Choosing a 2×72 belt grinder is a rite of passage for any knife maker serious about quality and consistency. But, unlike men, not all grinders are constructed equally. Whether you’re upgrading or buying your first machine, here are 10 essential features to look for—and how the Torus 2×72 delivers on every one of them:

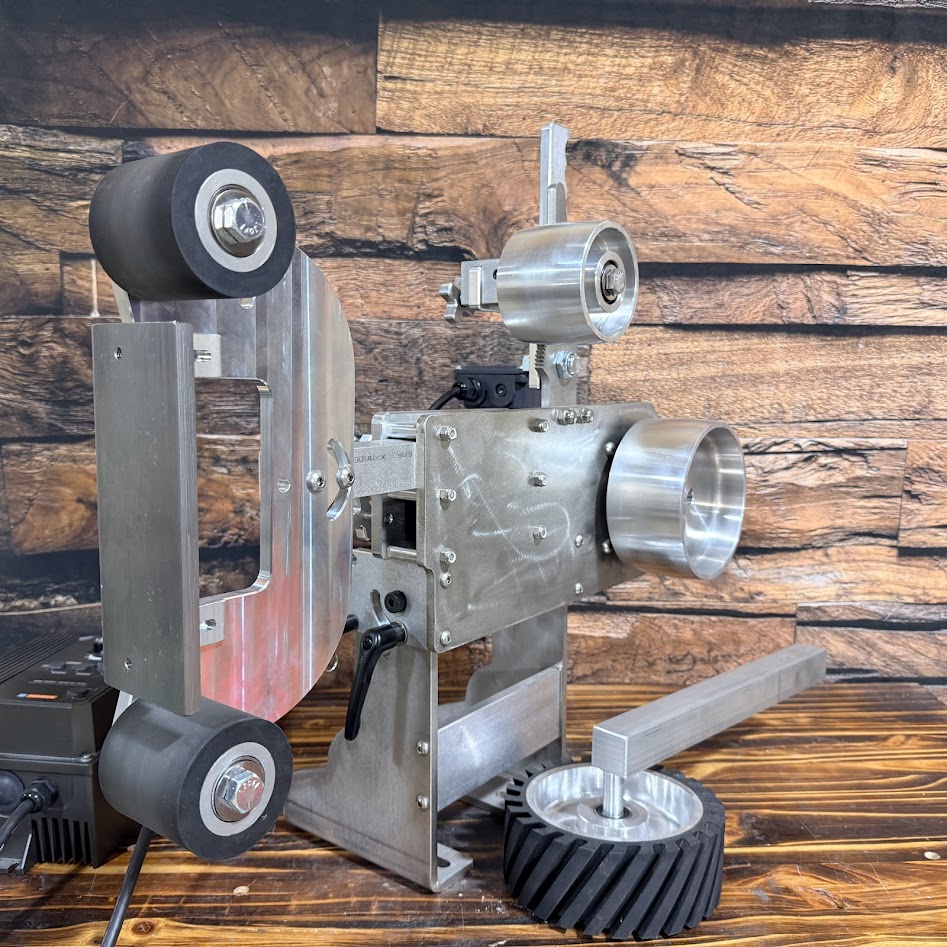

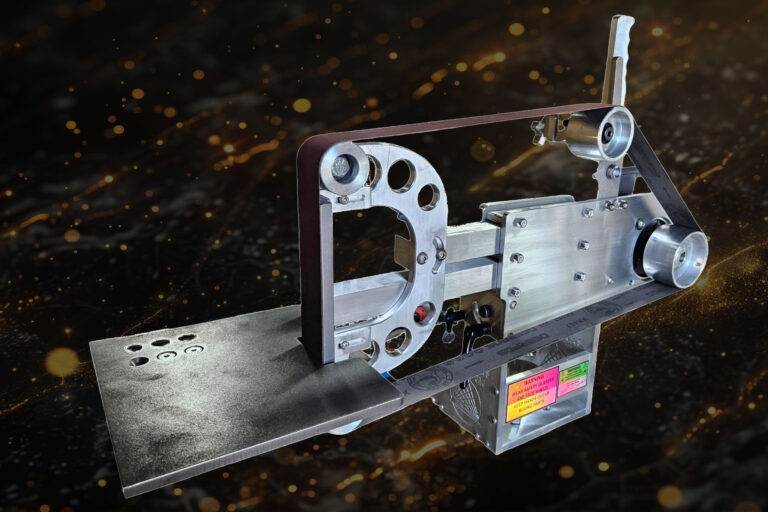

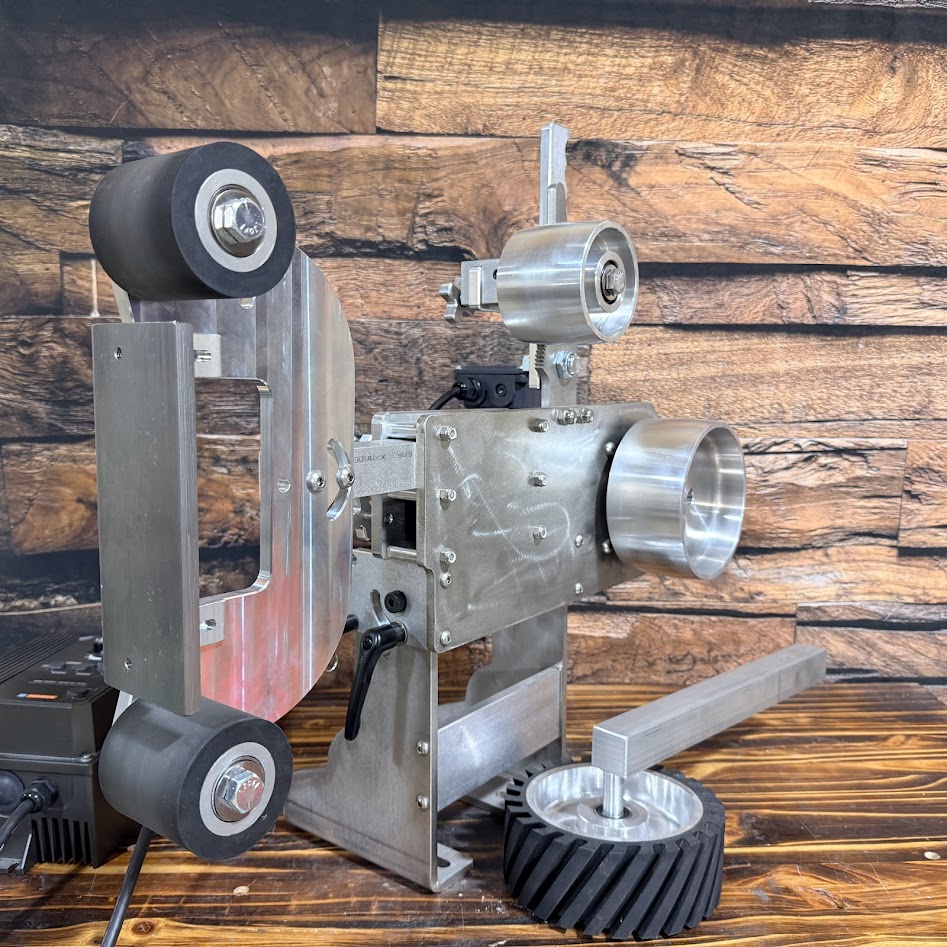

- Solid Frame Construction – The Torus 2×72 is machined from thick 6061 aluminum, offering exceptional strength without unnecessary weight. Built to handle daily grinding abuse without flexing.

- Tool-Free Adjustments – Our design prioritizes fast adjustments. From tensioning to tracking, everything is engineered for quick changeovers without tools.

- Variable Speed Control Ready – Pair the Torus chassis with a VFD and motor and you’re ready for precision control over belt speed—ideal for delicate handle work or hogging steel.

- Multiple Platen Options – The flat platen system on the Torus chassis accepts a variety of attachments—contact wheels, small wheel arms, rotary platens—for total flexibility.

- Modular Design – Future-proof your workshop. The Torus 2×72 is fully modular and designed for expansion, including vertical and horizontal configurations.

- Tilting Frame – Go from vertical to horizontal in seconds. Perfect for full-flat grinding, handle sculpting, and special jigs.

- Precision Tracking – Designed with high-tolerance components and dialed-in geometry for ultra-stable belt tracking.

- Belt Compatibility – Accepts all standard 2×72 grinding belts with room to spare.

- Robust Work Rest Included – The adjustable work rest that ships with the Torus 2×72 is rigid, easy to dial in, and ready for clean bevels.

- Proudly Made in the USA – Designed and built in Illinois by a one-man shop that understands what makers need. No outsourcing. No compromises.

And the best part? The Torus 2×72 starts at a competitive price without cutting corners. High-precision manufacturing, premium materials, and a fair price tag make it the clear choice for knife makers ready to upgrade.