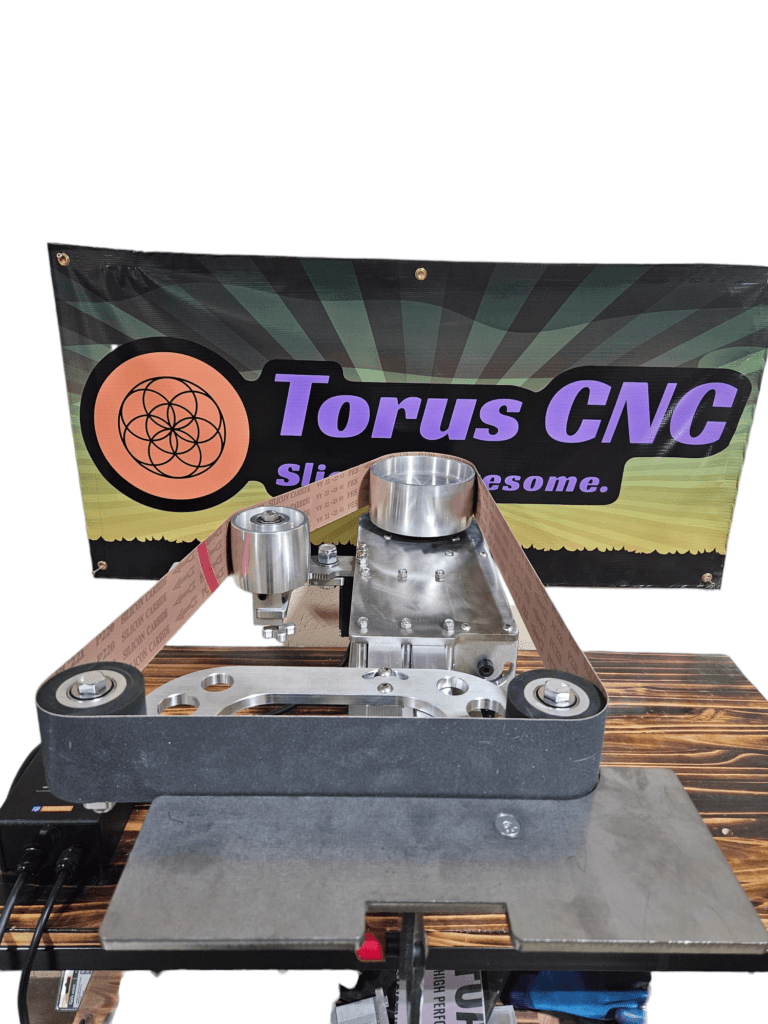

Aluminum has emerged as a favored material in various industries, particularly in workshops and manufacturing environments. One of the most significant benefits of aluminum is its lightweight nature, which makes it easier to handle and manipulate compared to heavier metals. This characteristic is particularly advantageous in a shop setting where tools and equipment are frequently moved or adjusted.

The reduced weight can lead to increased efficiency, allowing workers to focus on their tasks without the added strain of heavy materials. Additionally, aluminum’s malleability allows for easy fabrication, enabling shops to create custom tools and components tailored to specific needs. Another compelling advantage of aluminum is its excellent strength-to-weight ratio.

Despite being lightweight, aluminum possesses remarkable strength, making it suitable for a wide range of applications. This property allows for the construction of robust tools and equipment that can withstand the rigors of daily use in a shop environment. Furthermore, aluminum is resistant to corrosion, which enhances its longevity and reduces the need for frequent replacements.

By incorporating aluminum into your shop, you can benefit from a material that not only meets the demands of your operations but also contributes to a more efficient workflow.

Key Takeaways

- Aluminum is lightweight, strong, and resistant to rust, making it an ideal material for shop equipment and tools.

- Understanding the rust-resistance of aluminum is important for maintaining the quality and longevity of shop equipment.

- Aluminum is known for its longevity and durability in shop environments, making it a cost-effective choice for long-term use.

- Regular maintenance and proper care are essential for preserving the quality and performance of aluminum equipment and tools.

- When choosing aluminum products for your shop, consider factors such as strength, corrosion resistance, and cost-effectiveness.

Understanding the Rust-Resistance of Aluminum

One of the standout features of aluminum is its inherent rust-resistance, which sets it apart from many other metals. Unlike iron or steel, which are prone to rust when exposed to moisture, aluminum forms a protective oxide layer when it comes into contact with air. This oxide layer acts as a barrier, preventing further oxidation and corrosion from occurring.

As a result, aluminum can maintain its structural integrity and appearance even in humid or wet environments, making it an ideal choice for shops that may experience varying conditions. The rust-resistance of aluminum not only prolongs the lifespan of tools and equipment but also reduces maintenance efforts. Shop owners can spend less time worrying about rust-related issues and more time focusing on productivity.

This characteristic is particularly beneficial for outdoor applications or in environments where exposure to moisture is inevitable. By choosing aluminum products, you can ensure that your tools remain functional and visually appealing over time, ultimately leading to cost savings and improved operational efficiency.

Longevity and Durability of Aluminum in Shop Environments

Aluminum’s durability is another key factor that makes it an excellent choice for shop environments. The material is known for its ability to withstand wear and tear, making it suitable for tools and equipment that are subjected to heavy use. Unlike some materials that may become brittle or degrade over time, aluminum maintains its strength and performance even under challenging conditions.

This resilience translates into fewer replacements and repairs, allowing shop owners to allocate resources more effectively. Moreover, aluminum’s resistance to environmental factors such as moisture, chemicals, and temperature fluctuations further enhances its longevity. In a workshop where various substances may be present, aluminum’s ability to resist corrosion ensures that tools remain functional and safe for use.

This durability not only benefits the immediate operations of the shop but also contributes to a more sustainable approach by reducing waste associated with frequent replacements. By investing in aluminum products, you are making a long-term commitment to quality and reliability in your shop.

Maintenance Tips for Aluminum Equipment and Tools

| Tip | Description |

|---|---|

| Cleaning | Regularly clean aluminum equipment and tools with a mild detergent and water to remove dirt and grime. |

| Storage | Store aluminum tools in a dry area to prevent corrosion and damage. |

| Lubrication | Apply lubricant to moving parts of aluminum equipment to prevent rust and ensure smooth operation. |

| Inspection | Regularly inspect aluminum tools for any signs of wear, damage, or corrosion. |

| Protection | Use protective coatings or covers to shield aluminum equipment from harsh environments. |

While aluminum is known for its low maintenance requirements, implementing a few simple practices can help ensure that your equipment and tools remain in optimal condition. Regular cleaning is essential to prevent the buildup of dirt and grime that can affect performance. Using mild soap and water along with a soft cloth or sponge is often sufficient to keep aluminum surfaces clean without causing damage.

Avoid abrasive cleaners or scouring pads, as these can scratch the protective oxide layer and compromise the material’s rust-resistance. In addition to cleaning, periodic inspections of aluminum tools and equipment are advisable. Checking for any signs of wear or damage allows for timely repairs or replacements before issues escalate.

Lubricating moving parts with appropriate oils can also enhance performance and extend the lifespan of tools. By adopting these maintenance practices, shop owners can maximize the benefits of aluminum while ensuring that their equipment remains reliable and efficient.

Choosing the Right Aluminum Products for Your Shop

Selecting the appropriate aluminum products for your shop requires careful consideration of your specific needs and applications. Different grades of aluminum offer varying properties, so understanding these distinctions is crucial. For instance, some grades may be better suited for structural applications due to their strength, while others may excel in corrosion resistance or machinability.

Assessing the demands of your projects will guide you in choosing the right grade that aligns with your operational requirements. Additionally, consider the design and functionality of the aluminum products you intend to incorporate into your shop. Whether you are looking for tools, fixtures, or structural components, ensure that they are designed with ergonomics and usability in mind.

Investing in high-quality aluminum products from reputable manufacturers can further enhance your shop’s efficiency and productivity. By taking the time to choose the right aluminum solutions, you can create a workspace that meets your needs while maximizing the advantages of this versatile material.

Comparing Aluminum to Other Metals for Shop Use

When evaluating materials for shop use, it’s essential to consider how aluminum stacks up against other metals like steel or brass. While steel is known for its strength, it often comes with drawbacks such as susceptibility to rust and heavier weight. In contrast, aluminum provides a compelling alternative with its lightweight nature and rust-resistance, making it easier to handle without sacrificing performance.

This balance between strength and weight makes aluminum particularly appealing for tools that require frequent movement or adjustment. Brass, on the other hand, offers excellent corrosion resistance but tends to be more expensive than aluminum. While brass may be suitable for specific applications such as fittings or decorative elements, aluminum often provides a more cost-effective solution for general shop use.

Ultimately, the choice between these metals will depend on the specific requirements of your projects; however, aluminum’s unique combination of properties makes it a strong contender for a wide range of applications in any workshop.

Environmental Benefits of Using Aluminum in Your Shop

In today’s environmentally conscious world, choosing materials with sustainability in mind is increasingly important. Aluminum stands out as an eco-friendly option due to its recyclability and low environmental impact during production. The recycling process for aluminum requires significantly less energy compared to producing new aluminum from raw materials, making it a more sustainable choice for shops looking to reduce their carbon footprint.

By incorporating recycled aluminum products into your operations, you contribute to a circular economy that minimizes waste and conserves resources. Furthermore, using aluminum can lead to energy savings in your shop. Its lightweight nature means that less energy is required for transportation and handling compared to heavier metals.

This reduction in energy consumption not only benefits your bottom line but also aligns with broader sustainability goals. By prioritizing aluminum in your shop’s operations, you are making a conscious effort toward environmental stewardship while enjoying the numerous advantages this material has to offer.

Incorporating Aluminum into Your Shop’s Design and Layout

Integrating aluminum into your shop’s design and layout can enhance both functionality and aesthetics. The sleek appearance of aluminum lends itself well to modern design principles, creating an inviting workspace that promotes productivity. Consider using aluminum for shelving units, workbenches, or tool storage solutions that not only serve practical purposes but also contribute to an organized and visually appealing environment.

Moreover, the versatility of aluminum allows for creative design possibilities that can optimize workflow within your shop. Customizing workstations with aluminum components can facilitate better ergonomics and accessibility for workers. By strategically placing aluminum fixtures throughout your space, you can create an efficient layout that minimizes unnecessary movement and maximizes productivity.

Embracing aluminum as a design element not only enhances the functionality of your shop but also reflects a commitment to quality materials that support long-term success. In conclusion, incorporating aluminum into your shop offers numerous benefits ranging from its lightweight nature and rust-resistance to its durability and environmental advantages. By understanding how to maintain aluminum products effectively and selecting the right items for your specific needs, you can create an efficient workspace that stands the test of time.

As you consider the design and layout of your shop, embracing aluminum will not only enhance functionality but also contribute positively to your operational goals and sustainability efforts.

FAQs

What are the natural advantages of aluminum for rust-resistance and longevity in a shop?

Aluminum naturally forms a protective oxide layer when exposed to air, which helps prevent rust and corrosion. This makes it an ideal material for shop equipment and tools that are frequently exposed to moisture and other corrosive elements.

How does aluminum’s rust-resistance contribute to the longevity of shop equipment?

By being resistant to rust and corrosion, aluminum equipment and tools are less likely to degrade over time. This means they can maintain their functionality and structural integrity for a longer period, ultimately contributing to the longevity of the shop’s equipment.

What are some examples of shop equipment and tools that benefit from aluminum’s natural advantages?

Examples of shop equipment and tools that benefit from aluminum’s natural advantages include workbenches, storage cabinets, toolboxes, ladders, and various hand tools. These items are often exposed to moisture, chemicals, and other corrosive elements, making aluminum an ideal choice for their construction.

Are there any downsides to using aluminum for shop equipment and tools?

While aluminum offers many advantages for shop equipment and tools, it is not as strong as steel and may not be suitable for heavy-duty applications. Additionally, aluminum can be more expensive than other materials, which may impact the overall cost of outfitting a shop with aluminum equipment.