In the world of knife manufacturing, the processes that lead to a finished blade are critical in determining the quality and performance of the final product. Among these processes, the timing of grinding—specifically, whether to pre-grind before heat treatment or after—plays a significant role. Pre-grinding refers to the initial shaping and refining of the blade’s edge and surface before it undergoes heat treatment, which is essential for enhancing the material’s hardness and durability.

Conversely, post-heat treat grinding occurs after the blade has been hardened, allowing for final adjustments to be made to the edge and surface finish. The decision of when to grind can have profound implications on the overall quality of the knife. Each approach has its own set of advantages and disadvantages that can affect not only the efficiency of production but also the performance characteristics of the blade.

Understanding these differences is crucial for manufacturers aiming to optimize their processes and produce high-quality knives that meet the demands of both professional and amateur users.

Key Takeaways

- Pre-grinding before heat treat involves grinding the material before it undergoes the heat treatment process.

- The process of pre-grinding before heat treat includes rough grinding, stress relieving, and final grinding.

- The pros of pre-grinding before heat treat include improved material stability, reduced distortion, and better surface finish.

- The cons of pre-grinding before heat treat include the risk of material damage during heat treat and the need for additional handling.

- Pre-grinding after heat treat involves grinding the material after it has undergone the heat treatment process.

- The process of pre-grinding after heat treat includes final grinding and finishing operations.

- The pros of pre-grinding after heat treat include reduced risk of material damage during heat treat and the ability to achieve precise dimensional accuracy.

- The cons of pre-grinding after heat treat include potential distortion and the need for additional finishing processes.

- Comparing the results of pre-grinding before and after heat treat involves evaluating factors such as material stability, dimensional accuracy, and surface finish.

- Factors to consider when deciding whether to pre-grind before or after heat treat include material type, heat treat process, and desired final product specifications.

- Best practices for pre-grinding before or after heat treat include careful material handling, precise grinding techniques, and thorough quality control measures.

- In conclusion, the decision to pre-grind before or after heat treat should be based on a thorough evaluation of the specific material and process requirements, with a focus on achieving the desired final product quality.

The Process of Pre-Grinding Before Heat Treat

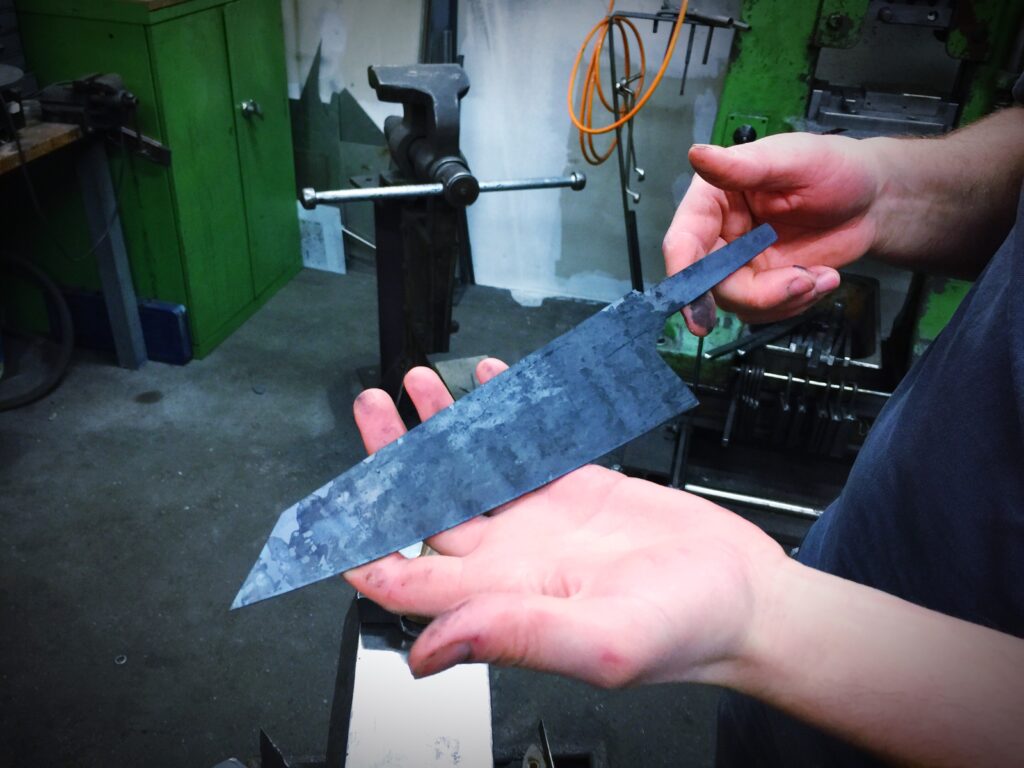

Pre-grinding before heat treatment involves shaping the blade while it is still in its softer, more malleable state. This process typically includes rough grinding to establish the basic profile of the knife, as well as finer grinding to refine the edge geometry. The softer state of the steel allows for easier material removal, enabling manufacturers to achieve precise shapes and contours without excessive wear on grinding tools.

During this stage, various grinding techniques may be employed, including belt grinding, wheel grinding, or even water jet cutting, depending on the desired outcome and the type of steel being used. The goal is to create a blade that is close to its final shape while still allowing for adjustments after heat treatment. This method not only streamlines the subsequent heat treatment process but also helps in achieving a more uniform hardness across the blade, as the material has been prepped for optimal heat absorption.

The Pros of Pre-Grinding Before Heat Treat

One of the primary advantages of pre-grinding before heat treatment is the ease with which material can be removed. Since the steel is in a softer state, it requires less effort and time to achieve the desired profile. This can lead to increased efficiency in production, allowing manufacturers to produce more blades in a shorter timeframe.

Additionally, pre-grinding can help in reducing tool wear, as grinding softer materials typically results in less strain on equipment. Another significant benefit is that pre-grinding allows for better control over the final properties of the blade. By shaping the knife before it undergoes hardening, manufacturers can ensure that any potential warping or distortion during heat treatment is minimized.

This proactive approach can lead to a more consistent final product, with improved edge retention and overall performance characteristics.

The Cons of Pre-Grinding Before Heat Treat

Despite its advantages, pre-grinding before heat treatment is not without its drawbacks. One notable concern is that any mistakes made during this stage can be more challenging to correct after hardening. If a blade is ground too thin or unevenly, it may not be possible to rectify these issues without compromising the integrity of the steel during subsequent processes.

Additionally, pre-grinding can introduce residual stresses into the material. These stresses may lead to warping or cracking during heat treatment if not properly managed. Manufacturers must be diligent in their techniques to ensure that they do not inadvertently create weaknesses in the blade that could affect its performance or longevity.

The Process of Pre-Grinding After Heat Treat

In contrast, pre-grinding after heat treatment involves shaping and refining the blade once it has been hardened. This process typically requires more robust grinding equipment due to the increased hardness of the material. Techniques such as diamond grinding or specialized abrasives may be necessary to effectively remove material from a hardened blade.

This method allows manufacturers to work with a fully hardened product, which can provide insights into how the blade will perform under real-world conditions. Any adjustments made during this stage can be based on actual performance characteristics rather than theoretical expectations. This can lead to a more tailored final product that meets specific user needs.

The Pros of Pre-Grinding After Heat Treat

One of the most significant advantages of pre-grinding after heat treatment is that it allows for precise adjustments based on the actual properties of the hardened steel. Manufacturers can assess how well the blade holds its edge and make necessary refinements accordingly. This adaptability can result in a superior final product that meets stringent performance standards.

Moreover, post-heat treat grinding can help eliminate any warping or distortion that may have occurred during hardening. By addressing these issues after heat treatment, manufacturers can ensure that their blades are not only aesthetically pleasing but also functionally sound. This approach often leads to improved edge geometry and surface finish, enhancing both performance and user satisfaction.

The Cons of Pre-Grinding After Heat Treat

While there are clear benefits to pre-grinding after heat treatment, this method also presents challenges. One major drawback is that grinding hardened steel requires more time and effort due to its increased hardness. This can lead to longer production times and potentially higher costs associated with tool wear and maintenance.

Additionally, if significant material removal is required during post-heat treat grinding, there is a risk of overheating the blade. Excessive heat generated during this process can compromise the tempering of the steel, leading to reduced hardness or brittleness in certain areas. Manufacturers must take care to manage their grinding techniques effectively to avoid these pitfalls.

Comparing the Results of Pre-Grinding Before and After Heat Treat

When comparing the results of pre-grinding before heat treatment versus after, several factors come into play. Pre-grinding often results in a more uniform hardness across the blade due to its preparation for optimal heat absorption. This can lead to improved edge retention and overall performance characteristics in many cases.

On the other hand, post-heat treat grinding allows for adjustments based on real-world performance metrics, which can enhance user satisfaction and functionality. The choice between these two methods ultimately depends on specific production goals and desired outcomes for each knife being manufactured.

Factors to Consider When Deciding Whether to Pre-Grind Before or After Heat Treat

Several factors should be taken into account when deciding whether to pre-grind before or after heat treatment. One key consideration is the type of steel being used; some materials may respond better to one method over another based on their inherent properties. Additionally, production volume and efficiency goals will play a significant role in determining which approach is most suitable.

Manufacturers should also consider their available equipment and expertise when making this decision. Certain grinding techniques may be better suited for either pre- or post-heat treat processes based on tool capabilities and operator skill levels. Ultimately, a thorough evaluation of these factors will help guide manufacturers toward an informed decision that aligns with their production objectives.

Best Practices for Pre-Grinding Before or After Heat Treat

To maximize efficiency and quality in either pre-grinding or post-heat treat processes, manufacturers should adhere to best practices tailored to each method. For pre-grinding before heat treatment, it is essential to maintain consistent pressure and speed during grinding to avoid introducing unwanted stresses into the material. Regularly inspecting tools for wear will also help ensure optimal performance throughout this stage.

In contrast, when pre-grinding after heat treatment, operators should focus on using appropriate cooling methods to prevent overheating during grinding. Employing techniques such as intermittent grinding or using coolant can help mitigate risks associated with excessive heat generation. Additionally, careful monitoring of blade geometry during this stage will ensure that any adjustments made enhance rather than detract from overall performance.

Conclusion and Recommendations for Pre-Grinding Before or After Heat Treat

In conclusion, both pre-grinding before heat treatment and post-heat treat grinding offer unique advantages and challenges that can significantly impact knife manufacturing outcomes. The choice between these methods should be guided by specific production goals, material properties, and available resources. For manufacturers seeking efficiency and uniformity in their blades, pre-grinding before heat treatment may be advantageous; however, those prioritizing precise adjustments based on real-world performance may find post-heat treat grinding more beneficial.

Ultimately, understanding these processes in depth will empower manufacturers to make informed decisions that enhance their production capabilities while delivering high-quality knives that meet user expectations. By adhering to best practices tailored to each method, manufacturers can optimize their processes and achieve superior results in their knife-making endeavors.

FAQs

What is pre-grinding before heat treat?

Pre-grinding before heat treat refers to the process of grinding a metal part to its final dimensions before it undergoes heat treatment. This is done to remove any surface imperfections and to achieve the desired shape and size.

What is post-grinding after heat treat?

Post-grinding after heat treat refers to the process of grinding a metal part to its final dimensions after it has undergone heat treatment. This is done to remove any distortion or warping that may have occurred during the heat treatment process and to achieve the desired shape and size.

What are the pros of pre-grinding before heat treat?

– Pre-grinding before heat treat allows for greater control over the final dimensions of the part.

– It can help to reduce the amount of material that needs to be removed during the grinding process, potentially saving time and cost.

– It can help to minimize the risk of distortion or warping during the heat treatment process.

What are the cons of pre-grinding before heat treat?

– There is a risk of removing too much material during the pre-grinding process, leading to potential waste and increased cost.

– Any surface imperfections that are present before heat treat may still be present after heat treat, requiring additional post-grinding.

What are the pros of post-grinding after heat treat?

– Post-grinding after heat treat allows for any distortion or warping that occurs during the heat treatment process to be corrected.

– It can help to ensure that the final dimensions of the part are accurate and precise.

What are the cons of post-grinding after heat treat?

– Post-grinding after heat treat may require more time and cost compared to pre-grinding before heat treat, as any distortion or warping will need to be corrected.

– There is a risk of removing too much material during the post-grinding process, potentially leading to waste and increased cost.