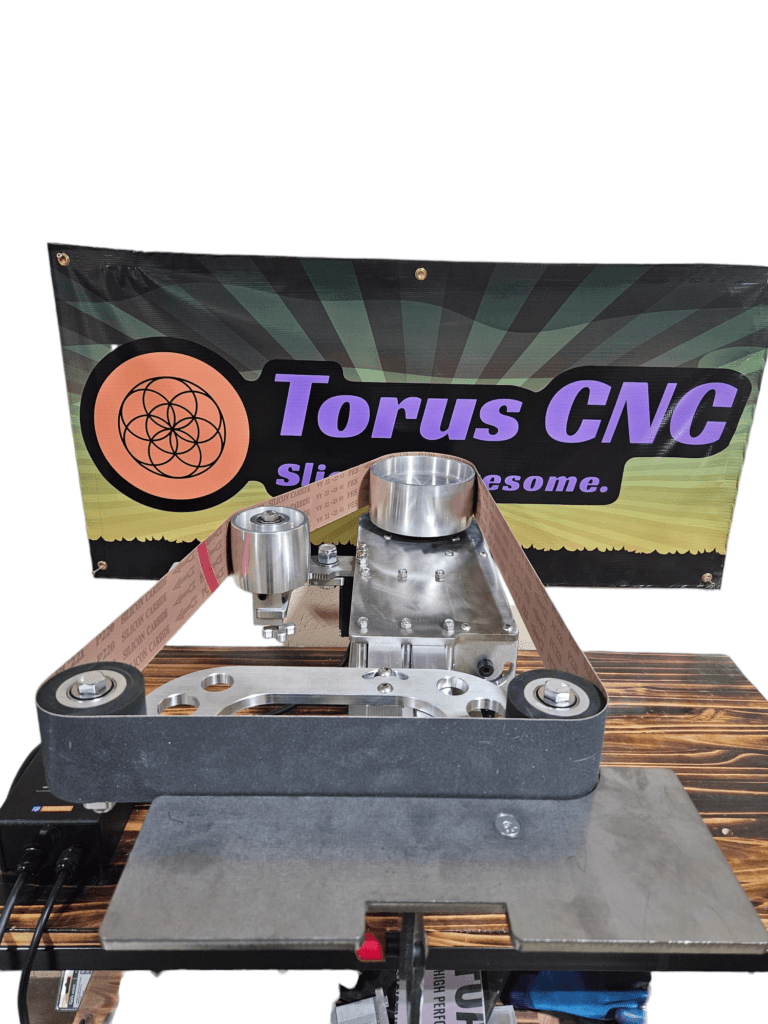

The 2×72 grinder has become a staple in the metalworking and woodworking industries, renowned for its versatility and efficiency. This machine is primarily used for shaping, grinding, and finishing materials, making it an essential tool for artisans, blacksmiths, and fabricators alike. The 2×72 designation refers to the size of the belt used in the grinding process, which measures two inches in width and seventy-two inches in length.

This specific size allows for a wide range of applications, from fine finishing to heavy material removal. TorusCNC has emerged as a prominent player in the market, offering high-quality 2×72 grinders that cater to both hobbyists and professionals. Their machines are designed with precision engineering and user-friendly features, making them accessible to a broad audience.

As the demand for efficient and reliable grinding solutions continues to grow, the integration of advanced materials and technologies, such as CNC aluminum, is becoming increasingly significant in enhancing the performance of these grinders.

Key Takeaways

- 2×72 grinders are powerful tools used for shaping and finishing metal, wood, and other materials.

- CNC aluminum offers numerous benefits in 2×72 grinders, including lightweight construction, corrosion resistance, and high precision.

- CNC aluminum significantly improves the precision and accuracy of 2×72 grinders, resulting in better quality and consistency in the finished products.

- The use of CNC aluminum in 2×72 grinders enhances their durability and longevity, reducing maintenance and replacement costs.

- CNC aluminum technology in 2×72 grinders improves efficiency and speed, allowing for faster material removal and increased productivity.

The Benefits of CNC Aluminum in 2×72 Grinders

CNC aluminum has revolutionized the manufacturing process of 2×72 grinders, providing numerous benefits that enhance their overall functionality. One of the primary advantages of using CNC aluminum is its lightweight nature. This characteristic allows for easier handling and maneuverability of the grinder, which is particularly beneficial for users who may need to transport their equipment frequently.

The reduced weight does not compromise strength; rather, it ensures that the grinder remains robust and capable of withstanding rigorous use. Moreover, CNC aluminum offers excellent thermal conductivity, which is crucial during grinding operations. The heat generated from friction can lead to overheating, potentially damaging both the grinder and the workpiece.

By utilizing CNC aluminum components, TorusCNC grinders can dissipate heat more effectively, maintaining optimal operating temperatures. This feature not only prolongs the life of the machine but also enhances the quality of the finished product by preventing heat-related distortions.

The Impact of CNC Aluminum on Precision and Accuracy

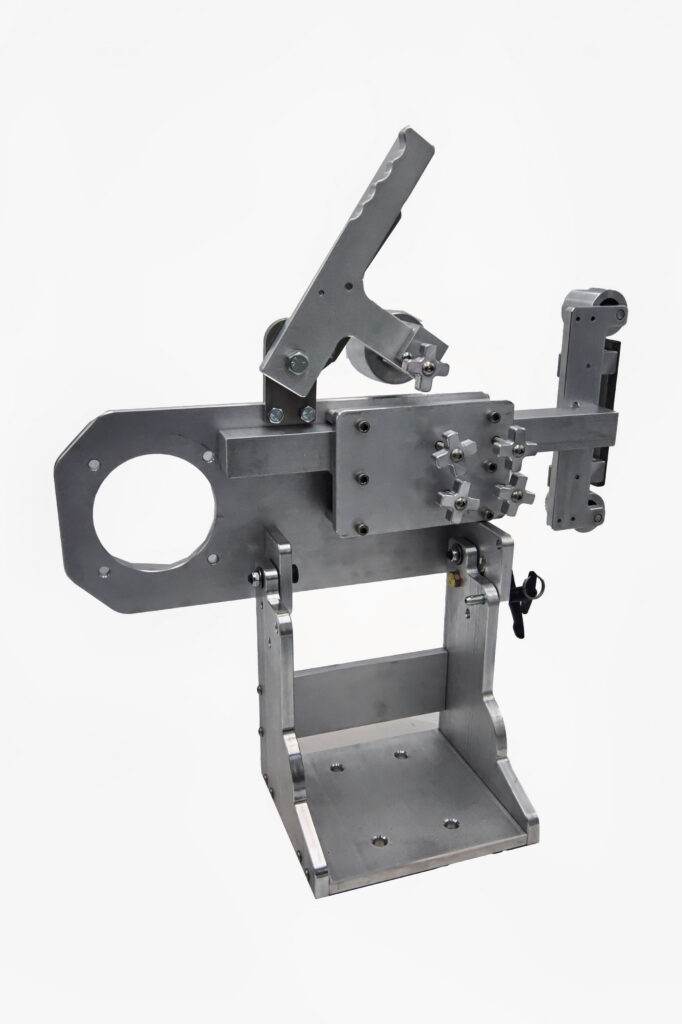

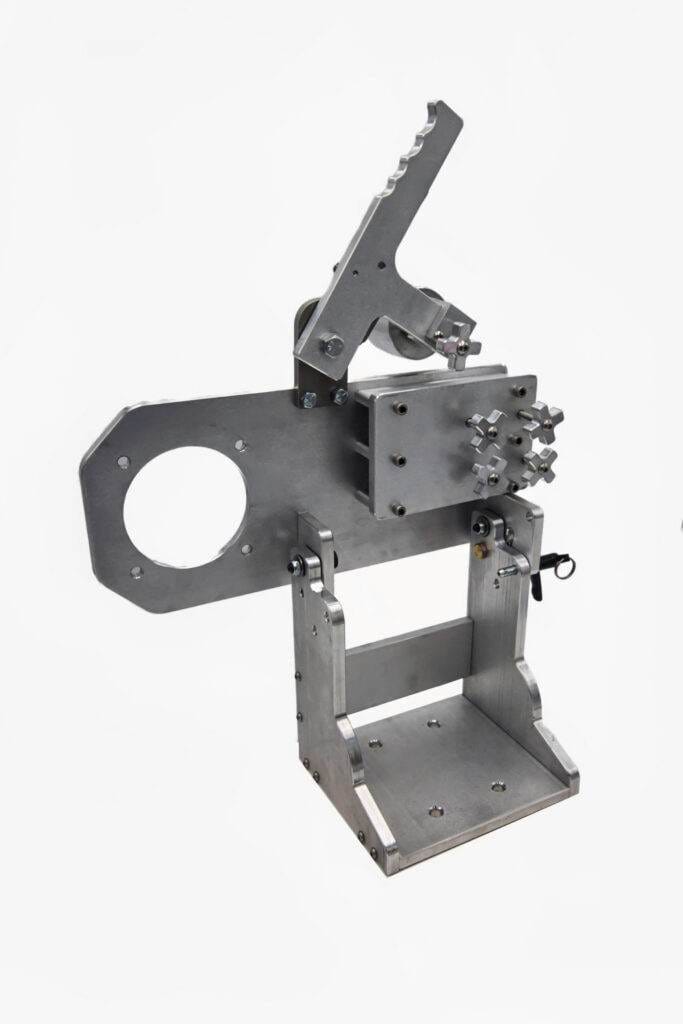

Precision and accuracy are paramount in any grinding operation, and CNC aluminum plays a vital role in achieving these standards. The manufacturing process of CNC aluminum involves computer numerical control technology, which ensures that each component is produced with exact specifications. This level of precision translates into tighter tolerances in the assembly of the grinder, resulting in improved alignment and stability during operation.

Furthermore, the rigidity of CNC aluminum contributes to enhanced accuracy in grinding tasks. When a grinder is constructed from materials that flex or warp under pressure, it can lead to inconsistencies in the finished product. However, with CNC aluminum’s inherent strength and stability, users can expect consistent results with every pass.

This reliability is particularly important for professionals who rely on their tools to produce high-quality work consistently.

How CNC Aluminum Revolutionizes the Durability and Longevity of 2×72 Grinders

| Metrics | Benefits |

|---|---|

| Material | Aluminum |

| Durability | High |

| Longevity | Extended lifespan |

| Grinder Type | 2×72 |

| Manufacturing Process | CNC |

Durability is a critical factor when selecting a 2×72 grinder, especially for those who engage in heavy-duty applications. CNC aluminum significantly enhances the longevity of these machines by providing resistance to wear and tear. Unlike traditional materials that may corrode or degrade over time, CNC aluminum maintains its structural integrity even under demanding conditions.

This resilience ensures that users can depend on their TorusCNC grinders for years without experiencing significant degradation in performance. Additionally, the surface finish of CNC aluminum components contributes to their durability. The machining process often results in a smooth finish that reduces friction between moving parts.

This reduction in friction not only minimizes wear but also decreases the likelihood of mechanical failures. As a result, users can enjoy a more reliable grinding experience with less downtime for maintenance or repairs.

The Role of CNC Aluminum in Enhancing the Efficiency and Speed of 2×72 Grinders

Efficiency is a key consideration for any tool used in production environments, and CNC aluminum significantly enhances the operational speed of 2×72 grinders. The lightweight nature of CNC aluminum allows for faster acceleration and deceleration during grinding operations. This responsiveness enables users to complete tasks more quickly without sacrificing quality or precision.

Moreover, the design flexibility afforded by CNC aluminum allows for innovative features that further improve efficiency. For instance, TorusCNC grinders can incorporate advanced cooling systems or optimized belt tracking mechanisms that streamline the grinding process. These enhancements not only save time but also reduce energy consumption, making CNC aluminum grinders an environmentally friendly choice for modern workshops.

The Advantages of CNC Aluminum in Customization and Versatility of 2×72 Grinders

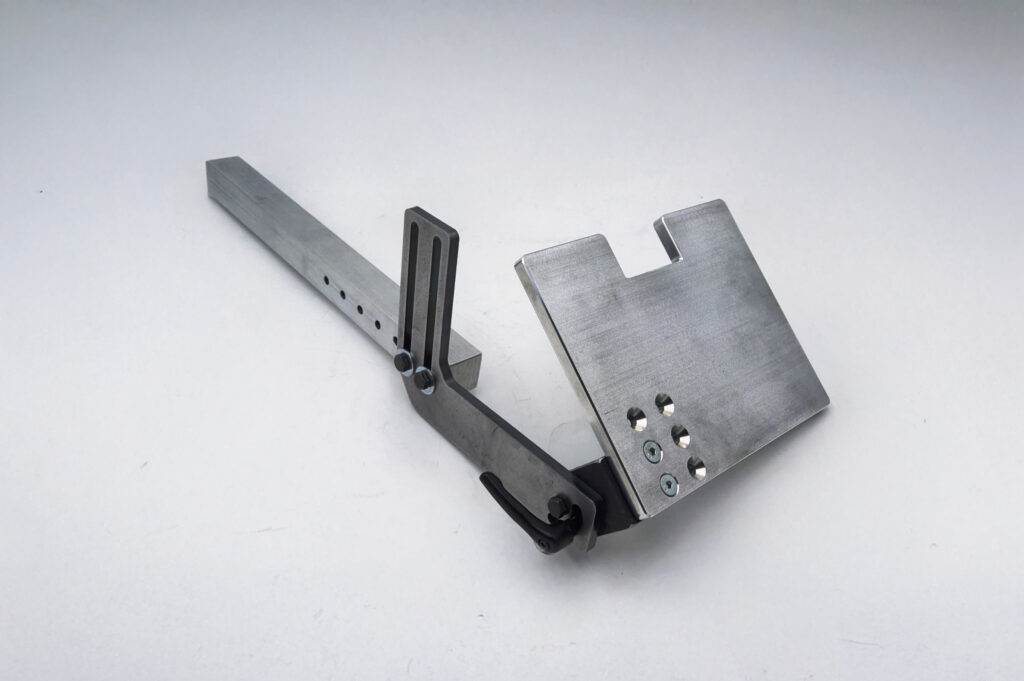

Customization is increasingly important in today’s manufacturing landscape, where unique projects often require tailored solutions. CNC aluminum provides an excellent platform for customization due to its malleability and ease of machining. TorusCNC offers a range of options that allow users to modify their 2×72 grinders according to specific needs or preferences.

Whether it’s adjusting the frame design or integrating specialized attachments, CNC aluminum facilitates a high degree of personalization. In addition to customization, the versatility of CNC aluminum enhances the overall functionality of 2×72 grinders. Users can easily switch between different grinding belts or attachments without compromising performance.

This adaptability makes it possible to tackle a wide variety of materials and applications, from metal fabrication to woodworking projects. As a result, craftsmen can maximize their investment in a single machine while expanding their capabilities.

The Future of 2×72 Grinders with CNC Aluminum Technology

The future of 2×72 grinders appears promising with the continued integration of CNC aluminum technology. As advancements in manufacturing processes evolve, we can expect even greater innovations that will further enhance the performance and capabilities of these machines. For instance, developments in alloy formulations may lead to even lighter yet stronger materials that push the boundaries of what is possible in grinder design.

Moreover, as industries increasingly prioritize sustainability, the use of CNC aluminum aligns with these goals by offering a recyclable material that reduces environmental impact. The potential for incorporating smart technology into 2×72 grinders also exists, allowing for real-time monitoring and adjustments during operation. This convergence of technology and material science will undoubtedly shape the future landscape of grinding equipment.

The Potential of CNC Aluminum to Transform the 2×72 Grinder Industry

In conclusion, CNC aluminum has emerged as a transformative force within the 2×72 grinder industry. Its lightweight nature enhances maneuverability while maintaining strength and durability essential for rigorous applications. The precision offered by CNC manufacturing processes ensures that users achieve consistent results with every use, while its thermal properties contribute to prolonged machine life.

As we look ahead, it is clear that the integration of CNC aluminum technology will continue to drive innovation within this sector. With companies like TorusCNC leading the charge, we can anticipate a future where 2×72 grinders are not only more efficient but also more customizable and versatile than ever before. The potential for this material to revolutionize grinding operations is immense, paving the way for enhanced productivity and creativity among craftsmen across various industries.

FAQs

What are 2×72 grinders?

2×72 grinders are industrial-grade belt grinders commonly used in metalworking and knife making. They are designed to accommodate 2-inch by 72-inch belts and are known for their versatility and precision in shaping and finishing metal.

What is CNC aluminum construction?

CNC aluminum construction refers to the use of computer numerical control (CNC) technology to precisely machine aluminum components for the construction of 2×72 grinders. This method allows for high levels of accuracy and repeatability in the manufacturing process.

Why are CNC aluminum constructions setting new industry standards for 2×72 grinders?

CNC aluminum constructions are setting new industry standards for 2×72 grinders due to their superior precision, durability, and consistency. The use of CNC technology ensures that each component is machined to exact specifications, resulting in high-quality and reliable grinders.

What are the benefits of CNC aluminum constructions in 2×72 grinders?

The benefits of CNC aluminum constructions in 2×72 grinders include increased durability, improved performance, and reduced maintenance. Additionally, the precision machining of aluminum components allows for tighter tolerances and smoother operation of the grinders.

How do CNC aluminum constructions impact the future of 2×72 grinders?

CNC aluminum constructions are shaping the future of 2×72 grinders by raising the bar for quality and performance in the industry. As more manufacturers adopt this advanced construction method, users can expect to see a new standard of excellence in 2×72 grinder design and functionality.