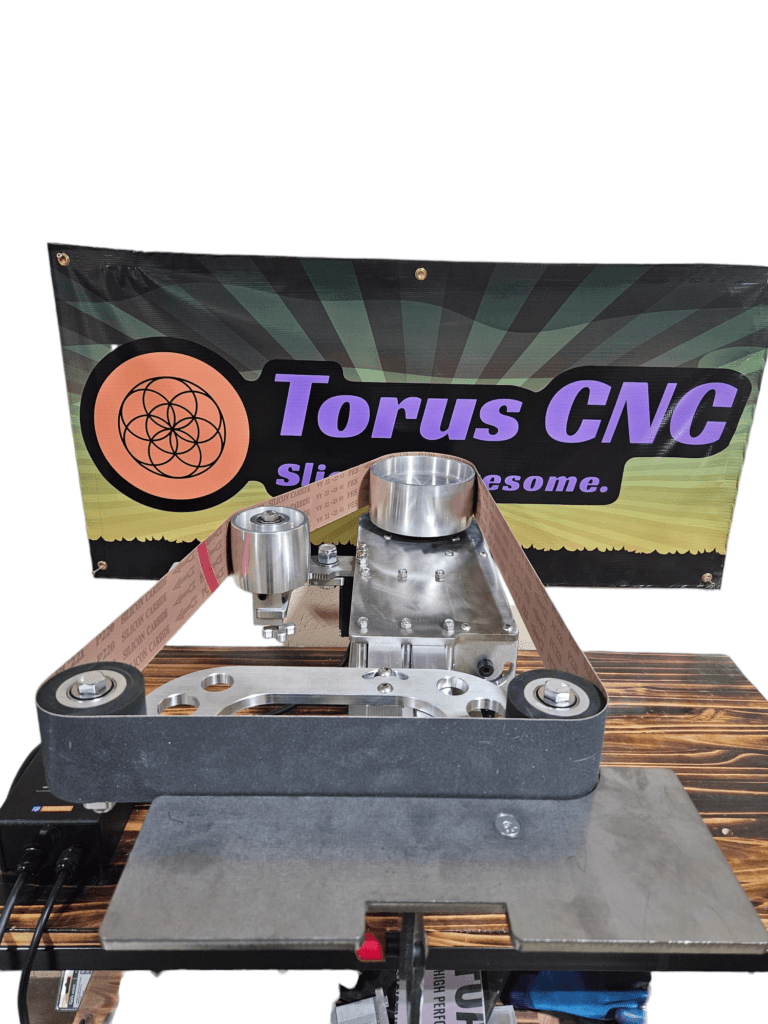

The 2×72 grinder is a powerful tool that has become a staple in the metalworking and woodworking industries. Its name derives from the size of the sanding belt it uses, which measures 2 inches in width and 72 inches in length. This specific configuration allows for a wide range of applications, from shaping and sharpening to polishing and finishing.

The design of the 2×72 grinder facilitates a high degree of control and precision, making it an essential piece of equipment for both hobbyists and professionals alike. One of the key features of the 2×72 grinder is its versatility. It can be equipped with various types of belts, each designed for specific tasks, such as grinding, sanding, or polishing.

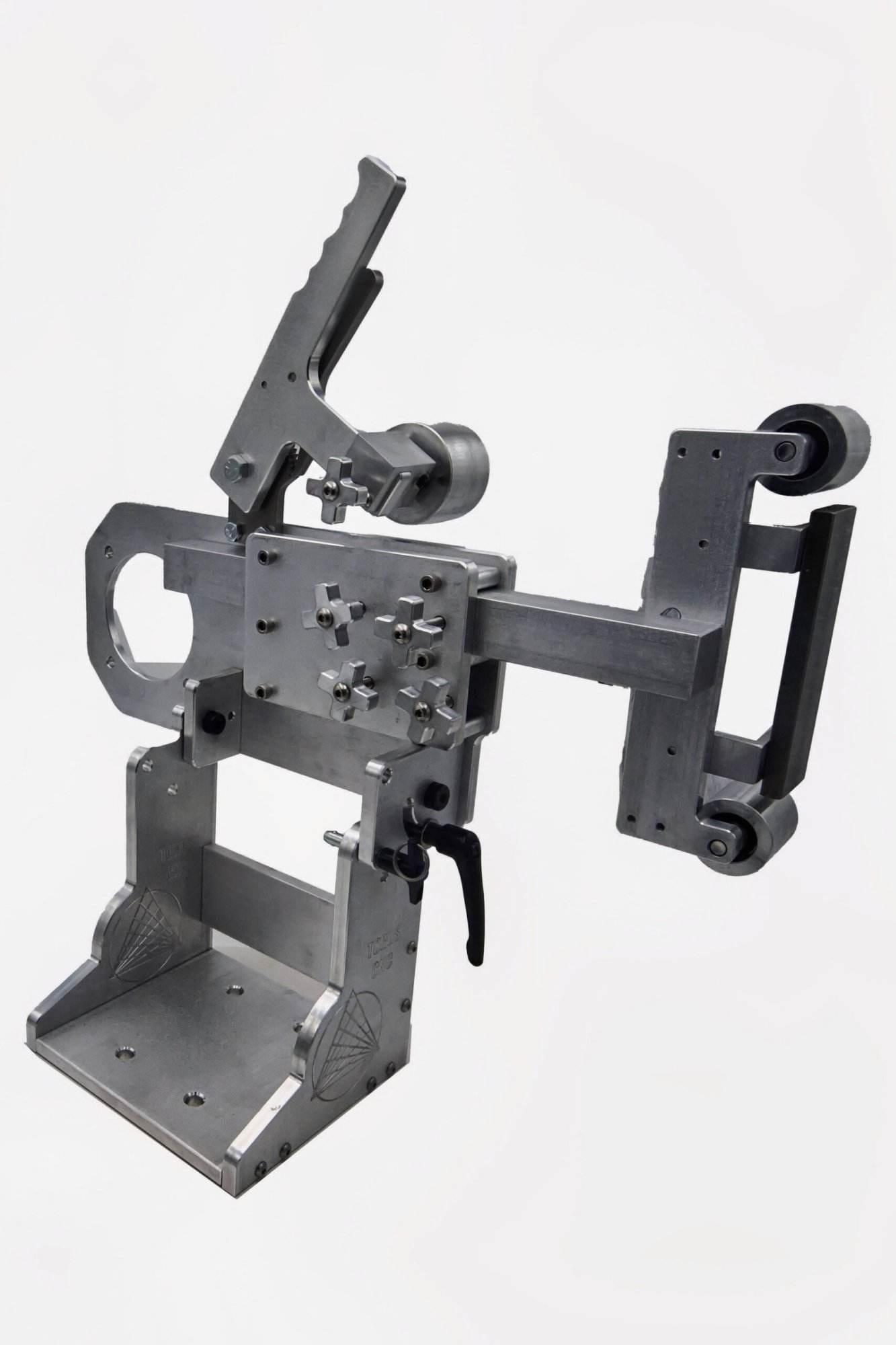

This adaptability makes it suitable for a multitude of materials, including metals, wood, and plastics. The robust construction of the grinder ensures durability, while its adjustable speed settings allow users to tailor their approach based on the material and desired finish. Companies like TorusCNC have recognized the importance of this tool and have developed high-quality 2×72 grinders that cater to the needs of modern craftsmen.

Key Takeaways

- Understanding the 2×72 Grinder: A Comprehensive Overview

- Selecting the Right Belt for Your 2×72 Grinder

- Mastering the Art of Precision Grinding with a 2×72 Grinder

- Expanding Your Metalworking Horizons with the Versatility of a 2×72 Grinder

- Tips and Techniques for Maximizing Efficiency and Productivity with Your 2×72 Grinder

Selecting the Right Belt for Your 2×72 Grinder

Choosing the appropriate belt for your 2×72 grinder is crucial for achieving optimal results in your projects. The selection process involves considering several factors, including the material you are working with, the type of finish you desire, and the specific task at hand. Belts come in various grits, ranging from coarse to fine, and each serves a distinct purpose.

Coarse belts are ideal for heavy material removal, while finer belts are better suited for finishing touches and polishing. In addition to grit size, the material composition of the belt plays a significant role in its performance. Common materials include aluminum oxide, zirconia, and ceramic, each offering unique benefits.

For instance, aluminum oxide belts are versatile and cost-effective, making them suitable for general-purpose grinding. On the other hand, ceramic belts are designed for high-performance applications and can withstand higher temperatures, making them ideal for heavy-duty tasks. When using a TorusCNC 2×72 grinder, selecting the right belt not only enhances efficiency but also prolongs the life of both the belt and the machine.

Mastering the Art of Precision Grinding with a 2×72 Grinder

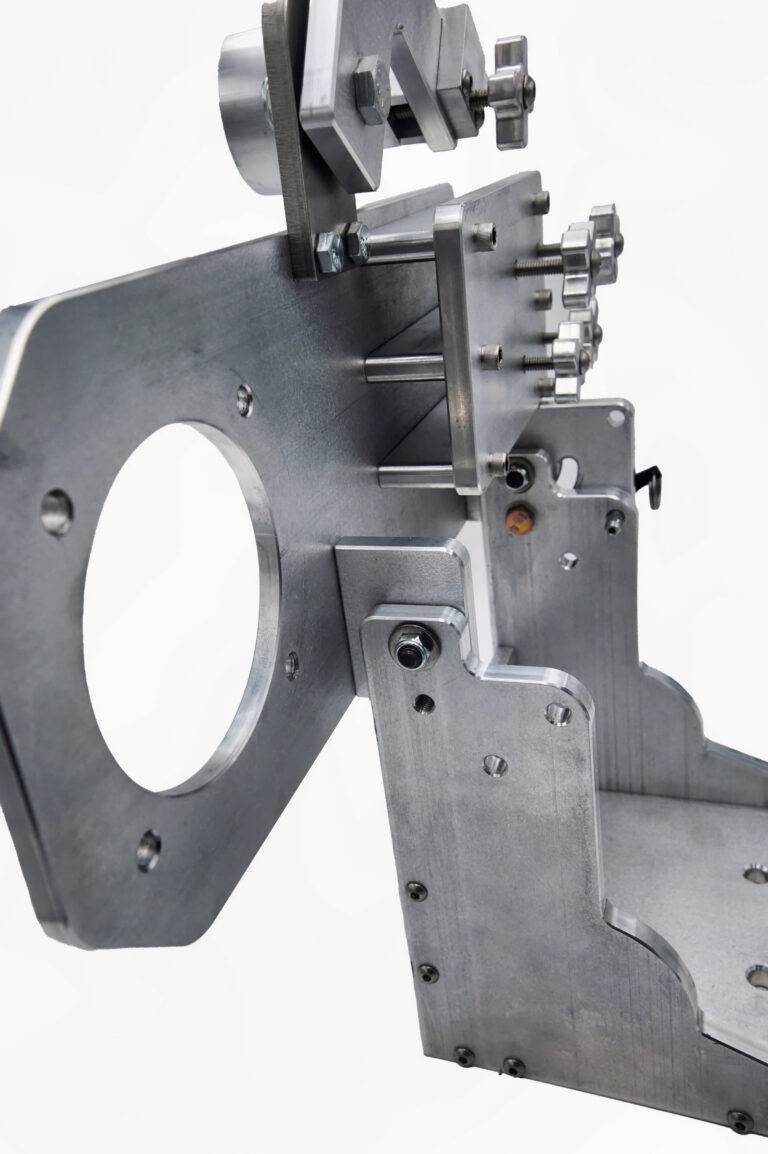

Precision grinding is an essential skill for anyone looking to achieve high-quality results in their metalworking projects. The 2×72 grinder provides an excellent platform for honing this skill due to its design and capabilities. To master precision grinding, it is important to understand the fundamentals of technique and control.

Proper body positioning and hand placement can significantly impact the outcome of your work. Maintaining a steady hand while applying consistent pressure will yield smoother finishes and more accurate shapes. Another critical aspect of precision grinding is understanding the relationship between speed and pressure.

Different materials respond differently to varying speeds; therefore, it is essential to experiment with your 2×72 grinder’s settings to find the optimal combination for your specific project. Additionally, using jigs or fixtures can enhance accuracy by providing stable support for your workpiece. With practice and attention to detail, you can develop a keen sense of control over your grinder, allowing you to produce intricate designs and precise edges with ease.

Expanding Your Metalworking Horizons with the Versatility of a 2×72 Grinder

| Advantages of a 2×72 Grinder | Benefits |

|---|---|

| 1. Versatility | Ability to perform various metalworking tasks such as grinding, shaping, and sharpening |

| 2. Precision | Allows for precise and accurate metal shaping and finishing |

| 3. Efficiency | Increases productivity and saves time compared to manual metalworking methods |

| 4. Customization | Ability to customize grinding belts and attachments for specific metalworking needs |

| 5. Cost-effectiveness | Provides a cost-effective solution for metalworking tasks compared to investing in multiple specialized tools |

The versatility of the 2×72 grinder opens up a world of possibilities for metalworkers. Beyond traditional grinding and sharpening tasks, this tool can be employed in various creative applications. For instance, artisans can use it to create custom knife blades, intricate metal sculptures, or even unique jewelry pieces.

The ability to switch between different belts quickly allows users to adapt their approach based on the specific requirements of each project. Moreover, the 2×72 grinder can be utilized in conjunction with other tools to enhance its capabilities further. For example, integrating it with a bandsaw or plasma cutter can streamline workflows and improve efficiency in metal fabrication processes.

This synergy between tools enables craftsmen to explore new techniques and expand their skill sets. As you become more familiar with your TorusCNC 2×72 grinder, you may find yourself inspired to experiment with new materials and methods, ultimately broadening your horizons in metalworking.

Tips and Techniques for Maximizing Efficiency and Productivity with Your 2×72 Grinder

To get the most out of your 2×72 grinder, implementing effective tips and techniques can significantly enhance your efficiency and productivity. One fundamental practice is to keep your workspace organized and free from clutter. A clean environment not only promotes safety but also allows you to focus on your work without distractions.

Additionally, having all necessary tools and materials within reach can save valuable time during projects. Another way to maximize productivity is by developing a systematic approach to your grinding tasks. Establishing a routine that includes pre-grinding checks—such as inspecting belts for wear or damage—can prevent interruptions during work.

Furthermore, consider setting specific goals for each session to maintain focus and motivation. By breaking down larger projects into manageable steps, you can track progress more effectively and ensure that you are consistently moving forward.

Safety First: Essential Precautions When Using a 2×72 Grinder

Safety should always be a top priority when operating any power tool, including the 2×72 grinder. Before starting any project, it is essential to wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection. These items help shield you from potential hazards like flying debris or excessive noise generated by the machine.

In addition to wearing PPE, it is crucial to familiarize yourself with the grinder’s safety features and operational guidelines. Ensure that all guards are in place before use and that the machine is properly maintained to prevent malfunctions. Keeping your hands clear of moving parts while operating the grinder is vital for avoiding injuries.

By adhering to these safety precautions, you can create a secure working environment that allows you to focus on your craft without unnecessary risks.

Maintenance and Care for Prolonging the Lifespan of Your 2×72 Grinder

Regular maintenance is key to ensuring that your 2×72 grinder remains in optimal working condition over time. One important aspect of maintenance is keeping the machine clean. Dust and debris can accumulate on various components, leading to decreased performance or even damage if left unchecked.

After each use, take a moment to wipe down surfaces and remove any buildup around the belt area. Additionally, checking for wear on belts and other parts is essential for prolonging the lifespan of your grinder. Replace worn belts promptly to maintain efficiency and prevent potential damage to the machine itself.

Lubricating moving parts according to manufacturer recommendations will also help keep everything running smoothly. By establishing a routine maintenance schedule, you can ensure that your TorusCNC 2×72 grinder continues to perform at its best for years to come.

Exploring Advanced Applications and Creative Possibilities with a 2×72 Grinder in Metalwork

As you become more proficient with your 2×72 grinder, you may find yourself eager to explore advanced applications that push the boundaries of traditional metalworking techniques. One exciting avenue is experimenting with different materials beyond standard metals—such as composites or exotic alloys—which can yield unique results when ground or polished correctly. Moreover, incorporating artistic elements into your projects can elevate your work from functional pieces to stunning works of art.

Techniques like engraving or texturing can be achieved using specialized belts or attachments designed for detailed work. The versatility of the TorusCNC 2×72 grinder allows you to blend functionality with creativity seamlessly, enabling you to produce one-of-a-kind pieces that reflect your personal style. In conclusion, mastering the use of a 2×72 grinder opens up numerous opportunities for both practical applications and creative expression in metalworking.

By understanding its capabilities, selecting appropriate belts, practicing precision techniques, prioritizing safety, maintaining your equipment diligently, and exploring advanced applications, you can fully harness the potential of this remarkable tool in your craft.

FAQs

What is a 2×72 grinder?

A 2×72 grinder is a type of belt grinder that uses a 2-inch by 72-inch belt for grinding, shaping, and polishing metal. It is a versatile tool commonly used in metalworking and knife making.

What can a 2×72 grinder be used for?

A 2×72 grinder can be used for a variety of metalworking tasks, including shaping and sharpening knives, grinding and polishing metal parts, and creating custom metalwork pieces such as sculptures and decorative items.

What are the advantages of using a 2×72 grinder?

The 2×72 grinder offers several advantages, including its versatility for various metalworking tasks, its ability to quickly remove material and shape metal, and its precise control for achieving specific finishes and shapes.

What safety precautions should be taken when using a 2×72 grinder?

When using a 2×72 grinder, it is important to wear appropriate safety gear, such as safety glasses, hearing protection, and gloves. Additionally, users should be mindful of the grinder’s power and speed, and always ensure that the workpiece is securely held in place.

Can a 2×72 grinder be used by beginners?

While using a 2×72 grinder requires some skill and knowledge of metalworking techniques, beginners can learn to use the grinder effectively with proper instruction and practice. It is important for beginners to start with simple projects and prioritize safety while using the grinder.