The Kukri blade is a distinctive and versatile tool that has its roots in the mountainous regions of Nepal. Characterized by its curved shape, the Kukri is not only a weapon but also a multi-functional tool used for various tasks, from chopping wood to preparing food. The design of the Kukri allows for powerful cutting strokes, making it an effective tool for both utility and combat.

Its unique geometry, with a pronounced belly and a tapered point, enables the user to apply significant force with minimal effort, which is why it has been favored by Gurkha soldiers and outdoor enthusiasts alike. The blade’s construction typically features a thick spine that tapers down to a sharp edge, providing durability and strength. Traditionally made from high-carbon steel, Kukris can hold an edge well and are relatively easy to sharpen.

Understanding the anatomy of the Kukri is essential for anyone looking to maintain or enhance its performance. The blade’s curvature not only contributes to its cutting efficiency but also influences how it should be sharpened. Recognizing these characteristics is crucial for achieving optimal sharpness and functionality.

Key Takeaways

- The Kukri blade is a traditional Nepalese knife with a unique curved shape that makes it ideal for chopping and slicing.

- A 2×72 belt grinder is a powerful tool for sharpening blades, with a wide variety of belt options for different sharpening needs.

- When selecting abrasive belts for sharpening, consider the grit, material, and backing of the belt to ensure the best results.

- Properly preparing the Kukri blade for sharpening includes cleaning, inspecting for damage, and securing it in the grinder.

- Setting up the 2×72 belt grinder for sharpening involves adjusting the speed, tracking, and tension of the belt for optimal sharpening results.

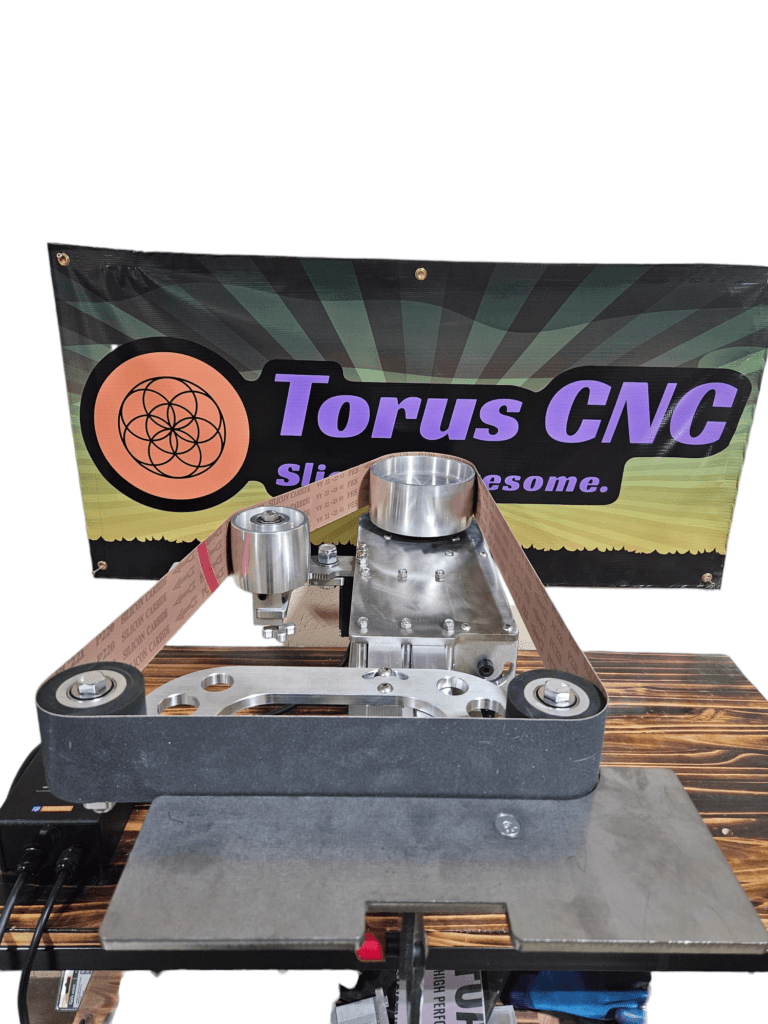

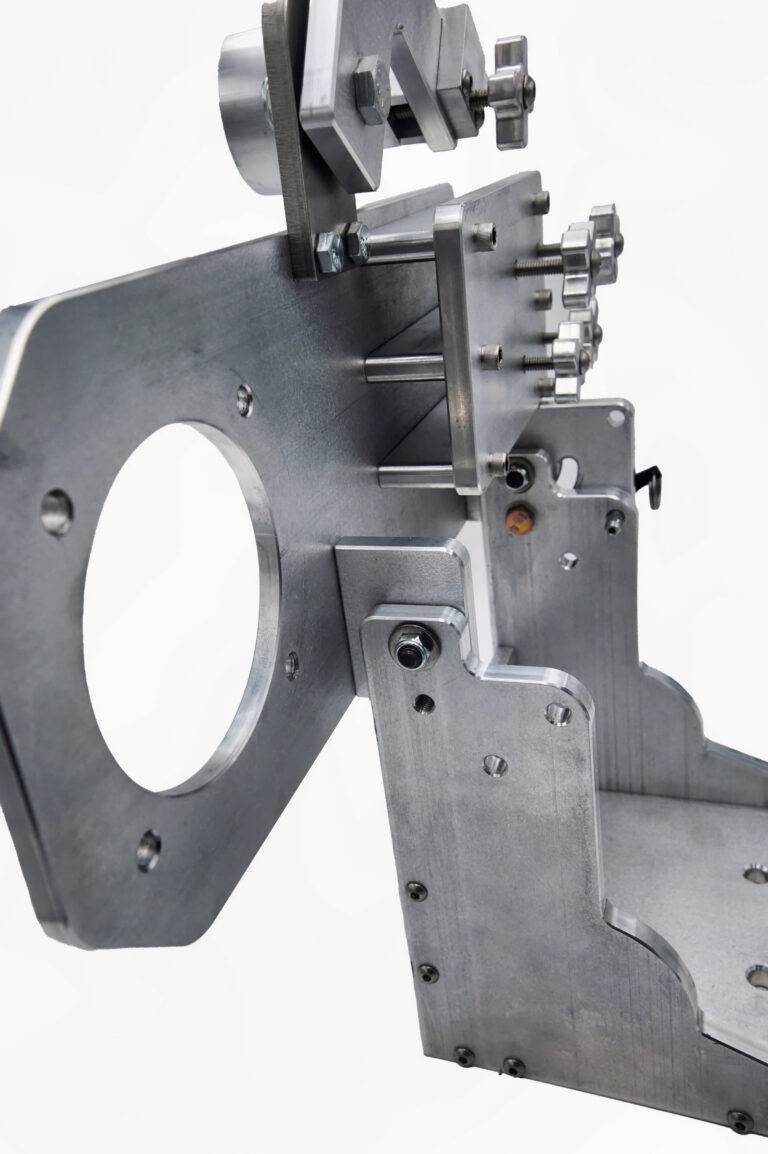

Introduction to the 2×72 Belt Grinder

The 2×72 belt grinder is an indispensable tool for knife makers and enthusiasts alike, particularly when it comes to sharpening blades like the Kukri. This machine features a belt that is 2 inches wide and 72 inches long, allowing for a variety of grinding and sharpening tasks. Its versatility makes it suitable for shaping, grinding, and polishing metal, which is essential for maintaining the edge of a Kukri blade.

The 2×72 belt grinder can accommodate different types of belts, enabling users to switch between coarse and fine grits depending on their sharpening needs. One of the key advantages of using a 2×72 belt grinder is its efficiency. Unlike traditional sharpening methods that can be time-consuming and labor-intensive, this machine allows for quick material removal while maintaining control over the sharpening process.

The ability to adjust the speed and angle of the belt further enhances its usability, making it an ideal choice for both novice and experienced sharpeners. With the right setup and technique, a 2×72 belt grinder can transform a dull Kukri into a razor-sharp tool in a matter of minutes.

Selecting the Right Abrasive Belts for Sharpening

Choosing the appropriate abrasive belts is critical when sharpening a Kukri blade on a 2×72 belt grinder. The selection process begins with understanding the grit levels available. Coarse grits, typically ranging from 36 to 80, are ideal for initial shaping and removing significant material from the blade.

These belts are particularly useful for repairing damaged edges or reshaping the blade profile. As you progress through the sharpening process, transitioning to medium grits (120 to 220) allows for refining the edge and preparing it for final polishing. Fine grits, usually above 400, are essential for achieving a polished finish on the Kukri blade.

These belts help in honing the edge to a razor-sharp point while minimizing scratches on the blade surface. It’s also important to consider the type of abrasive material used in the belts. Aluminum oxide belts are common and effective for general sharpening tasks, while ceramic belts offer superior durability and cutting performance, making them suitable for high-carbon steel blades like those found in Kukris.

Selecting the right combination of belts will ensure that you achieve optimal results while sharpening your Kukri.

Preparing the Kukri Blade for Sharpening

Before beginning the sharpening process, proper preparation of the Kukri blade is essential. Start by thoroughly cleaning the blade to remove any dirt, grime, or residue that may have accumulated over time. A clean surface not only ensures better contact with the abrasive belt but also prevents contaminants from scratching or damaging the blade during sharpening.

Use warm soapy water and a soft cloth or sponge to clean the blade, followed by drying it completely to avoid rust formation. Once cleaned, inspect the blade for any nicks or chips along the edge. If any damage is present, it may require more aggressive grinding with coarse belts before moving on to finer grits.

Additionally, consider marking the areas that need attention with a marker; this will help you keep track of your progress as you sharpen. Properly preparing your Kukri blade sets the stage for an effective sharpening session, ensuring that you achieve a sharp edge while maintaining the integrity of the blade.

Setting up the 2×72 Belt Grinder for Sharpening

Setting up your 2×72 belt grinder correctly is crucial for effective sharpening of your Kukri blade. Begin by ensuring that the grinder is securely mounted on a stable workbench or stand to minimize vibrations during operation. Check that all components are in good working order, including the motor, tracking mechanism, and tensioning system for the belt.

Proper tension on the belt is vital; too loose can cause slippage while too tight can lead to premature wear or damage. Next, adjust the angle of the platen or work rest according to the desired bevel angle of your Kukri blade. Most Kukris have a bevel angle between 15 to 20 degrees, but this can vary based on personal preference or intended use.

Use an angle finder or protractor to ensure accuracy in your setup. Once everything is adjusted and secured, run the grinder briefly without any load to check for smooth operation and proper tracking of the belt. A well-set-up grinder will make your sharpening process more efficient and effective.

Techniques for Sharpening the Kukri Blade

Sharpening a Kukri blade requires specific techniques to ensure that you maintain its unique shape while achieving a sharp edge. Begin by holding the Kukri firmly against the belt at the established bevel angle. Use smooth, even strokes along the length of the blade, allowing the abrasive belt to do most of the work without applying excessive pressure.

It’s important to keep your movements fluid; jerky motions can lead to uneven sharpening or damage to the blade. As you work through different grits, periodically check your progress by inspecting the edge visually and feeling for sharpness with your fingers (taking care not to cut yourself). Pay attention to any areas that may require additional work; if certain sections are not sharpening evenly, adjust your technique accordingly.

For instance, if you notice that one side is sharper than the other, you may need to spend more time on that side or adjust your angle slightly during sharpening. Consistency in technique will yield better results and prolong the life of your Kukri.

Tips for Maintaining the Proper Angle while Sharpening

Maintaining a consistent angle while sharpening is crucial for achieving an even edge on your Kukri blade. One effective method is to use a guide or jig that can help hold the blade at a fixed angle against the belt grinder. This can be particularly useful for beginners who may struggle with maintaining an accurate angle throughout their sharpening process.

Many jigs are adjustable, allowing you to set them according to your desired bevel angle. If you prefer freehand sharpening, practice is key. Focus on keeping your wrist steady and using your body as a pivot point rather than moving your arm excessively.

It can be helpful to visualize or mark reference points on your grinder or work surface that align with your desired angle. Additionally, take breaks during sharpening sessions to reassess your technique; stepping back can provide perspective on whether you are maintaining consistency in your angle.

Testing the Sharpness of the Kukri Blade

After completing your sharpening session, it’s essential to test the sharpness of your Kukri blade before putting it back into use. One common method is known as the “paper test,” where you attempt to slice through a piece of paper with minimal effort. A well-sharpened Kukri should cut cleanly through paper without tearing or dragging.

This test provides immediate feedback on how effective your sharpening efforts have been. Another method involves using soft materials like tomatoes or other fruits; if your Kukri can slice through them effortlessly, it indicates that you have achieved a satisfactory level of sharpness. However, always exercise caution when testing sharpness; ensure you are handling the blade safely and away from yourself or others.

Regular testing after each sharpening session will help you gauge how well your techniques are working and whether adjustments are needed in future sessions.

Finishing and Polishing the Sharpened Kukri Blade

Once you have achieved a sharp edge on your Kukri blade, finishing and polishing are essential steps that enhance both appearance and performance. Transitioning to finer grit belts will help remove any scratches left from previous grits while refining the edge further. Polishing belts or compounds can also be used at this stage; these products help create a mirror-like finish on the blade surface while improving corrosion resistance.

To polish effectively, use light pressure and allow the belt or compound to do most of the work. Move along the length of the blade in consistent strokes until you achieve your desired finish. After polishing, wipe down the blade with a clean cloth to remove any residue from polishing compounds or dust generated during grinding.

A well-finished Kukri not only looks impressive but also performs better due to reduced friction during cutting tasks.

Safety Precautions when Sharpening with a 2×72 Belt Grinder

Safety should always be a top priority when using power tools like a 2×72 belt grinder for sharpening tasks. Start by wearing appropriate personal protective equipment (PPE), including safety glasses or goggles to protect your eyes from flying debris and dust particles generated during grinding. Hearing protection is also advisable due to potential noise levels produced by the machine.

Ensure that long hair is tied back and loose clothing is secured away from moving parts of the grinder. Additionally, keep your workspace organized; clutter can lead to accidents or distractions while operating machinery. Familiarize yourself with emergency shut-off procedures in case something goes wrong during operation.

By taking these precautions seriously, you can create a safer environment for yourself while sharpening your Kukri blade.

Conclusion and Final Thoughts on Sharpening Kukri Blades on a 2×72

Sharpening Kukri blades using a 2×72 belt grinder is an efficient way to maintain their performance and longevity. By understanding both the unique characteristics of Kukris and how to effectively use a belt grinder, enthusiasts can achieve impressive results in their sharpening endeavors. From selecting appropriate abrasive belts to mastering techniques that maintain proper angles, each step plays an integral role in ensuring that your Kukri remains sharp and functional.

Ultimately, regular maintenance through proper sharpening not only enhances performance but also preserves the beauty of this iconic blade design. With practice and attention to detail, anyone can become proficient in sharpening their Kukri blades using a 2×72 belt grinder, ensuring they remain reliable tools for years to come. Embracing this process not only fosters skill development but also deepens appreciation for these remarkable blades and their rich heritage.

FAQs

What is a Kukri blade?

A Kukri blade is a type of knife originating from Nepal, traditionally used as both a tool and a weapon. It is characterized by its inwardly curved blade.

What is a 2×72 grinder?

A 2×72 grinder is a type of belt grinder commonly used by knife makers and metalworkers for shaping, sharpening, and polishing metal objects, including knives and blades.

Why is it important to grind curved Kukri blades carefully?

Grinding curved Kukri blades requires precision and attention to detail in order to maintain the proper shape and functionality of the blade. Careful grinding ensures that the blade retains its intended curvature and cutting ability.

What are some tips for grinding curved Kukri blades on a 2×72 grinder?

Some tips for grinding curved Kukri blades on a 2×72 grinder include using the appropriate belt grit, maintaining a consistent angle and pressure, and frequently checking the progress to avoid overgrinding.

What safety precautions should be taken when grinding curved Kukri blades on a 2×72 grinder?

Safety precautions when grinding curved Kukri blades on a 2×72 grinder include wearing appropriate eye and ear protection, using a dust mask, and ensuring that the grinder is securely mounted and stable. It is also important to keep hands and clothing away from the moving belt.