Selecting the appropriate wheel for honing full hollow straight razors is a critical aspect of achieving optimal sharpness and performance. The right wheel can significantly influence the razor’s edge, affecting not only the quality of the shave but also the longevity of the blade. A well-chosen wheel can enhance the honing process, allowing for a finer edge that glides effortlessly across the skin.

Conversely, using an unsuitable wheel can lead to subpar results, resulting in a dull blade that may cause irritation or discomfort during shaving. Moreover, the right wheel contributes to the overall efficiency of the honing process. Different wheels are designed for specific tasks, and understanding their unique characteristics can help users achieve their desired outcomes more effectively.

Whether one is looking for a quick touch-up or a complete restoration of a razor’s edge, selecting the right wheel is paramount. This choice not only impacts the immediate results but also plays a role in the long-term maintenance of the razor, ensuring that it remains in peak condition for years to come.

Key Takeaways

- The right wheel is crucial for achieving the desired sharpness and smoothness in full hollow straight razors.

- Different types of wheels, such as synthetic and natural stones, offer varying benefits for razor sharpening.

- Factors to consider when choosing a wheel include grit size, hardness, and porosity for optimal sharpening results.

- Finding the right balance between sharpness and smoothness is essential for a comfortable and effective shaving experience.

- The material of the wheel, whether it’s natural stone, synthetic, or diamond, plays a significant role in the sharpening process.

Different Types of Wheels for Full Hollow Straight Razors

Diamond Wheels: Precision and Durability

One common type is the diamond wheel, known for its durability and ability to maintain a consistent grit over time. Diamond wheels are particularly effective for achieving a fine edge, making them a popular choice among enthusiasts who prioritize precision in their honing process. Their longevity and effectiveness make them a worthwhile investment for those serious about maintaining their razors.

Ceramic Wheels: Smooth Edges and Heat Control

Another option is the ceramic wheel, which offers a different honing experience. Ceramic wheels are known for their ability to produce a smooth edge while minimizing heat buildup during the honing process. This characteristic is crucial for full hollow razors, as excessive heat can compromise the integrity of the blade.

Choosing the Right Wheel for Your Needs

Each type of wheel has its unique advantages, and understanding these differences is essential for selecting the right one for your specific needs. By considering factors such as precision, durability, and heat control, you can make an informed decision and achieve the best possible results in your honing process.

Factors to Consider When Choosing a Wheel

Choosing the right wheel involves several factors that can significantly impact the honing process and the final results. One of the primary considerations is the grit of the wheel. Grit refers to the size of the abrasive particles on the wheel’s surface, and it plays a crucial role in determining how much material is removed from the blade during honing.

Finer grits are ideal for polishing and refining an edge, while coarser grits are better suited for reshaping or repairing damaged blades. Understanding your specific needs will help you select a wheel with the appropriate grit. Another important factor is the wheel’s hardness.

Harder wheels tend to last longer and maintain their shape better over time, making them suitable for frequent use. However, they may not be as forgiving on softer steel blades, which can lead to chipping or other damage if not used carefully. Conversely, softer wheels may wear down more quickly but can provide a gentler honing experience.

Balancing these factors based on your razor’s material and your honing frequency is essential for achieving optimal results.

Finding the Right Balance Between Sharpness and Smoothness

Achieving the perfect balance between sharpness and smoothness is a key goal when honing full hollow straight razors. A razor that is too sharp may cause irritation or nicks during shaving, while one that is not sharp enough will fail to provide a close shave. The choice of wheel plays a significant role in this balance, as different wheels can produce varying levels of sharpness and smoothness.

To find this equilibrium, it is essential to consider both the honing technique and the type of wheel being used. For instance, using a finer grit wheel can enhance smoothness while still allowing for adequate sharpness. Additionally, honing techniques such as adjusting pressure and angle can further refine the balance between these two critical aspects.

Ultimately, achieving this balance requires practice and experimentation, as each razor and user may have unique preferences.

The Role of Material in Wheel Selection

The material of the honing wheel is another crucial factor that influences its performance and suitability for full hollow straight razors. Different materials offer distinct advantages and disadvantages that can affect both the honing process and the final edge quality. For example, diamond wheels are renowned for their durability and cutting efficiency, making them an excellent choice for those seeking long-lasting performance.

However, they may not be suitable for all types of steel, particularly softer varieties that could be damaged by aggressive honing. Ceramic wheels, on the other hand, provide a gentler honing experience while still delivering impressive results. Their ability to produce a smooth edge without excessive heat buildup makes them ideal for full hollow razors.

Additionally, natural stone wheels offer a traditional approach to honing that many enthusiasts appreciate for its craftsmanship and effectiveness. Each material has its unique characteristics, and understanding these differences is essential for selecting the right wheel based on your specific needs and preferences.

How to Test and Evaluate a Wheel for Full Hollow Straight Razors

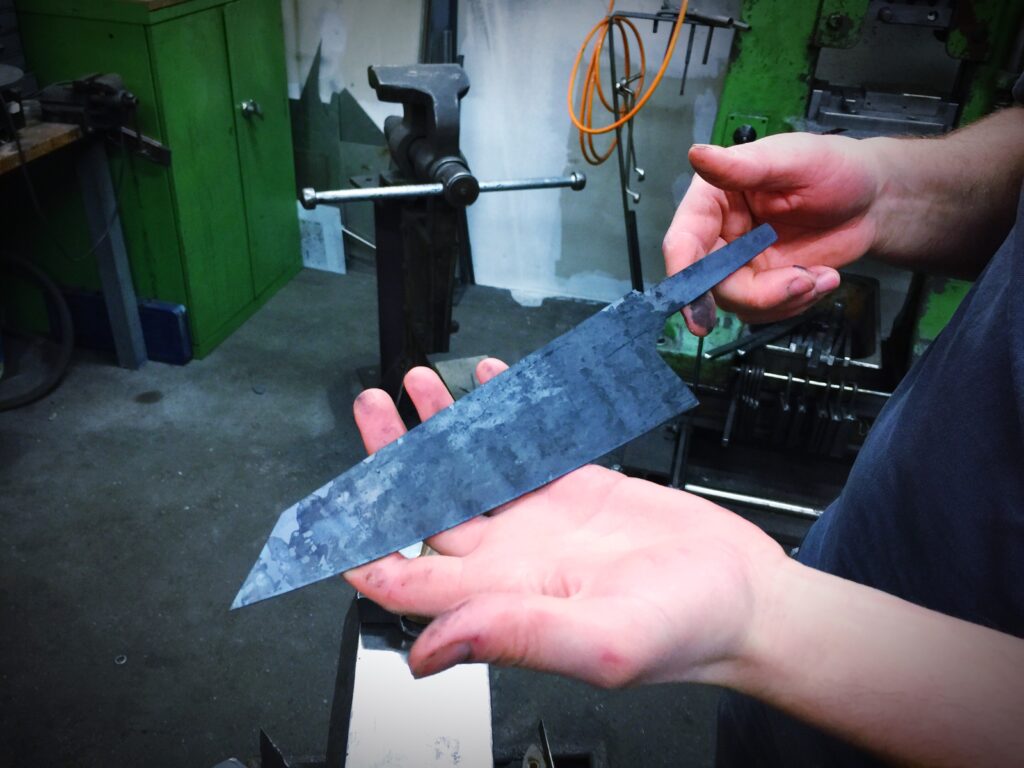

Testing and evaluating a honing wheel is an essential step in ensuring that it meets your needs and expectations. One effective method is to perform a series of test honings on a less valuable razor or blade before committing to using it on your primary tool. This practice allows you to assess how well the wheel performs in terms of sharpening speed, edge quality, and overall ease of use without risking damage to your favorite razor.

During testing, pay close attention to how the wheel interacts with the blade. Observe how much material is removed during each pass and whether you achieve your desired level of sharpness and smoothness. Additionally, consider factors such as heat generation and noise during honing; excessive heat can indicate that the wheel may be too aggressive or not suitable for your specific razor type.

By conducting thorough evaluations, you can make informed decisions about which wheels best suit your honing style and requirements.

Understanding the Impact of Wheel Size and Shape

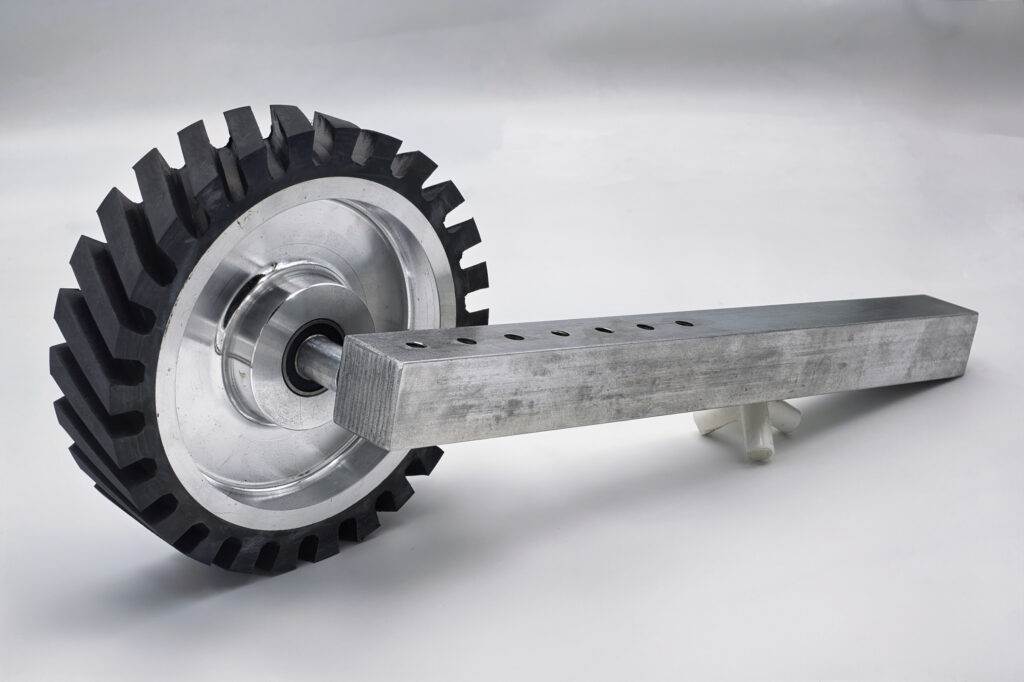

The size and shape of a honing wheel can significantly influence its performance when working with full hollow straight razors. Larger wheels tend to cover more surface area during honing, which can lead to faster results but may also require more skill to control effectively. Smaller wheels offer greater precision but may take longer to achieve desired results due to their limited surface area.

The shape of the wheel also plays a role in its effectiveness. For instance, flat wheels are ideal for achieving consistent edges across larger surfaces, while convex or concave shapes can help hone specific areas more effectively. Understanding how these factors interact with your honing technique will enable you to select a wheel that complements your style and enhances your overall results.

The Importance of Maintenance and Care for Razor Wheels

Proper maintenance and care for honing wheels are essential for ensuring their longevity and performance over time. Regular cleaning is crucial to remove any debris or metal shavings that may accumulate during use. Neglecting this step can lead to uneven wear on the wheel’s surface, ultimately affecting its effectiveness in honing your razors.

Additionally, storing wheels in a dry environment away from direct sunlight can help prevent deterioration of materials such as rubber or resin used in some wheels. Regularly inspecting your wheels for signs of wear or damage will also allow you to address any issues before they impact your honing process. By prioritizing maintenance and care, you can extend the lifespan of your chosen wheels and ensure consistent performance throughout their use.

Choosing the Right Wheel for Different Hair and Skin Types

Selecting the appropriate honing wheel also involves considering individual hair and skin types when using full hollow straight razors. Different hair textures may require varying levels of sharpness to achieve an effective shave without causing irritation or discomfort. For instance, individuals with coarse hair may benefit from sharper edges produced by more aggressive wheels, while those with fine hair might prefer smoother edges that reduce the risk of nicks.

Similarly, skin sensitivity plays a crucial role in determining which wheel is best suited for your needs. Users with sensitive skin may want to opt for gentler wheels that produce smoother edges to minimize irritation during shaving. Understanding these factors will help you make informed decisions about which wheels will provide optimal results based on your unique hair and skin characteristics.

Seeking Professional Advice for Wheel Selection

When navigating the world of honing wheels for full hollow straight razors, seeking professional advice can be invaluable in making informed decisions. Experts in razor maintenance often have extensive knowledge about various wheel types, materials, and techniques that can help you find the perfect match for your specific needs. Consulting with professionals allows you to gain insights into best practices and recommendations tailored to your unique situation.

Whether through online forums or local shaving communities, connecting with experienced users can provide valuable guidance on selecting wheels that align with your goals and preferences.

Tips for Extending the Lifespan of Your Chosen Wheel

To maximize the lifespan of your chosen honing wheel for full hollow straight razors, several practical tips can be implemented. First and foremost, regular cleaning after each use is essential to prevent buildup that could compromise performance over time. Using a soft brush or cloth to remove debris will help maintain optimal conditions for honing.

Additionally, avoid applying excessive pressure during honing sessions; this practice not only prolongs wear on the wheel but also increases the risk of damaging your razor blade. Instead, focus on maintaining consistent pressure throughout each pass to achieve desired results without unnecessary strain on either tool. By following these tips and prioritizing proper care and maintenance practices, you can ensure that your honing wheels remain effective tools in your shaving arsenal for years to come.

FAQs

What is a 14-inch wheel used for in the context of full hollow straight razors?

A 14-inch wheel is used for honing and sharpening full hollow straight razors. It is a crucial tool in the process of maintaining the razor’s edge and ensuring a smooth and effective shave.

Why is a 14-inch wheel specifically used for full hollow straight razors?

The 14-inch wheel is specifically designed for full hollow straight razors because it provides the right surface area and curvature to effectively hone and sharpen the delicate blade of the razor.

How does using a 14-inch wheel benefit the maintenance of full hollow straight razors?

Using a 14-inch wheel allows for precise and controlled sharpening of the razor’s edge, ensuring that it remains sharp and effective for shaving. It also helps maintain the integrity of the blade, prolonging its lifespan.

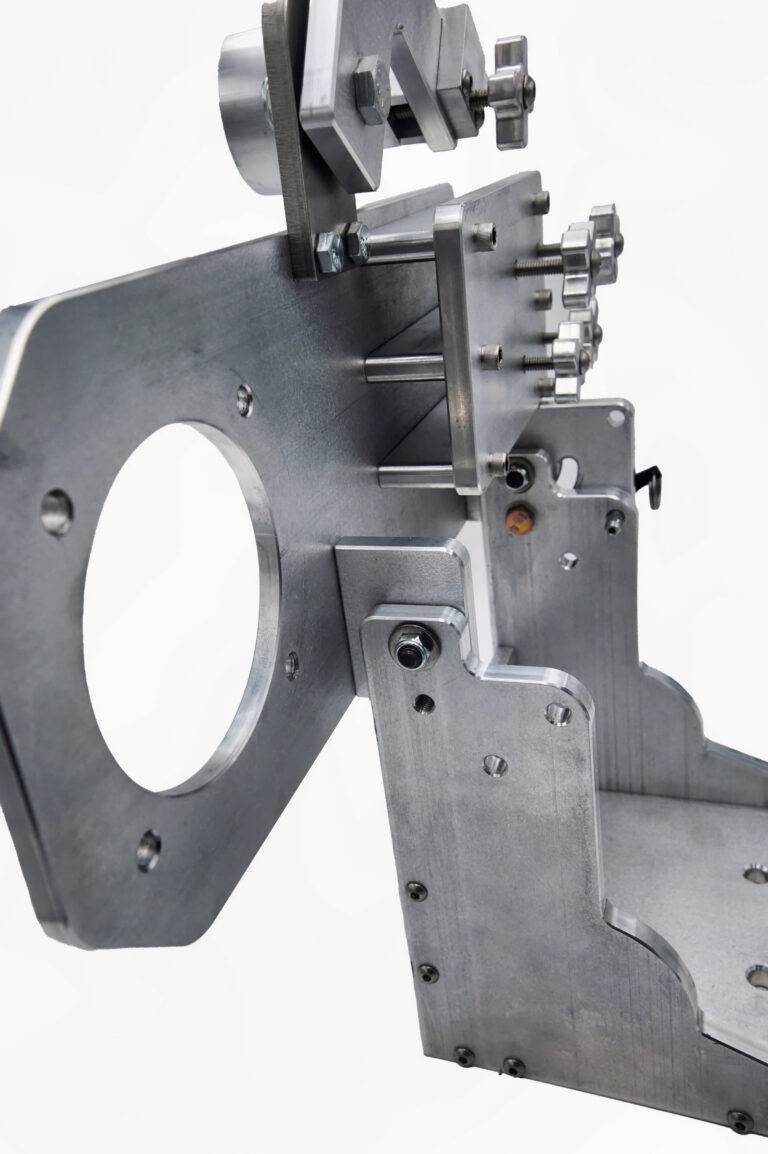

What are the key considerations when using a 14-inch wheel for full hollow straight razors?

When using a 14-inch wheel for full hollow straight razors, it is important to ensure that the wheel is properly aligned and balanced to avoid damaging the razor. Additionally, using the correct honing techniques and maintaining the wheel’s surface are crucial for achieving optimal results.

Are there any safety precautions to keep in mind when using a 14-inch wheel for full hollow straight razors?

It is important to handle the razor and the 14-inch wheel with care to avoid accidents or injuries. Proper safety equipment, such as gloves and eye protection, should be used when honing and sharpening the razor on the wheel.