In the realm of manufacturing and craftsmanship, two distinct methodologies stand out: CNC machining and hand-fabrication. CNC, or Computer Numerical Control, represents a technological advancement that has revolutionized the way components are produced. This method employs computer software to control machine tools, allowing for high levels of precision and repeatability.

On the other hand, hand-fabrication embodies the traditional approach, where artisans rely on their skills and experience to create products manually. Each method has its unique strengths and applications, making them suitable for different types of projects. The choice between CNC machining and hand-fabrication often depends on the specific requirements of a project.

While CNC machining excels in producing large quantities of identical parts with remarkable accuracy, hand-fabrication offers a level of creativity and customization that is hard to replicate with machines. Understanding the nuances of both methods is essential for anyone looking to embark on a manufacturing journey, whether they are hobbyists, small business owners, or large-scale manufacturers.

Key Takeaways

- CNC machining offers high precision and accuracy due to its computer-controlled process

- Hand-fabrication allows for more flexibility and creativity in the manufacturing process

- CNC machining is faster and more cost-effective for large production runs

- Hand-fabrication is ideal for small-scale projects and custom designs

- CNC machining provides a wide range of material options, while hand-fabrication allows for more flexibility in material choices

The Advantages of CNC Machining

CNC machining boasts several advantages that make it an attractive option for many industries. One of the most significant benefits is its ability to produce complex geometries with ease. The precision of CNC machines allows for intricate designs that would be nearly impossible to achieve through manual methods.

This capability is particularly valuable in sectors such as aerospace, automotive, and medical device manufacturing, where precision is paramount. Another advantage of CNC machining is its efficiency in production. Once a design is programmed into the machine, it can run continuously with minimal human intervention.

This automation not only speeds up the manufacturing process but also reduces the likelihood of human error. As a result, businesses can meet tight deadlines and maintain high levels of productivity without compromising on quality. Additionally, CNC machines can operate on various materials, including metals, plastics, and composites, making them versatile tools in any workshop.

The Advantages of Hand-Fabrication

Hand-fabrication offers a unique set of advantages that appeal to artisans and craftsmen alike. One of the most notable benefits is the level of creativity it allows. When working by hand, artisans can make real-time adjustments to their designs, responding intuitively to the material and the project’s evolving needs.

This flexibility fosters innovation and can lead to one-of-a-kind creations that stand out in a market increasingly dominated by mass production. Moreover, hand-fabrication often results in a personal touch that resonates with consumers. Products crafted by skilled hands carry a sense of authenticity and craftsmanship that automated processes cannot replicate.

This aspect is particularly important in industries such as furniture making, jewelry design, and bespoke tailoring, where customers value uniqueness and quality over quantity. The connection between the maker and the product can enhance customer satisfaction and loyalty, making hand-fabricated items highly sought after.

Precision and Accuracy in CNC Machining

| Metrics | Description |

|---|---|

| Precision | The degree to which the measurements of a CNC machine match the intended specifications or dimensions. |

| Accuracy | The closeness of the measurements of a CNC machine to the true or actual value of the intended specifications or dimensions. |

| Tolerance | The allowable deviation from a specified dimension in CNC machining, which affects both precision and accuracy. |

| Repeatability | The ability of a CNC machine to consistently produce the same results under the same operating conditions, which is crucial for achieving precision and accuracy. |

Precision and accuracy are hallmarks of CNC machining. The technology behind CNC machines allows for tolerances as tight as a few microns, ensuring that each part produced meets exact specifications. This level of precision is crucial in industries where even the slightest deviation can lead to catastrophic failures or safety issues.

For instance, in aerospace manufacturing, components must fit together perfectly to ensure the safety and functionality of aircraft. The repeatability of CNC machining further enhances its precision capabilities. Once a program is established, the machine can produce thousands of identical parts without variation.

This consistency is invaluable for manufacturers who require large quantities of components that must all adhere to strict quality standards. By minimizing human involvement in the production process, CNC machining significantly reduces the risk of errors that can occur during manual fabrication.

Precision and Accuracy in Hand-Fabrication

While hand-fabrication may not achieve the same level of precision as CNC machining, it offers a different kind of accuracy rooted in the artisan’s skill and experience. Craftsmen often develop an intuitive understanding of their materials and tools, allowing them to make adjustments on the fly that can enhance the final product’s quality. This hands-on approach can lead to unique characteristics in each piece, giving it a personality that mass-produced items lack.

Moreover, hand-fabrication allows for a level of detail that can be difficult to achieve with machines. Artisans can incorporate intricate designs and embellishments that reflect their personal style or the specific desires of their clients. This attention to detail can elevate a product from functional to extraordinary, making it more appealing to consumers who appreciate craftsmanship over uniformity.

Cost and Time Considerations

When evaluating CNC machining versus hand-fabrication, cost and time are critical factors to consider. CNC machining typically requires a higher initial investment due to the cost of machinery and software. However, this investment can pay off in the long run through increased efficiency and reduced labor costs.

For businesses that require large volumes of parts or complex designs, CNC machining can ultimately be more cost-effective than hand-fabrication. On the other hand, hand-fabrication often involves lower upfront costs since it primarily relies on tools and materials rather than expensive machinery. However, the time required for manual production can be significantly longer than automated processes.

For small-scale projects or custom pieces where quantity is not a primary concern, hand-fabrication may be more suitable despite its longer lead times. Ultimately, the decision will depend on the specific needs of the project and the resources available.

Material Options and Flexibility

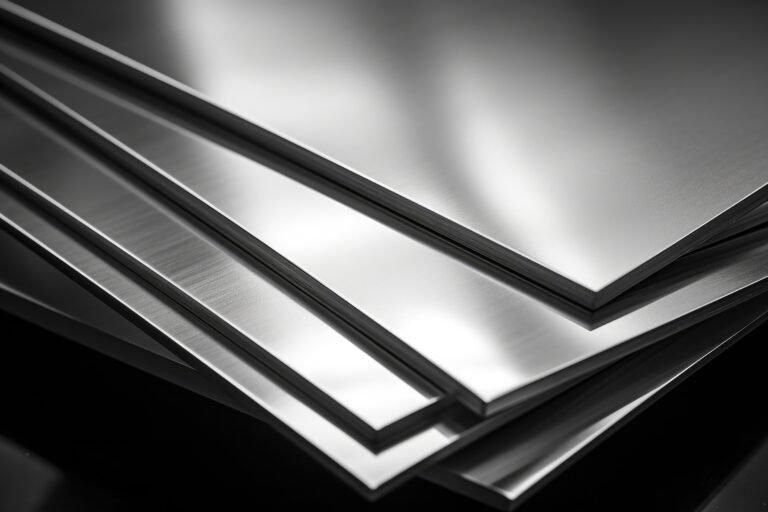

CNC machining offers a wide range of material options, allowing manufacturers to work with various metals, plastics, wood, and composites. This versatility enables businesses to select materials that best suit their project requirements while maintaining high levels of precision and quality. Additionally, CNC machines can handle complex shapes and designs across different materials without compromising performance.

Conversely, hand-fabrication also provides flexibility in material selection but often emphasizes traditional materials such as wood or metal. Artisans may choose materials based on their tactile qualities or aesthetic appeal rather than solely on functionality. This approach allows for creative expression and experimentation with different textures and finishes that may not be feasible with CNC machining.

Ultimately, both methods offer unique opportunities for material exploration depending on the project’s goals.

Choosing the Right Method for Your Project

Selecting between CNC machining and hand-fabrication requires careful consideration of various factors related to your project’s goals. If precision, speed, and scalability are paramount—especially for large production runs—CNC machining may be the ideal choice. Its ability to produce consistent results quickly makes it well-suited for industries where time-to-market is critical.

Conversely, if your project emphasizes creativity, customization, or artisanal quality, hand-fabrication may be more appropriate. The personal touch inherent in handcrafted items can resonate deeply with consumers seeking unique products that reflect individual craftsmanship. Ultimately, understanding your project’s specific needs will guide you toward the most suitable manufacturing method—whether it be the technological prowess of CNC machining or the artistry of hand-fabrication.

In conclusion, both CNC machining and hand-fabrication have their distinct advantages and applications within the manufacturing landscape. By weighing factors such as precision, cost, material options, and project requirements, you can make an informed decision that aligns with your vision and goals. Whether you choose to harness the power of technology or embrace traditional craftsmanship, each method offers unique pathways to bring your ideas to life.

FAQ

What is CNC machining?

CNC machining is a manufacturing process that uses computer-controlled machines to accurately remove material from a workpiece. This process allows for high precision and repeatability in the production of complex parts.

What is hand-fabrication?

Hand-fabrication refers to the process of manually shaping and assembling materials to create a final product. This can involve techniques such as welding, cutting, bending, and shaping metal or other materials.

What are the advantages of CNC machining over hand-fabrication?

CNC machining offers higher precision, faster production times, and the ability to create complex geometries that may be difficult or impossible to achieve through hand-fabrication. Additionally, CNC machining allows for greater consistency and repeatability in the production of parts.

What are the advantages of hand-fabrication over CNC machining?

Hand-fabrication allows for greater flexibility and creativity in the production process, as skilled artisans can manipulate materials in ways that may not be possible with CNC machining. Hand-fabrication also tends to be more cost-effective for small production runs or one-of-a-kind custom pieces.

How does precision machining deliver higher performance?

Precision machining, whether through CNC or hand-fabrication, results in parts and components that meet tight tolerances and specifications. This level of precision ensures that the final products perform reliably and consistently, making them ideal for high-performance applications.