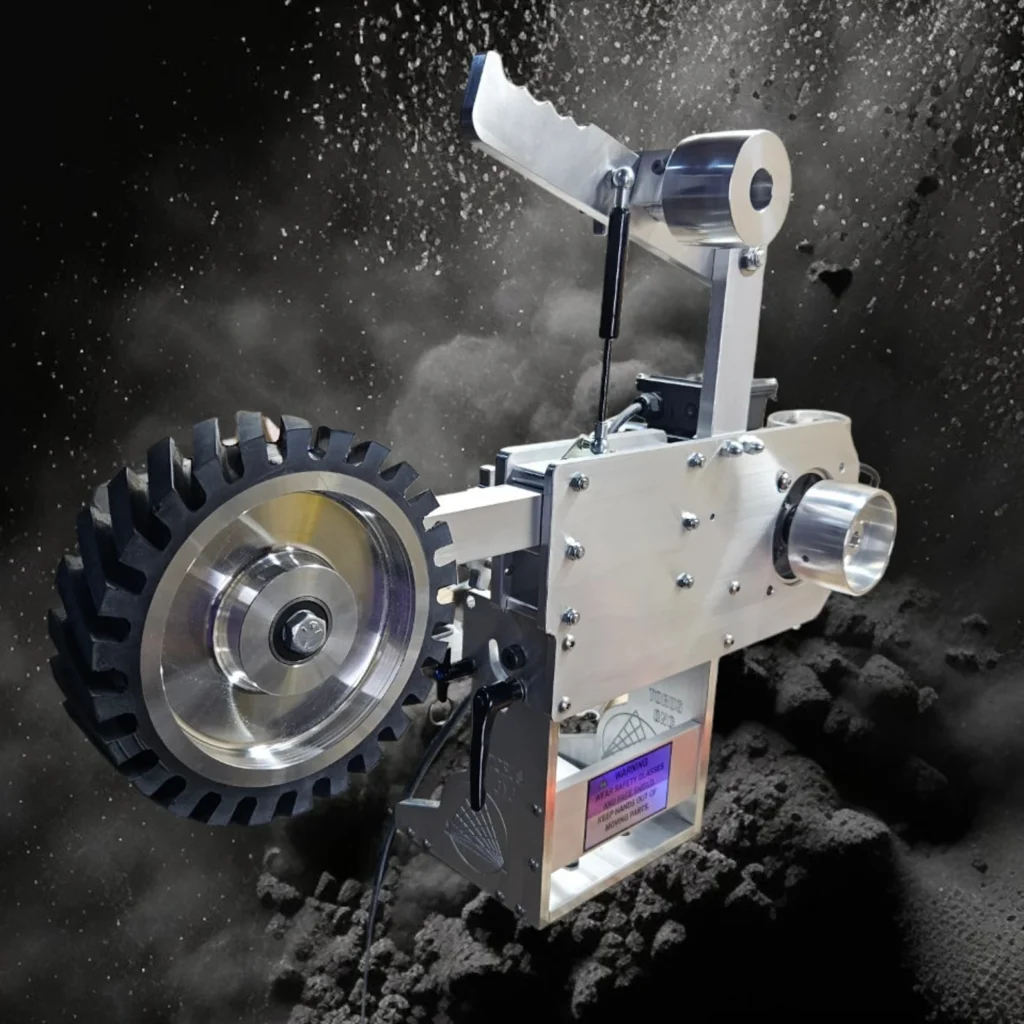

A 2×72 grinder is an essential tool for many metalworkers, blacksmiths, and knife makers. This machine features a belt that is 2 inches wide and 72 inches long, allowing for a versatile range of grinding, shaping, and finishing tasks. The design of the 2×72 grinder enables users to work on various materials, including steel, aluminum, and wood, making it a staple in workshops.

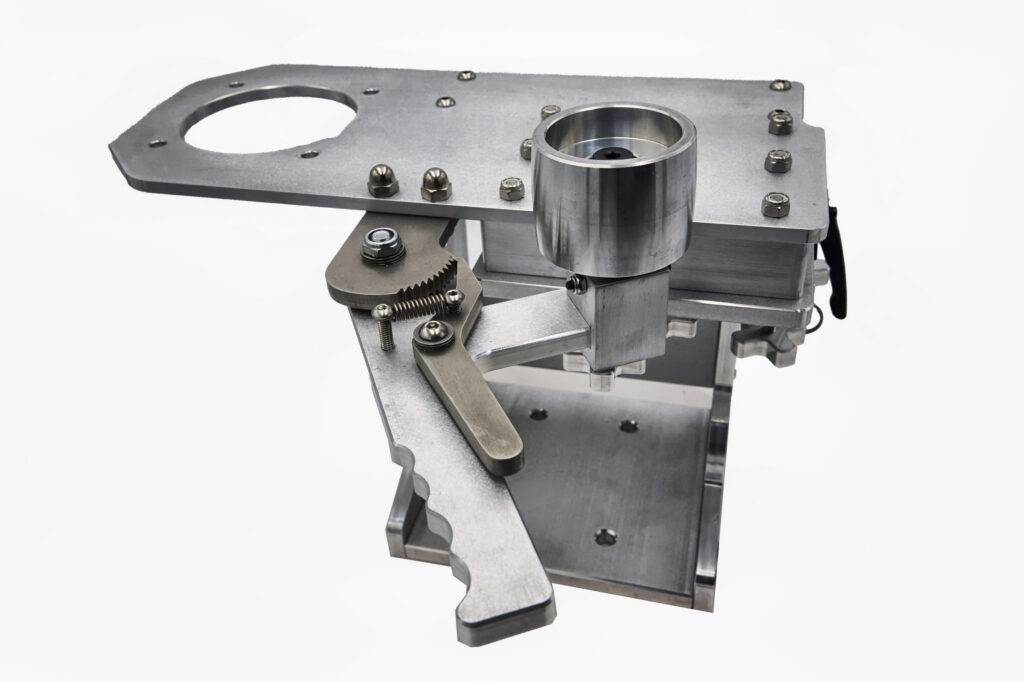

The belt’s length provides ample surface area for grinding, while the width allows for precision in shaping and contouring. The operation of a 2×72 grinder is relatively straightforward, but it requires an understanding of its components and functions. The grinder typically consists of a motor that drives the belt, a tracking mechanism to keep the belt aligned, and various attachments that can be used for different grinding tasks.

Users can adjust the speed of the motor to suit their specific needs, allowing for both aggressive material removal and fine finishing work. Familiarity with these basics is crucial for anyone looking to maximize the potential of their 2×72 grinder.

Key Takeaways

- Understanding the Basics of a 2×72 Grinder:

- A 2×72 grinder is a powerful tool used for shaping, sharpening, and polishing metal and other materials.

- It consists of a motor, a belt, and various attachments for different grinding tasks.

- Safety Precautions and Gear for Using a 2×72 Grinder:

- Always wear safety goggles, gloves, and a dust mask when operating a 2×72 grinder.

- Ensure the work area is well-ventilated and free from clutter to prevent accidents.

- Choosing the Right Abrasives for Your 2×72 Grinder:

- Select the appropriate grit and material for the task at hand, such as ceramic, aluminum oxide, or zirconia belts.

- Consider the type of material being worked on when choosing abrasives.

- Setting Up Your Workspace for Using a 2×72 Grinder:

- Secure the grinder to a stable workbench or stand to prevent movement during operation.

- Organize tools and materials within easy reach to streamline the grinding process.

- Adjusting and Maintaining Your 2×72 Grinder:

- Regularly check and adjust belt tension to ensure optimal performance.

- Keep the grinder clean and lubricated to prevent wear and tear on moving parts.

Safety Precautions and Gear for Using a 2×72 Grinder

Safety should always be the top priority when operating a 2×72 grinder. The high-speed operation of the machine can pose significant risks if proper precautions are not taken. First and foremost, wearing appropriate personal protective equipment (PPE) is essential.

This includes safety glasses or goggles to protect the eyes from flying debris, hearing protection to guard against noise exposure, and gloves to protect the hands from sharp edges and hot surfaces. Additionally, a dust mask or respirator may be necessary to prevent inhalation of harmful particles generated during grinding. Beyond personal protective gear, it is vital to maintain a safe working environment.

Ensure that the workspace is well-lit and free from clutter to minimize the risk of accidents. It is also advisable to keep flammable materials away from the grinder, as sparks generated during operation can ignite them. Regularly inspecting the grinder for any signs of wear or malfunction can further enhance safety.

By adhering to these precautions, users can significantly reduce the risk of injury while enjoying the benefits of their 2×72 grinder.

Choosing the Right Abrasives for Your 2×72 Grinder

Selecting the appropriate abrasives for your 2×72 grinder is crucial for achieving optimal results in your projects. Abrasive belts come in various grits, materials, and types, each designed for specific applications. Coarse grits, such as 36 or 60 grit, are ideal for heavy material removal and shaping, while finer grits like 120 or 220 are better suited for finishing work and achieving a polished surface.

Understanding the grit scale and its applications will help you choose the right belt for your specific task. In addition to grit size, the material composition of the abrasive belt plays a significant role in its performance. Common materials include aluminum oxide, zirconia alumina, and ceramic.

Aluminum oxide belts are versatile and suitable for general-purpose grinding, while zirconia alumina belts offer greater durability and are ideal for heavy-duty applications. Ceramic belts are designed for high-performance grinding on tough materials but may come at a higher cost. By carefully considering both grit size and material type, you can ensure that your 2×72 grinder operates efficiently and effectively.

Setting Up Your Workspace for Using a 2×72 Grinder

Creating an efficient workspace is essential for maximizing productivity when using a 2×72 grinder. Start by selecting a sturdy workbench or stand that can support the weight of the grinder and provide stability during operation. The grinder should be positioned at a comfortable height to minimize strain on your back and arms while working.

Additionally, ensure that there is ample space around the grinder to allow for easy movement and access to tools and materials. Lighting is another critical aspect of setting up your workspace. Adequate illumination will help you see your work clearly and reduce the risk of mistakes or accidents.

Consider using adjustable task lighting that can be directed toward your work area. Furthermore, organizing your tools and materials within reach will streamline your workflow and enhance efficiency. By taking the time to set up your workspace thoughtfully, you can create an environment that fosters creativity and productivity.

Adjusting and Maintaining Your 2×72 Grinder

Regular maintenance and adjustments are vital for keeping your 2×72 grinder in optimal working condition. One of the first steps in maintenance is ensuring that the belt is properly tensioned. A loose belt can slip during operation, leading to inefficient grinding and potential damage to both the belt and the machine.

Conversely, an overly tight belt can cause excessive wear on the motor and bearings. Regularly check the tension according to the manufacturer’s specifications to ensure smooth operation. In addition to belt tension, it is essential to keep the grinder clean and free from debris.

Dust and metal shavings can accumulate over time, affecting performance and potentially causing overheating. Periodically cleaning the machine with compressed air or a soft brush will help maintain its efficiency. Furthermore, lubricating moving parts as recommended by the manufacturer will prolong the life of your grinder.

By incorporating these maintenance practices into your routine, you can ensure that your 2×72 grinder remains reliable and effective.

Basic Grinding Techniques for Beginners

Consistency is Key

Maintaining a consistent angle is a fundamental technique for achieving quality results when using a 2×72 grinder. Whether you’re shaping a blade or refining an edge, keeping a steady angle ensures uniformity in your work. Practice holding your workpiece at a consistent angle against the belt while applying even pressure throughout the process.

Speed Control is Crucial

Learning to control the speed of your movements is another essential technique for mastering the 2×72 grinder. Beginners often make the mistake of rushing through their work, which can lead to uneven surfaces or mistakes. Instead, take your time and focus on smooth, deliberate movements. This approach not only enhances precision but also allows you to develop a better feel for how different materials respond to grinding.

Building Confidence with Practice

As you gain experience with these basic techniques, you’ll find yourself becoming more confident in your abilities. With consistent practice, you’ll develop a better understanding of how to work with different materials and achieve the desired results. By mastering the basics of 2×72 grinding, you’ll be able to tackle more complex projects with ease and precision.

Understanding the Different Types of Grinds

Understanding the various types of grinds is crucial for anyone looking to use a 2×72 grinder effectively. Different grinds serve specific purposes in shaping blades or other metal components. For instance, a flat grind features a flat surface that tapers down from the spine to the edge, providing excellent cutting performance while being relatively easy to sharpen.

This type of grind is commonly used in kitchen knives and utility blades. Conversely, a hollow grind involves concave surfaces that create a thinner edge profile, making it ideal for slicing tasks. Hollow grinds are often found on traditional straight razors and some types of hunting knives due to their sharpness and ease of maintenance.

Additionally, there are other grinds such as convex grinds and saber grinds that offer unique advantages depending on their intended use. Familiarizing yourself with these different types of grinds will enable you to select the right technique for your specific project.

Tips for Achieving Precision and Consistency with Your 2×72 Grinder

Achieving precision and consistency with your 2×72 grinder requires practice and attention to detail. One effective tip is to use jigs or fixtures designed specifically for grinding tasks. These tools can help maintain consistent angles and positions while reducing variability in your workpieces.

For example, using a sharpening jig can ensure that you achieve uniform bevels on knife edges every time. Another important aspect is developing muscle memory through repetition. As you practice grinding techniques over time, you will become more adept at controlling your movements and maintaining consistent pressure on the workpiece.

Additionally, regularly inspecting your progress during grinding will allow you to make adjustments as needed before completing your project. By incorporating these tips into your routine, you can enhance both precision and consistency in your grinding endeavors.

Exploring Different Applications for Your 2×72 Grinder

The versatility of a 2×72 grinder opens up numerous applications beyond just knife making. Metalworkers often use this tool for shaping various components in fabrication projects, such as creating custom brackets or fittings. The ability to grind different materials makes it suitable for tasks ranging from smoothing welds to refining edges on metal parts.

In addition to metalworking applications, woodworkers can also benefit from using a 2×72 grinder equipped with appropriate belts designed for wood finishing. This allows them to shape wooden handles or create intricate designs with precision. Furthermore, hobbyists may find creative uses for their grinders in crafting unique items or artistic pieces by combining different materials like metal and wood.

The possibilities are vast when it comes to exploring different applications for your 2×72 grinder.

Troubleshooting Common Issues with Your 2×72 Grinder

Even with proper maintenance and care, users may encounter common issues with their 2×72 grinders from time to time. One frequent problem is belt slippage during operation, which can hinder performance and lead to uneven grinding results. If you notice this issue, first check the tension of the belt; adjusting it according to manufacturer specifications may resolve the problem.

Another common issue is overheating of either the motor or the belt itself during prolonged use. If you find that either component is getting excessively hot, it may be necessary to take breaks between grinding sessions or reduce the pressure applied during operation. Additionally, ensuring proper airflow around the machine can help dissipate heat more effectively.

By being aware of these common issues and knowing how to troubleshoot them effectively, you can maintain optimal performance from your 2×72 grinder.

Resources for Further Learning and Improvement with Your 2×72 Grinder

To continue improving your skills with a 2×72 grinder, numerous resources are available for further learning. Online forums dedicated to metalworking or knife making often provide valuable insights from experienced users who share tips, techniques, and troubleshooting advice based on their own experiences. Engaging with these communities can foster connections with fellow enthusiasts while expanding your knowledge base.

Additionally, instructional videos on platforms like YouTube offer visual demonstrations of various grinding techniques and setups tailored specifically for 2×72 grinders. These resources allow you to see firsthand how experienced craftsmen approach their work while providing inspiration for your projects. Books focused on knife making or metalworking also serve as excellent references for honing your skills further.

By leveraging these resources effectively, you can continue to grow as a craftsman while maximizing the potential of your 2×72 grinder.

FAQs

What is a 2×72 grinder?

A 2×72 grinder is a type of belt grinder commonly used in metalworking and knife making. It consists of a motor-driven abrasive belt that is used for grinding, shaping, and polishing metal and other materials.

Why would I need a 2×72 grinder?

A 2×72 grinder is a versatile tool that can be used for a variety of metalworking tasks, including shaping and sharpening knives, grinding metal parts, and creating custom metal pieces. It is commonly used by knife makers, blacksmiths, and metal fabricators.

What are the key components of a 2×72 grinder?

The key components of a 2×72 grinder include the motor, abrasive belt, belt tracking system, work rest, and various safety features such as guards and emergency stop buttons.

How do I set up a 2×72 grinder for the first time?

Setting up a 2×72 grinder for the first time involves assembling the various components, adjusting the belt tracking system, and ensuring that all safety features are in place and functioning properly. It is important to carefully follow the manufacturer’s instructions and safety guidelines.

What safety precautions should I take when using a 2×72 grinder?

When using a 2×72 grinder, it is important to wear appropriate personal protective equipment, such as safety glasses, hearing protection, and gloves. It is also important to ensure that the grinder is securely mounted to a stable surface and that all safety features are in place and functioning properly.

What are some common beginner mistakes when setting up a 2×72 grinder?

Common beginner mistakes when setting up a 2×72 grinder include not properly adjusting the belt tracking system, failing to secure the grinder to a stable surface, and not using appropriate personal protective equipment. It is important to carefully read the manufacturer’s instructions and seek guidance from experienced users.