Are 2×72 Belt Grinders Really Worth It?

If you’ve ever lurked on knife-making forums or scrolled through community threads, you’ve seen the question pop up time and time again: “Are 2×72 belt grinders really worth it?”

Let’s keep it simple—yes. If you’re shaping steel regularly, a 2×72 belt grinder is one of the smartest tools you can add to your shop. It’s not just about speed (though they’re fast). It’s about control, versatility, and the ability to dial in clean, consistent results whether you’re a weekend bladesmith or running a full-time shop.

Why Size Matters

- More working surface on the belt – Better for beveling, profiling, and handle work.

- Higher belt speeds – Faster stock removal without excessive heat buildup.

- More abrasive options – 2×72 belts are standard in the industry, so you get more variety at better prices.

Once you experience smoother tracking, cleaner grinds, and less belt waste, it’s hard to imagine going back to anything else.

Why I Built the Torus 2×72

We designed the Torus 2×72 because makers like you needed more:

More rigidity. More precision. More value.

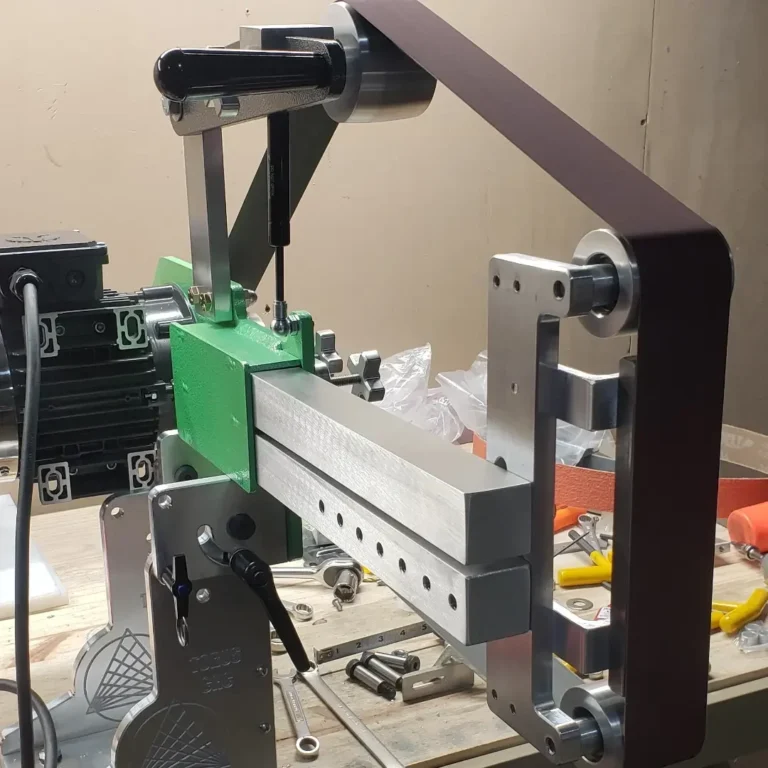

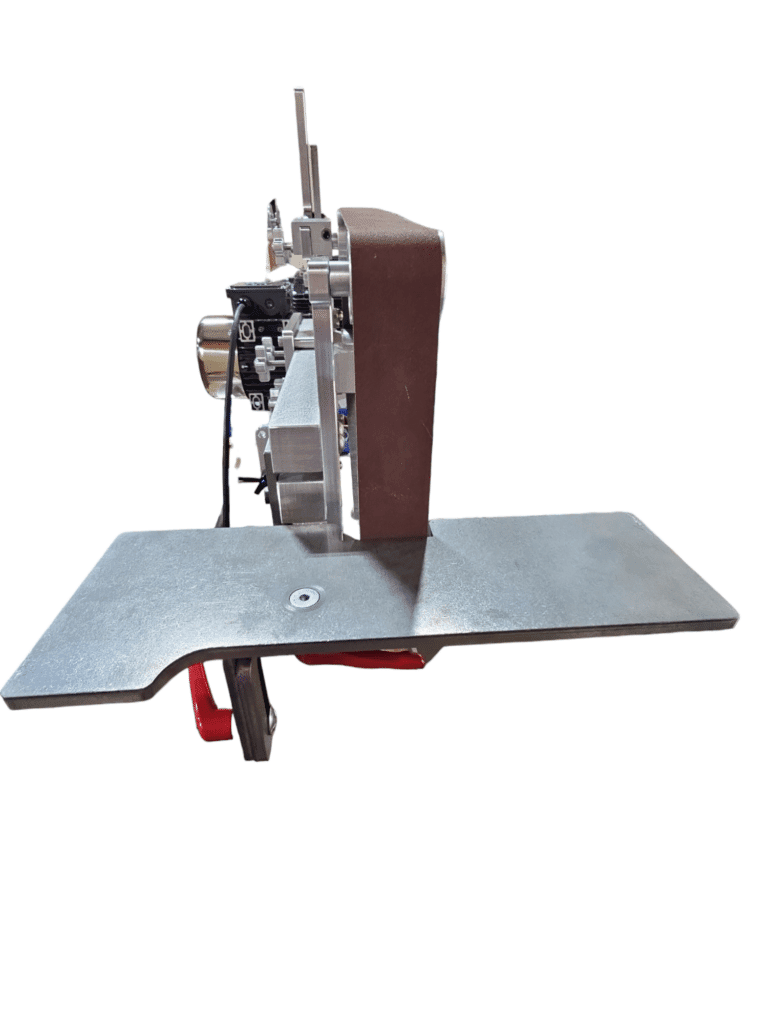

Each grinder is CNC-machined in the USA using premium aluminum and steel components. It’s built for real-world knife shops—with smart features like precise tracking, rock-solid construction, and a modular layout that grows with you.

And while some brands inflate their prices for bells and whistles, we keep our pricing competitive without cutting corners. That’s why the Torus has become the go-to choice for knife makers who expect more—and want a grinder that can keep up.

🔧 Key Takeaways

- 2×72 grinders offer superior control, speed, and flexibility for serious knife making.

- The Torus 2×72 delivers pro-level performance, tight tolerances, and top-shelf materials.

- Designed, machined, and assembled in the USA.

👉 Check out the Torus 2×72 here and see why so many makers are making the switch.