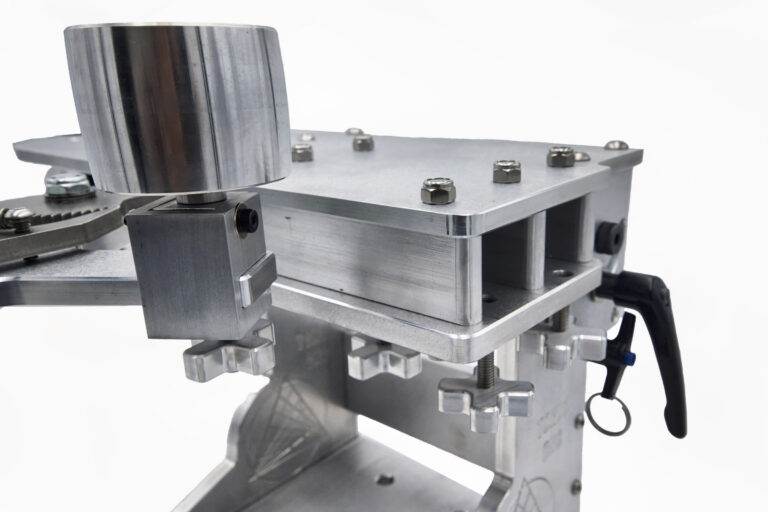

Aluminum has emerged as a favored material in the construction of grinders, particularly in the realm of high-performance tools like those produced by TorusCNOne of the primary advantages of aluminum is its remarkable strength-to-weight ratio. This means that while aluminum is lightweight, it does not compromise on durability. Grinders made from aluminum can withstand the rigors of daily use without succumbing to wear and tear, making them a reliable choice for both hobbyists and professionals alike.

The inherent properties of aluminum allow for precision engineering, which is essential in creating finely-tuned grinders that deliver consistent performance. Moreover, aluminum is an excellent conductor of heat, which plays a crucial role in the functionality of grinders. When grinding materials, friction generates heat, and aluminum’s ability to dissipate this heat effectively helps maintain optimal performance.

This characteristic not only enhances the longevity of the grinder but also ensures that the grinding process remains smooth and efficient. As a result, users can enjoy a seamless experience without the worry of overheating or damaging their equipment.

Key Takeaways

- Aluminum construction makes grinders lightweight and durable, perfect for on-the-go use.

- Aluminum’s corrosion resistance makes it ideal for travel and outdoor use.

- Aluminum allows for compact grinder sizes, enhancing portability and convenience.

- Aluminum contributes to heat dissipation in grinders, preventing overheating during use.

- The environmental impact of aluminum in grinder manufacturing is relatively low, making it a sustainable choice.

Lightweight and Durable: How Aluminum Enhances Portability

One of the standout features of aluminum grinders is their lightweight nature, which significantly enhances portability. For individuals who frequently travel or engage in outdoor activities, having a grinder that is easy to carry is essential. TorusCNC’s aluminum grinders are designed with this in mind, allowing users to easily pack them into bags or backpacks without adding unnecessary weight.

This portability factor is particularly appealing to those who enjoy cannabis on the go, as it allows for convenient access to freshly ground material wherever they may be. In addition to being lightweight, aluminum’s durability ensures that these grinders can withstand the bumps and scrapes that often accompany travel. Unlike heavier materials that may be prone to damage or breakage, aluminum maintains its structural integrity even when subjected to rough handling.

This combination of lightweight design and robust construction makes aluminum grinders an ideal choice for those who value both convenience and reliability in their tools.

Aluminum’s Corrosion Resistance: Perfect for On-the-Go Use

Another significant advantage of aluminum in grinder construction is its natural resistance to corrosion. This property is particularly beneficial for users who may find themselves in various environments, whether it be at the beach, in the mountains, or at a friend’s house. Aluminum does not rust like some other metals, ensuring that the grinder remains functional and aesthetically pleasing over time.

TorusCNC’s commitment to quality means that their aluminum grinders are designed to withstand exposure to moisture and other elements without deteriorating. This corrosion resistance also translates into lower maintenance requirements for users. Unlike grinders made from materials that may require regular cleaning or protective coatings, aluminum grinders can be easily wiped down and maintained with minimal effort.

This ease of care is especially advantageous for those who lead busy lifestyles or prefer to spend their time enjoying their activities rather than worrying about equipment upkeep.

Design Flexibility: How Aluminum Allows for Compact Grinder Sizes

| Feature | Benefit |

|---|---|

| High Strength-to-Weight Ratio | Allows for compact and lightweight grinder designs |

| Malleability | Enables intricate and space-saving grinder components |

| Corrosion Resistance | Ensures long-lasting and durable grinder construction |

| Conductivity | Facilitates efficient heat dissipation in compact grinder sizes |

Aluminum’s versatility extends beyond its physical properties; it also offers significant design flexibility that allows manufacturers like TorusCNC to create compact grinder sizes without sacrificing performance. The malleability of aluminum enables intricate designs that can incorporate various features while maintaining a lightweight profile. This is particularly important for users who may prefer smaller grinders that are easier to handle and store.

The ability to create compact designs means that users can enjoy the benefits of a high-quality grinder without needing to compromise on space. Whether it’s for home use or travel, a smaller grinder can fit seamlessly into any setting. Additionally, these compact designs often come equipped with advanced features such as precision cutting edges and ergonomic grips, enhancing the overall user experience while still being easy to transport.

Aluminum’s Contribution to Heat Dissipation in Grinders

Heat dissipation is a critical factor in the performance of any grinder, and aluminum excels in this area due to its thermal conductivity. When grinding materials, friction generates heat, which can affect both the quality of the grind and the longevity of the tool itself. TorusCNC’s aluminum grinders are engineered to effectively dissipate this heat, ensuring that users can grind materials efficiently without experiencing overheating issues.

The ability of aluminum to manage heat not only enhances performance but also contributes to user comfort. A grinder that remains cool during operation allows for longer grinding sessions without discomfort or risk of burns. This feature is particularly beneficial for those who engage in extensive grinding tasks or require consistent results over time.

By prioritizing heat dissipation in their designs, TorusCNC ensures that their aluminum grinders deliver optimal performance while keeping user experience at the forefront.

The Environmental Impact of Aluminum in Grinder Manufacturing

The environmental impact of materials used in manufacturing is an increasingly important consideration for consumers today. Aluminum stands out as a sustainable choice due to its recyclability and lower carbon footprint compared to other metals. The production process for aluminum has evolved significantly, with advancements in technology leading to more efficient methods that reduce energy consumption and waste.

TorusCNC recognizes the importance of sustainability and incorporates these practices into their manufacturing processes. By choosing aluminum for their grinders, TorusCNC not only provides users with high-quality tools but also contributes to a more sustainable future. The recyclability of aluminum means that even after a grinder reaches the end of its life cycle, it can be repurposed into new products without losing its inherent properties.

This closed-loop system minimizes waste and promotes responsible consumption, aligning with the values of environmentally conscious consumers.

Aluminum Grinders: The Ideal Travel Companion for Cannabis Enthusiasts

For cannabis enthusiasts, having a reliable grinder is essential for achieving the perfect consistency when preparing material for consumption. Aluminum grinders from TorusCNC are particularly well-suited for this purpose due to their lightweight design, durability, and ease of use. Whether at home or on the go, these grinders provide an efficient solution for breaking down cannabis into manageable pieces.

The portability of aluminum grinders makes them an ideal travel companion for those who enjoy outdoor adventures or social gatherings. Their compact size allows them to fit easily into pockets or bags, ensuring that users can always have access to freshly ground material. Additionally, the corrosion resistance of aluminum means that these grinders can withstand various environmental conditions without compromising performance or aesthetics.

The Future of Aluminum in Grinder Technology

As technology continues to advance, the future of aluminum in grinder construction looks promising. Innovations in manufacturing techniques and design capabilities will likely lead to even more efficient and user-friendly products. TorusCNC is at the forefront of this evolution, continually exploring new ways to enhance their aluminum grinders while maintaining their commitment to quality and performance.

Future developments may include improved ergonomic designs that cater to user comfort or advanced features that further optimize grinding efficiency. Additionally, as sustainability becomes an even greater priority across industries, we can expect continued emphasis on eco-friendly practices in aluminum production and recycling efforts. The ongoing evolution of aluminum technology will undoubtedly shape the landscape of grinder manufacturing, ensuring that users have access to cutting-edge tools that meet their needs while promoting responsible consumption practices.

In conclusion, aluminum’s unique properties make it an ideal material for grinder construction, particularly for brands like TorusCNC that prioritize quality and performance. From its lightweight nature and corrosion resistance to its design flexibility and contribution to heat dissipation, aluminum offers numerous benefits that enhance the user experience. As we look toward the future, it is clear that aluminum will continue to play a pivotal role in shaping the next generation of grinders, catering to the needs of enthusiasts and professionals alike while promoting sustainability in manufacturing practices.

FAQs

What are the benefits of aluminum’s lightweight nature for grinders?

Aluminum’s lightweight nature makes grinders more portable and easier to transport, allowing users to take their grinder with them on the go.

How does aluminum compare to other materials in terms of portability for grinders?

Aluminum is significantly lighter than materials such as steel or iron, making it a preferred choice for those seeking enhanced portability in their grinders.

Can aluminum grinders withstand regular use despite their lightweight nature?

Yes, aluminum grinders are durable and can withstand regular use despite being lightweight. They are designed to be sturdy and long-lasting.

Are there any downsides to using aluminum for grinders?

One potential downside of using aluminum for grinders is that it may not be as resistant to wear and tear as some other materials. However, this can be mitigated through proper care and maintenance.

What are some common uses for portable aluminum grinders?

Portable aluminum grinders are commonly used for grinding herbs, spices, and tobacco. They are popular among travelers, outdoor enthusiasts, and those who value convenience and mobility.