The handle shaping station is an essential setup for any woodworker or knife maker looking to create custom handles for their tools. This dedicated workspace allows for precision and creativity, enabling artisans to transform raw materials into beautifully crafted handles that not only enhance the aesthetic appeal of a knife but also improve its functionality. A well-designed handle can significantly influence the grip and comfort of a tool, making it crucial for both performance and user satisfaction.

In this article, we will explore the various aspects of setting up and utilizing a handle shaping station. From the tools and materials required to the techniques for shaping and finishing handles, we will provide a comprehensive guide that will help you create stunning handles tailored to your specific needs. Whether you are a seasoned craftsman or a novice eager to learn, understanding the intricacies of handle shaping will elevate your woodworking skills and enhance your projects.

Key Takeaways

- A handle shaping station is a useful tool for creating custom handles for various woodworking projects.

- Tools and materials needed for handle shaping include a bandsaw, spokeshave, sandpaper, and oil or varnish for finishing.

- Setting up a work area with proper lighting and ventilation is essential for safe and efficient handle shaping.

- Creating a template for handle shapes helps ensure consistency and precision in the shaping process.

- Using a bandsaw to rough cut the handles and a spokeshave to shape and smooth them is an effective method for handle shaping.

Tools and Materials Needed

To embark on the journey of handle shaping, it is vital to gather the right tools and materials. The primary materials typically include hardwoods such as walnut, maple, or oak, which are favored for their durability and aesthetic qualities. Additionally, synthetic materials like G10 or Micarta can be used for those seeking modern alternatives that offer unique textures and colors.

Selecting the right material is crucial, as it will affect not only the appearance of the handle but also its weight and feel in hand. In terms of tools, a handle shaping station requires several key instruments. A bandsaw is essential for rough cutting the handle shapes from larger blocks of material.

A spokeshave is invaluable for refining the contours and achieving the desired ergonomic shape. Sanding tools, including various grits of sandpaper and possibly a power sander, are necessary for smoothing the surface and preparing it for finishing. Other helpful tools include clamps for securing the workpiece, a drill for adding holes if needed, and chisels for intricate detailing.

Having these tools at your disposal will streamline the process and ensure that you can execute your designs with precision.

Setting Up the Work Area

Creating an efficient work area is a critical step in establishing a handle shaping station. The workspace should be well-lit and organized to facilitate easy access to tools and materials. A sturdy workbench is essential, providing a stable surface for cutting and shaping.

It is advisable to have ample space around the bench to allow for movement and to accommodate larger pieces of wood without obstruction. Additionally, consider incorporating storage solutions such as shelves or toolboxes to keep your tools organized and within reach. This organization not only saves time but also enhances safety by reducing clutter.

Ensure that your workspace is equipped with proper ventilation, especially if you are working with materials that produce dust or fumes during sanding or finishing. A clean and well-structured work area will significantly improve your efficiency and enjoyment while working on handle shaping projects.

Creating a Template for Handle Shapes

Before diving into the actual shaping process, creating a template for your handle shapes is a wise step. A template serves as a guide that ensures consistency across multiple handles, allowing you to replicate designs with ease. You can create templates from cardboard or thin plywood, tracing out the desired shape based on ergonomic principles or personal preferences.

When designing your template, consider factors such as grip size, contouring, and any specific features you want to incorporate into the handle. It’s beneficial to create several variations of templates to experiment with different shapes before committing to a final design. Once you have your templates ready, they can be used to trace onto your chosen material, providing a clear outline for your cutting and shaping processes.

Using a Bandsaw to Rough Cut the Handles

With your template in hand, it’s time to use a bandsaw for rough cutting the handles from your selected material. The bandsaw is an excellent tool for this task due to its ability to make precise cuts while handling thicker pieces of wood or synthetic materials. Begin by securing your material firmly on the bandsaw table, ensuring it is stable throughout the cutting process.

As you cut along the lines of your template, maintain a steady pace and focus on following the contours accurately. It’s important to remember that this step is just the initial rough cut; precision can be refined later in the shaping process. After completing the rough cuts, you will have a basic handle shape that can be further refined using other tools in your handle shaping station.

Shaping the Handles with a Spokeshave

Once you have your rough-cut handles, it’s time to refine their shape using a spokeshave. This tool is particularly effective for creating smooth curves and contours that enhance both aesthetics and ergonomics. Begin by holding the spokeshave firmly with both hands, positioning it at an angle that allows for effective material removal.

As you work with the spokeshave, take your time to gradually shape the handle according to your design specifications. Focus on areas where comfort is paramount, such as finger grooves or palm rests. The beauty of using a spokeshave lies in its ability to provide tactile feedback; you can feel how much material you are removing and adjust your pressure accordingly.

This hands-on approach allows for greater control over the final shape of the handle.

Sanding and Smoothing the Handles

After achieving the desired shape with the spokeshave, sanding becomes essential for creating a smooth finish on your handles. Start with coarser grits of sandpaper to remove any tool marks left from previous shaping processes. Gradually progress to finer grits, ensuring that each pass removes scratches from the previous grit until you achieve a silky-smooth surface.

Pay special attention to corners and edges during sanding; these areas often require extra care to ensure they are comfortable to hold. It’s also beneficial to sand in the direction of the wood grain to avoid creating unsightly scratches that could detract from the overall appearance of the handle. Once satisfied with the smoothness, wipe down the handles with a damp cloth to remove any dust particles before proceeding to the finishing stage.

Adding Decorative Details to the Handles

To elevate your handles beyond mere functionality, consider adding decorative details that reflect your personal style or enhance their visual appeal. This could involve carving intricate patterns into the wood or incorporating contrasting materials such as brass or resin inlays. These embellishments not only add character but can also serve practical purposes, such as improving grip or balance.

When adding decorative elements, take care to maintain harmony with the overall design of the handle. The goal is to enhance its beauty without compromising its functionality or comfort. Experimenting with different techniques—such as burning designs into wood or using dyes—can yield stunning results that make each handle unique.

Finishing the Handles with Oil or Varnish

The final step in creating beautiful handles involves applying a finish that protects the wood while enhancing its natural beauty. Options such as oil or varnish can be used depending on your desired outcome. Oil finishes penetrate deeply into the wood fibers, providing a warm glow while allowing for easy maintenance over time.

On the other hand, varnish creates a protective layer on top of the wood, offering durability against wear and moisture. Before applying any finish, ensure that your handles are completely free of dust from sanding. Apply your chosen finish evenly using a clean cloth or brush, following manufacturer instructions regarding drying times between coats.

Multiple layers may be necessary to achieve optimal protection and appearance; be patient during this process as it significantly impacts the final look of your handles.

Safety Precautions to Consider

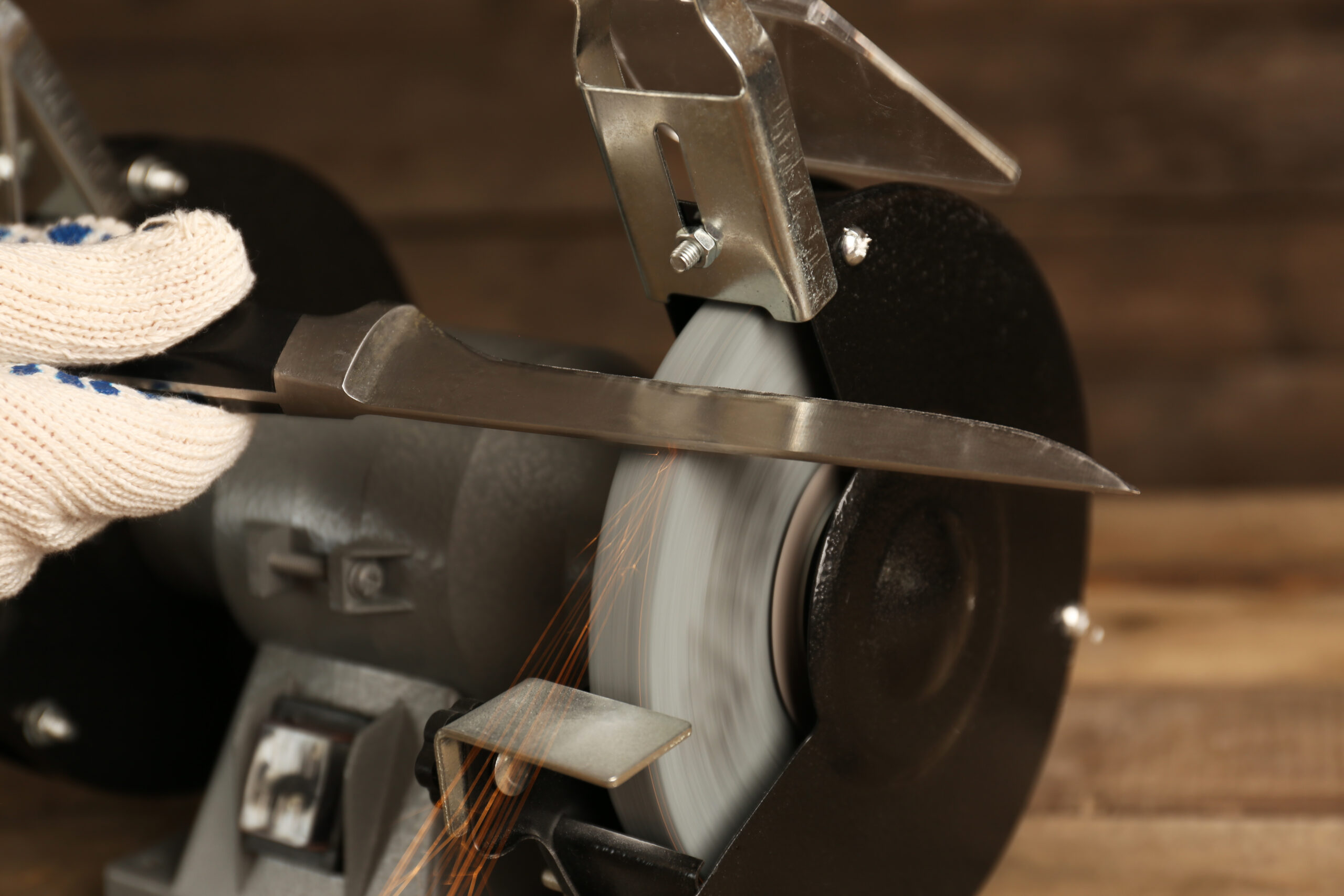

Safety should always be a top priority when working in a handle shaping station. Ensure you are wearing appropriate personal protective equipment (PPE), including safety glasses to protect your eyes from flying debris and dust masks to avoid inhaling harmful particles during sanding or cutting processes. Additionally, hearing protection may be necessary when using power tools like bandsaws.

It’s also crucial to maintain a clean workspace free from clutter that could lead to accidents. Keep tools organized and ensure that cords from power tools do not pose tripping hazards. Familiarize yourself with each tool’s operation before use, paying attention to safety features and guidelines provided by manufacturers.

Tips for Maintaining and Using the Handle Shaping Station

To ensure longevity and efficiency in your handle shaping station, regular maintenance of tools and equipment is essential. Keep blades sharp on tools like bandsaws and spokeshaves; dull blades can lead to poor results and increase the risk of accidents due to excessive force being applied during use. Clean tools after each session to prevent resin buildup or rust formation.

Additionally, consider documenting your processes and designs as you work through various projects; this can help refine techniques over time and serve as valuable references for future endeavors. Engaging with communities of fellow woodworkers can also provide insights into new methods or tools that could enhance your handle shaping experience. In conclusion, establishing a handle shaping station opens up a world of possibilities for creating custom handles tailored to individual preferences and needs.

By following these steps—from gathering materials and setting up your workspace to refining shapes and applying finishes—you can develop skills that will elevate your craftsmanship in woodworking or knife making significantly. Embrace creativity while adhering to safety practices, and enjoy the rewarding journey of bringing beautiful handles to life.

FAQs

What is a dedicated handle shaping station?

A dedicated handle shaping station is a specialized work area or setup used for shaping and finishing the handles of various tools, such as hammers, axes, chisels, and other hand tools.

What are the benefits of setting up a dedicated handle shaping station?

Setting up a dedicated handle shaping station allows for a more efficient and organized process for shaping and finishing tool handles. It can also help improve the quality and consistency of the finished handles.

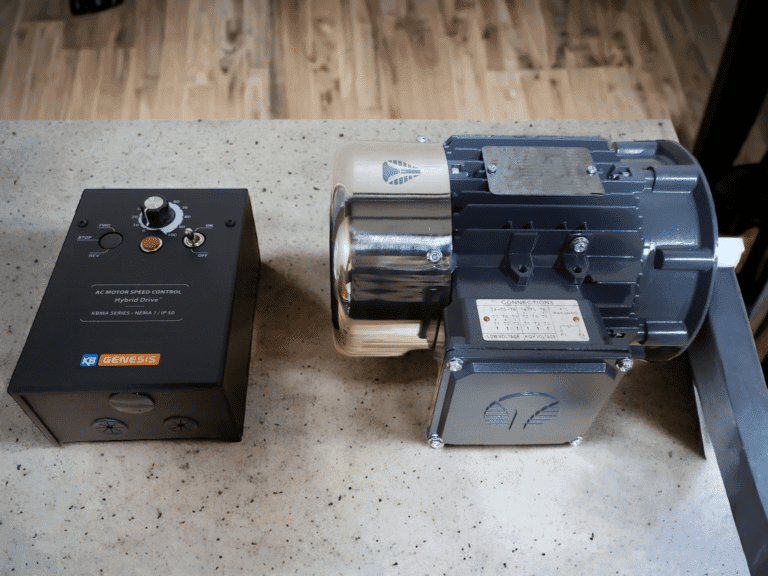

What equipment is typically included in a dedicated handle shaping station?

A dedicated handle shaping station may include equipment such as a lathe, sanders, rasps, files, carving tools, and other specialized tools for shaping and finishing handles.

How can one set up a dedicated handle shaping station?

Setting up a dedicated handle shaping station involves selecting a suitable work area, acquiring the necessary equipment and tools, and organizing the space for efficient workflow and safety.

What are some safety considerations when using a dedicated handle shaping station?

Safety considerations when using a dedicated handle shaping station include wearing appropriate personal protective equipment, following proper tool usage and handling procedures, and maintaining a clean and organized work area to prevent accidents.