Vertical and horizontal grinding are two distinct methods that offer unique advantages in various machining applications. Vertical grinding typically involves the workpiece being held stationary while the grinding wheel rotates around it. This method is particularly effective for achieving precision on flat surfaces and is often favored for its ability to produce fine finishes.

The vertical orientation allows for better chip removal, reducing the risk of clogging and overheating, which can compromise the quality of the finished product. Additionally, vertical grinders are often more compact, making them suitable for smaller workshops or facilities with limited space. On the other hand, horizontal grinding presents its own set of benefits.

In this configuration, the workpiece is rotated while the grinding wheel remains stationary, allowing for a different approach to material removal. Horizontal grinders excel in processing larger and heavier components, as they can accommodate more substantial workpieces without compromising stability. This method is particularly advantageous for tasks that require significant material removal or when working with complex geometries.

The versatility of horizontal grinding makes it an essential technique in industries where diverse machining tasks are commonplace.

Key Takeaways

- Understanding the benefits of vertical and horizontal grinding:

- Vertical grinding allows for precise control and accuracy, while horizontal grinding is ideal for heavy-duty material removal.

- The Importance of a versatile grinder:

- A versatile grinder can handle a wide range of materials and applications, increasing efficiency and productivity.

- Key features to look for in a grinder with tilt capability:

- Look for a sturdy and reliable tilt mechanism, adjustable speed settings, and easy-to-use controls.

- Step-by-step guide to switching your grinder from vertical to horizontal:

- Follow manufacturer instructions carefully, secure the workpiece properly, and make sure the grinder is stable before switching positions.

- Tips for ensuring smooth and effortless tilt functionality:

- Keep the grinder clean and well-maintained, use the appropriate accessories, and practice proper technique to ensure smooth tilt functionality.

- Safety precautions when adjusting your grinder:

- Always wear appropriate safety gear, keep hands and clothing clear of moving parts, and never force the grinder into position.

- Common mistakes to avoid when using tilt functionality:

- Avoid overloading the grinder, neglecting maintenance, and using the wrong accessories for the tilt function.

- Maximizing efficiency with vertical and horizontal grinding:

- Utilize the appropriate grinding method for the task at hand, adjust speed and pressure as needed, and maintain a consistent feed rate.

- Innovative applications for tilt-enabled grinders:

- Tilt-enabled grinders can be used for beveling, edge profiling, and other specialized tasks that require precise angle adjustments.

- Maintenance and care for tilt-enabled grinders:

- Regularly clean and inspect the tilt mechanism, lubricate moving parts, and replace worn components to ensure optimal performance.

- Choosing the right tilt-enabled grinder for your needs:

- Consider the materials you will be working with, the type of applications you will be performing, and the level of precision and control required when selecting a tilt-enabled grinder.

The Importance of a Versatile Grinder

A versatile grinder is an invaluable asset in any machining environment, as it can adapt to a wide range of tasks and materials. The ability to switch between vertical and horizontal grinding not only enhances productivity but also allows operators to tackle various projects without needing multiple machines. This adaptability can lead to significant cost savings, as businesses can invest in a single piece of equipment that meets multiple needs rather than purchasing separate machines for each grinding method.

Moreover, a versatile grinder can improve workflow efficiency. When operators can seamlessly transition between different grinding orientations, they can reduce downtime associated with setup changes. This flexibility enables manufacturers to respond quickly to changing production demands, whether they need to process small batches of custom parts or large volumes of standardized components.

Ultimately, investing in a versatile grinder can lead to increased competitiveness in the market by allowing businesses to take on a broader range of projects with greater ease.

Key Features to Look for in a Grinder with Tilt Capability

When selecting a grinder with tilt capability, several key features should be considered to ensure optimal performance and usability. First and foremost, the tilt mechanism itself should be robust and easy to operate. A reliable tilt system allows for smooth transitions between vertical and horizontal positions without requiring excessive force or complicated adjustments.

Look for grinders that incorporate precision engineering in their tilt mechanisms, as this will contribute to consistent performance over time. Another important feature is the range of tilt angles available. A grinder that offers multiple tilt settings can provide greater flexibility in achieving specific grinding tasks.

This versatility allows operators to fine-tune their approach based on the workpiece’s geometry and the desired finish. Additionally, consider the overall build quality of the grinder, including the materials used in its construction. A well-built machine will not only withstand the rigors of daily use but also maintain accuracy and precision throughout its lifespan.

Step-by-Step Guide to Switching Your Grinder from Vertical to Horizontal

Switching your grinder from vertical to horizontal orientation may seem daunting at first, but following a systematic approach can simplify the process. Begin by ensuring that the machine is powered off and unplugged to prevent any accidental activation during the adjustment. Next, consult the manufacturer’s manual for specific instructions related to your grinder model, as different machines may have unique mechanisms for transitioning between orientations.

Once you have familiarized yourself with the manual, locate the tilt adjustment lever or mechanism on your grinder. Gently release any locking mechanisms that may be in place before carefully tilting the grinder into the horizontal position. It is essential to do this slowly and steadily to avoid any sudden movements that could damage the machine or cause injury.

After achieving the desired angle, securely lock the tilt mechanism back into place before reconnecting power and performing a test run to ensure everything is functioning correctly.

Tips for Ensuring Smooth and Effortless Tilt Functionality

To maintain smooth and effortless tilt functionality on your grinder, regular maintenance is crucial. Start by keeping the tilt mechanism clean and free from debris that could impede movement. Periodically inspect the pivot points and joints for signs of wear or damage, as these areas are critical for maintaining proper function.

Lubricating these components with appropriate oils or greases can also help reduce friction and ensure smooth operation. Additionally, it is beneficial to develop a routine for checking the alignment of your grinder after switching orientations. Misalignment can lead to uneven grinding results and may even cause damage over time.

By taking a moment to verify that everything is properly aligned before starting your work, you can prevent potential issues and enhance the overall performance of your grinder.

Safety Precautions When Adjusting Your Grinder

Safety should always be a top priority when adjusting your grinder from vertical to horizontal orientation. Before making any adjustments, ensure that you are wearing appropriate personal protective equipment (PPE), including safety goggles, gloves, and hearing protection if necessary. These precautions will help protect you from potential hazards associated with moving machinery.

When adjusting the grinder, always follow the manufacturer’s guidelines closely. Avoid placing your hands near moving parts during the transition process, as this could lead to serious injuries. Additionally, ensure that all locking mechanisms are securely engaged after making adjustments to prevent accidental movement during operation.

By adhering to these safety precautions, you can create a safer working environment while maximizing the efficiency of your grinding tasks.

Common Mistakes to Avoid When Using Tilt Functionality

While utilizing tilt functionality on your grinder can enhance versatility, there are common mistakes that operators should be aware of to avoid compromising performance or safety. One frequent error is neglecting to properly secure the tilt mechanism after making adjustments. Failing to lock the grinder in place can lead to unexpected shifts during operation, resulting in inaccurate grinding results or even damage to both the machine and workpiece.

Another mistake is not taking into account the specific requirements of each grinding task when switching orientations. Each method has its advantages and limitations; therefore, understanding when to use vertical versus horizontal grinding is essential for achieving optimal results. Operators should assess factors such as workpiece size, material type, and desired finish before deciding on an orientation to ensure they are using their grinder effectively.

Maximizing Efficiency with Vertical and Horizontal Grinding

To maximize efficiency when utilizing both vertical and horizontal grinding methods, it is essential to develop a strategic approach tailored to your specific machining needs. Start by analyzing your workflow and identifying which tasks benefit most from each orientation. For instance, use vertical grinding for precision finishing on flat surfaces while reserving horizontal grinding for larger components requiring significant material removal.

Additionally, consider implementing a systematic scheduling process that allows you to alternate between vertical and horizontal tasks seamlessly. By organizing your workload in this manner, you can minimize downtime associated with switching orientations and maintain a steady production flow. This proactive approach not only enhances efficiency but also contributes to improved overall productivity within your machining operations.

Innovative Applications for Tilt-Enabled Grinders

Tilt-enabled grinders have opened up new avenues for innovative applications across various industries. One notable application is in aerospace manufacturing, where precision components often require complex geometries that benefit from both vertical and horizontal grinding techniques. The ability to switch orientations allows manufacturers to achieve tight tolerances while maintaining high-quality finishes on intricate parts.

Another exciting application lies within the automotive sector, where tilt-enabled grinders can be used for processing engine components and transmission parts. The versatility of these machines enables manufacturers to efficiently handle diverse materials while ensuring consistent quality across different production runs. As industries continue to evolve, the potential applications for tilt-enabled grinders will likely expand further, driving innovation in machining processes.

Maintenance and Care for Tilt-Enabled Grinders

Proper maintenance and care are vital for ensuring the longevity and performance of tilt-enabled grinders. Regularly inspect all moving parts for signs of wear or damage, paying particular attention to the tilt mechanism itself. Keeping these components clean and well-lubricated will help prevent unnecessary friction and prolong their lifespan.

In addition to mechanical upkeep, it is essential to maintain a clean working environment around your grinder. Dust and debris can accumulate over time, potentially affecting both performance and safety. Implementing a routine cleaning schedule will help keep your workspace organized while minimizing risks associated with cluttered areas around machinery.

Choosing the Right Tilt-Enabled Grinder for Your Needs

Selecting the right tilt-enabled grinder requires careful consideration of several factors tailored to your specific needs. Begin by assessing your typical workload and identifying whether you primarily require vertical or horizontal grinding capabilities—or if both are necessary for your operations. Understanding your production requirements will guide you toward a machine that best fits your needs.

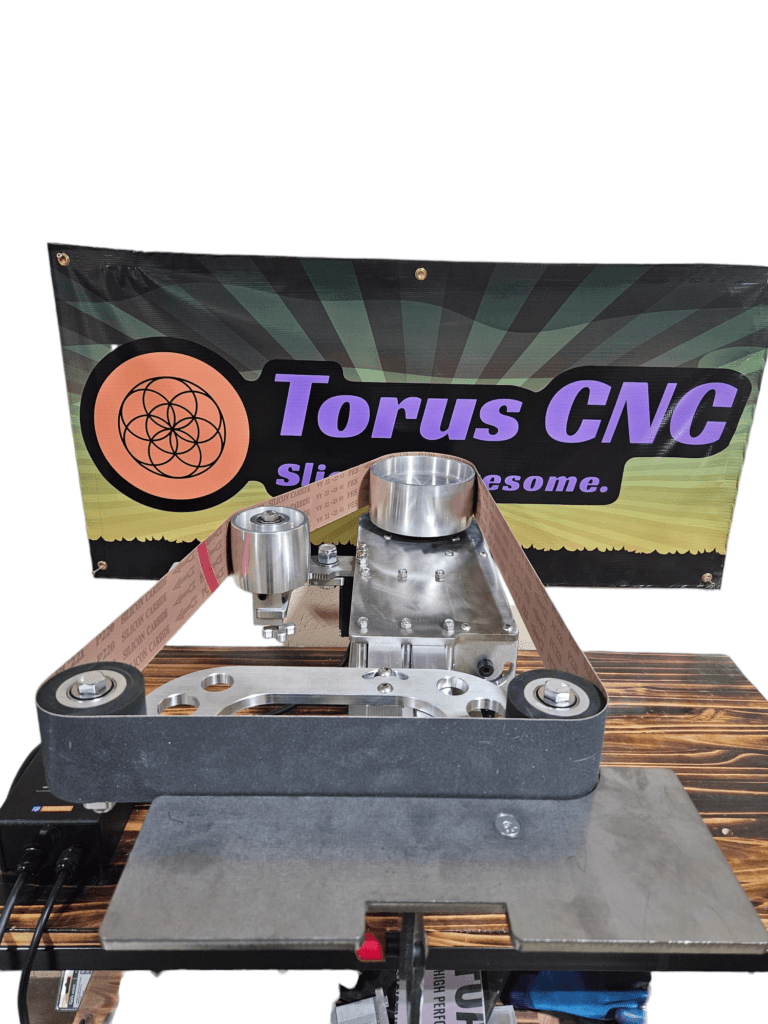

Next, evaluate the features offered by different models on the market. Look for grinders with robust construction, reliable tilt mechanisms, and adjustable settings that allow you to customize performance based on various tasks. Additionally, consider factors such as ease of use, maintenance requirements, and available support from manufacturers like TorusCNC when making your decision.

By taking these elements into account, you can confidently choose a tilt-enabled grinder that will enhance your machining capabilities for years to come.

FAQs

What is the Fast Tool-Less Tilt feature on a grinder?

The Fast Tool-Less Tilt feature on a grinder allows the user to easily switch the grinder from a vertical to a horizontal position without the need for tools.

How does the Fast Tool-Less Tilt feature work?

The Fast Tool-Less Tilt feature typically involves a quick-release mechanism that allows the user to adjust the position of the grinder without the need for additional tools. This can save time and effort when switching between vertical and horizontal grinding tasks.

What are the benefits of the Fast Tool-Less Tilt feature?

The Fast Tool-Less Tilt feature offers increased versatility and efficiency, as it allows the user to quickly and easily change the orientation of the grinder to suit different grinding tasks. This can save time and effort, and make the grinder more versatile for a range of applications.

Are there any limitations to the Fast Tool-Less Tilt feature?

While the Fast Tool-Less Tilt feature can make it easier to switch the grinder from vertical to horizontal positions, it’s important to follow the manufacturer’s guidelines for safe operation and to ensure that the feature is used correctly to avoid any potential safety hazards.