In the world of machining and metalworking, precision is paramount. One of the often-overlooked components that can significantly enhance the quality of work is the tool rest. A custom tool rest is not merely an accessory; it is an essential element that can improve accuracy, stability, and overall efficiency in various applications.

By tailoring a tool rest to specific needs, users can achieve better results and streamline their processes. This article delves into the intricacies of creating a custom tool rest, exploring its importance, material selection, design considerations, and more. Custom tool rests are designed to meet the unique requirements of individual projects or machines.

Unlike standard tool rests, which may not fit perfectly or provide the desired support, a custom solution allows for adjustments that cater to specific tools and techniques. Whether you are working with lathes, grinders, or other machinery, a well-crafted tool rest can make a significant difference in the quality of your work. This article will guide you through the entire process of creating a custom tool rest, from understanding its importance to maintenance tips for longevity.

Key Takeaways

- Custom tool rests are essential accessories for woodturning and metalworking, providing support and stability for tools.

- A well-designed custom tool rest can improve precision, safety, and comfort during the crafting process.

- Selecting the right materials for your custom tool rest is crucial for durability, stability, and performance.

- Designing and shaping the materials of your custom tool rest requires careful planning and attention to detail.

- Proper maintenance and care are necessary to ensure the longevity and effectiveness of your custom tool rest.

Understanding the Importance of a Custom Tool Rest

The significance of a custom tool rest cannot be overstated. It serves as a foundation for stability and precision during machining operations. A well-designed tool rest provides the necessary support for tools, allowing for accurate cuts and consistent results.

When tools are properly supported, the risk of vibration and movement is minimized, leading to enhanced performance and reduced wear on both the tools and the workpiece. Moreover, a custom tool rest can be tailored to accommodate specific machining techniques or materials. For instance, if you frequently work with delicate materials that require careful handling, a custom tool rest can be designed to provide additional support without compromising the integrity of the workpiece.

This adaptability not only improves the quality of your work but also enhances safety by reducing the likelihood of accidents caused by unstable setups.

Selecting the Right Materials for Your Custom Tool Rest

Choosing the right materials for your custom tool rest is crucial for ensuring durability and functionality. The material selection process should consider factors such as strength, weight, and resistance to wear. Common materials used in crafting tool rests include steel, aluminum, and various composites.

Steel is often favored for its strength and rigidity, making it ideal for heavy-duty applications. On the other hand, aluminum offers a lightweight alternative that is easier to handle while still providing adequate support. In addition to strength and weight, it is essential to consider the environmental conditions in which the tool rest will be used.

If your workspace is prone to moisture or corrosive substances, selecting materials with appropriate protective coatings or corrosion-resistant properties becomes vital. Ultimately, the choice of material will impact not only the performance of the tool rest but also its longevity and maintenance requirements.

Designing Your Custom Tool Rest

The design phase is where creativity meets functionality in crafting a custom tool rest. Before diving into the actual construction, it is essential to sketch out your ideas and consider the specific requirements of your machining tasks. Factors such as height, width, and adjustability should be taken into account to ensure that the tool rest meets your needs effectively.

When designing your tool rest, think about how it will interact with your existing machinery and tools. Consider incorporating features such as adjustable angles or modular components that allow for versatility in different applications. Additionally, ensure that your design promotes ease of use; a well-thought-out design can save time and effort during setup and operation.

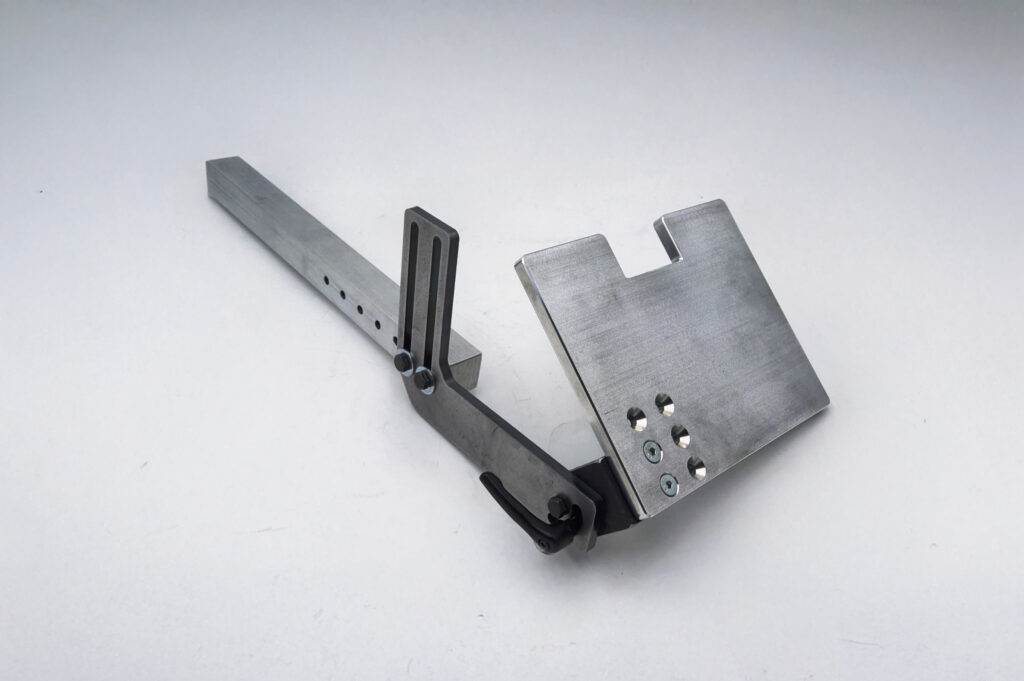

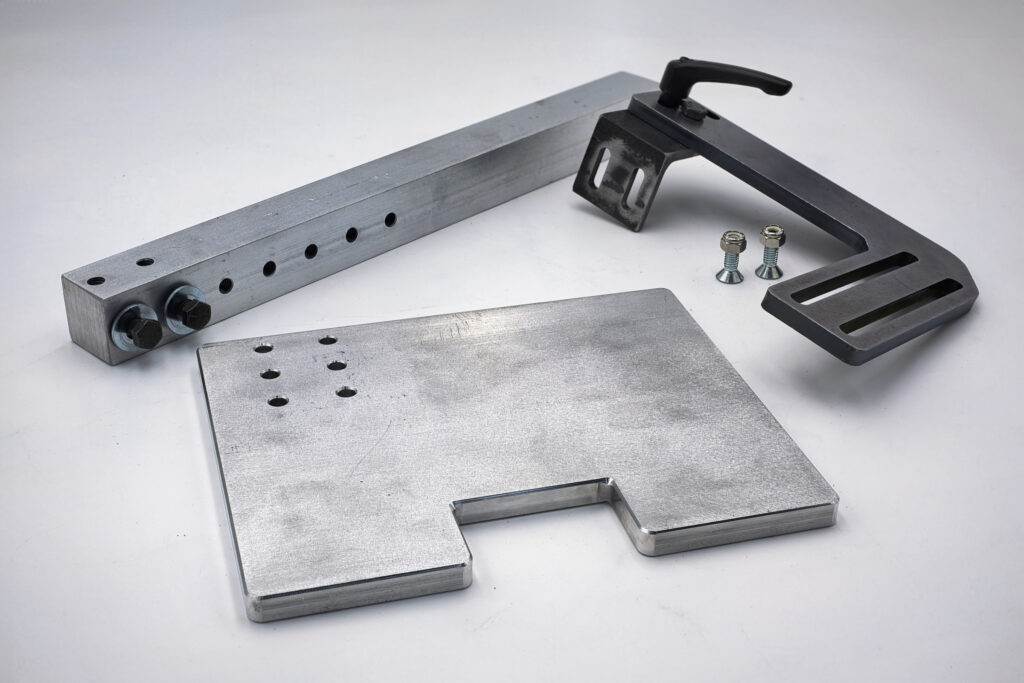

Cutting and Shaping the Materials

Once you have finalized your design, it’s time to move on to cutting and shaping the materials. This stage requires precision and attention to detail to ensure that each component fits together seamlessly. Depending on the materials chosen, you may need specialized tools such as saws, grinders, or CNC machines to achieve the desired shapes and dimensions.

During this process, it is crucial to follow safety protocols and use appropriate protective gear. Proper handling of tools and materials will not only ensure your safety but also contribute to achieving high-quality results. Take your time during this phase; rushing through cutting and shaping can lead to mistakes that may compromise the integrity of your custom tool rest.

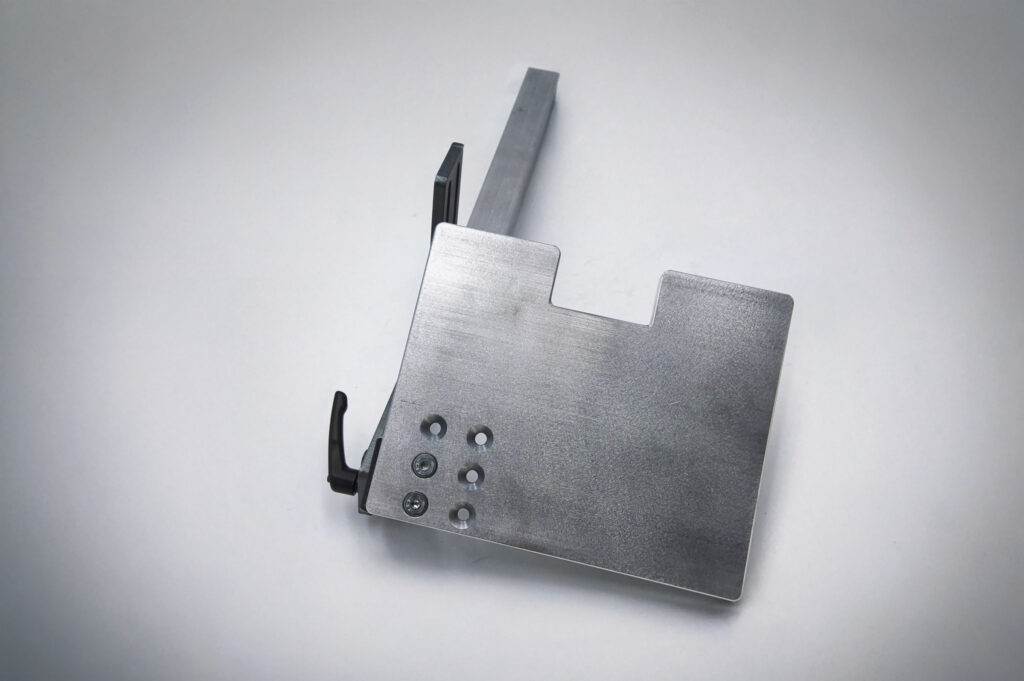

Welding and Assembling the Custom Tool Rest

With all components cut and shaped, the next step involves welding and assembling your custom tool rest. This stage requires skill and precision, as proper welding techniques are essential for creating strong joints that can withstand the rigors of machining operations. If you are not experienced in welding, consider seeking assistance from someone who is or investing time in learning proper techniques.

As you assemble your tool rest, pay close attention to alignment and fitment. Ensuring that all parts are correctly positioned will contribute to the overall stability and functionality of the final product. Once assembled, inspect all joints for strength and integrity before proceeding to testing.

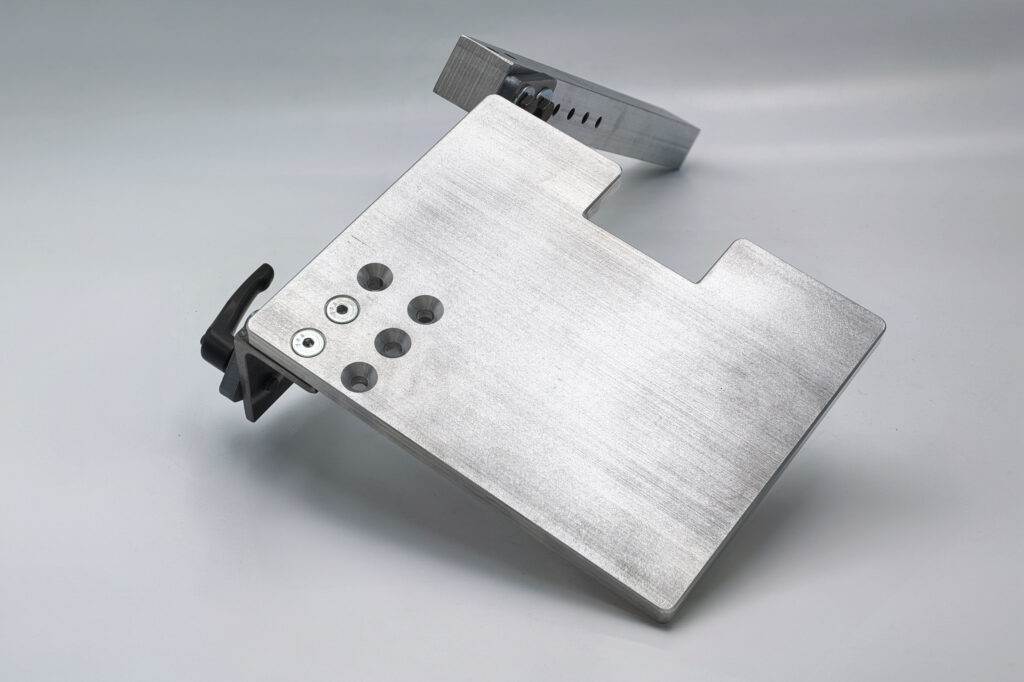

Testing and Adjusting the Tool Rest

After assembling your custom tool rest, it’s time for testing. This phase is critical in determining whether your design meets its intended purpose. Set up your tool rest with the appropriate machinery and tools, then conduct a series of tests to evaluate its performance under real working conditions.

Pay attention to factors such as stability, ease of adjustment, and overall functionality. If any issues arise during testing—such as wobbling or difficulty in adjusting—take note of these problems for further adjustments. Fine-tuning your custom tool rest may involve making minor modifications or even reworking certain components to achieve optimal performance.

The goal is to ensure that your tool rest enhances your machining capabilities rather than hindering them.

Adding Finishing Touches to Your Custom Tool Rest

Once testing is complete and any necessary adjustments have been made, it’s time to add finishing touches to your custom tool rest. This stage not only enhances aesthetics but also contributes to durability and functionality. Consider applying protective coatings or paints that can prevent rusting or corrosion over time.

Additionally, adding features such as rubber feet or non-slip surfaces can improve stability during use. These finishing touches may seem minor but can significantly impact the overall performance and longevity of your custom tool rest.

Using Your Custom Tool Rest for Different Applications

A well-designed custom tool rest can be utilized across various applications in machining and metalworking. Whether you are working on intricate designs or heavy-duty tasks, having a reliable tool rest can enhance your efficiency and precision. For instance, when using a lathe for turning operations, a properly adjusted tool rest can provide consistent support for cutting tools, resulting in smoother finishes.

Moreover, versatility is one of the key advantages of a custom tool rest. Depending on its design features—such as adjustable angles or modular components—you can adapt it for different types of machining tasks without needing multiple specialized rests. This adaptability not only saves space in your workshop but also streamlines your workflow.

Maintenance and Care for Your Custom Tool Rest

To ensure that your custom tool rest remains functional over time, regular maintenance is essential. Start by keeping it clean; debris or metal shavings can accumulate over time and affect performance. Use appropriate cleaning agents that won’t damage any protective coatings you may have applied.

Additionally, periodically inspect all components for signs of wear or damage. Addressing any issues promptly will help maintain the integrity of your tool rest and prolong its lifespan. Lubricating moving parts or adjustable components can also enhance performance and ease of use.

Conclusion and Final Tips for Crafting a Custom Tool Rest

In conclusion, crafting a custom tool rest is an investment in precision and efficiency for any machining operation. By understanding its importance, selecting appropriate materials, designing thoughtfully, and maintaining it properly, you can create a tool rest that significantly enhances your work quality. Remember that each step—from cutting to testing—plays a vital role in achieving a successful outcome.

As you embark on this journey of creating a custom tool rest, keep in mind that patience and attention to detail are key elements in ensuring success. Embrace the learning process; each project will provide valuable insights that can be applied to future endeavors. With dedication and care, your custom tool rest will serve as an indispensable asset in your machining toolkit for years to come.

FAQs

What is a dedicated sharpening tool rest?

A dedicated sharpening tool rest is a specialized tool rest designed for use with a 2×72 belt grinder. It is used to hold and support the blade or tool being sharpened, providing a stable and precise platform for sharpening.

Why is a dedicated sharpening tool rest important?

A dedicated sharpening tool rest is important because it allows for consistent and accurate sharpening of blades and tools on a 2×72 belt grinder. It provides a secure and stable platform for sharpening, which is essential for achieving precise and uniform results.

What are the benefits of building a dedicated sharpening tool rest?

Building a dedicated sharpening tool rest allows for customization to fit specific sharpening needs. It also provides the opportunity to create a tool rest that is tailored to the user’s preferences and requirements, resulting in a more efficient and effective sharpening process.

What materials are typically used to build a dedicated sharpening tool rest?

Materials commonly used to build a dedicated sharpening tool rest include steel, aluminum, and other sturdy metals. Additionally, wood or other materials may be used for the base or support structure of the tool rest.

Are there any safety considerations when using a dedicated sharpening tool rest?

When using a dedicated sharpening tool rest, it is important to follow proper safety precautions, such as wearing eye protection and ensuring that the tool rest is securely attached to the 2×72 belt grinder. Additionally, it is important to use the tool rest as intended and to avoid any potential hazards while sharpening.