Belt grinders are essential tools in various industries, particularly in metalworking and woodworking. These machines utilize a continuous loop of abrasive material to grind, shape, and finish workpieces, making them invaluable for tasks that require precision and efficiency. The versatility of belt grinders allows them to be used for a wide range of applications, from sharpening tools to polishing surfaces.

Their design typically includes a motor that drives the belt, which can be adjusted for speed and tension, enabling users to achieve the desired finish on different materials. The significance of belt grinders extends beyond their functionality; they are also a cornerstone in the production of high-quality products. In the knife-making industry, for instance, belt grinders play a pivotal role in shaping blades and achieving the desired edge geometry.

As such, understanding how to operate these machines safely and effectively is crucial for anyone involved in their use. This article aims to provide comprehensive insights into the potential hazards associated with belt grinders, the necessary personal protective equipment (PPE), safe operating procedures, and more, ensuring that users can maximize productivity while minimizing risks.

Key Takeaways

- Belt grinders are versatile tools used for shaping, finishing, and sharpening metal, wood, and other materials.

- Potential hazards of belt grinders include flying debris, electrical hazards, and contact with the moving belt.

- Personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection should be worn when operating a belt grinder.

- Regular machine inspection and maintenance are essential to ensure safe and efficient operation of belt grinders.

- Safe operating procedures for belt grinders include securing the workpiece, adjusting the belt tension, and using the appropriate speed and pressure.

Understanding the Potential Hazards

While belt grinders are powerful tools that enhance productivity, they also pose several hazards that users must be aware of. One of the primary risks is the potential for physical injury due to contact with the moving belt. The abrasive surface can cause severe lacerations or abrasions if proper precautions are not taken.

Additionally, the high-speed operation of these machines can lead to flying debris, which may result in eye injuries or other bodily harm. Understanding these risks is the first step toward creating a safe working environment. Another significant hazard associated with belt grinders is the generation of heat and sparks during operation.

The friction created by grinding can lead to overheating of both the workpiece and the machine itself. This not only poses a risk of burns but also increases the likelihood of fire hazards, especially when working with flammable materials. Furthermore, inhalation of dust and fine particles produced during grinding can lead to respiratory issues over time.

Recognizing these potential hazards is essential for implementing effective safety measures and ensuring that all operators are adequately prepared.

Personal Protective Equipment (PPE) Requirements

To mitigate the risks associated with belt grinders, wearing appropriate personal protective equipment (PPE) is crucial. At a minimum, operators should wear safety goggles or face shields to protect their eyes from flying debris and sparks. These protective eyewear options are designed to withstand impact and provide a clear line of sight while ensuring safety during operation.

Additionally, hearing protection is recommended, as belt grinders can produce noise levels that may lead to hearing damage over prolonged exposure. In addition to eye and ear protection, operators should wear gloves made from cut-resistant materials to safeguard their hands from sharp edges and abrasive surfaces. However, it is essential to choose gloves that allow for dexterity and do not pose a risk of entanglement with the moving parts of the grinder.

Furthermore, long-sleeved shirts and durable work pants should be worn to protect against sparks and heat generated during grinding. By adhering to these PPE requirements, operators can significantly reduce their risk of injury while using belt grinders.

Machine Inspection and Maintenance

Regular inspection and maintenance of belt grinders are vital for ensuring safe operation and optimal performance. Before each use, operators should conduct a thorough visual inspection of the machine, checking for any signs of wear or damage. This includes examining the condition of the abrasive belt, ensuring it is properly tensioned and aligned.

A worn or damaged belt can lead to unpredictable performance and increase the risk of accidents. In addition to visual inspections, routine maintenance tasks should be performed according to the manufacturer’s guidelines. This may include lubricating moving parts, tightening loose components, and replacing worn belts or other accessories.

Keeping the machine clean is also essential; accumulated dust and debris can interfere with its operation and pose additional hazards. By establishing a regular maintenance schedule and adhering to it diligently, operators can prolong the life of their belt grinders while ensuring a safer working environment.

Safe Operating Procedures

Establishing safe operating procedures is critical for minimizing risks when using belt grinders. Operators should always familiarize themselves with the specific model they are using, as different machines may have unique features or requirements. Before starting the grinder, it is essential to ensure that all safety guards are in place and functioning correctly.

These guards serve as barriers that help prevent accidental contact with moving parts. When operating a belt grinder, maintaining a clear workspace is equally important. Operators should ensure that there are no obstructions or clutter around the machine that could lead to tripping hazards or distractions during use.

Additionally, it is advisable to keep hands away from the grinding area and maintain a firm grip on the workpiece at all times. By following these safe operating procedures, users can significantly reduce the likelihood of accidents and injuries while maximizing productivity.

Proper Workpiece Handling

Proper handling of workpieces is an essential aspect of safe belt grinder operation. Operators should always secure workpieces firmly before grinding to prevent them from slipping or moving unexpectedly during the process. Using clamps or vises can provide additional stability and control, allowing for more precise grinding results.

It is also important to select the appropriate size and shape of workpieces for grinding; overly large or awkwardly shaped items can be challenging to manage safely. Furthermore, operators should be mindful of their body positioning while handling workpieces. Maintaining a stable stance with feet shoulder-width apart can enhance balance and control during operation.

Leaning too far over the grinder or reaching awkwardly can increase the risk of losing balance or making contact with moving parts. By adopting proper workpiece handling techniques, operators can ensure safer interactions with belt grinders while achieving optimal results.

Fire Prevention Measures

Given the potential for sparks and heat generation during grinding operations, implementing fire prevention measures is crucial when using belt grinders. Operators should always be aware of their surroundings and ensure that flammable materials are kept at a safe distance from the grinding area. This includes not only obvious items like paper or wood but also less apparent materials such as certain types of oils or solvents that may ignite when exposed to sparks.

In addition to maintaining a clean workspace free from flammable debris, having fire extinguishing equipment readily available is essential for any workshop using belt grinders. Operators should familiarize themselves with the location and proper use of fire extinguishers in case of an emergency. Regular fire drills and training sessions can also help ensure that all personnel know how to respond effectively in case of a fire incident.

By prioritizing fire prevention measures, operators can create a safer working environment while minimizing risks associated with belt grinder operations.

Emergency Shutdown Procedures

In any industrial setting, having clear emergency shutdown procedures is vital for ensuring safety during unexpected situations. Operators should be trained on how to quickly shut down the belt grinder in case of an emergency, such as equipment malfunction or an injury incident. Familiarity with emergency stop buttons or switches is essential; these features are designed to halt machine operation immediately when activated.

Additionally, it is important for all personnel in the vicinity to understand these emergency procedures as well. Regular drills can help reinforce this knowledge and ensure that everyone knows how to respond quickly and effectively in case of an emergency. By establishing clear emergency shutdown procedures and conducting regular training sessions, organizations can enhance safety protocols surrounding belt grinder operations.

Proper Dust and Debris Management

Effective dust and debris management is another critical aspect of maintaining a safe working environment when using belt grinders. The grinding process generates fine particles that can accumulate quickly in the workspace, posing both health risks and potential fire hazards. Implementing proper dust collection systems can significantly reduce airborne particles while keeping work areas clean.

Operators should regularly clean their workspaces to prevent dust buildup on surfaces and equipment. Using vacuum systems designed for industrial applications can help efficiently remove debris without creating additional airborne dust clouds. Additionally, wearing appropriate respiratory protection may be necessary when working in environments where dust levels are high or when using materials known to produce harmful particles during grinding.

By prioritizing dust and debris management practices, operators can create a healthier workplace while minimizing risks associated with belt grinder operations.

Training and Supervision

Training and supervision play crucial roles in ensuring safe operations when using belt grinders. All operators should receive comprehensive training on machine operation, safety protocols, and emergency procedures before being allowed to use the equipment independently. This training should cover not only how to operate the machine but also how to recognize potential hazards and respond appropriately.

Supervision is equally important, especially for less experienced operators or those new to using belt grinders. Having a knowledgeable supervisor present can provide guidance on best practices while ensuring adherence to safety protocols. Regular refresher courses can also help reinforce training concepts over time, keeping safety at the forefront of operations within any workshop utilizing belt grinders.

Resources for Further Information and Training

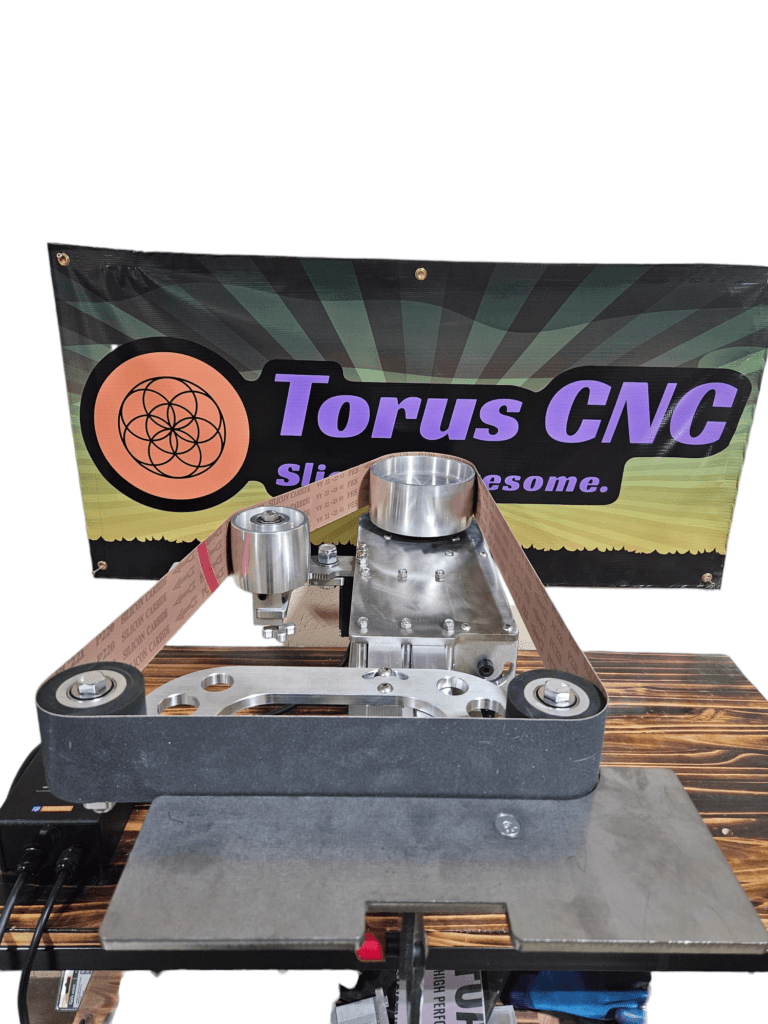

For those seeking additional information on safe practices related to belt grinders, numerous resources are available through industry organizations and educational institutions. Online platforms often offer training modules specifically focused on machine safety, including best practices for operating belt grinders effectively. Additionally, manufacturers like TorusCNC provide valuable resources such as user manuals that outline specific safety guidelines tailored to their equipment models.

Engaging with professional organizations dedicated to workplace safety can also provide access to workshops or seminars focused on machine operation best practices. By utilizing these resources, operators can enhance their knowledge base while fostering a culture of safety within their workplaces when using belt grinders.

FAQs

What is a belt grinder?

A belt grinder is a machine used to shape and finish metal and other materials by means of an abrasive belt. It is commonly used in metalworking and fabrication.

Why is it important to use a safety checklist for first-time belt grinder users?

Using a safety checklist for first-time belt grinder users is important to ensure that they are aware of the potential hazards and safety precautions associated with operating the machine. This helps to prevent accidents and injuries.

What are some common safety hazards associated with belt grinders?

Common safety hazards associated with belt grinders include flying debris, contact with the moving belt, electrical hazards, and exposure to harmful dust and fumes.

What are some items that should be included in a safety checklist for first-time belt grinder users?

A safety checklist for first-time belt grinder users should include items such as wearing appropriate personal protective equipment (PPE), inspecting the machine for any defects or damage, ensuring proper training and supervision, and following safe operating procedures.

How can first-time belt grinder users protect themselves from potential hazards?

First-time belt grinder users can protect themselves from potential hazards by wearing appropriate PPE such as safety glasses, hearing protection, and gloves, following safe operating procedures, and being aware of their surroundings at all times.

What should first-time belt grinder users do if they are unsure about how to operate the machine safely?

If first-time belt grinder users are unsure about how to operate the machine safely, they should seek guidance and training from a qualified and experienced operator or supervisor. It is important to never operate the machine without proper training and supervision.