Belt speed is a critical factor in the performance of any grinding machine, particularly when it comes to 2×72 grinders like those offered by TorusCNThe speed at which the belt moves can significantly influence the efficiency of the grinding process, affecting everything from material removal rates to the quality of the finished surface. A higher belt speed typically results in faster material removal, which can be advantageous for heavy stock removal tasks. However, it is essential to balance speed with control, as excessive speed can lead to overheating and damage to both the workpiece and the grinding belt.

When using a TorusCNC 2×72 grinder, understanding the relationship between belt speed and the type of material being worked on is crucial. Different materials respond differently to various speeds; for instance, softer metals may require a slower speed to prevent gouging, while harder materials can often withstand higher speeds without compromising quality. By adjusting the belt speed according to the specific requirements of each project, users can achieve optimal results, ensuring both efficiency and precision in their grinding tasks.

Key Takeaways

- Belt speed is crucial for efficient grinding, as it affects material removal rate and heat generation.

- Choosing the right grits is essential for achieving the desired surface finish and material removal rate in your project.

- To maximize the potential of your 2×72 grinder, understand and harness its power by adjusting speed and pressure.

- Proper belt tracking is important for smooth and consistent grinding, and can be achieved through regular maintenance and adjustments.

- Safety should always be a priority when using a 2×72 grinder, including wearing appropriate protective gear and following best practices.

Choosing the Right Grits: Finding the Perfect Balance for Your Project

Selecting the appropriate grit for your grinding project is essential for achieving the desired finish and performance. The grit size determines how aggressively the belt will cut into the material, with lower numbers indicating coarser grits and higher numbers representing finer grits. For instance, if you are working on heavy stock removal or shaping a rough piece of metal, starting with a coarser grit will allow for faster material removal.

As you progress, transitioning to finer grits will help refine the surface finish and eliminate any scratches left by the coarser belts. TorusCNC offers a range of belts with varying grit sizes, allowing users to tailor their approach based on the specific needs of their projects. It is important to consider not only the material being worked on but also the final finish desired.

For example, if you are preparing a blade for sharpening, you may want to start with a medium grit to establish the edge before moving to finer grits for polishing. This strategic approach to grit selection can significantly enhance both the efficiency and quality of your grinding work.

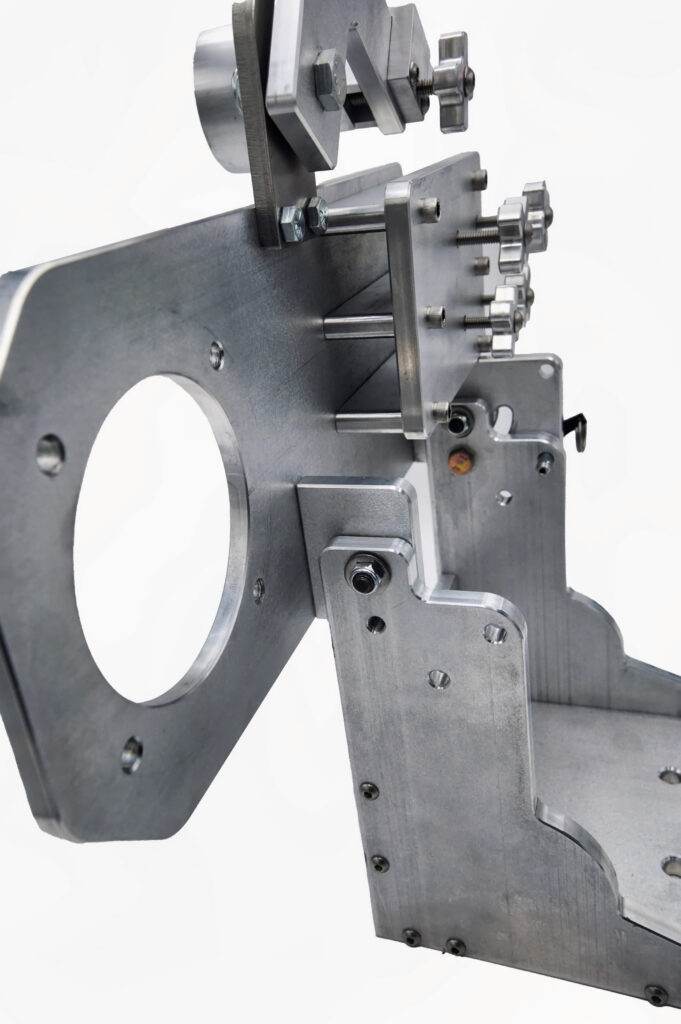

Harnessing Power: How to Maximize the Potential of Your 2×72 Grinder

To fully leverage the capabilities of a TorusCNC 2×72 grinder, it is essential to understand how to harness its power effectively. These grinders are designed with robust motors that provide ample torque and speed, making them suitable for a wide range of applications. To maximize performance, users should familiarize themselves with the machine’s settings and features, such as variable speed controls and adjustable tracking mechanisms.

By experimenting with different settings, users can find the optimal configuration for their specific tasks. Additionally, proper technique plays a significant role in maximizing the potential of your grinder. Maintaining consistent pressure and angle while grinding can lead to more uniform results and reduce wear on both the belt and the machine itself.

It is also beneficial to keep the workpiece moving across the belt rather than holding it in one spot, as this helps prevent overheating and ensures even material removal. By combining an understanding of the machine’s capabilities with effective grinding techniques, users can achieve superior results with their TorusCNC 2×72 grinder.

Belt Tracking: Tips for Ensuring Smooth and Consistent Grinding

| Tip | Description |

|---|---|

| Check belt tension | Ensure the belt is properly tensioned to prevent tracking issues |

| Inspect pulleys | Check for wear or damage on the pulleys that could affect tracking |

| Clean the belt | Remove any debris or buildup on the belt that could cause tracking problems |

| Adjust tracking knob | Use the tracking knob to make small adjustments to the belt’s alignment |

| Monitor belt temperature | Excessive heat can cause the belt to stretch and affect tracking |

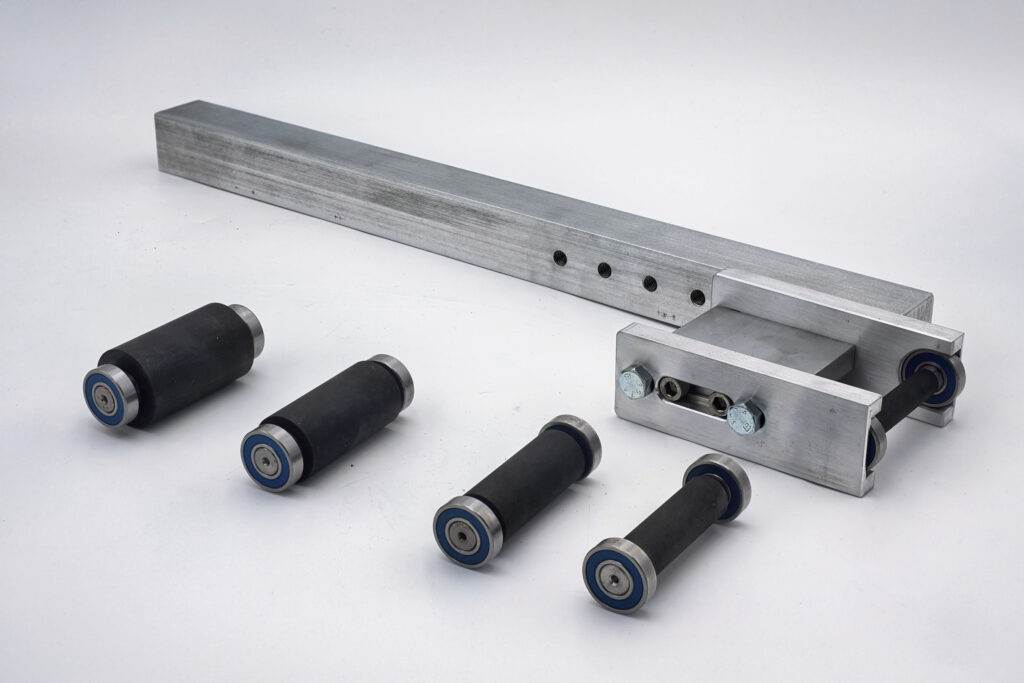

Belt tracking is a vital aspect of operating a 2×72 grinder that directly impacts performance and efficiency. Proper tracking ensures that the belt runs smoothly along the pulleys without drifting off to one side or becoming misaligned. When a belt is correctly tracked, it not only enhances grinding efficiency but also prolongs the life of both the belt and the machine components.

To achieve optimal tracking, users should regularly check and adjust their grinder’s tracking mechanism as needed. One effective method for ensuring proper belt tracking is to observe how the belt behaves during operation. If you notice that it tends to drift towards one side, adjustments can be made using the tracking adjustment knobs typically found on TorusCNC grinders.

Small adjustments can make a significant difference, so it’s important to proceed gradually and test the belt’s alignment after each change. Additionally, keeping the grinder clean and free from debris will help maintain consistent tracking and prevent unnecessary wear on both the belt and machine parts.

Safety First: Best Practices for Using a 2×72 Grinder

Safety should always be a top priority when operating any power tool, including a 2×72 grinder. To ensure a safe working environment, users should wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection. These items help protect against flying debris, noise exposure, and potential injuries from accidental contact with moving parts.

Additionally, it is crucial to keep long hair tied back and avoid loose clothing that could become entangled in the machine. Before starting any grinding project with a TorusCNC 2×72 grinder, users should familiarize themselves with the machine’s safety features and operational guidelines. This includes understanding emergency shut-off mechanisms and ensuring that all components are securely fastened before use.

Regularly inspecting belts for wear or damage is also essential; using worn or damaged belts can lead to accidents or subpar results. By adhering to these best practices, users can create a safer workspace while maximizing their productivity.

Maintenance Matters: Keeping Your 2×72 Grinder in Top Condition

Regular maintenance is key to ensuring that your TorusCNC 2×72 grinder operates at peak performance over time. A well-maintained machine not only performs better but also has a longer lifespan, making it a worthwhile investment for any workshop. Routine maintenance tasks include cleaning dust and debris from the machine after each use, checking for loose bolts or components, and lubricating moving parts as recommended by the manufacturer.

In addition to routine cleaning and inspections, users should also pay attention to belt condition. Worn or damaged belts can lead to inefficient grinding and may even pose safety risks. Replacing belts at appropriate intervals based on usage will help maintain optimal performance levels.

By establishing a regular maintenance schedule and adhering to it diligently, users can ensure that their 2×72 grinder remains in top condition for years to come.

Advanced Techniques: Taking Your Grinding Skills to the Next Level

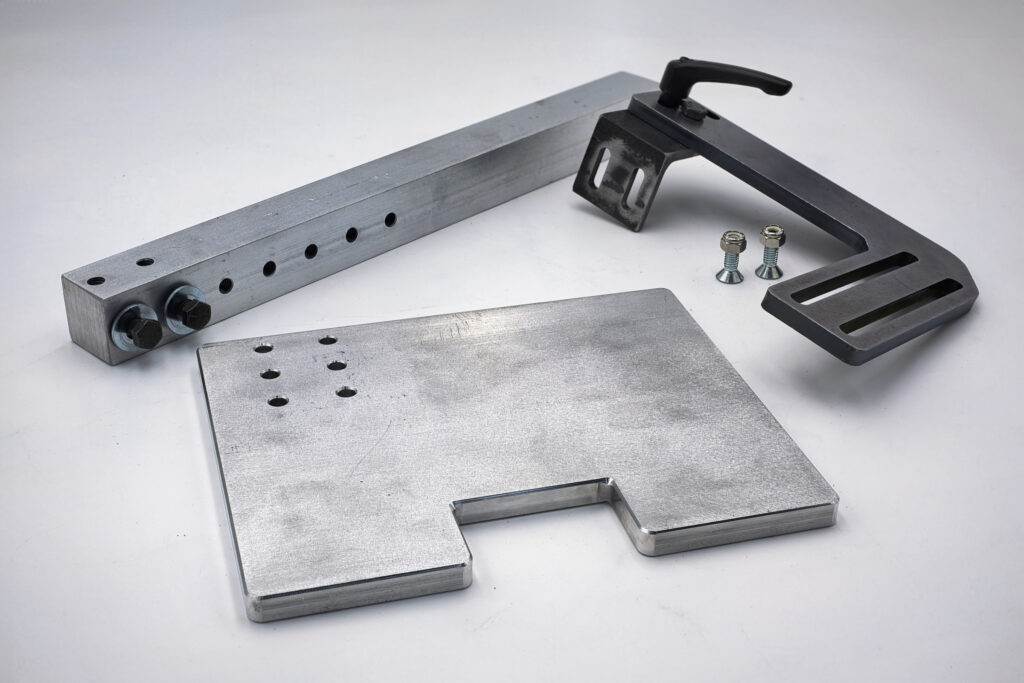

Once you have mastered the basics of using a TorusCNC 2×72 grinder, you may want to explore advanced techniques that can elevate your grinding skills further. One such technique is utilizing different angles and approaches when grinding edges or profiles on materials. By experimenting with various angles, you can create unique shapes or finishes that enhance your projects’ overall aesthetics and functionality.

Another advanced technique involves using jigs or fixtures to achieve precise results consistently. Jigs can help maintain specific angles or profiles while grinding, allowing for repeatable outcomes that are difficult to achieve by hand alone. Investing time in learning how to create or use jigs effectively can significantly improve your efficiency and accuracy when working with a 2×72 grinder.

Troubleshooting: Common Issues and How to Address Them

Even with proper care and maintenance, users may encounter common issues when operating their TorusCNC 2×72 grinders. One frequent problem is belt slippage or misalignment during operation. If you notice that your belt is slipping or not tracking correctly, it may be necessary to adjust the tension or tracking settings on your machine.

Regularly checking these settings can help prevent slippage before it becomes an issue. Another common concern is overheating during prolonged use. If you find that your workpiece or belt is getting excessively hot, consider reducing your feed rate or taking breaks between grinding sessions to allow for cooling.

Additionally, using appropriate grits for your material can help minimize heat generation during grinding. By being proactive in addressing these issues, users can maintain optimal performance and extend the life of their 2×72 grinder while achieving high-quality results in their projects.

FAQs

What is a 2×72 grinder?

A 2×72 grinder is a type of belt grinder that uses a 2-inch by 72-inch belt for grinding, shaping, and polishing metal and other materials. It is commonly used in metalworking and knife making.

What is belt speed and why is it important in a 2×72 grinder?

Belt speed refers to the speed at which the belt moves across the grinding surface. It is important in a 2×72 grinder because it determines the rate at which material is removed and the quality of the finish. Higher belt speeds are generally better for metal removal, while lower belt speeds are better for finer finishes.

What are the different grits available for 2×72 grinder belts?

2×72 grinder belts come in a variety of grits, ranging from coarse (low grit) to fine (high grit). Coarse grits are used for heavy material removal, while fine grits are used for finishing and polishing. Common grits include 36, 60, 80, 120, 220, 400, and 600.

How does motor power affect the performance of a 2×72 grinder?

Motor power affects the performance of a 2×72 grinder by determining the amount of torque and speed the grinder can produce. Higher motor power generally allows for faster material removal and more consistent performance, especially when working with harder materials.