Running a knifemaking business often starts as a passion project—late nights in the shop, weekends at the grinder, and a growing pile of custom orders. Over time, though, many makers find themselves overwhelmed, stretched thin, and working harder without seeing proportional growth.

Sustainability in a small knifemaking business isn’t about slowing down—it’s about building repeatable systems that protect your time and energy while maintaining quality. When processes are consistent, decisions become easier and output becomes more predictable.

Burnout doesn’t come from making knives—it comes from chaos. Structuring your workflow, pricing, and customer communication can transform your shop from a constant scramble into a professional operation that still feels personal.

Key Takeaways

- Systems reduce stress and increase consistency

- Not every task deserves the same level of attention

- Clear boundaries improve customer relationships

- Sustainable pacing leads to better craftsmanship

2. Pricing Custom Knives: Why Most Makers Undervalue Their Work

One of the most common struggles for small knifemaking businesses is pricing. Many makers price based on what they feel comfortable charging rather than what the work truly costs. Over time, this leads to thin margins, frustration, and stalled growth.

Proper pricing isn’t about being expensive—it’s about being accurate. Materials, consumables, tooling wear, electricity, and time all factor into the real cost of a knife. Ignoring any of these silently erodes profitability.

When pricing reflects reality, makers gain freedom: fewer rushed orders, better tools, and the ability to say no when needed.

- Time is the most expensive input in knifemaking

- Underpricing leads to burnout, not more sales

- Consistent pricing builds customer trust

- Healthy margins fund better tools and processes

3. Shop Layout Mistakes That Slow Down Knife Production

Many knifemakers accumulate tools organically—one machine at a time—without ever revisiting layout. Over time, this leads to unnecessary walking, awkward material handling, and inefficient workflows.

A well-organized shop reduces wasted motion, improves safety, and speeds up production without rushing the work. Even small layout changes can yield noticeable gains in efficiency.

Optimizing your workspace doesn’t require a bigger shop—just intentional placement and flow.

- Workflow matters more than shop size

- Reduce walking, lifting, and backtracking

- Keep high-use tools within arm’s reach

- Good layout improves safety and focus

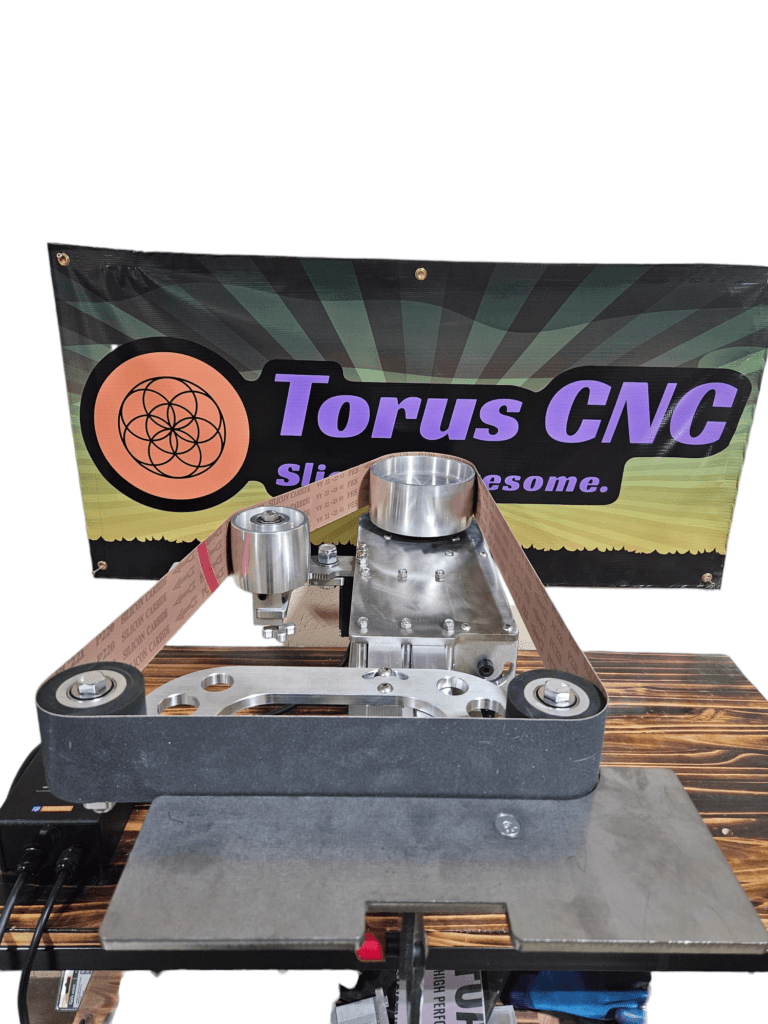

4. Choosing Equipment That Grows With Your Knifemaking Business

Early in a knifemaking journey, equipment choices are often driven by budget. As the business grows, those same tools can become bottlenecks—slowing production and limiting consistency.

Buying equipment with scalability in mind allows makers to grow without replacing entire systems. Rigid frames, modular setups, and expandable tooling options extend the life of your investment.

The goal isn’t owning the most tools—it’s owning the right ones.

- Cheap tools often cost more long-term

- Rigidity and repeatability matter

- Modular equipment adapts to growth

- Good machines improve consistency, not just speed

5. Why Consistency Matters More Than Speed in Knifemaking

Many makers focus on speeding up production, but speed without consistency creates problems—uneven grinds, rework, and dissatisfied customers. Consistency is what turns craftsmanship into a reliable business.

Processes that produce predictable results reduce mistakes and improve confidence. Over time, consistency naturally leads to speed without sacrificing quality.

Professional results come from control, not haste. In many small shops, long-term sustainability comes down to working consistently rather than rushing, which is why consistency often matters more than speed.

- Repeatability builds reputation

- Consistency reduces rework and scrap

- Speed improves naturally with control

- Customers value reliability over volume