The 2×72 grinder is a powerful tool widely used in metalworking, woodworking, and knife-making. While it offers exceptional versatility and efficiency, it also poses significant risks if not handled properly. The high-speed operation of the grinder can lead to severe injuries, including lacerations, burns, and even amputations.

The abrasive belts used in these machines can generate intense heat and debris, which can cause eye injuries or respiratory issues if proper precautions are not taken. Understanding these dangers is crucial for anyone who operates or works near a 2×72 grinder. Moreover, the risk of entanglement is another critical concern.

Loose clothing, long hair, or dangling accessories can easily get caught in the moving parts of the grinder, leading to potentially life-threatening situations. Additionally, the noise generated by the grinder can be significant, which may lead to hearing damage over time if adequate hearing protection is not utilized. Recognizing these hazards is the first step toward creating a safe working environment and ensuring that all operators are aware of the potential dangers associated with 2×72 grinders.

Key Takeaways

- Understanding the Dangers of 2×72 Grinders

- 2×72 grinders can cause serious injuries if not used properly

- High speed and power of the grinder can lead to accidents

- Proper training and understanding of the equipment is crucial for safe use

- Proper Personal Protective Equipment (PPE) for 2×72 Grinder Use

- Always wear eye protection, such as safety glasses or a face shield

- Use hearing protection to prevent damage from the loud noise

- Wear gloves and a long-sleeved shirt to protect from sparks and debris

- Setting Up a Safe Workspace for 2×72 Grinder Operations

- Ensure the grinder is securely mounted to a stable surface

- Keep the work area clean and free of clutter to prevent tripping hazards

- Have a fire extinguisher nearby in case of sparks igniting flammable materials

- Safe Handling and Storage of 2×72 Grinder Accessories

- Store grinder accessories in a designated area to prevent loss or damage

- Handle grinder belts and discs with care to avoid cuts or punctures

- Keep accessories clean and free of debris to maintain their effectiveness

- Best Practices for Operating a 2×72 Grinder

- Always inspect the grinder and accessories before use for any damage or wear

- Use the appropriate speed and pressure for the material being worked on

- Take regular breaks to prevent fatigue and maintain focus on the task at hand

Proper Personal Protective Equipment (PPE) for 2×72 Grinder Use

To mitigate the risks associated with operating a 2×72 grinder, wearing appropriate personal protective equipment (PPE) is essential. The most critical piece of PPE is safety goggles or a face shield, which protects the eyes from flying debris and sparks generated during grinding. Additionally, a dust mask or respirator should be worn to prevent inhalation of harmful particles that may be released into the air during operation.

These protective measures are vital for maintaining long-term health and safety while working with this powerful tool. In addition to eye and respiratory protection, operators should wear gloves designed for heavy-duty work. However, it is crucial to choose gloves that fit snugly and do not have loose cuffs or dangling material that could become entangled in the grinder.

Hearing protection, such as earplugs or earmuffs, is also recommended due to the high noise levels produced by the machine. Finally, wearing sturdy footwear with slip-resistant soles can help prevent slips and falls in the workshop environment. By equipping oneself with the right PPE, operators can significantly reduce their risk of injury while using a 2×72 grinder.

Setting Up a Safe Workspace for 2×72 Grinder Operations

Creating a safe workspace is paramount when operating a 2×72 grinder. The area should be well-lit and free from clutter to ensure that operators can see clearly and move around without obstruction. It is advisable to designate a specific zone for grinding activities, away from other operations that may pose additional hazards.

This separation helps minimize distractions and allows for focused attention on the task at hand. Furthermore, ensuring that the grinder is placed on a stable surface is essential for safe operation. The workbench or stand should be sturdy enough to absorb vibrations and prevent movement during use.

Additionally, it is important to keep flammable materials away from the grinding area, as sparks generated during operation can ignite nearby substances. By taking these precautions and establishing a well-organized workspace, operators can significantly enhance their safety while using a 2×72 grinder.

Safe Handling and Storage of 2×72 Grinder Accessories

| Accessory | Safe Handling | Storage |

|---|---|---|

| Grinding Belts | Avoid contact with skin while in use. Use appropriate safety gear. | Store in a dry and clean area, away from moisture and direct sunlight. |

| Grinding Wheels | Inspect for any damage before use. Use with proper safety precautions. | Store in a cool, dry place and avoid stacking to prevent damage. |

| Tool Rests | Ensure proper installation and secure positioning before use. | Store in a designated area to prevent damage and ensure easy access. |

| Work Rests | Adjust and secure properly before using the grinder. | Store in a clean and organized manner to prevent misplacement. |

Proper handling and storage of accessories related to the 2×72 grinder are crucial for maintaining safety and efficiency in the workshop. Accessories such as grinding belts, wheels, and attachments should be stored in a designated area that is dry and free from moisture to prevent deterioration. It is essential to inspect these accessories regularly for signs of wear or damage before use.

Using worn or damaged components can lead to accidents or equipment failure during operation. When handling accessories, operators should always follow manufacturer guidelines for installation and removal. This includes ensuring that belts are properly tensioned and aligned before starting the grinder.

Additionally, it is important to use appropriate tools when changing accessories to avoid injury. By adhering to these practices, operators can ensure that their 2×72 grinder remains in optimal working condition while minimizing risks associated with improper handling.

Best Practices for Operating a 2×72 Grinder

Operating a 2×72 grinder requires adherence to best practices to ensure both safety and efficiency. One of the most important practices is to maintain a firm grip on the workpiece while grinding. This helps prevent slippage and allows for better control over the material being worked on.

Operators should also be mindful of their body positioning; standing at an appropriate distance from the grinder while keeping hands clear of moving parts is essential for avoiding accidents. Another best practice involves using the correct grinding technique based on the material being worked on. Different materials require different approaches; for instance, softer metals may need lighter pressure compared to harder materials.

Additionally, taking breaks during prolonged use can help prevent fatigue, which can lead to lapses in concentration and increased risk of injury. By following these best practices, operators can enhance their productivity while ensuring their safety when using a 2×72 grinder.

Common Mistakes to Avoid When Using a 2×72 Grinder

While operating a 2×72 grinder can be straightforward, there are several common mistakes that operators should avoid to ensure safety and efficiency. One frequent error is neglecting to wear appropriate PPE before starting work. Skipping this crucial step can lead to serious injuries from flying debris or exposure to harmful dust particles.

It is vital for operators to make wearing PPE a non-negotiable part of their routine. Another common mistake involves improper setup of the grinder itself. Failing to secure the machine on a stable surface or not checking that all components are correctly installed can lead to accidents during operation.

Additionally, many operators underestimate the importance of regular maintenance checks on their equipment. Ignoring signs of wear or malfunction can result in equipment failure at critical moments, posing significant risks. By being aware of these common pitfalls and taking proactive measures to avoid them, operators can create a safer working environment.

Emergency Procedures for Accidents and Injuries Involving 2×72 Grinders

Despite taking all necessary precautions, accidents can still occur when operating a 2×72 grinder. Therefore, having clear emergency procedures in place is essential for minimizing harm in case of an incident. The first step in any emergency situation is to stop the machine immediately to prevent further injury or damage.

Operators should be familiar with the location of emergency shut-off switches and ensure they are easily accessible. In case of an injury, it is crucial to assess the situation quickly and determine whether first aid is needed or if professional medical assistance should be sought. Having a well-stocked first aid kit readily available in the workshop can make a significant difference in managing minor injuries effectively.

Additionally, all operators should be trained in basic first aid procedures so they can respond appropriately in emergencies. By establishing clear emergency protocols and ensuring all personnel are trained accordingly, workshops can better handle accidents involving 2×72 grinders.

Regular Maintenance and Inspections for 2×72 Grinders

Regular maintenance and inspections are vital for ensuring the longevity and safe operation of 2×72 grinders. Operators should develop a routine maintenance schedule that includes checking belts for wear, inspecting electrical components for damage, and ensuring that all moving parts are lubricated as needed. This proactive approach helps identify potential issues before they escalate into serious problems that could compromise safety.

Additionally, keeping a log of maintenance activities can be beneficial for tracking performance over time and identifying patterns that may indicate underlying issues with the equipment. Operators should also familiarize themselves with the manufacturer’s guidelines regarding maintenance intervals and procedures specific to their model of grinder. By prioritizing regular inspections and maintenance tasks, operators can enhance both safety and efficiency when using their 2×72 grinders, ultimately leading to better results in their projects.

FAQs

What is a 2×72 grinder?

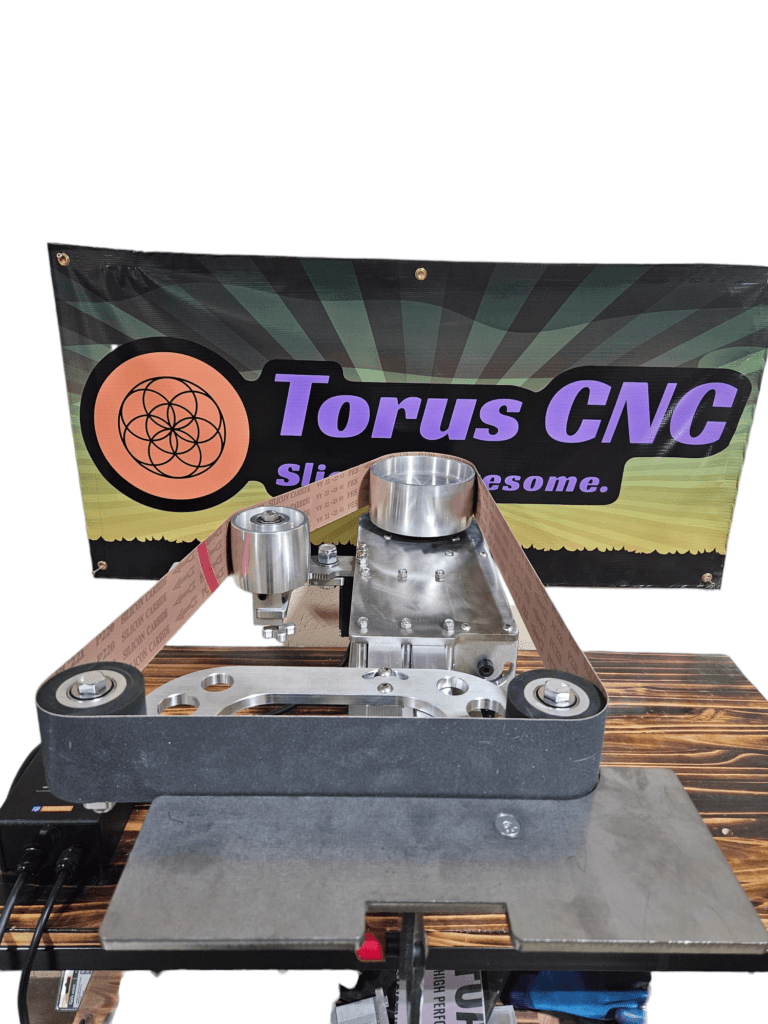

A 2×72 grinder is a type of belt grinder commonly used in metalworking and woodworking. It consists of a motor that drives a belt around two rollers, allowing for material removal and shaping.

What are the safety tips for operating a 2×72 grinder in a small workshop?

Some safety tips for operating a 2×72 grinder in a small workshop include wearing appropriate personal protective equipment, ensuring the grinder is securely mounted, using the appropriate grit and type of belt for the task, and keeping the work area clean and free of clutter.

Why is it important to wear personal protective equipment when operating a 2×72 grinder?

Wearing personal protective equipment such as safety glasses, hearing protection, and gloves is important when operating a 2×72 grinder to protect against potential hazards such as flying debris, noise, and sharp edges.

How should the 2×72 grinder be securely mounted in a small workshop?

The 2×72 grinder should be securely mounted to a stable workbench or stand to prevent movement or tipping during operation. This helps to ensure safe and accurate use of the grinder.

What type of belt should be used for the 2×72 grinder?

The type and grit of the belt used for the 2×72 grinder should be selected based on the specific material and task being performed. Different belts are designed for grinding, shaping, and finishing various types of materials.

Why is it important to keep the work area clean and free of clutter when operating a 2×72 grinder?

Keeping the work area clean and free of clutter when operating a 2×72 grinder is important to prevent tripping hazards, ensure proper ventilation, and maintain a clear line of sight while using the grinder.