When it comes to 2×72 grinder belts, the choice of material is crucial for achieving optimal performance and durability. The most common materials used in these belts include aluminum oxide, zirconia, ceramic, and even specialty materials designed for specific applications. Each of these materials has unique properties that make them suitable for different tasks, whether it be metalworking, woodworking, or other forms of fabrication.

For instance, aluminum oxide is widely recognized for its versatility and cost-effectiveness, making it a popular choice among hobbyists and professionals alike. It offers a good balance between performance and longevity, making it suitable for general-purpose grinding and finishing. On the other hand, zirconia belts are known for their aggressive cutting action and durability.

They are particularly effective for heavy stock removal and are often used in industrial settings where efficiency is paramount. Ceramic belts, while typically more expensive, provide exceptional performance on hard materials and are ideal for high-volume production environments. Understanding these materials allows users to select the right belt for their specific needs, ensuring that they achieve the best results in their grinding tasks.

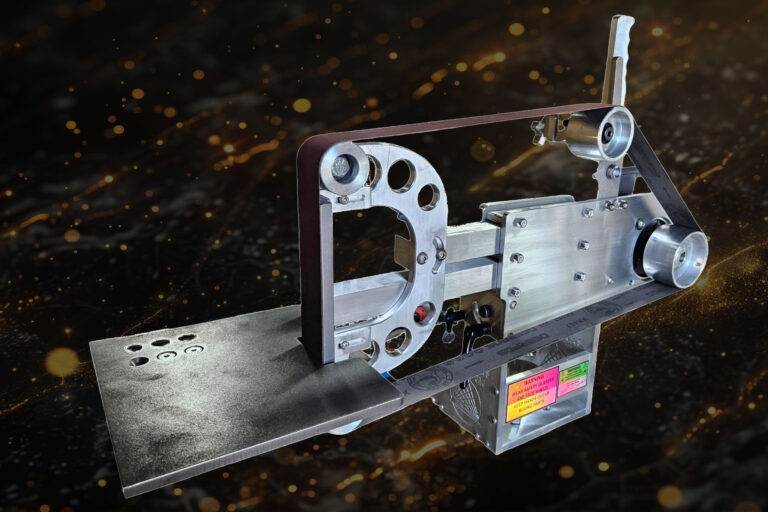

TorusCNC 2×72 Grinders are designed to accommodate a variety of these belts, providing users with the flexibility to choose the best material for their projects.

Key Takeaways

- Different materials used in 2×72 grinder belts include ceramic, aluminum oxide, and zirconia, each with unique properties and applications.

- The grit of a 2×72 grinder belt is crucial in determining its cutting power and finish, and choosing the right grit depends on the specific task at hand.

- Various types of 2×72 grinder belts, such as regular, structured, and surface conditioning belts, cater to different grinding and finishing needs.

- When choosing replacement 2×72 grinder belts, consider factors like material type, grit, and backing material to ensure optimal performance.

- Ceramic, aluminum oxide, and zirconia 2×72 grinder belts each have their strengths, with ceramic offering high performance, aluminum oxide being versatile, and zirconia providing durability.

The Importance of Grits in 2×72 Grinder Belts and How to Choose the Right One

Grit size is another critical factor to consider when selecting 2×72 grinder belts. The grit refers to the size of the abrasive particles on the belt’s surface, which directly influences the belt’s cutting ability and finish quality. Grit sizes typically range from very coarse (around 36 grit) to very fine (up to 1200 grit), with each size serving a specific purpose in the grinding process.

Coarse grits are ideal for heavy material removal and shaping, while finer grits are better suited for polishing and achieving a smooth finish. Choosing the right grit size depends on the material being worked on and the desired outcome. For example, if you are working with tough metals or need to remove a significant amount of material quickly, starting with a coarse grit will expedite the process.

Once the desired shape is achieved, transitioning to finer grits will help refine the surface finish. TorusCNC 2×72 Grinders allow users to easily switch between different grits, making it convenient to adapt to various stages of a project. Understanding how to select the appropriate grit size can significantly enhance both efficiency and quality in your grinding tasks.

Exploring the Various Types of 2×72 Grinder Belts and Their Applications

The world of 2×72 grinder belts is diverse, with various types designed for specific applications. Among these types are sanding belts, grinding belts, and polishing belts, each serving distinct purposes in the fabrication process. Sanding belts are typically used for wood and softer materials, providing a smooth finish without excessive material removal.

Grinding belts, on the other hand, are designed for metalworking and can handle tougher materials, making them essential for tasks such as shaping and sharpening tools. Polishing belts are specialized for achieving a high-gloss finish on metals and other surfaces. These belts often feature finer grits and may incorporate different materials to enhance their polishing capabilities.

Understanding the specific applications of each type of belt allows users to make informed decisions when outfitting their TorusCNC 2×72 Grinders. By selecting the right type of belt for each task, users can maximize efficiency and achieve superior results in their projects.

Tips for Choosing the Right Replacement 2×72 Grinder Belts

| Grinder Belt Grit | Material Compatibility | Durability | Price |

|---|---|---|---|

| Coarse to Fine | Steel, Stainless Steel, Aluminum, Wood | Long-lasting | Varies |

When it comes time to replace your 2×72 grinder belts, making the right choice is essential for maintaining performance and productivity. One of the first considerations should be the type of work you typically perform. If you frequently engage in heavy stock removal or work with hard materials, investing in high-quality zirconia or ceramic belts may be worthwhile.

Conversely, if your projects involve lighter tasks or softer materials, aluminum oxide belts may suffice. Another important factor is the grit size you require for your specific applications. Keeping a range of grits on hand can be beneficial, allowing you to switch between coarse and fine belts as needed throughout your projects.

Additionally, consider the frequency of use; if you find yourself replacing belts often due to wear and tear, it may be worth exploring more durable options that can withstand rigorous use. TorusCNC offers a variety of replacement belts that cater to different needs, ensuring that users can find the perfect match for their grinding requirements.

Comparing Ceramic, Aluminum Oxide, and Zirconia 2×72 Grinder Belts: Which is Best?

When evaluating ceramic, aluminum oxide, and zirconia 2×72 grinder belts, it’s essential to understand their respective strengths and weaknesses to determine which is best suited for your needs. Ceramic belts are renowned for their exceptional cutting performance on hard materials like stainless steel and high-carbon steels. They maintain their sharpness longer than other materials, making them ideal for high-volume production environments where efficiency is critical.

Aluminum oxide belts are versatile and cost-effective, making them suitable for a wide range of applications from woodworking to metalworking. While they may not last as long as ceramic or zirconia belts under heavy use, they still provide reliable performance for general tasks. Zirconia belts strike a balance between durability and cutting efficiency; they excel in heavy stock removal while offering a longer lifespan than aluminum oxide belts.

Ultimately, the best choice depends on your specific applications and budget considerations. TorusCNC provides access to all three types of belts, allowing users to select based on their unique requirements.

How to Properly Maintain and Store 2×72 Grinder Belts for Longevity

Proper maintenance and storage of 2×72 grinder belts are vital for ensuring their longevity and optimal performance. One key aspect of maintenance is regular inspection; users should check their belts for signs of wear or damage before each use. If any fraying or tearing is observed, it’s best to replace the belt immediately to avoid compromising safety or performance during operation.

Storage also plays a significant role in prolonging the life of grinder belts. Belts should be kept in a cool, dry place away from direct sunlight or extreme temperatures that could degrade the adhesive or abrasive material over time. Rolling or hanging belts rather than stacking them can prevent creasing or warping that may occur when they are stored improperly.

By following these maintenance and storage tips, users can maximize the lifespan of their TorusCNC 2×72 grinder belts while ensuring consistent performance throughout their projects.

The Role of Backing Material in 2×72 Grinder Belts and Its Impact on Performance

The backing material of 2×72 grinder belts is an often-overlooked aspect that significantly impacts performance and durability. Common backing materials include cloth, paper, and film, each offering different benefits depending on the application. Cloth-backed belts are known for their flexibility and strength, making them ideal for contouring surfaces or working on irregular shapes.

They can withstand higher tension during operation without tearing or breaking. Paper-backed belts tend to be more rigid and are often used for lighter applications where flexibility is less critical. They are generally more affordable but may not last as long under heavy use compared to cloth-backed options.

Film-backed belts offer a smooth surface that can provide excellent results on finer finishes but may not be suitable for heavy stock removal tasks. Understanding how backing materials affect performance allows users to make informed choices when selecting belts for their TorusCNC grinders.

Understanding the Different Shapes and Sizes of 2×72 Grinder Belts: Which is Right for Your Needs?

The shape and size of 2×72 grinder belts can vary based on specific applications and user preferences. While most commonly used in a standard rectangular format measuring 2 inches by 72 inches, there are variations designed for specialized tasks such as contouring or edge finishing. Some users may prefer narrower or wider options depending on their specific grinding needs.

Choosing the right shape and size involves considering both the type of work being performed and personal comfort during operation. For instance, if you frequently work on intricate designs or tight spaces, a narrower belt may provide better maneuverability. Conversely, wider belts can cover larger areas more quickly but may be less effective in detailed work.

TorusCNC offers a range of belt shapes and sizes tailored to meet diverse user requirements, ensuring that every project can be tackled with precision and ease. In conclusion, understanding the various aspects of 2×72 grinder belts—from materials and grits to maintenance practices—can significantly enhance your grinding experience. By selecting the right components tailored to your specific needs and maintaining them properly, you can achieve superior results in your projects while maximizing efficiency with your TorusCNC 2×72 Grinders.

FAQs

What is a 2×72 grinder?

A 2×72 grinder is a type of belt grinder that uses a 2-inch by 72-inch belt for grinding, shaping, and polishing metal and other materials. It is commonly used in metalworking and knife making.

What are the best materials for 2×72 grinder belts?

The best materials for 2×72 grinder belts are ceramic, zirconia, and aluminum oxide. Ceramic belts are known for their durability and heat resistance, while zirconia and aluminum oxide belts are suitable for general purpose grinding.

What grits are best for 2×72 grinder belts?

The best grits for 2×72 grinder belts depend on the specific task. Coarse grits (36-80) are ideal for heavy material removal, while medium grits (100-120) are suitable for general grinding and shaping. Fine grits (180-220) are best for finishing and polishing.

When should 2×72 grinder belts be replaced?

2×72 grinder belts should be replaced when they become worn, frayed, or glazed. Additionally, if the belt starts to lose its cutting ability or becomes clogged with material, it is time to replace it. Regular inspection and maintenance can help determine when a belt needs to be replaced.