Non-ferrous metals are a category of metals that do not contain significant amounts of iron, making them resistant to rust and corrosion. This group includes a variety of materials such as aluminum, copper, brass, lead, nickel, and titanium, each with unique properties that make them suitable for specific applications. Non-ferrous metals are widely used in industries ranging from aerospace and automotive to construction and electronics due to their lightweight nature, excellent conductivity, and malleability.

The versatility of these metals allows for innovative designs and applications, making them essential in modern manufacturing processes. The processing of non-ferrous metals often involves various machining techniques, including grinding. Grinding is a critical operation that shapes and finishes metal components to meet precise specifications.

However, the unique characteristics of non-ferrous metals require specialized knowledge and equipment to ensure optimal results. Understanding the properties of these materials and the best practices for working with them is crucial for achieving high-quality outcomes while maintaining safety in the workplace.

Key Takeaways

- Non-ferrous metals do not contain iron and are commonly used in various industries.

- Grinding non-ferrous metals can create hazardous dust and debris that pose health risks.

- Select a belt grinder specifically designed for non-ferrous metals to ensure safety and quality results.

- Using the correct abrasives is crucial for achieving the desired finish and preventing damage to the metal.

- Proper safety precautions, PPE, and maintenance are essential for a safe work environment when grinding non-ferrous metals.

Understanding the Hazards of Grinding Non-Ferrous Metals

Grinding non-ferrous metals presents several hazards that operators must be aware of to ensure a safe working environment. One of the primary concerns is the generation of fine metal dust during the grinding process. This dust can be highly flammable and poses a significant risk of fire or explosion if not properly managed.

Additionally, the dust can create respiratory hazards if inhaled, leading to long-term health issues for workers. Therefore, it is essential to implement effective dust control measures to minimize exposure. Another hazard associated with grinding non-ferrous metals is the potential for heat generation.

The grinding process can produce significant heat, which may lead to thermal injuries or even ignite combustible materials nearby. Operators must be vigilant about monitoring temperatures during grinding and using appropriate cooling methods to mitigate this risk. Furthermore, the use of improper grinding techniques can result in accidents or equipment damage, emphasizing the need for proper training and adherence to safety protocols.

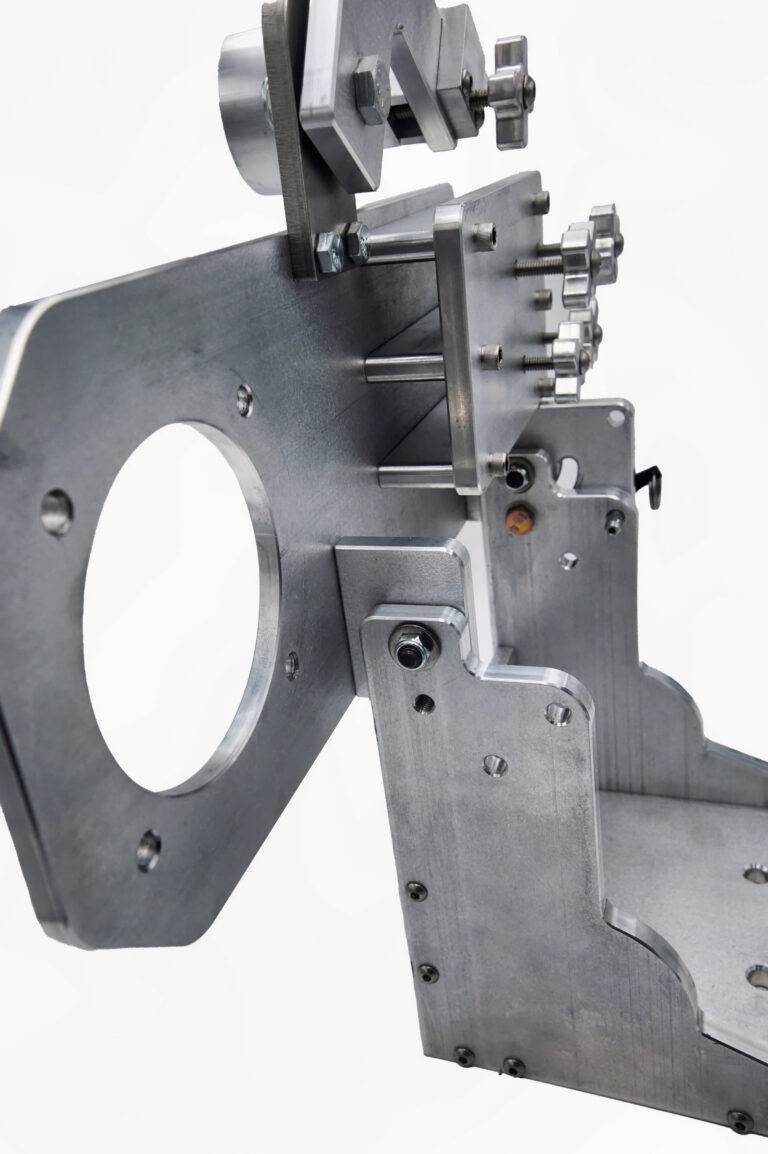

Selecting the Right Belt Grinder for Non-Ferrous Metals

Choosing the appropriate belt grinder is crucial when working with non-ferrous metals. The right grinder will not only enhance efficiency but also ensure safety during operations. When selecting a belt grinder, consider factors such as motor power, belt speed, and the type of belt used.

A grinder with adjustable speed settings allows for greater control over the grinding process, enabling operators to tailor their approach based on the specific metal being worked on. Additionally, the design of the grinder plays a significant role in its effectiveness. A well-designed belt grinder should provide easy access to the workpiece while allowing for optimal visibility.

Features such as dust collection systems can also be beneficial in managing metal dust and maintaining a clean workspace. Ultimately, investing in a high-quality belt grinder specifically designed for non-ferrous metals can lead to improved productivity and better results.

Importance of Using the Correct Abrasives

The choice of abrasives is another critical factor when grinding non-ferrous metals. Different materials require specific types of abrasives to achieve optimal results without damaging the workpiece. For instance, aluminum often requires aluminum oxide or ceramic abrasives due to their ability to cut efficiently without clogging.

On the other hand, softer metals like copper may benefit from silicon carbide abrasives that provide a finer finish. Using the correct abrasives not only enhances the quality of the grind but also prolongs the life of the grinding belts and equipment. Mismatched abrasives can lead to excessive wear on both the grinder and the workpiece, resulting in increased costs and downtime.

Therefore, it is essential to consult manufacturer guidelines and industry standards when selecting abrasives for specific non-ferrous metals.

Safety Precautions for Grinding Non-Ferrous Metals

Implementing safety precautions is paramount when grinding non-ferrous metals. Operators should always conduct a thorough risk assessment before beginning any grinding operation. This assessment should include identifying potential hazards, evaluating existing safety measures, and determining necessary improvements.

Regular maintenance checks on equipment are also essential to ensure that all safety features are functioning correctly. In addition to equipment checks, operators should establish clear protocols for handling non-ferrous metals during grinding. This includes ensuring that work areas are free from clutter and that all tools are in good condition.

Proper training on safe grinding techniques should be provided to all personnel involved in the process. By fostering a culture of safety awareness, organizations can significantly reduce the risk of accidents and injuries associated with grinding operations.

Proper Personal Protective Equipment (PPE) for Grinding Non-Ferrous Metals

Personal protective equipment (PPE) is an essential component of any safe grinding operation involving non-ferrous metals. Operators should wear appropriate eye protection, such as safety goggles or face shields, to guard against flying debris and sparks generated during grinding. Hearing protection is also crucial, as belt grinders can produce high noise levels that may lead to hearing damage over time.

In addition to eye and ear protection, operators should wear gloves designed for metalworking tasks. These gloves should provide a good grip while allowing for dexterity when handling workpieces. Respirators may also be necessary if there is a risk of inhaling metal dust or fumes during grinding operations.

By equipping workers with the right PPE, organizations can significantly enhance safety and reduce the likelihood of injuries.

Tips for Maintaining a Safe Work Environment

Creating a safe work environment for grinding non-ferrous metals involves several key practices that go beyond individual safety measures. First and foremost, maintaining cleanliness in the workspace is vital. Regularly cleaning up metal shavings and dust not only reduces fire hazards but also minimizes slip-and-fall accidents.

Implementing a routine cleaning schedule can help ensure that work areas remain organized and safe. Another important aspect of maintaining a safe work environment is ensuring proper ventilation. Adequate airflow helps dissipate harmful fumes and dust generated during grinding operations.

Installing exhaust systems or using local exhaust ventilation can significantly improve air quality in the workspace. Additionally, providing clear signage regarding safety protocols and emergency procedures can help reinforce safety awareness among all personnel.

Techniques for Achieving the Best Results when Grinding Non-Ferrous Metals

To achieve optimal results when grinding non-ferrous metals, operators should employ specific techniques tailored to the material being processed. One effective technique is to use a consistent feed rate while grinding, which helps maintain uniformity in surface finish and reduces the risk of overheating. Operators should also be mindful of their angle of approach; maintaining an appropriate angle can enhance cutting efficiency while minimizing wear on both the abrasive belt and the workpiece.

Another technique involves utilizing cooling methods during grinding operations. Applying coolant or using water-based lubricants can help dissipate heat generated during grinding, preventing thermal damage to both the metal and the abrasive material. Additionally, taking breaks between grinding sessions allows both the operator and equipment to cool down, further enhancing safety and performance.

Common Mistakes to Avoid when Grinding Non-Ferrous Metals

When grinding non-ferrous metals, certain common mistakes can lead to suboptimal results or even accidents. One frequent error is using incorrect abrasive materials for specific metals, which can result in poor finishes or excessive wear on equipment. Operators should always verify that they are using abrasives suited for the particular type of non-ferrous metal they are working with.

Another mistake involves neglecting proper machine setup before starting a grind. Failing to adjust belt tension or alignment can lead to uneven grinding and increased risk of accidents. Additionally, rushing through operations without adhering to safety protocols can compromise both quality and safety outcomes.

By being aware of these common pitfalls and taking proactive measures to avoid them, operators can enhance their efficiency and maintain a safer working environment.

Proper Storage and Handling of Non-Ferrous Metal Dust and Debris

The proper storage and handling of non-ferrous metal dust and debris are critical components of maintaining workplace safety and compliance with environmental regulations. Metal dust should be collected using appropriate dust collection systems designed specifically for non-ferrous materials. These systems help prevent dust accumulation that could pose fire hazards or respiratory risks.

Once collected, non-ferrous metal dust should be stored in designated containers that are clearly labeled and made from materials resistant to corrosion or combustion. It is essential to follow local regulations regarding waste disposal for metal dust, as improper disposal can lead to environmental contamination or legal repercussions. By implementing effective dust management practices, organizations can ensure a safer workplace while adhering to regulatory requirements.

Ensuring Safety and Quality Results when Grinding Non-Ferrous Metals

In conclusion, grinding non-ferrous metals requires careful consideration of various factors to ensure both safety and quality results. Understanding the unique properties of these materials, selecting appropriate equipment and abrasives, and adhering to safety protocols are all essential components of successful operations. By prioritizing safety through proper training, PPE usage, and workplace organization, organizations can significantly reduce risks associated with grinding processes.

Moreover, employing best practices in techniques and maintenance will lead to improved efficiency and product quality in non-ferrous metal grinding operations. As industries continue to evolve and innovate with non-ferrous materials, staying informed about advancements in technology and safety measures will be crucial for achieving optimal outcomes while safeguarding worker health and well-being.

FAQs

What are non-ferrous metals?

Non-ferrous metals are metals that do not contain significant amounts of iron. Common non-ferrous metals include aluminum, copper, brass, and bronze.

Why is it important to grind non-ferrous metals safely?

Grinding non-ferrous metals can produce fine dust particles that can be harmful if inhaled. Additionally, non-ferrous metals can be softer than ferrous metals, making them more prone to overheating and causing damage to the workpiece if not ground safely.

What safety precautions should be taken when grinding non-ferrous metals on a belt grinder?

Safety precautions when grinding non-ferrous metals on a belt grinder include wearing appropriate personal protective equipment such as safety glasses, a dust mask, and gloves. It is also important to ensure that the belt grinder is properly grounded and that the workpiece is securely clamped in place.

What type of abrasive belt should be used for grinding non-ferrous metals?

When grinding non-ferrous metals, it is important to use abrasive belts specifically designed for non-ferrous materials. These belts are typically made of materials such as silicon carbide or aluminum oxide, which are better suited for grinding non-ferrous metals.

What are some best practices for grinding non-ferrous metals safely on a belt grinder?

Best practices for grinding non-ferrous metals safely on a belt grinder include using light pressure, keeping the workpiece cool by periodically dipping it in water, and avoiding excessive heat buildup. It is also important to regularly inspect the abrasive belt for wear and replace it as needed.