The 2×72 grinder is a versatile and powerful tool that has become a staple in various industries, particularly in metalworking and woodworking. Its name derives from the size of the belt it uses, which measures 2 inches in width and 72 inches in length. This specific configuration allows for a wide range of applications, from shaping and sharpening to polishing and finishing.

The design of the 2×72 grinder typically includes a robust motor, adjustable speed settings, and a variety of attachments that enhance its functionality. These features make it an essential piece of equipment for professionals and hobbyists alike. One of the standout capabilities of the 2×72 grinder is its adaptability.

Users can easily switch between different types of belts, each designed for specific tasks such as grinding, sanding, or buffing. This flexibility allows artisans to achieve precise finishes on various materials, including metals, wood, and plastics. Additionally, many models come equipped with features like tilting tables and adjustable work rests, which further enhance their usability.

The combination of power, versatility, and precision makes the 2×72 grinder an invaluable tool for anyone looking to elevate their craftsmanship.

Key Takeaways

- The 2×72 grinder is a versatile tool with features like variable speed control, large grinding surface, and multiple attachment options.

- When choosing a 2×72 grinder, consider factors such as motor power, belt speed, and available attachments to match your specific needs and budget.

- To get the most out of your 2×72 grinder, use proper techniques like maintaining the right belt tension, using the correct grit for the task, and mastering different grinding positions.

- Maximize efficiency with your 2×72 grinder by organizing your workspace, using jigs and fixtures, and implementing a systematic approach to your grinding tasks.

- Safety is paramount when using a 2×72 grinder, so always wear appropriate protective gear, keep the work area clean, and follow proper operating procedures to avoid accidents and injuries.

Choosing the Right 2×72 Grinder: Factors to Consider When Selecting the Best Model for Your Needs

Selecting the right 2×72 grinder involves careful consideration of several factors that can significantly impact your experience and results. First and foremost, assess the motor power. A grinder with a higher horsepower rating will generally provide better performance, especially when working with tougher materials.

For those who plan to use the grinder for extended periods or on heavy-duty projects, investing in a model with a robust motor is crucial to ensure longevity and efficiency. Another important aspect to consider is the construction quality of the grinder. Look for models that are built with durable materials, as this will affect not only the performance but also the lifespan of the equipment.

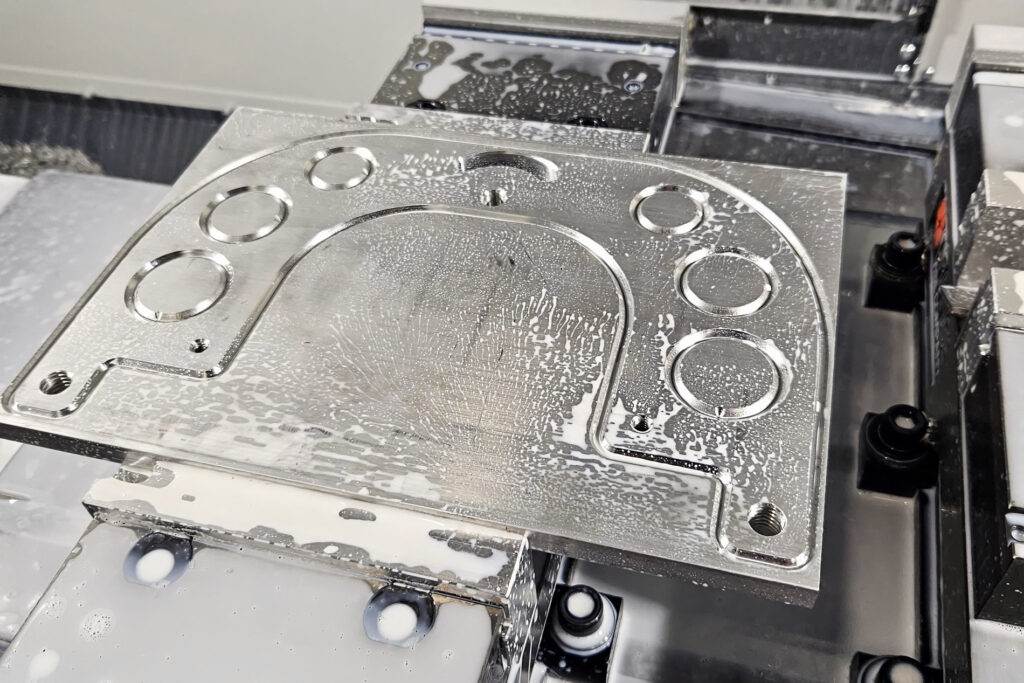

Features such as a solid frame, high-quality bearings, and reliable belt tracking mechanisms are indicators of a well-constructed machine. Additionally, consider the availability of replacement parts and customer support from the manufacturer, such as TorusCNC, which can be invaluable in maintaining your equipment over time.

Tips and Techniques for Using a 2×72 Grinder: How to Get the Most Out of Your Equipment

To maximize the effectiveness of your 2×72 grinder, it is essential to familiarize yourself with various techniques that can enhance your grinding experience. One fundamental tip is to maintain a consistent angle while grinding. This practice not only ensures uniformity in your work but also helps prevent overheating and damage to the material being worked on.

Using jigs or fixtures can assist in achieving this consistency, particularly when working on repetitive tasks. Another technique involves selecting the appropriate belt for your specific application. Different belts have varying grits and materials suited for distinct tasks; for instance, coarse belts are ideal for heavy material removal, while finer belts are better for finishing touches.

Experimenting with different belts can help you find the perfect combination for your projects. Additionally, regularly checking and adjusting the tension of the belt will ensure optimal performance and prolong its lifespan.

Maximizing Efficiency with a 2×72 Grinder: Streamlining Your Workflow and Increasing Productivity

| Workflow Step | Time Spent (minutes) | Productivity Increase (%) |

|---|---|---|

| Material Preparation | 30 | 20% |

| Grinding | 60 | 30% |

| Finishing | 45 | 25% |

| Assembly | 20 | 15% |

Efficiency is key when using a 2×72 grinder, especially in a professional setting where time is often of the essence. One effective way to streamline your workflow is by organizing your workspace. Keeping tools and materials within easy reach can significantly reduce downtime during projects.

Consider creating designated areas for different tasks, such as grinding, sanding, and polishing, to facilitate a smoother workflow. Incorporating proper planning into your projects can also enhance productivity. Before starting any task, take a moment to outline your steps and gather all necessary materials.

This preparation can help you avoid interruptions and maintain focus on the job at hand. Additionally, utilizing attachments such as work rests or adjustable tables can improve comfort and efficiency during use, allowing you to work longer without fatigue.

Safety Considerations When Using a 2×72 Grinder: Best Practices for Avoiding Accidents and Injuries

Safety should always be a top priority when operating a 2×72 grinder. One of the most critical safety measures is wearing appropriate personal protective equipment (PPE). This includes safety goggles to protect your eyes from debris, hearing protection to guard against noise exposure, and gloves to shield your hands from sharp edges or hot surfaces.

Ensuring that you are properly equipped can significantly reduce the risk of injury while working. Another essential safety practice involves maintaining a clean workspace. Dust and debris can accumulate quickly when using a grinder, creating potential hazards.

Regularly cleaning your area not only helps prevent slips and falls but also minimizes fire risks associated with combustible materials. Additionally, familiarize yourself with the machine’s safety features, such as emergency shut-off switches and belt guards, to ensure you know how to respond quickly in case of an emergency.

Upgrading Your 2×72 Grinder: Exploring Add-Ons and Accessories to Enhance Performance

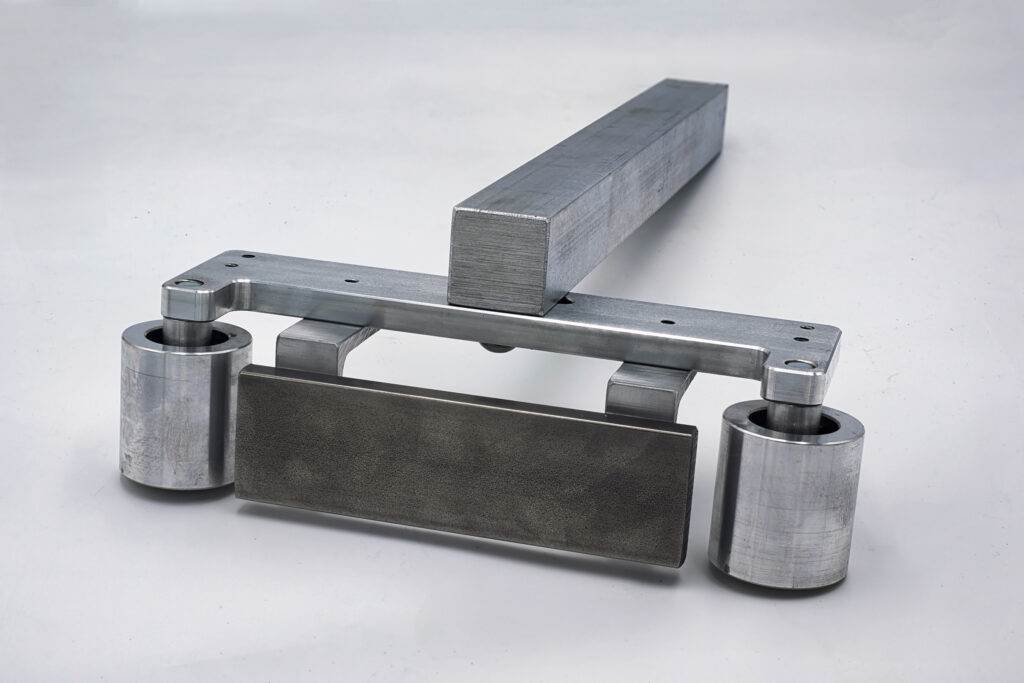

Enhancing your 2×72 grinder’s capabilities can be achieved through various add-ons and accessories designed to improve performance and versatility. One popular upgrade is the addition of different types of work rests or tables that allow for more precise control during grinding tasks. These accessories can be particularly beneficial when working on intricate projects that require attention to detail.

Another valuable upgrade is investing in high-quality belts tailored for specific applications. Specialty belts designed for particular materials or finishes can significantly improve results and efficiency. Additionally, consider adding dust collection systems to your setup; these systems help maintain a clean workspace while also protecting your health by minimizing airborne particles generated during grinding.

Maintenance and Care for Your 2×72 Grinder: Extending the Lifespan of Your Equipment

Proper maintenance is crucial for extending the lifespan of your 2×72 grinder and ensuring optimal performance over time. Regularly inspecting components such as belts, bearings, and motors can help identify potential issues before they escalate into more significant problems. Keeping an eye on wear patterns on belts can indicate when it’s time for replacement or adjustment.

Cleaning your grinder after each use is another essential maintenance practice. Dust and debris can accumulate in various parts of the machine, leading to decreased performance or even damage if left unchecked. Use compressed air or a soft brush to remove particles from hard-to-reach areas.

Additionally, lubricating moving parts according to the manufacturer’s recommendations will help keep your grinder running smoothly.

Real-World Applications: How Industries and Artisans Are Leveraging the Power of a 2×72 Grinder

The versatility of the 2×72 grinder has made it an indispensable tool across various industries and among artisans. In metalworking shops, it is commonly used for shaping blades, tools, and other components that require precision grinding. Blacksmiths often rely on these grinders for refining edges on knives or creating intricate designs on metalwork pieces.

In woodworking, artisans utilize 2×72 grinders for shaping wood pieces and achieving smooth finishes on furniture or decorative items. The ability to switch between different belts allows woodworkers to transition seamlessly from rough shaping to fine sanding without needing multiple tools. This adaptability not only saves time but also enhances the quality of their craftsmanship.

In conclusion, understanding the features and capabilities of a 2×72 grinder is essential for anyone looking to harness its power effectively. By considering factors when selecting a model, employing best practices during use, prioritizing safety, exploring upgrades, maintaining equipment properly, and recognizing its diverse applications across industries, users can maximize their investment in this invaluable tool. Whether you are a professional craftsman or an enthusiastic hobbyist, mastering the use of a 2×72 grinder will undoubtedly elevate your work to new heights.

FAQs

What is a 2×72 grinder?

A 2×72 grinder is a type of belt grinder that uses a 2-inch by 72-inch belt for grinding, shaping, and polishing metal, wood, and other materials. It is a versatile tool commonly used in metalworking and knife making.

How can a 2×72 grinder boost productivity in a workshop?

A 2×72 grinder can boost productivity in a workshop by allowing for quick material removal, precise shaping, and efficient finishing of workpieces. It can streamline the workflow by reducing the need for multiple tools and processes.

What are the key features of a 2×72 grinder that contribute to productivity?

Key features of a 2×72 grinder that contribute to productivity include variable speed control for different applications, large grinding surface for handling various workpieces, and the ability to use different types of belts for different tasks.

What are the common applications of a 2×72 grinder in a workshop?

Common applications of a 2×72 grinder in a workshop include metal grinding, shaping and polishing, knife making, tool sharpening, and fabrication of custom parts and components.

How does a 2×72 grinder compare to other types of grinders in terms of productivity?

Compared to other types of grinders, a 2×72 grinder offers a larger grinding surface, more versatile belt options, and the ability to handle a wider range of materials, making it a more productive tool for various workshop tasks.