What 2×72 Belt Grinder Should I Buy? (2025 Buyer’s Guide for Knife Makers)

If you’re getting into knife making—or leveling up your shop—one of the biggest questions you eventually hit is: What 2×72 grinder should I buy? With so many models and opinions out there, it’s hard to know what actually matters and what’s just noise. This guide breaks everything down in a straightforward, practical way, written from a knifemaker’s perspective rather than a big marketing department.

Why a 2×72 Grinder Matters

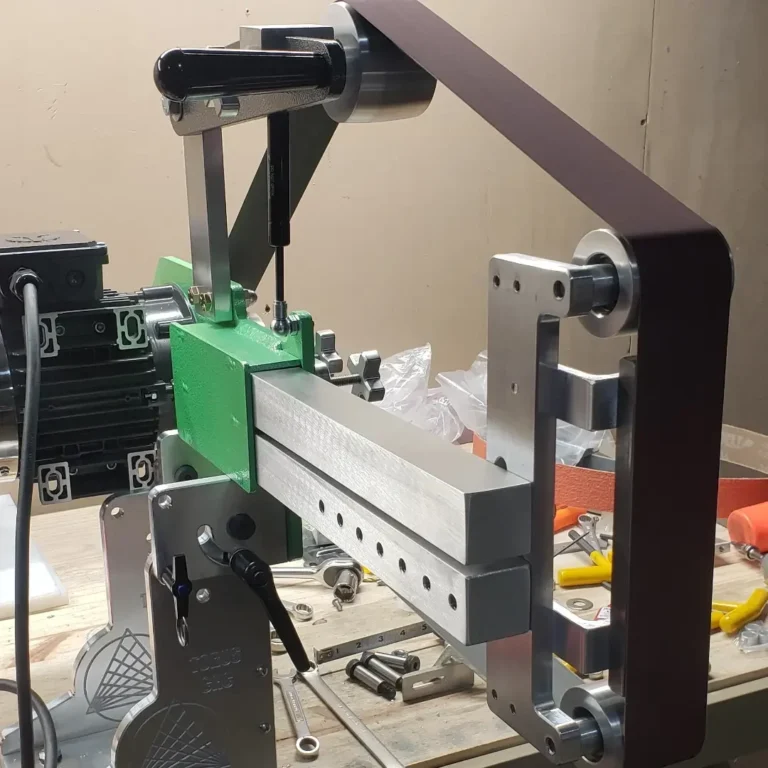

A 2×72 belt grinder is the workhorse of a knife shop. It shapes bevels, cleans profiles, removes scale after heat treat, flattens surfaces, and handles finishing work. If the grinder is built well, knife making becomes more enjoyable. If it’s not, you end up fighting the machine the entire time.

This is one of those tools where choosing the right one makes a huge difference.

The Four Tiers of 2×72 Grinders

After years of watching makers buy, upgrade, and outgrow equipment, the market naturally falls into four categories.

Tier 1 — Professional, Precision-Level Grinders

These are the top grinders used by serious knife makers, schools, and full-time shops. They’re designed for smooth tracking, rigidity, precision, and versatility.

Want to see how Torus stacks up against other major brands?

Check out our 2025 2×72 Grinder Comparison Chart

This tier includes respected names like:

- Torus CNC 2×72

- Brodbeck Ironworks

- HouseMade (Revolution 2×72)

- AmeriBrade

- Burr King

- Wuertz Machine Works TW90

- KMG (Beaumont Metal Works)

- Pheer

- Black Fox

- AMK

- Esteem Grinders

These machines usually offer:

- Rigid CNC-machined or heavy steel frames

- Very stable, predictable tracking

- Tool-less belt changes

- Multiple tooling arm options

- Horizontal and vertical grinding positions

- High-quality wheels and bearings

- Real customer support and long-term parts availability

This is the “buy once, cry once” category!

Tier 2 — Mid-Range Hobbyist Grinders

These grinders are solid for hobbyists and weekend makers. They can produce excellent knives, but they may show limitations over time.

They tend to have:

- Welded frames

- Basic tracking systems

- Fewer attachment options

- More vibration

- Lower-cost hardware

- Less refined

A good starting point if you’re testing the waters, but most people eventually upgrade.

Tier 3 — DIY Kits and Budget Grinders

These are commonly discussed in forums and maker groups. They can grind steel, but you’ll work harder to get clean results.

Expect:

- Noticeable vibration

- Less accurate tracking

- Limited adjustability

- Minimal accessories

- Shorter lifespan components

- Less fun to use

These are great for tinkerers or makers building on a tight budget.

Tier 4 — Amazon and No-Name Imports

If a “2×72 grinder” is listed under $700 from an unknown brand, it’s not a true 2×72 in the sense that knifemakers mean it. These usually come with poor tracking, weak motors, and limited adjustability. Not recommended if you want to enjoy knife making.

So Which Grinder Should You Actually Buy?

Here’s the straightforward answer:

If you want to make high-quality knives, improve quickly, and enjoy the craft

Buy a Tier 1 grinder.

This is the right tool for long-term growth, clean bevels, freedom to expand, and frustration-free grinding.

That’s where the Torus 2×72 fits—rigid construction, smooth tracking, fast belt changes, tilt capability, quality wheels, and an expanding ecosystem of attachments.

If you’re unsure whether you’ll stick with the hobby

A Tier 2 grinder will get you started, but you’ll likely want to upgrade later.

If you want the best value for serious work

A USA-made, CNC-machined grinder like the Torus 2×72 strikes the balance between premium performance and accessible pricing.

The Features That Actually Matter

A lot of marketing fluff gets thrown around in this space, so here are the features that truly make a difference:

Tracking Stability

Your bevels rely on this. Good tracking equals predictable results; poor tracking leads to frustration and wasted belts.

Frame Rigidity

A flexing grinder washes out bevels and ruins precision. CNC-machined aluminum or thick steel frames are ideal.

Tooling Arm System

The more modular your arms, the more attachments you can use. Modularity adds capability.

Horizontal and Vertical Tilt

This dramatically expands what you can do—handle shaping, sculpting, detail grinding, deburring, and finishing.

Wheel Quality

Good wheels reduce vibration, noise, and premature bearing failure.

Motor and VFD

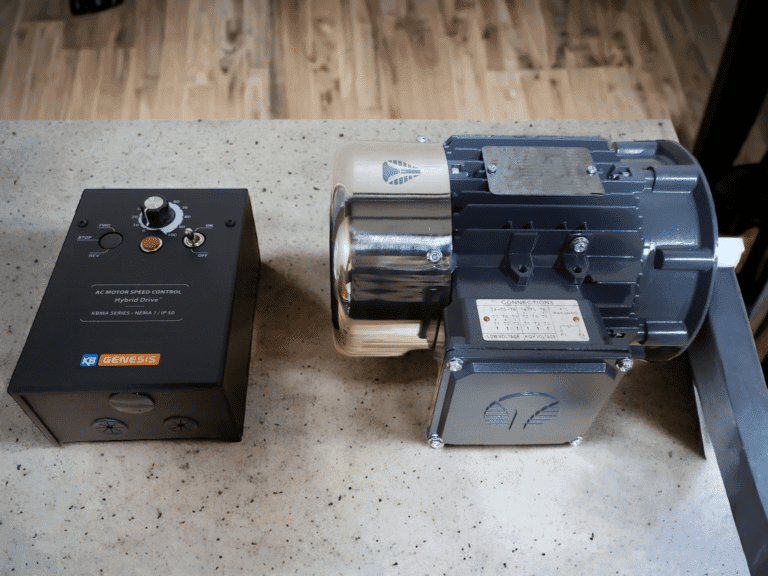

A 1.5 to 2 horsepower motor with variable speed gives you full control, from heavy stock removal down to finishing work.

Why Many Makers Choose Torus CNC

Knife makers choose the Torus 2×72 for several reasons:

- CNC-machined aluminum chassis for serious rigidity and corrosion resistance

- Exceptionally stable tracking

- Quick and smooth belt changes

- Vertical and horizontal operation

- A growing line of attachments and accessories

- Made in the USA

- Clear assembly guides and video walk-throughs

- Strong customer support

- High performance without the premium-tier price tag

It’s a grinder built for makers who want reliable, repeatable results without overspending.

Final Answer: What’s the Best 2×72 Grinder?

If you want to grow as a knife maker, build better blades, and enjoy the process, invest in a Tier 1 grinder. Look for:

- A rigid, precision-built frame

- Excellent tracking

- Quality wheels

- A tilt system

- Modular tooling arms

- Variable speed

- Dependable support

For many makers, a well-designed machine like the Torus 2×72 offers the best balance of performance, price, and long-term value.

The right grinder doesn’t just shape steel.

It shapes your entire knife making experience.