The 2×72 grinder is a powerful tool that has become a staple in the metalworking and knife-making communities. Its name derives from the size of the belt it uses, which is 2 inches wide and 72 inches long. This specific configuration allows for a versatile range of applications, from shaping and sharpening to polishing and finishing.

The design of the 2×72 grinder typically features a robust motor that drives the belt at high speeds, enabling users to work efficiently on various materials, including steel, aluminum, and even wood. The versatility of this tool makes it an essential piece of equipment for both hobbyists and professionals alike. One of the key aspects that sets the 2×72 grinder apart from other grinding tools is its ability to accommodate different types of belts.

Users can easily switch between coarse, medium, and fine grits, allowing for a seamless transition from rough shaping to fine finishing. This adaptability not only enhances productivity but also provides greater control over the final outcome of the workpiece. Additionally, many models come equipped with adjustable tracking and tensioning systems, which further improve usability and precision.

As a result, the 2×72 grinder has gained a reputation for being an indispensable tool in workshops focused on metal fabrication and knife making.

Key Takeaways

- The 2×72 grinder is a versatile and powerful tool that is essential for serious metalworking and knife making.

- Upgrading to a 2×72 grinder offers increased speed, precision, and control for metalworking projects.

- When choosing a 2×72 grinder, look for essential features such as variable speed control, durable construction, and a variety of attachment options.

- Mastering the art of knife making with a 2×72 grinder requires practice, patience, and attention to detail.

- To use a 2×72 grinder like a pro, follow tips and techniques such as proper belt selection, maintaining the right belt tension, and using the correct grinding angles.

The Advantages of Upgrading to a 2×72 Grinder for Serious Metalworking

Upgrading to a 2×72 grinder can significantly enhance the quality and efficiency of metalworking projects. One of the primary advantages is the increased surface area provided by the wider belt. This feature allows for faster material removal, which is particularly beneficial when working on larger pieces or when significant shaping is required.

The speed and power of a 2×72 grinder enable users to achieve their desired results in a fraction of the time compared to smaller grinders, making it an ideal choice for those who take their craft seriously. Moreover, the precision offered by a 2×72 grinder cannot be overstated. With its adjustable speed settings and customizable belt options, users can fine-tune their approach to suit specific tasks.

Whether one is crafting intricate knife designs or performing detailed metalwork, the ability to control both speed and pressure leads to more consistent results. This level of precision not only improves the quality of the finished product but also enhances the overall experience for the craftsman, allowing for greater creativity and experimentation in their work.

Essential Features to Look for When Choosing a 2×72 Grinder

When selecting a 2×72 grinder, several essential features should be considered to ensure optimal performance and satisfaction. First and foremost, the motor’s power rating is crucial; a more powerful motor will provide better torque and speed, allowing for efficient material removal. Typically, motors ranging from 1 to 3 horsepower are common in high-quality models.

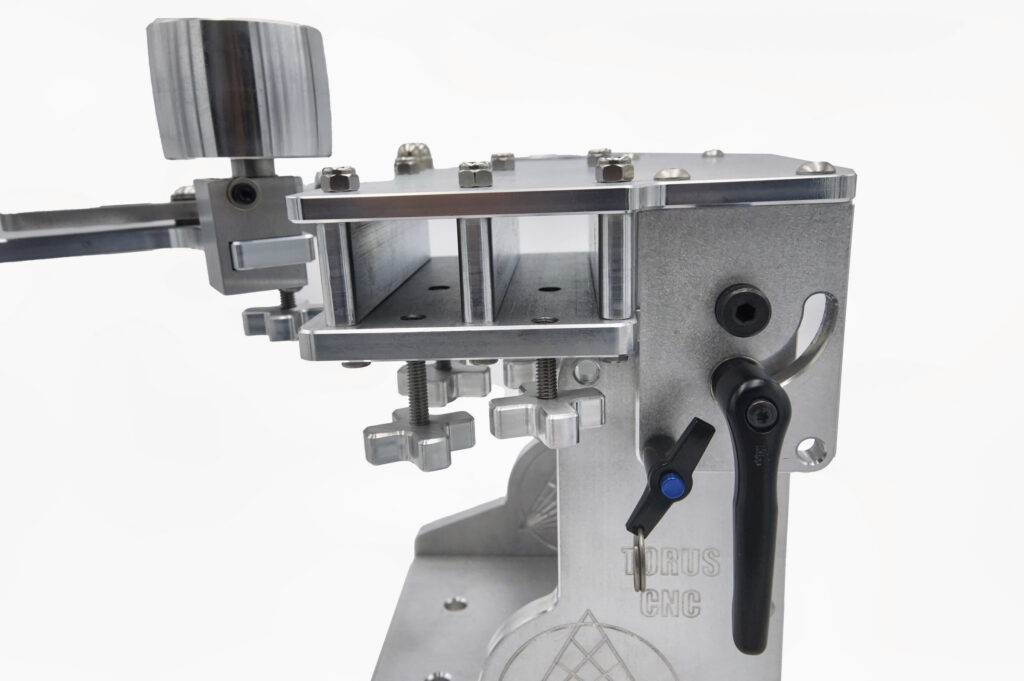

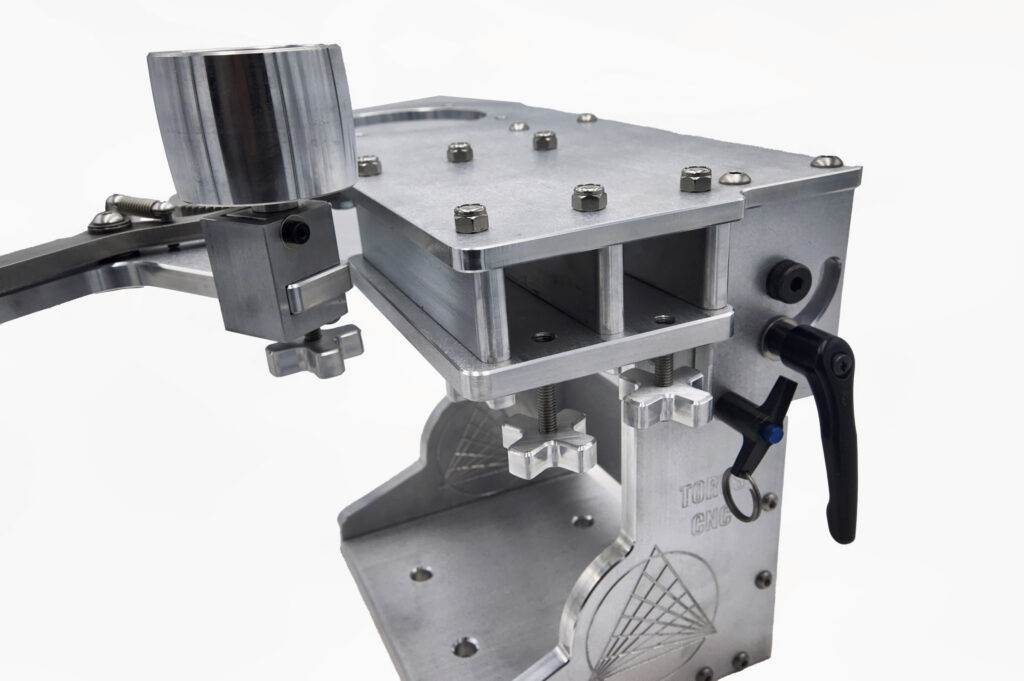

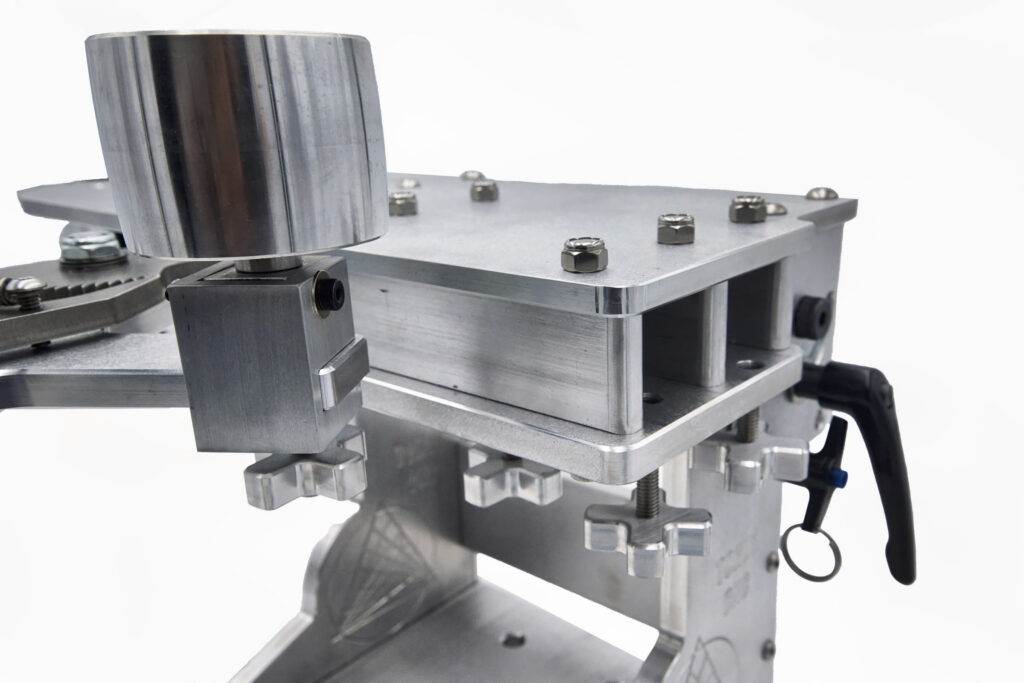

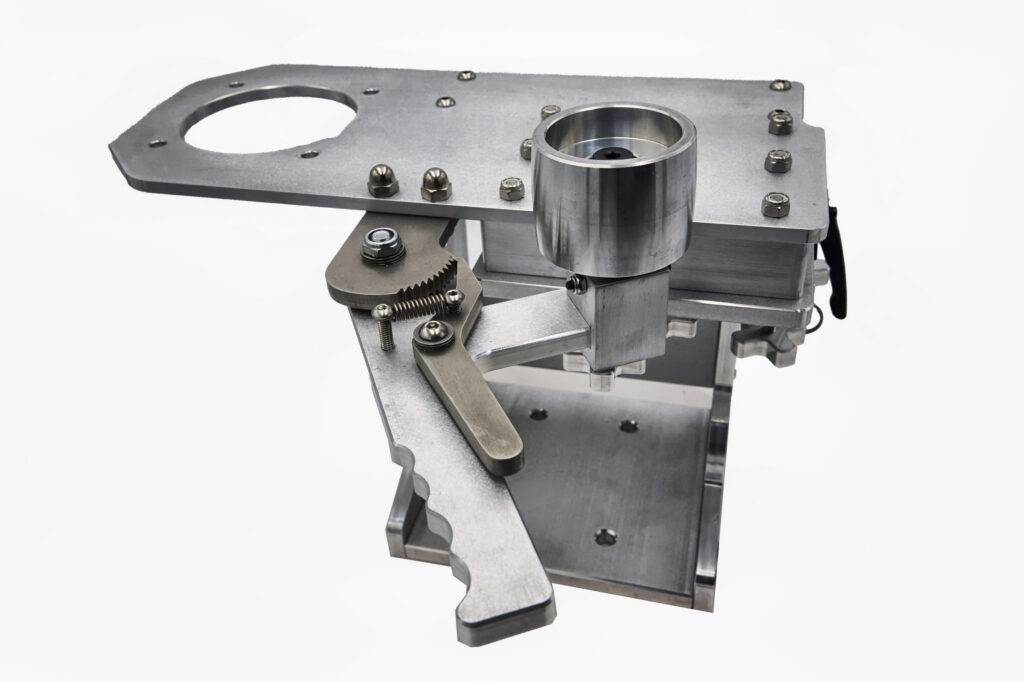

Additionally, look for grinders with variable speed controls, as this feature enables users to adjust the speed according to their specific needs, whether they are grinding, sanding, or polishing. Another important aspect to consider is the construction quality of the grinder itself. A sturdy frame made from durable materials will not only enhance stability during operation but also prolong the lifespan of the tool.

Features such as adjustable tracking mechanisms and easy belt changes are also vital for user convenience. Furthermore, consider additional attachments or accessories that may come with the grinder, such as work tables or dust collection systems, as these can significantly improve the overall functionality and cleanliness of your workspace.

Mastering the Art of Knife Making with a 2×72 Grinder

| Metrics | Value |

|---|---|

| Grinder Type | 2×72 |

| Knife Making Skill Level | Mastering |

| Grinding Speed | Variable |

| Grinding Belt Size | 2×72 inches |

| Material Removal Rate | High |

The 2×72 grinder has become synonymous with knife making due to its unparalleled ability to shape and refine blades with precision. Mastering this art requires not only skill but also an understanding of how to effectively utilize the grinder’s capabilities. The process typically begins with selecting the right type of steel for the blade, followed by rough shaping using a coarse grit belt on the grinder.

This initial phase is crucial as it sets the foundation for the blade’s profile and geometry. Once the rough shape is established, transitioning to finer grit belts allows for refining the edge and achieving a polished finish. The versatility of the 2×72 grinder enables knife makers to experiment with different angles and techniques, ultimately leading to unique designs that reflect their personal style.

Additionally, many craftsmen appreciate how this tool facilitates consistent results across multiple projects, making it easier to replicate successful designs or create custom orders for clients.

Tips and Techniques for Using a 2×72 Grinder Like a Pro

To maximize efficiency when using a 2×72 grinder, several tips and techniques can be employed. First, maintaining a steady hand while guiding the workpiece against the belt is essential for achieving uniform results. Practicing control over pressure and angle will lead to smoother finishes and more precise edges.

Additionally, utilizing jigs or fixtures can help stabilize smaller pieces during grinding, allowing for greater accuracy without compromising safety. Another effective technique involves regularly changing belts based on their wear and tear. Dull belts can lead to overheating and uneven grinding, which can negatively impact both the workpiece and the grinder itself.

Keeping an assortment of belts on hand ensures that users can quickly switch out worn belts for fresh ones, maintaining optimal performance throughout various stages of their projects. Lastly, taking time to clean and maintain the grinder will prolong its lifespan and ensure consistent results over time.

Safety Precautions and Best Practices for Operating a 2×72 Grinder

Safety should always be a top priority when operating a 2×72 grinder. Wearing appropriate personal protective equipment (PPE) is essential; this includes safety glasses or goggles to protect against flying debris, gloves to shield hands from sharp edges, and hearing protection due to potential noise levels generated by the machine. Additionally, it is advisable to wear a dust mask or respirator when working with materials that produce harmful dust particles.

Proper workspace organization also plays a significant role in ensuring safety while using a 2×72 grinder. Keeping tools and materials neatly arranged minimizes distractions and reduces the risk of accidents. Furthermore, ensuring that all safety guards are in place before operating the grinder is crucial; these guards help prevent accidental contact with moving parts.

Regularly inspecting the machine for any signs of wear or malfunction will also contribute to a safer working environment.

Customizing and Upgrading Your 2×72 Grinder for Maximum Efficiency

Customization options for a 2×72 grinder can significantly enhance its performance and tailor it to specific needs. Many users opt to add various attachments such as work tables or tool rests that provide additional support during grinding tasks. These enhancements not only improve stability but also allow for more intricate work by providing better control over angles and pressure.

Upgrading components such as motors or pulleys can also lead to improved efficiency. A more powerful motor can increase speed and torque, enabling faster material removal without sacrificing precision. Additionally, investing in high-quality belts designed for specific applications can further enhance performance; specialized belts are available for tasks ranging from heavy stock removal to fine finishing work.

By customizing their grinders in these ways, users can create a machine that perfectly suits their individual requirements.

Taking Your Craft to the Next Level: Building a Business with Your 2×72 Grinder

For those passionate about metalworking or knife making, leveraging a 2×72 grinder can open doors to entrepreneurial opportunities. The quality and precision achievable with this tool allow craftsmen to produce high-end products that appeal to discerning customers. Establishing an online presence through social media platforms or e-commerce websites can help showcase creations and attract potential buyers.

Additionally, participating in local craft fairs or markets provides an excellent opportunity to connect with customers directly while gaining valuable feedback on products. Offering custom orders or personalized designs can further differentiate one’s business in a competitive market. As skills develop over time, expanding product lines or even offering workshops can create additional revenue streams while fostering community engagement among fellow enthusiasts.

With dedication and creativity, turning a passion for metalworking into a thriving business is entirely achievable with the right tools at hand, particularly a reliable 2×72 grinder like those offered by TorusCNC.

FAQs

What is a 2×72 grinder?

A 2×72 grinder is a type of belt grinder specifically designed for metalworking and knife making. It features a 2-inch by 72-inch belt, which provides a large grinding surface for precision and efficiency.

Why would a hobbyist want to upgrade to a 2×72 grinder for custom knife making?

Upgrading to a 2×72 grinder offers several advantages for hobbyist knife makers, including increased precision, speed, and control over the grinding process. The larger grinding surface also allows for more intricate and detailed knife designs.

What are the key features to look for in a 2×72 grinder?

Key features to consider when upgrading to a 2×72 grinder include variable speed control, durable construction, adjustable tool rest, and the ability to accommodate different types of grinding belts. Additionally, a reliable motor and sturdy work surface are important for consistent and accurate grinding.

What are the potential challenges of upgrading to a 2×72 grinder?

Challenges of upgrading to a 2×72 grinder may include the initial cost of the equipment, the learning curve associated with using a larger and more powerful grinder, and the need for proper safety precautions and training. Additionally, finding the right balance of speed and pressure for different types of knife materials can take some practice.

Are there any safety considerations when using a 2×72 grinder?

Yes, safety is paramount when using a 2×72 grinder. It’s important to wear appropriate safety gear, such as eye protection and gloves, and to follow proper operating procedures to avoid accidents. Additionally, proper ventilation and dust collection systems should be in place to minimize the inhalation of metal dust and particles.