The process of forging blades is a time-honored tradition in the world of metallurgy and knife-making. It involves shaping metal through the application of heat and pressure, resulting in a blade that possesses both strength and durability. However, one critical step that often gets overlooked in the forging process is the flattening of the blades before they undergo heat treatment.

This step is essential for ensuring that the blade achieves optimal performance characteristics, such as hardness and edge retention. Flattening not only prepares the blade for heat treatment but also sets the stage for a successful final product. Flattening forged blades is not merely a cosmetic procedure; it plays a vital role in the overall functionality of the knife.

A blade that is uneven or warped can lead to inconsistent heat treatment, which may compromise its structural integrity. By addressing these issues before heat treating, knife makers can ensure that their blades will perform as intended, providing users with a reliable tool that meets their expectations. In this article, we will explore the importance of flattening forged blades, the technology behind the Torus CNC machine, and best practices for achieving optimal results.

Key Takeaways

- Flattening forged blades before heat treat is a critical step in the manufacturing process to ensure uniform thickness and flatness.

- The importance of flattening forged blades lies in improving the overall quality, performance, and durability of the final product.

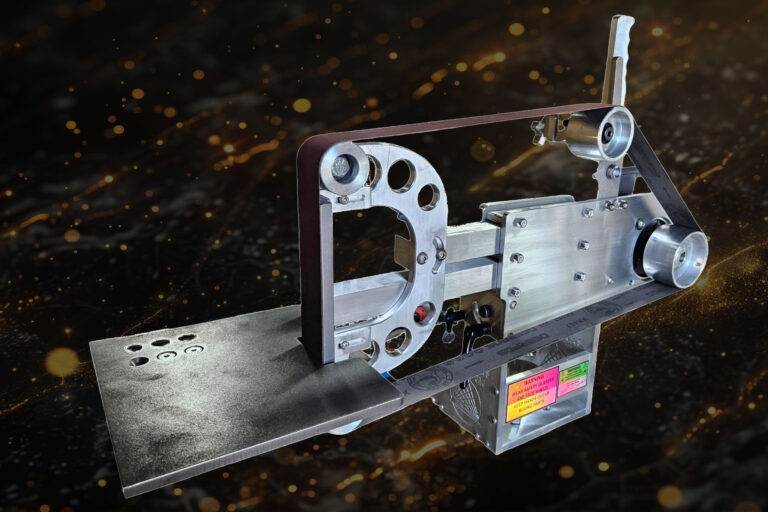

- The Torus CNC machine is a specialized equipment designed for precision flattening of forged blades, offering high efficiency and accuracy.

- Preparing the forged blades for flattening involves proper cleaning, inspection, and securing them in the CNC machine for the process.

- Setting up the Torus CNC for flattening requires precise programming and tooling adjustments to achieve the desired flatness and thickness.

The Importance of Flattening Forged Blades

Flattening forged blades is crucial for several reasons. First and foremost, it ensures that the blade’s surface is uniform, which is essential for achieving consistent heat treatment. When a blade is uneven, certain areas may absorb heat differently during the heat treatment process, leading to variations in hardness and tempering.

This inconsistency can result in a blade that is either too brittle or too soft, ultimately affecting its performance and longevity. Moreover, flattening helps to eliminate any warping or distortion that may have occurred during the forging process. These imperfections can hinder the blade’s cutting ability and overall functionality.

By taking the time to flatten the blade before heat treatment, knife makers can enhance the blade’s performance characteristics, ensuring that it meets the high standards expected by users. Additionally, a flat surface allows for better adhesion of any coatings or finishes applied after heat treatment, further improving the blade’s durability and aesthetic appeal.

Understanding the Torus CNC Machine

The Torus CNC machine represents a significant advancement in the field of blade manufacturing. Designed specifically for precision machining, this computer numerical control (CNC) machine offers unparalleled accuracy and efficiency in flattening forged blades. The Torus CNC utilizes advanced algorithms and high-speed cutting tools to achieve a level of precision that manual methods simply cannot match.

This technology allows knife makers to produce blades with tight tolerances, ensuring that each piece meets exact specifications. One of the standout features of the Torus CNC machine is its ability to automate the flattening process. This automation not only speeds up production but also reduces the risk of human error.

With programmable settings, operators can easily adjust parameters such as feed rate and cutting depth to suit different blade profiles and materials. This flexibility makes the Torus CNC an invaluable tool for both small-scale artisans and large-scale manufacturers alike, as it can accommodate a wide range of forging styles and blade designs.

Preparing the Forged Blades for Flattening

Before initiating the flattening process on the Torus CNC machine, proper preparation of the forged blades is essential. This preparation begins with a thorough inspection of each blade to identify any visible defects or irregularities. Any significant warping or surface imperfections should be noted, as these factors will influence how the blades are set up on the CNC machine.

Additionally, cleaning the blades to remove any residual scale or debris from the forging process is crucial for achieving optimal results. Once inspected and cleaned, the blades must be securely mounted onto the CNC machine’s worktable. Proper alignment is key to ensuring that each blade is flattened uniformly.

Depending on the design of the blade, various clamping methods may be employed to hold it in place during machining. It is important to ensure that there is no movement during the flattening process, as even slight shifts can lead to inaccuracies in the final product.

Setting Up the Torus CNC for Flattening

Setting up the Torus CNC machine for flattening involves several critical steps that require attention to detail. First, operators must input specific parameters into the machine’s control system based on the characteristics of the forged blades being processed. This includes selecting appropriate cutting tools and determining optimal feed rates and cutting depths.

The precision of these settings directly impacts the quality of the flattening process. Additionally, operators should conduct a test run with a sample blade to verify that all settings are correct before proceeding with full production. This test run allows for adjustments to be made if necessary, ensuring that each blade will be flattened to perfection.

Once satisfied with the setup, operators can begin processing multiple blades efficiently, taking advantage of the Torus CNC’s capabilities to streamline production while maintaining high standards of quality.

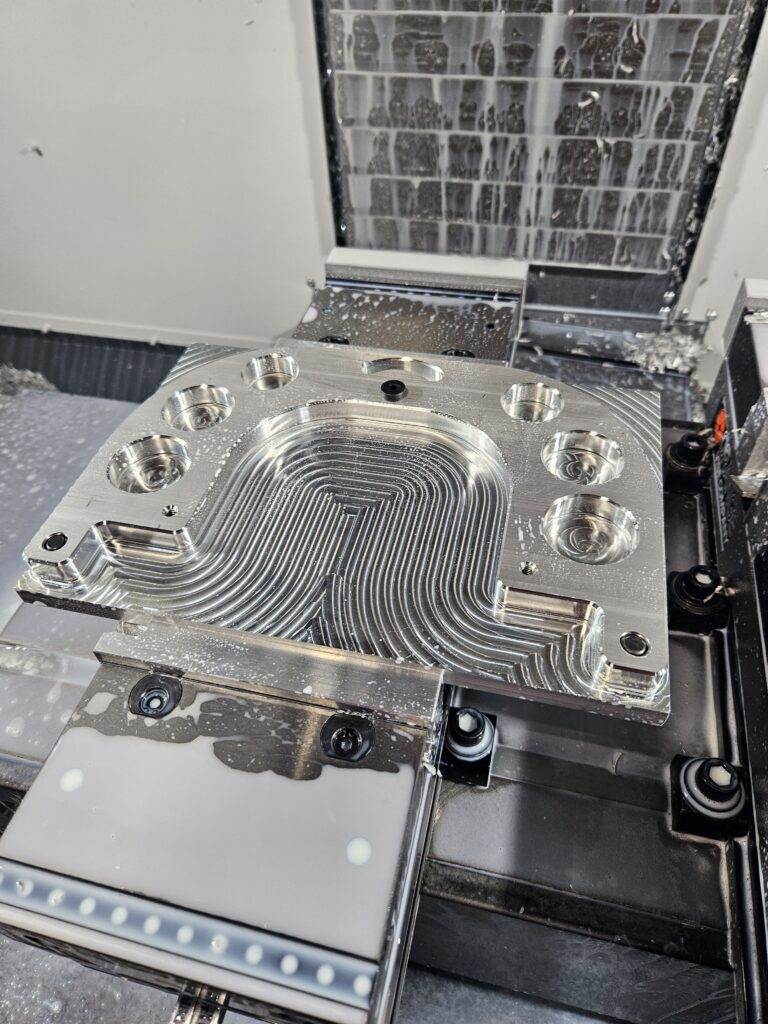

Flattening Process on the Torus CNC

The actual flattening process on the Torus CNC machine is where technology meets craftsmanship. As the machine begins its operation, high-speed cutting tools engage with the surface of each forged blade, removing material in a controlled manner to achieve a flat profile. The precision of this process allows for consistent results across multiple blades, which is particularly beneficial for manufacturers producing large quantities.

Throughout this process, operators must monitor the machine’s performance closely. While CNC machines are designed for automation, human oversight remains essential to ensure that everything runs smoothly. Any unusual sounds or vibrations may indicate an issue that requires immediate attention.

By maintaining vigilance during flattening, operators can prevent potential problems that could compromise both efficiency and quality.

Quality Control and Inspection After Flattening

Once the flattening process is complete, quality control becomes paramount. Each blade should undergo a thorough inspection to ensure that it meets specified tolerances and quality standards. This inspection typically involves measuring key dimensions and checking for any remaining imperfections or inconsistencies in surface flatness.

Advanced measuring tools may be employed to assess these characteristics accurately. In addition to dimensional checks, visual inspections are also crucial. Operators should look for any signs of tool marks or surface damage that may have occurred during machining.

If any issues are identified during this inspection phase, corrective actions must be taken before proceeding to heat treatment. This commitment to quality control ensures that only blades meeting rigorous standards move forward in the production process.

Advantages of Flattening Forged Blades Before Heat Treat

The advantages of flattening forged blades before heat treatment are manifold and significantly impact both performance and longevity. One primary benefit is enhanced consistency in heat treatment results. By starting with a flat surface, knife makers can achieve uniform heating across the entire blade, leading to improved hardness and tempering characteristics.

This consistency translates into better edge retention and overall performance during use. Another advantage lies in improved aesthetics and finish quality post-heat treatment. A flat blade surface allows for more effective application of coatings or finishes, resulting in a visually appealing product that also offers enhanced protection against corrosion and wear.

Furthermore, by investing time in flattening before heat treatment, knife makers can reduce post-treatment grinding or polishing efforts, streamlining their workflow and saving valuable time.

Common Challenges and Solutions in Flattening Forged Blades

While flattening forged blades is essential, it does come with its own set of challenges. One common issue is dealing with significant warping or distortion from the forging process. In such cases, operators may need to adjust their approach by using specialized cutting tools or altering feed rates to accommodate these irregularities effectively.

Understanding how different materials respond to machining can help mitigate these challenges. Another challenge lies in maintaining consistent quality across multiple blades during production runs. Variations in material properties or inconsistencies in forging can lead to discrepancies in flattening results.

To address this issue, operators should implement rigorous quality control measures throughout the process, including regular calibration of machinery and ongoing training for staff on best practices for handling different materials.

Best Practices for Flattening Forged Blades on the Torus CNC

To achieve optimal results when flattening forged blades on the Torus CNC machine, several best practices should be followed. First and foremost, thorough preparation is key; this includes inspecting each blade carefully and ensuring proper cleaning before mounting them on the machine. Additionally, maintaining accurate settings on the CNC machine will help ensure consistent results across all blades.

Operators should also prioritize regular maintenance of their Torus CNC equipment to prevent any mechanical issues that could affect performance during flattening operations. Keeping cutting tools sharp and well-maintained will enhance machining efficiency while reducing wear on both tools and blades alike. Finally, fostering an environment of continuous learning among staff will help ensure that everyone involved in the process remains informed about advancements in technology and techniques related to blade manufacturing.

Conclusion and Future Considerations

In conclusion, flattening forged blades before heat treatment is an indispensable step in producing high-quality knives that meet user expectations for performance and durability. The use of advanced technology like the Torus CNC machine has revolutionized this process, allowing for greater precision and efficiency than ever before. By understanding the importance of flattening and implementing best practices throughout production, knife makers can enhance their craft while minimizing challenges associated with inconsistencies in heat treatment.

Looking ahead, continued advancements in CNC technology will likely further improve methods for flattening forged blades and other aspects of knife manufacturing. As materials science evolves and new techniques emerge, knife makers will have even more tools at their disposal to create exceptional products that stand out in a competitive market. Embracing these innovations while adhering to traditional craftsmanship principles will ensure that future generations continue to enjoy high-quality knives built on a foundation of excellence.

FAQs

What is flattening forged blades before heat treat?

Flattening forged blades before heat treat is the process of using a CNC machine, such as the Torus CNC, to flatten and smooth out the surface of a forged blade before it undergoes the heat treatment process.

Why is it important to flatten forged blades before heat treat?

Flattening forged blades before heat treat is important because it helps to ensure that the blade has a uniform and smooth surface, which is essential for achieving the desired hardness, strength, and performance characteristics during the heat treatment process.

How does the Torus CNC help in flattening forged blades?

The Torus CNC is a precision machining tool that uses computer-controlled movements to accurately flatten and smooth out the surface of forged blades. It can remove any imperfections or irregularities in the blade’s surface, ensuring a consistent and even finish.

What are the benefits of flattening forged blades before heat treat?

Flattening forged blades before heat treat helps to improve the overall quality and performance of the finished blade. It can also reduce the amount of material that needs to be removed during the grinding and finishing stages, saving time and resources.

Are there any potential drawbacks to flattening forged blades before heat treat?

One potential drawback of flattening forged blades before heat treat is the risk of removing too much material, which can affect the final dimensions and shape of the blade. It is important to carefully control the flattening process to avoid over-machining the blade.