using 36-grit ceramic belts, ultimately leading to beautifully crafted knives that stand out in both performance and design.

FAQs

What is a Chef Knife Blank?

A chef knife blank is the unfinished form of a chef knife, typically made of high-quality steel, that has not yet been shaped, ground, or sharpened.

What is Profiling a Chef Knife Blank?

Profiling a chef knife blank refers to the process of shaping the blank into the desired knife design, including establishing the blade’s bevels, curves, and overall geometry.

What is a Ceramic 36-Grit Belt?

A ceramic 36-grit belt is an abrasive belt used in knife making and metalworking to quickly remove material and shape metal. The 36-grit designation refers to the coarseness of the abrasive particles on the belt.

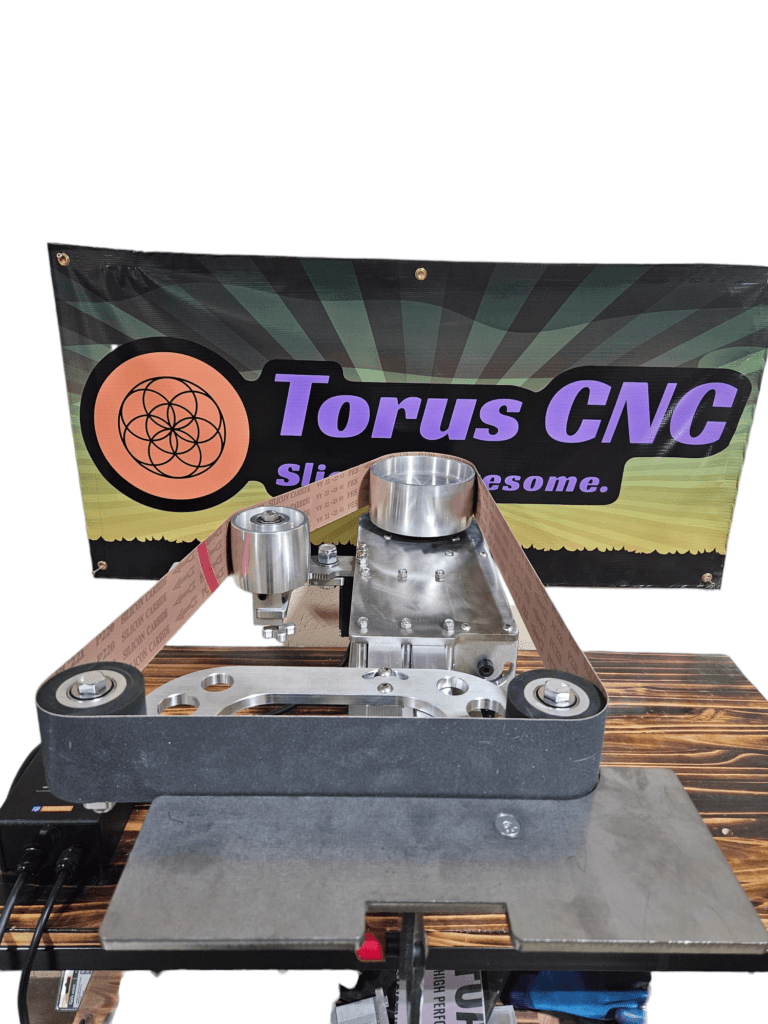

How is a Ceramic 36-Grit Belt Used to Profile Chef Knife Blanks?

A ceramic 36-grit belt is used with a belt grinder to rapidly remove material from the chef knife blank, allowing for efficient shaping and profiling of the blade and handle.

What are the Benefits of Using a Ceramic 36-Grit Belt for Profiling Chef Knife Blanks?

Using a ceramic 36-grit belt allows for fast material removal, which is essential for efficiently shaping and profiling chef knife blanks. The ceramic abrasive is also durable and long-lasting, making it suitable for heavy-duty metal shaping tasks.