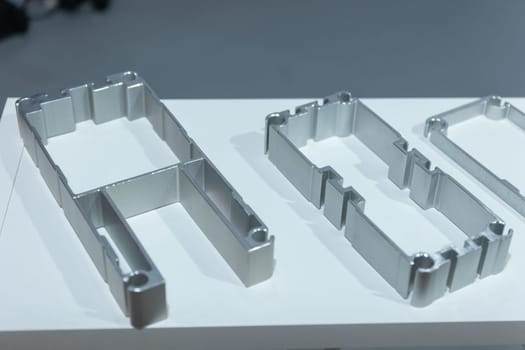

CNC-machined aluminum frames have become increasingly popular in various industries, particularly in the realm of 2×72 grinders. One of the primary advantages of using aluminum is its lightweight nature, which significantly enhances the overall usability of the equipment. This lightweight characteristic allows for easier maneuverability and transport, making it an ideal choice for both professional and hobbyist applications.

Additionally, aluminum’s inherent resistance to corrosion ensures that the frames maintain their aesthetic appeal and structural integrity over time, even when exposed to various environmental conditions. Another notable advantage of CNC-machined aluminum frames is their ability to be produced with high precision. The CNC (Computer Numerical Control) machining process allows for intricate designs and specifications to be met with remarkable accuracy.

This precision not only contributes to the overall performance of the grinder but also ensures that all components fit together seamlessly. As a result, users can expect a higher level of efficiency and effectiveness in their grinding tasks, leading to superior outcomes in their projects.

Key Takeaways

- CNC-machined aluminum frames offer lightweight and high strength, making them advantageous for 2×72 grinders.

- Steel frames in 2×72 grinders have limitations in terms of weight and portability compared to aluminum frames.

- Aluminum frames have a positive impact on the performance of 2×72 grinders due to their rigidity and stability.

- CNC-machined aluminum frames are durable and have a long lifespan, making them a reliable choice for 2×72 grinders.

- Aluminum frames are cost-efficient and offer precision and customization options for 2×72 grinders, making them a promising choice for the future.

The Limitations of Steel Frames in 2×72 Grinders

While steel frames have traditionally been used in the construction of 2×72 grinders, they come with several limitations that can hinder performance and usability. One significant drawback is the weight of steel, which can make these grinders cumbersome and less portable. For users who require mobility—such as those who attend trade shows or work in various locations—this added weight can be a considerable disadvantage.

The difficulty in transporting steel-framed grinders can limit their practicality for many users. Moreover, steel frames are more susceptible to rust and corrosion, especially when exposed to moisture or harsh working environments. This vulnerability can lead to a decline in performance over time, as rust can compromise the structural integrity of the frame.

In contrast, CNC-machined aluminum frames offer a more resilient solution, providing users with a long-lasting option that requires less maintenance and care. The limitations of steel frames highlight the need for alternative materials that can better meet the demands of modern grinding applications.

The Impact of Aluminum Frames on Performance

The performance of 2×72 grinders is significantly influenced by the choice of frame material. CNC-machined aluminum frames contribute to enhanced performance through their lightweight design and structural rigidity. The reduced weight allows for quicker adjustments and easier handling during operation, enabling users to achieve precise results without unnecessary strain.

Additionally, the rigidity of aluminum ensures that the grinder remains stable during use, minimizing vibrations that could affect the quality of the grind. Furthermore, aluminum’s thermal conductivity plays a crucial role in performance. During grinding operations, heat is generated, which can affect both the material being worked on and the grinder itself.

Aluminum dissipates heat more effectively than steel, helping to maintain optimal operating temperatures. This characteristic not only prolongs the life of the grinder but also enhances the quality of the finished product by preventing overheating that could lead to warping or other issues.

The Durability and Longevity of CNC-Machined Aluminum Frames

| Metrics | Results |

|---|---|

| Material | Aluminum |

| Durability | High |

| Longevity | Excellent |

| Corrosion Resistance | Good |

| Strength-to-Weight Ratio | High |

Durability is a critical factor when selecting materials for 2×72 grinders, and CNC-machined aluminum frames excel in this regard. The manufacturing process ensures that these frames are crafted with precision and care, resulting in a robust structure capable of withstanding rigorous use. Unlike steel, which can suffer from rust and corrosion over time, aluminum’s natural resistance to these issues means that users can expect a longer lifespan from their equipment.

Moreover, the longevity of CNC-machined aluminum frames is further enhanced by their ability to endure various environmental conditions without compromising performance. Whether used in a workshop or an outdoor setting, these frames maintain their integrity and functionality over time. This durability translates into cost savings for users, as they will not need to replace their equipment as frequently as they might with steel-framed alternatives.

The Weight and Portability of Aluminum Frames

One of the standout features of CNC-machined aluminum frames is their lightweight nature, which greatly enhances portability. For professionals who need to transport their 2×72 grinders between job sites or for hobbyists who may want to move their equipment around their workspace, this aspect cannot be overstated. The reduced weight allows for easier lifting and loading into vehicles, making it a practical choice for those who value mobility.

In addition to ease of transport, the lightweight design also contributes to user comfort during operation. Users can adjust and reposition their grinders with minimal effort, allowing for greater flexibility in their work processes. This ease of use can lead to increased productivity, as users spend less time struggling with heavy equipment and more time focusing on their projects.

The Cost-Efficiency of CNC-Machined Aluminum Frames

Long-term Savings through Durability

While the initial investment may be higher than that of steel frames, the long-term savings associated with durability and reduced maintenance costs make aluminum a wise choice. Users can expect fewer repairs and replacements over time due to aluminum’s resistance to corrosion and wear.

Efficiency Gains for Increased Productivity

Additionally, the efficiency gains provided by aluminum frames can lead to increased productivity, further enhancing cost-effectiveness. As users experience improved performance and reduced downtime due to equipment failure or maintenance issues, they can complete more projects in less time.

Increased Profitability and Satisfaction

This increased output translates into higher profitability for businesses and greater satisfaction for hobbyists who wish to maximize their crafting endeavors.

The Precision and Customization of Aluminum Frames

CNC machining offers unparalleled precision in the manufacturing of aluminum frames for 2×72 grinders. This level of accuracy allows for tight tolerances and intricate designs that are essential for optimal performance. Users benefit from components that fit together seamlessly, reducing play and enhancing stability during operation.

The precision afforded by CNC machining ensures that every grinder operates at its best, delivering consistent results across various applications. Moreover, the customization options available with CNC-machined aluminum frames are extensive. Users can specify dimensions, features, and finishes tailored to their specific needs and preferences.

This level of customization allows for a more personalized experience, enabling users to create grinders that align perfectly with their unique requirements. Whether it’s adjusting frame size or incorporating specific mounting points for accessories, the possibilities are virtually limitless.

The Future of CNC-Machined Aluminum Frames in 2×72 Grinders

As technology continues to advance, the future of CNC-machined aluminum frames in 2×72 grinders looks promising. Innovations in machining techniques and materials will likely lead to even greater enhancements in performance, durability, and customization options. Manufacturers like TorusCNC are at the forefront of this evolution, continually refining their processes to deliver superior products that meet the demands of modern users.

The growing trend toward lightweight yet durable materials suggests that aluminum will remain a popular choice among manufacturers and users alike. As more individuals recognize the benefits associated with CNC-machined aluminum frames—such as improved portability, cost-efficiency, and precision—the demand for these products is expected to rise. This shift will likely drive further advancements in design and technology, ensuring that CNC-machined aluminum frames continue to play a vital role in the future landscape of 2×72 grinders.

FAQs

What are the advantages of CNC-machined aluminum frames in 2×72 grinders?

CNC-machined aluminum frames offer several advantages in 2×72 grinders, including lightweight construction, high strength-to-weight ratio, corrosion resistance, and the ability to be precision-machined for optimal performance.

How do aluminum frames compare to steel frames in 2×72 grinders?

Aluminum frames are generally lighter than steel frames, making them easier to handle and transport. They also offer better corrosion resistance and can be machined to tighter tolerances for improved performance.

Are there any drawbacks to using CNC-machined aluminum frames in 2×72 grinders?

While aluminum frames offer many advantages, they may not be as impact-resistant as steel frames. However, advancements in aluminum alloys and CNC machining techniques have minimized this drawback in many cases.

What industries or applications benefit most from CNC-machined aluminum frames in 2×72 grinders?

CNC-machined aluminum frames are commonly used in metalworking, knife making, and fabrication industries where precision, durability, and corrosion resistance are important factors in grinder performance.

Can aluminum frames withstand the rigors of heavy-duty grinding applications?

Yes, CNC-machined aluminum frames can withstand the rigors of heavy-duty grinding applications when designed and manufactured to appropriate specifications. The use of high-quality aluminum alloys and precision CNC machining ensures their durability and performance.