Blade sharpening is an essential skill that has been practiced for centuries, serving both practical and artistic purposes. Whether for kitchen knives, woodworking tools, or outdoor equipment, the ability to maintain a sharp edge is crucial for efficiency and safety. A well-sharpened blade not only enhances performance but also prolongs the life of the tool, making it a worthwhile investment for both professionals and hobbyists alike.

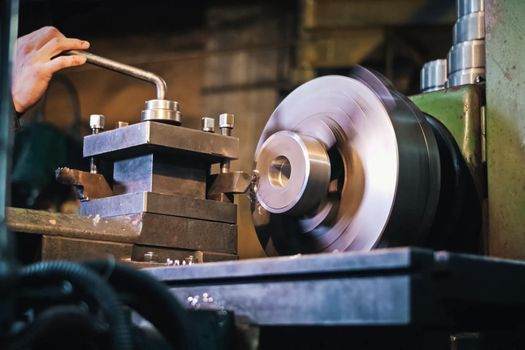

The process of sharpening involves removing material from the blade to create a new edge, which can be achieved through various methods and tools. In recent years, advancements in technology have transformed the way blades are sharpened. Among these innovations, the 2×72 grinder has emerged as a popular choice for many craftsmen and enthusiasts.

This powerful tool offers precision and versatility, making it an ideal solution for achieving razor-sharp edges on a wide range of blades. As we delve deeper into the evolution and advantages of 2×72 grinders, it becomes clear that they represent a significant leap forward in the art of blade sharpening.

Key Takeaways

- Blade sharpening is an essential skill for maintaining the performance and longevity of cutting tools.

- The evolution of 2×72 grinders has revolutionized the blade sharpening process, providing efficiency and precision.

- 2×72 grinders offer advantages such as speed, versatility, and the ability to handle various types of blades.

- Innovative features of 2×72 grinders include adjustable speed, different belt options, and customizable attachments.

- Tips and techniques for using 2×72 grinders include proper belt tension, angle adjustment, and regular maintenance for optimal performance.

The Evolution of 2×72 Grinders

The journey of blade sharpening tools has seen remarkable changes over time, with the introduction of various grinding machines that cater to different needs. The 2×72 grinder, in particular, has gained prominence due to its unique design and functionality. Originally developed for industrial applications, these grinders have been adapted for use in workshops and home garages, allowing users to sharpen blades with greater efficiency and precision.

The name “2×72” refers to the size of the belt used in the grinder, which measures two inches in width and seventy-two inches in length. Over the years, the design of 2×72 grinders has evolved significantly. Early models were often bulky and limited in their capabilities, but modern iterations have incorporated advanced features that enhance usability and performance.

Manufacturers have focused on improving motor power, belt tracking systems, and overall ergonomics, making these grinders more accessible to users of all skill levels. As a result, the 2×72 grinder has become a staple in many workshops, providing a reliable solution for blade sharpening tasks.

Advantages of 2×72 Grinders for Blade Sharpening

One of the primary advantages of using a 2×72 grinder for blade sharpening is its versatility. This tool can accommodate a wide range of belts, allowing users to select the appropriate grit for their specific sharpening needs. From coarse belts for initial shaping to fine belts for honing edges, the flexibility offered by 2×72 grinders makes them suitable for various applications.

This adaptability is particularly beneficial for those who work with different types of blades, as it eliminates the need for multiple sharpening tools. Another significant benefit of 2×72 grinders is their efficiency. The powerful motors found in these machines enable users to sharpen blades quickly and effectively, reducing the time spent on maintenance tasks.

This efficiency is especially valuable for professionals who rely on sharp tools to perform their work effectively. Additionally, the consistent results achieved with a 2×72 grinder contribute to improved performance and safety when using sharpened blades.

Innovative Features of 2×72 Grinders

| Feature | Description |

|---|---|

| Variable Speed Control | Allows users to adjust the speed of the grinder for different applications. |

| Tilt Table | Enables the user to grind at different angles for more versatile use. |

| Quick Belt Change | Facilitates easy and fast replacement of grinding belts for efficiency. |

| Tool Rest | Provides support and stability for accurate grinding and sharpening. |

| Large Grinding Surface | Offers a spacious area for grinding larger workpieces. |

Modern 2×72 grinders are equipped with a variety of innovative features that enhance their functionality and ease of use. One such feature is the adjustable tracking system, which allows users to fine-tune the alignment of the grinding belt. This ensures that the belt runs smoothly and maintains consistent contact with the blade, resulting in a more uniform sharpening process.

The ability to adjust tracking is particularly important when working with different blade shapes and sizes. Another noteworthy innovation is the inclusion of variable speed controls in many 2×72 grinder models. This feature enables users to adjust the speed of the grinding belt according to their specific needs.

Slower speeds can be beneficial for delicate work or when honing an edge, while higher speeds are ideal for more aggressive material removal. This level of control allows users to achieve optimal results while minimizing the risk of overheating or damaging the blade.

Tips and Techniques for Using 2×72 Grinders

To maximize the effectiveness of a 2×72 grinder, it is essential to employ proper techniques during the sharpening process. One key tip is to maintain a consistent angle while sharpening the blade. This can be achieved by using jigs or guides that help stabilize the blade at the desired angle throughout the sharpening process.

Consistency in angle not only leads to better results but also helps prevent uneven wear on the blade. Another important technique is to regularly check the condition of the grinding belt. Worn or damaged belts can lead to subpar sharpening results and may even cause harm to the blade being sharpened.

It is advisable to replace belts as needed and to keep an eye on their performance during use. Additionally, using appropriate pressure while sharpening is crucial; applying too much force can lead to overheating or uneven edges, while too little pressure may result in ineffective sharpening.

Comparing 2×72 Grinders to Other Sharpening Methods

While there are various methods available for blade sharpening, 2×72 grinders stand out due to their efficiency and versatility. Traditional methods such as whetstones or manual sharpeners require significant time and effort, often yielding inconsistent results. In contrast, 2×72 grinders provide a more streamlined approach that allows users to achieve professional-quality edges with relative ease.

Moreover, electric sharpeners may offer convenience but often lack the precision that a skilled user can achieve with a 2×72 grinder. The ability to control speed and angle with a grinder allows for greater customization based on individual preferences and specific blade requirements. This level of control is particularly advantageous for those who take pride in their craftsmanship and seek to produce finely honed edges.

Maintenance and Care of 2×72 Grinders

Proper maintenance is crucial for ensuring the longevity and performance of a 2×72 grinder. Regular cleaning is essential to remove debris and metal shavings that can accumulate during use. Keeping the machine clean not only enhances its appearance but also prevents potential issues that could arise from buildup affecting moving parts.

A simple routine involving wiping down surfaces and checking for loose components can go a long way in maintaining optimal performance. Additionally, it is important to periodically inspect belts for signs of wear or damage. Replacing worn belts promptly will help maintain consistent sharpening results and prevent any potential damage to blades being sharpened.

Lubricating moving parts as recommended by the manufacturer can also contribute to smoother operation and reduce wear over time.

Future Developments in 2×72 Grinder Technology

As technology continues to advance, it is likely that we will see further innovations in 2×72 grinder design and functionality. One area of potential development is the integration of smart technology into these machines. Features such as digital displays that provide real-time feedback on speed and belt condition could enhance user experience and improve precision during sharpening tasks.

Moreover, advancements in materials used for grinding belts may lead to even more efficient sharpening processes. Research into new composites could result in belts that last longer while providing superior cutting performance. As manufacturers like TorusCNC continue to push the boundaries of what is possible with 2×72 grinders, users can look forward to an exciting future filled with enhanced capabilities and improved results in blade sharpening.

In conclusion, blade sharpening remains an essential skill that benefits from modern advancements in technology. The evolution of 2×72 grinders has revolutionized this process, offering users unparalleled versatility and efficiency. With innovative features designed to enhance usability and performance, these machines have become indispensable tools for craftsmen across various fields.

By employing proper techniques and maintaining their equipment diligently, users can ensure that their 2×72 grinders continue to deliver exceptional results for years to come. As we look ahead, it is clear that ongoing developments will further refine this already impressive tool, solidifying its place at the forefront of blade sharpening technology.

FAQs

What is a 2×72 grinder?

A 2×72 grinder is a type of belt grinder that uses a 2-inch by 72-inch belt for sharpening and shaping blades. It is commonly used by knife makers and metalworkers for its versatility and efficiency.

How does a 2×72 grinder innovate blade sharpening?

The 2×72 grinder continues to innovate blade sharpening by offering a wide range of belt options, adjustable speed controls, and various attachments for different sharpening techniques. This allows for precise and customizable sharpening for different types of blades.

What are the future trends in blade sharpening with the 2×72 grinder?

Future trends in blade sharpening with the 2×72 grinder include advancements in belt technology, such as longer-lasting and more durable belts, as well as improvements in grinder design for increased precision and ease of use. Additionally, there is a growing trend towards automation and computerized controls for consistent and repeatable sharpening results.

How does the 2×72 grinder benefit knife makers and metalworkers?

The 2×72 grinder benefits knife makers and metalworkers by providing a versatile and efficient tool for sharpening and shaping blades. It allows for precise and customizable sharpening, which is essential for creating high-quality knives and metalwork. Additionally, the 2×72 grinder saves time and effort compared to traditional sharpening methods.