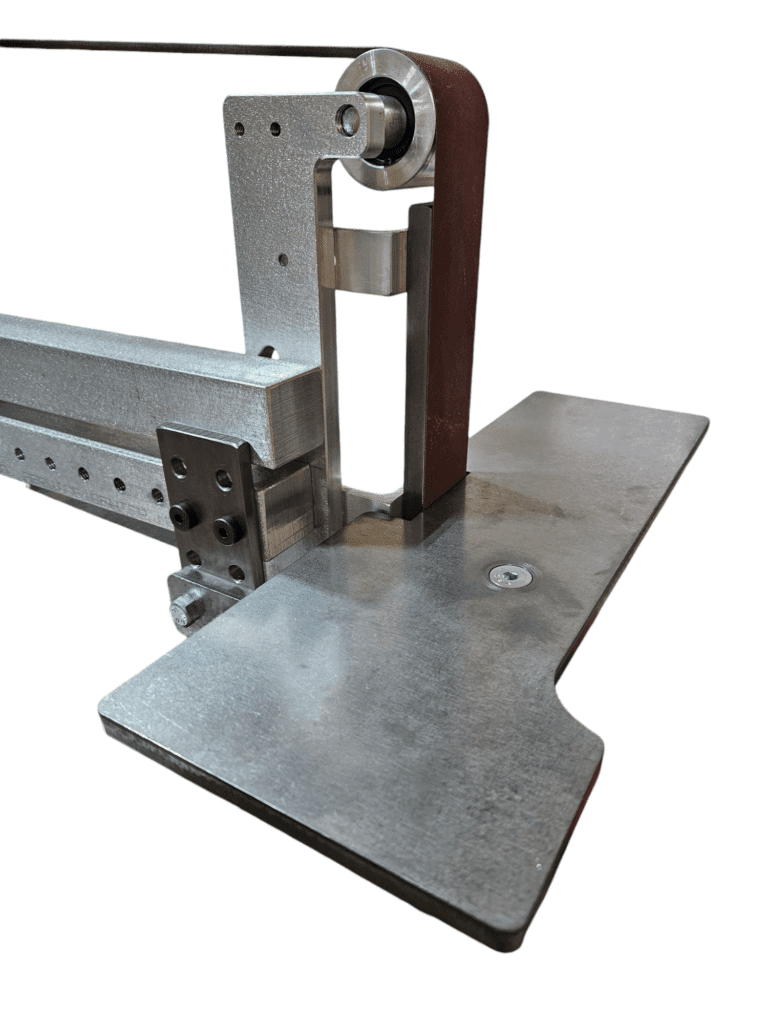

A 2×72 grinder is an essential tool for many metalworkers, woodworkers, and knife makers. Its versatility and efficiency make it a staple in workshops across various industries. The term “2×72” refers to the size of the sanding belt used, which is two inches wide and seventy-two inches long.

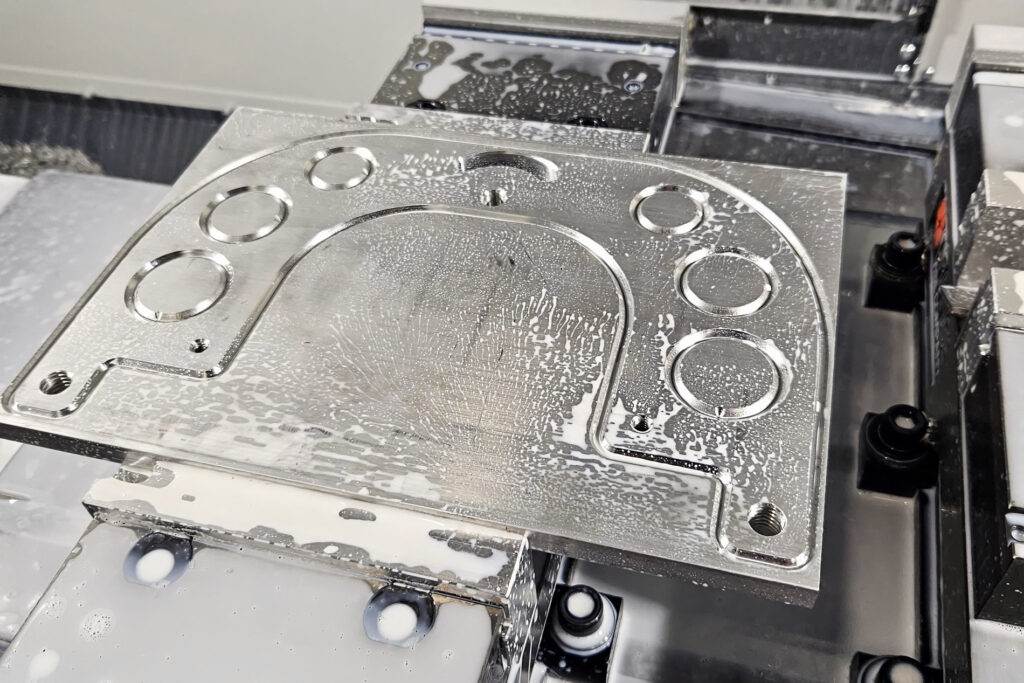

This specific size allows for a wide range of applications, from shaping and sharpening to polishing and finishing. Understanding the basic components of your grinder is crucial for maximizing its potential and ensuring optimal performance. At the heart of the 2×72 grinder is the motor, which powers the belt and determines the speed at which it operates.

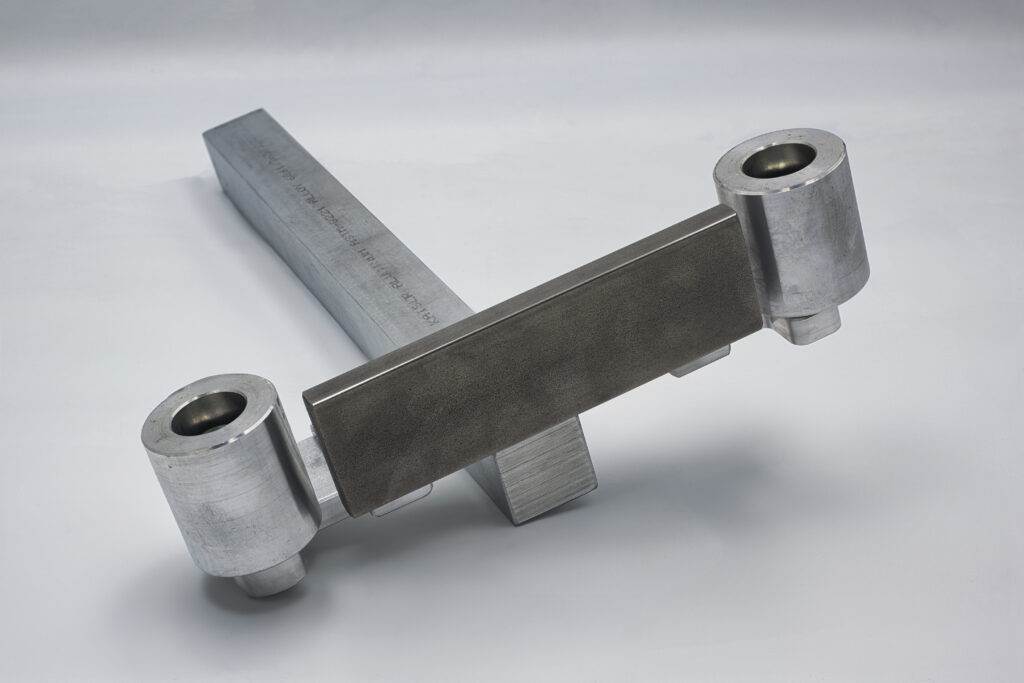

The speed can significantly affect the material removal rate and the quality of the finish. Additionally, the frame of the grinder provides stability and support, allowing for precise control during operation. Familiarizing yourself with these components, along with the various attachments and accessories available, will enable you to utilize your TorusCNC 2×72 Grinder effectively.

Knowing how to adjust settings and switch out belts for different tasks can enhance your workflow and improve your results.

Key Takeaways

- Understanding the basics of your 2×72 grinder is essential for safe and effective operation.

- Regular cleaning and lubrication of your grinder will help maintain its performance and longevity.

- Checking and replacing wear parts is crucial to prevent damage and ensure smooth operation.

- Properly adjusting and aligning the tool rest is important for accurate and safe grinding.

- Maintaining the motor and belts will help prevent breakdowns and ensure consistent performance.

Regular Cleaning and Lubrication

Maintaining a clean workspace is vital for any tool, and the 2×72 grinder is no exception. Regular cleaning not only prolongs the life of your equipment but also ensures that it operates efficiently. Dust and debris can accumulate on the grinder’s components, leading to potential malfunctions or decreased performance.

After each use, take a moment to wipe down the machine, removing any metal shavings or dust that may have settled on the frame or motor. This simple practice can prevent buildup that could interfere with the grinder’s operation. Lubrication is another critical aspect of maintenance that should not be overlooked.

The moving parts of your TorusCNC 2×72 Grinder require proper lubrication to function smoothly. Regularly check the bearings and other pivot points for signs of wear or dryness. Applying a suitable lubricant can reduce friction, minimize wear, and extend the lifespan of these components.

Establishing a routine for cleaning and lubrication will help keep your grinder in top condition, ensuring it remains a reliable tool in your workshop.

Checking and Replacing Wear Parts

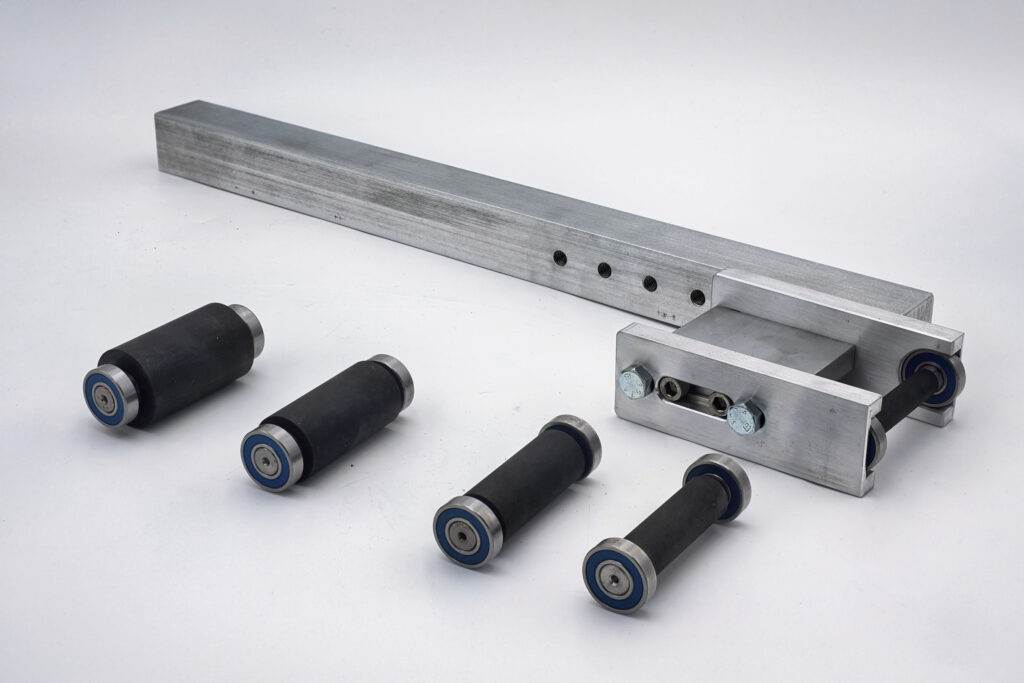

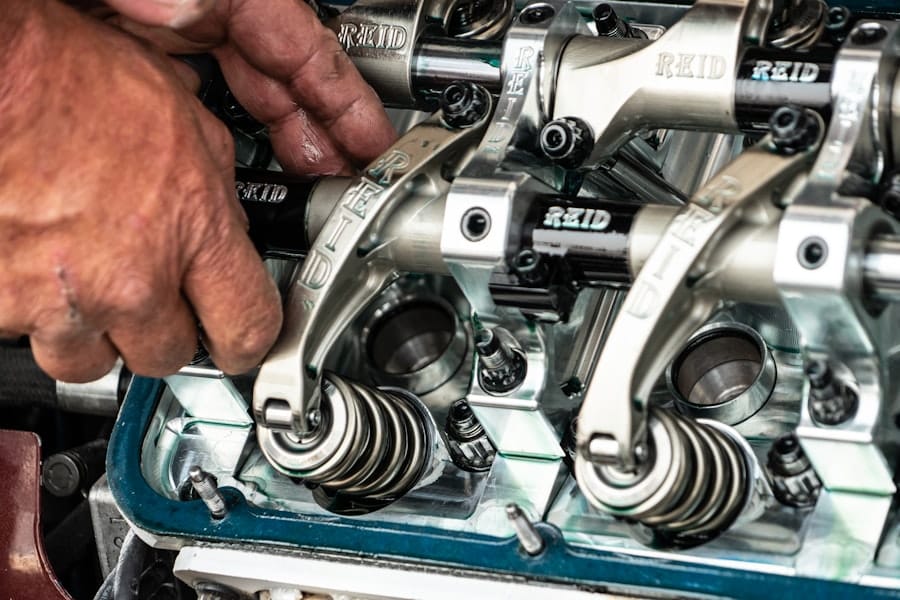

Over time, certain parts of your 2×72 grinder will experience wear due to constant use. Identifying these wear parts and replacing them as needed is essential for maintaining optimal performance. Common wear parts include belts, bearings, and wheels.

The sanding belt, in particular, will show signs of wear through fraying or reduced effectiveness in material removal. Regularly inspecting the belt for damage will help you determine when it needs to be replaced. Bearings are another critical component that can wear out over time.

If you notice unusual noises or vibrations while operating your grinder, it may be time to check the bearings for wear or damage. Replacing worn bearings promptly can prevent further issues and ensure smooth operation. By staying vigilant about checking and replacing these wear parts, you can maintain the efficiency of your TorusCNC 2×72 Grinder and avoid costly repairs down the line.

Adjusting and Aligning the Tool Rest

| Adjustment/Metric | Value |

|---|---|

| Tool Rest Height | 5 inches |

| Tool Rest Angle | 30 degrees |

| Tool Rest Distance from Wheel | 1/8 inch |

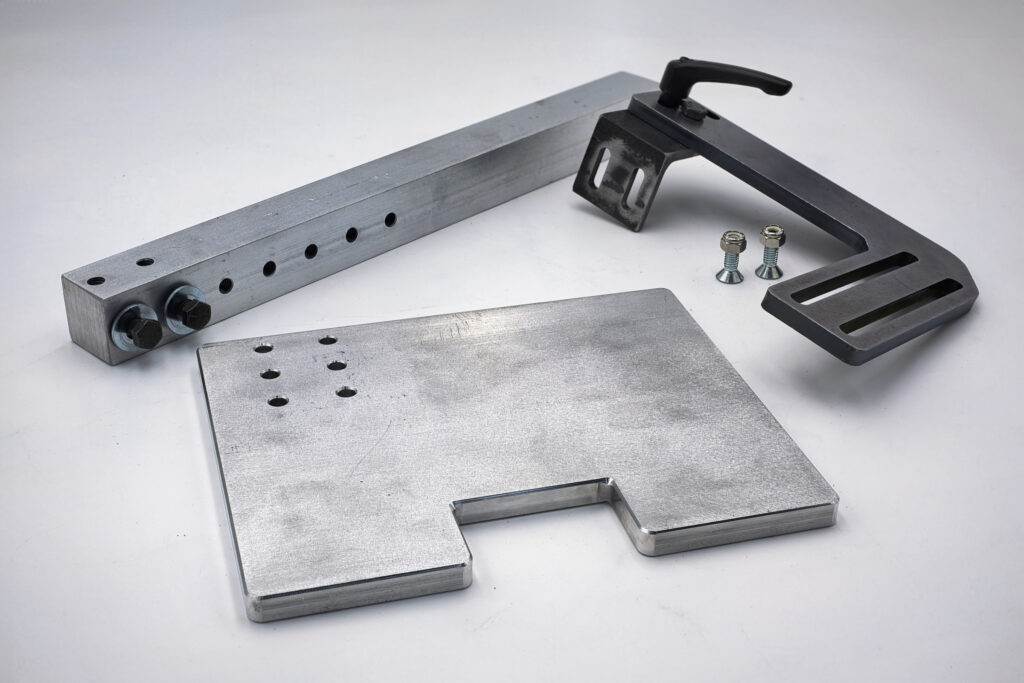

The tool rest on your 2×72 grinder plays a significant role in achieving accurate results during grinding operations. Proper alignment of the tool rest is essential for ensuring that your workpiece is held securely and at the correct angle. If the tool rest is misaligned, it can lead to uneven grinding or even damage to both the workpiece and the grinder itself.

Regularly checking the alignment of the tool rest should be part of your maintenance routine. To adjust the tool rest, start by loosening any locking mechanisms that hold it in place. Position it so that it is parallel to the belt and at a comfortable height for your working style.

Once you have made adjustments, tighten the locking mechanisms securely to prevent any movement during operation. Taking the time to ensure that your tool rest is properly aligned will enhance your grinding accuracy and contribute to better overall results.

Maintaining the Motor and Belts

The motor is arguably one of the most critical components of your 2×72 grinder, as it provides the power necessary for operation. Regular maintenance of the motor is essential to ensure its longevity and efficiency. Start by checking for any signs of overheating or unusual noises during operation.

If you notice any irregularities, it may be time to inspect the motor for potential issues such as loose connections or worn-out components. In addition to motor maintenance, keeping an eye on the belts is equally important. The belts are responsible for transferring power from the motor to the grinding surface, so any wear or damage can significantly impact performance.

Inspect belts regularly for signs of fraying or cracking, and replace them as needed to maintain optimal functionality. By prioritizing both motor and belt maintenance, you can ensure that your TorusCNC 2×72 Grinder operates smoothly and efficiently.

Monitoring the Tracking and Tension

Identifying Tracking Issues

Regularly monitoring the tracking will help you identify any issues early on, preventing potential problems.

Adjusting Tracking and Tension

To adjust tracking, most grinders have a mechanism that allows you to shift the position of the belt slightly until it runs true along its path. Tension is another important factor that affects belt performance. A belt that is too loose may slip during operation, while one that is too tight can cause excessive wear on both the belt and motor components.

Achieving Consistent Performance

Finding the right balance is key; refer to your TorusCNC 2×72 Grinder’s manual for specific guidelines on how to adjust tension properly. By keeping a close eye on both tracking and tension, you can ensure consistent performance from your grinder.

Upgrading and Customizing Your Grinder

One of the appealing aspects of owning a 2×72 grinder is its potential for upgrades and customization. Many users choose to enhance their grinders with various attachments or modifications tailored to their specific needs. For instance, adding a variable speed control can provide greater flexibility in adjusting grinding speeds based on different materials or tasks.

This feature allows for more precise control over your work, leading to improved results. Additionally, consider investing in different types of belts designed for specific applications—such as ceramic belts for aggressive material removal or finer belts for polishing tasks. Customizing your TorusCNC 2×72 Grinder with these options can significantly enhance its versatility and performance in your workshop.

Exploring various upgrades not only improves functionality but also allows you to tailor your equipment to suit your unique crafting style.

Troubleshooting Common Issues

Even with diligent maintenance, issues may occasionally arise with your 2×72 grinder. Being prepared to troubleshoot common problems can save you time and frustration in your workshop. One frequent issue is overheating during prolonged use; if this occurs, allow the motor to cool down before continuing operation.

Additionally, ensure that ventilation around the motor is adequate to prevent overheating in future sessions. Another common problem involves belt slippage or misalignment during operation. If you notice this happening frequently, double-check both tracking and tension settings as previously discussed.

Ensuring that these parameters are correctly set can often resolve slippage issues quickly. By familiarizing yourself with these troubleshooting techniques, you can maintain productivity in your workshop while ensuring that your TorusCNC 2×72 Grinder remains a reliable tool for all your crafting needs.

FAQs

What is a 2×72 grinder?

A 2×72 grinder is a type of belt grinder commonly used in metalworking and knife making. It features a 2-inch by 72-inch belt for grinding, shaping, and polishing metal.

Why is maintenance important for a 2×72 grinder?

Regular maintenance is important for keeping a 2×72 grinder running at peak performance. It helps prevent wear and tear, ensures safety, and prolongs the lifespan of the machine.

What are some essential maintenance tips for a 2×72 grinder?

Some essential maintenance tips for a 2×72 grinder include keeping the machine clean, checking and tightening bolts and fasteners, lubricating moving parts, inspecting the electrical components, and replacing worn-out or damaged parts.

How often should maintenance be performed on a 2×72 grinder?

Maintenance should be performed on a 2×72 grinder on a regular basis, depending on the frequency of use and the operating conditions. It is recommended to perform basic maintenance tasks after each use and more thorough maintenance at regular intervals.

What are the consequences of neglecting maintenance on a 2×72 grinder?

Neglecting maintenance on a 2×72 grinder can lead to decreased performance, increased risk of accidents, and premature wear and tear on the machine. It can also result in higher repair costs and downtime.