Micro tracking is an essential technique in various fields, including manufacturing, audio engineering, and robotics, where precision is paramount. This method allows for minute adjustments that can significantly impact the overall performance of a system. In many cases, the tools used for micro tracking can be enhanced through modifications, particularly with dial knobs.

Dial knobs serve as the primary interface for users to make these fine adjustments, and their design can greatly influence the ease and accuracy of micro tracking. Modifying dial knobs can transform a standard tool into a highly efficient instrument for fine-tuning. These modifications can range from simple aesthetic changes to complex mechanical enhancements that improve functionality.

As industries continue to evolve and demand higher precision, the importance of effective micro tracking and the role of dial knob modifications cannot be overstated. This article will delve into the significance of fine-tuning in micro tracking, explore the limitations of standard dial knobs, and discuss the benefits and methods of modifying these knobs for optimal performance.

Key Takeaways

- Micro tracking and dial knob mods are essential for fine-tuning precision in various industries.

- Fine-tuning in micro tracking is crucial for achieving accurate and reliable results in data collection and analysis.

- Standard dial knobs have limitations in providing the level of precision required for micro tracking applications.

- Modifying dial knobs for fine-tuning in micro tracking offers benefits such as increased accuracy and improved control.

- Different types of dial knob mods, such as digital and precision knobs, cater to specific micro tracking needs and applications.

Understanding the Importance of Fine-Tuning in Micro Tracking

Fine-tuning in micro tracking is crucial because it allows operators to achieve the highest level of accuracy in their work. Whether adjusting a machine tool, calibrating audio equipment, or fine-tuning a robotic arm, the ability to make precise adjustments can mean the difference between success and failure. In manufacturing, for instance, even a slight deviation in measurements can lead to defective products, resulting in wasted materials and increased costs.

Therefore, mastering the art of fine-tuning is essential for maintaining quality control and ensuring operational efficiency. Moreover, fine-tuning enhances the overall user experience by providing greater control over the equipment being used. When operators can make minute adjustments with confidence, they are more likely to achieve their desired outcomes.

This level of precision not only improves productivity but also fosters innovation as users experiment with new techniques and applications. As industries continue to push the boundaries of what is possible, the role of fine-tuning in micro tracking will only become more significant.

Exploring the Limitations of Standard Dial Knobs in Micro Tracking

While standard dial knobs are designed to facilitate adjustments, they often come with inherent limitations that can hinder effective micro tracking. One major drawback is the lack of tactile feedback; many standard knobs do not provide sufficient resistance or feedback when turned, making it difficult for users to gauge how much they are adjusting their settings. This can lead to over-adjustments or under-adjustments, ultimately compromising precision.

Additionally, standard dial knobs may not offer enough range or granularity for fine-tuning applications. In scenarios where minute adjustments are necessary, a standard knob may not allow for the level of control required. This limitation can be particularly frustrating in high-stakes environments where accuracy is critical.

As a result, users may find themselves struggling to achieve their desired settings, leading to inefficiencies and potential errors in their work.

The Benefits of Modifying Dial Knobs for Fine-Tuning in Micro Tracking

Modifying dial knobs presents numerous advantages that can significantly enhance the micro tracking process. One of the primary benefits is improved precision. By customizing the design and functionality of dial knobs, users can achieve finer control over their adjustments.

This increased precision allows for more accurate settings, which is especially important in fields where even minor discrepancies can have substantial consequences. Another advantage of modified dial knobs is enhanced user experience. Custom modifications can include features such as textured grips or ergonomic designs that make it easier for users to manipulate the knobs with confidence.

Additionally, modifications can incorporate visual indicators or detents that provide clear feedback on adjustments made. These enhancements not only improve usability but also empower users to engage more effectively with their equipment, ultimately leading to better outcomes in their work.

Different Types of Dial Knob Mods for Micro Tracking

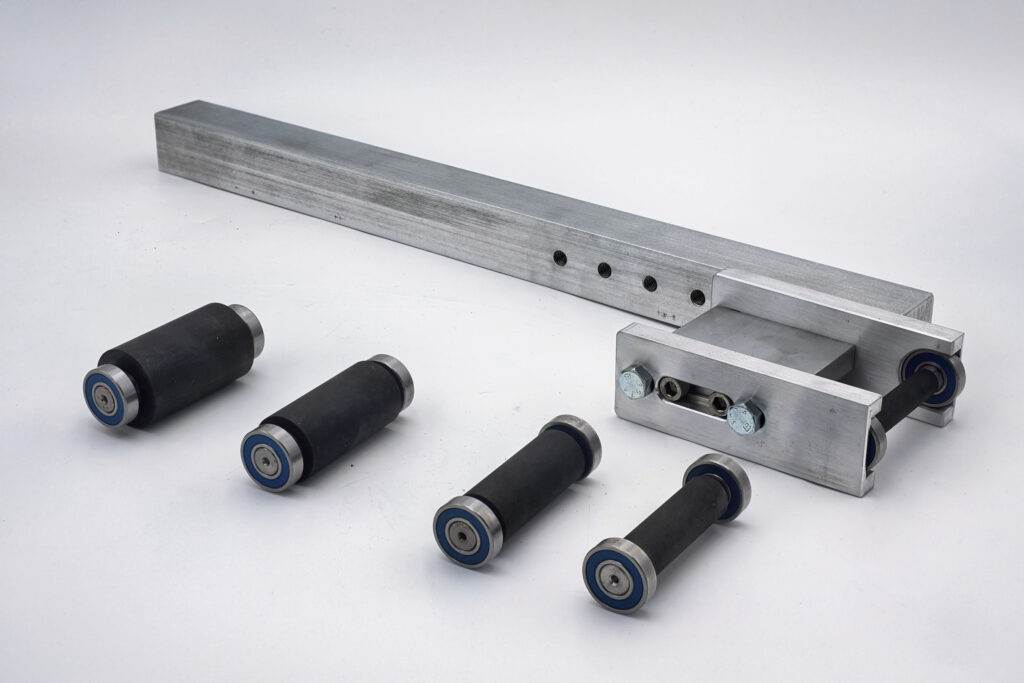

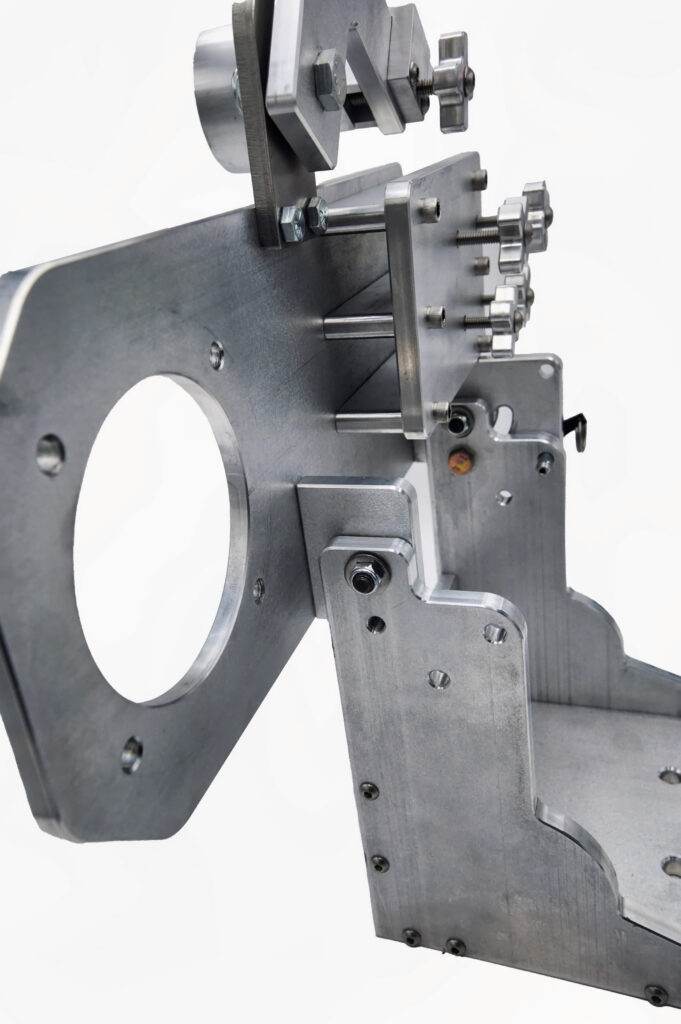

There are various types of dial knob modifications that can be implemented to improve micro tracking capabilities. One common modification involves changing the material or texture of the knob itself. For instance, replacing a smooth plastic knob with one made from rubber or metal can provide better grip and tactile feedback, allowing for more precise adjustments.

Another popular modification is the addition of visual indicators or markings on the dial knob. These indicators can help users quickly identify specific settings or adjustments made, reducing the likelihood of errors during operation. Furthermore, some modifications may involve altering the internal mechanics of the knob to create a more defined resistance when turning, which can enhance control during fine-tuning processes.

Step-by-Step Guide to Modifying Dial Knobs for Fine-Tuning

Modifying dial knobs for fine-tuning requires careful planning and execution to ensure optimal results. The first step is to assess the existing dial knob and identify its limitations. This evaluation will help determine which modifications will be most beneficial for your specific needs.

Once you have identified the necessary changes, gather the required tools and materials for the modification process. Depending on your chosen modifications, you may need items such as replacement knobs, adhesives, or specialized tools for reshaping or resizing components. After preparing your workspace and ensuring you have everything you need, proceed with the modifications carefully.

Begin by removing the existing dial knob from its base. This may involve unscrewing it or gently prying it off, depending on its design. Once removed, you can make any necessary alterations, such as reshaping or adding new materials for improved grip.

After completing your modifications, reattach the knob securely and test its functionality to ensure it meets your expectations.

Tips for Choosing the Right Dial Knob Mods for Your Micro Tracking Needs

When selecting dial knob modifications for micro tracking applications, it is essential to consider several factors to ensure you make informed choices. First and foremost, assess your specific requirements based on the tasks you will be performing. Different applications may necessitate varying levels of precision and control; therefore, understanding your needs will guide your selection process.

Additionally, consider the compatibility of any modifications with your existing equipment. Not all knobs will fit every device seamlessly; therefore, it is crucial to verify that any new components will work well with your current setup. Finally, prioritize quality when choosing materials and designs for your modified dial knobs.

High-quality components will not only enhance performance but also ensure durability over time.

Common Mistakes to Avoid When Modifying Dial Knobs for Fine-Tuning

While modifying dial knobs can yield significant benefits, there are common pitfalls that individuals should avoid during this process. One frequent mistake is rushing through the modification without thoroughly assessing existing limitations or requirements. Taking time to evaluate your needs will lead to more effective modifications tailored to your specific applications.

Another common error is neglecting compatibility issues between modified components and existing equipment. Failing to ensure that new knobs fit properly can lead to frustration and wasted resources. Additionally, some individuals may overlook the importance of testing modified knobs after installation; this step is crucial for confirming that adjustments have improved functionality as intended.

Case Studies: How Dial Knob Mods Have Improved Micro Tracking for Different Industries

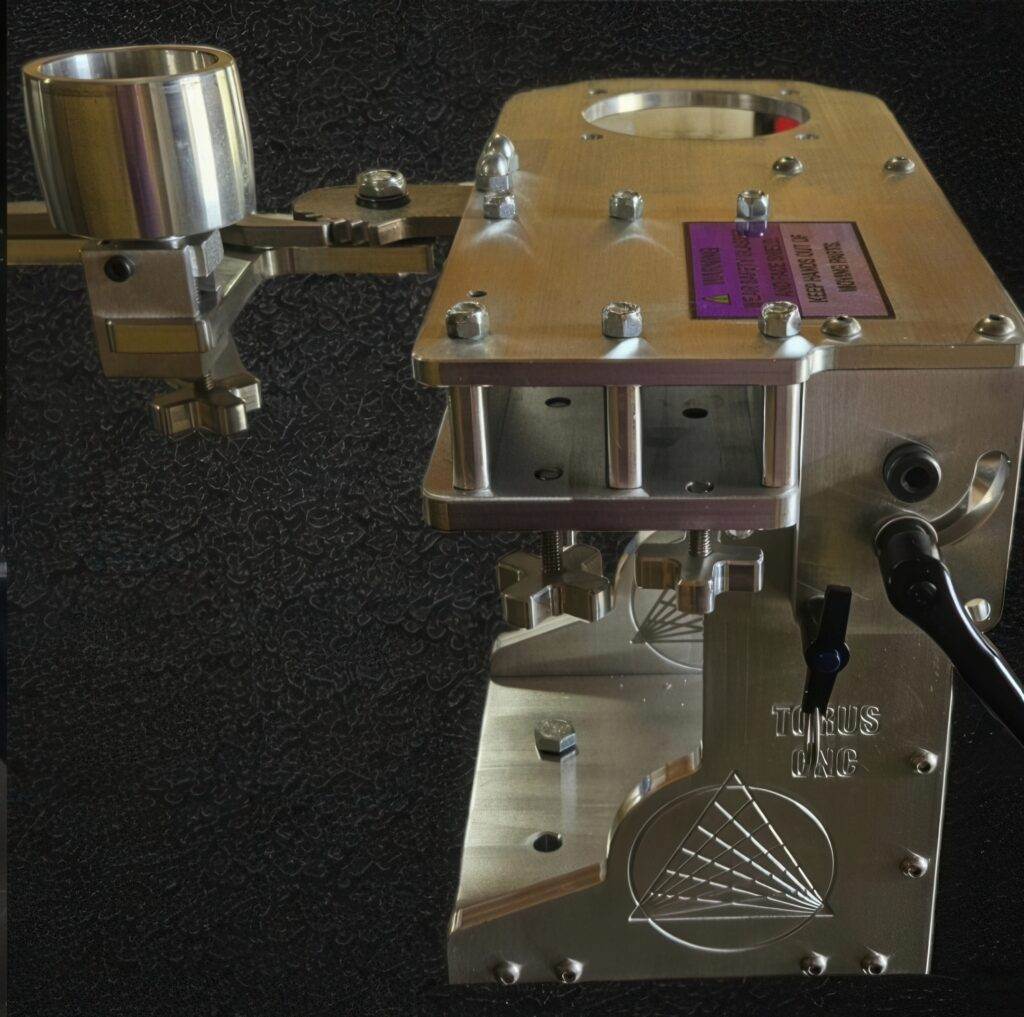

In various industries, modified dial knobs have proven instrumental in enhancing micro tracking capabilities. For example, in audio engineering, professionals have reported significant improvements in sound quality after upgrading standard knobs with custom-designed alternatives that offer better tactile feedback and precision control over levels and frequencies. Similarly, in manufacturing settings where CNC machines are prevalent, operators have found that modified dial knobs allow for finer adjustments during machining processes.

By incorporating features such as detents or visual indicators on their knobs, machinists can achieve greater accuracy in their work while minimizing errors associated with standard equipment.

Future Trends in Dial Knob Mods for Fine-Tuning Micro Tracking

As technology continues to advance, so too will the possibilities for dial knob modifications in micro tracking applications. One emerging trend is the integration of smart technology into dial knobs, allowing users to connect their devices via Bluetooth or other wireless methods for real-time monitoring and adjustments. This innovation could revolutionize how operators interact with their equipment by providing instant feedback on settings and performance.

Additionally, advancements in materials science may lead to new options for creating more durable and responsive dial knobs that enhance user experience further. As industries demand higher precision and efficiency levels, these trends will likely shape the future landscape of micro tracking tools and techniques.

The Impact of Fine-Tuning Micro Tracking with Dial Knob Mods

In conclusion, fine-tuning micro tracking through dial knob modifications offers significant advantages across various industries. By addressing the limitations of standard knobs and implementing thoughtful enhancements, users can achieve greater precision and control over their equipment. The benefits extend beyond improved performance; they also foster a more engaging user experience that encourages innovation and experimentation.

As technology continues to evolve, so too will the opportunities for enhancing micro tracking capabilities through dial knob mods. By staying informed about emerging trends and best practices in this area, professionals can ensure they remain at the forefront of their respective fields while maximizing efficiency and accuracy in their work.

FAQs

What are fine adjust dial knob mods for micro tracking tweaks?

Fine adjust dial knob mods are modifications made to the dial knobs on electronic devices, such as audio equipment or cameras, to allow for more precise and delicate adjustments. These mods are often used for micro tracking tweaks, which involve making very small and precise adjustments to the tracking or alignment of a device.

How do fine adjust dial knob mods work?

Fine adjust dial knob mods typically involve replacing the existing dial knobs with ones that have a finer degree of control. This can be achieved by using different materials, changing the gear ratio, or adding additional components to the dial knob mechanism. These modifications allow for more precise and delicate adjustments to be made.

What are the benefits of using fine adjust dial knob mods for micro tracking tweaks?

The main benefit of using fine adjust dial knob mods for micro tracking tweaks is the ability to make very small and precise adjustments to the tracking or alignment of a device. This can be particularly useful in situations where a high level of precision is required, such as in professional audio recording or photography.

Are there any risks or drawbacks to using fine adjust dial knob mods?

There can be risks and drawbacks to using fine adjust dial knob mods, particularly if the modifications are not done correctly. Improperly modified dial knobs may not function as intended, or could potentially damage the device. Additionally, making modifications to electronic devices may void warranties or violate manufacturer agreements.

Where can I find fine adjust dial knob mods for micro tracking tweaks?

Fine adjust dial knob mods can often be found through specialized retailers or online marketplaces that cater to enthusiasts and professionals in fields such as audio engineering, photography, and videography. Additionally, some individuals may offer custom modification services for specific devices.