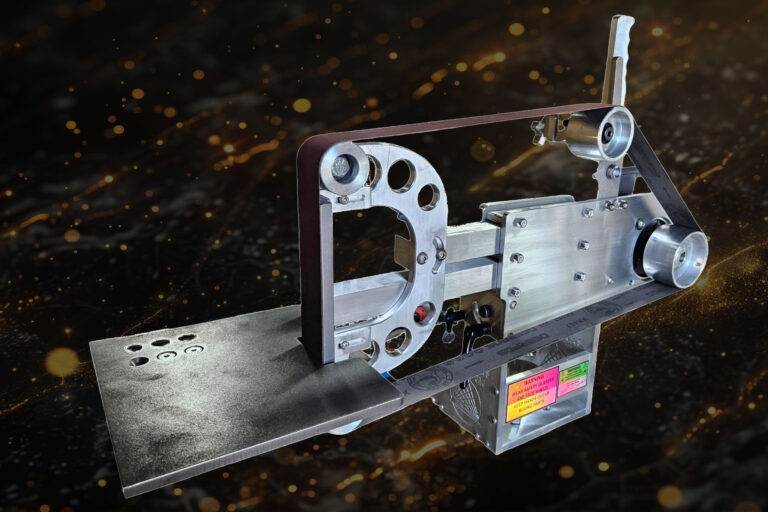

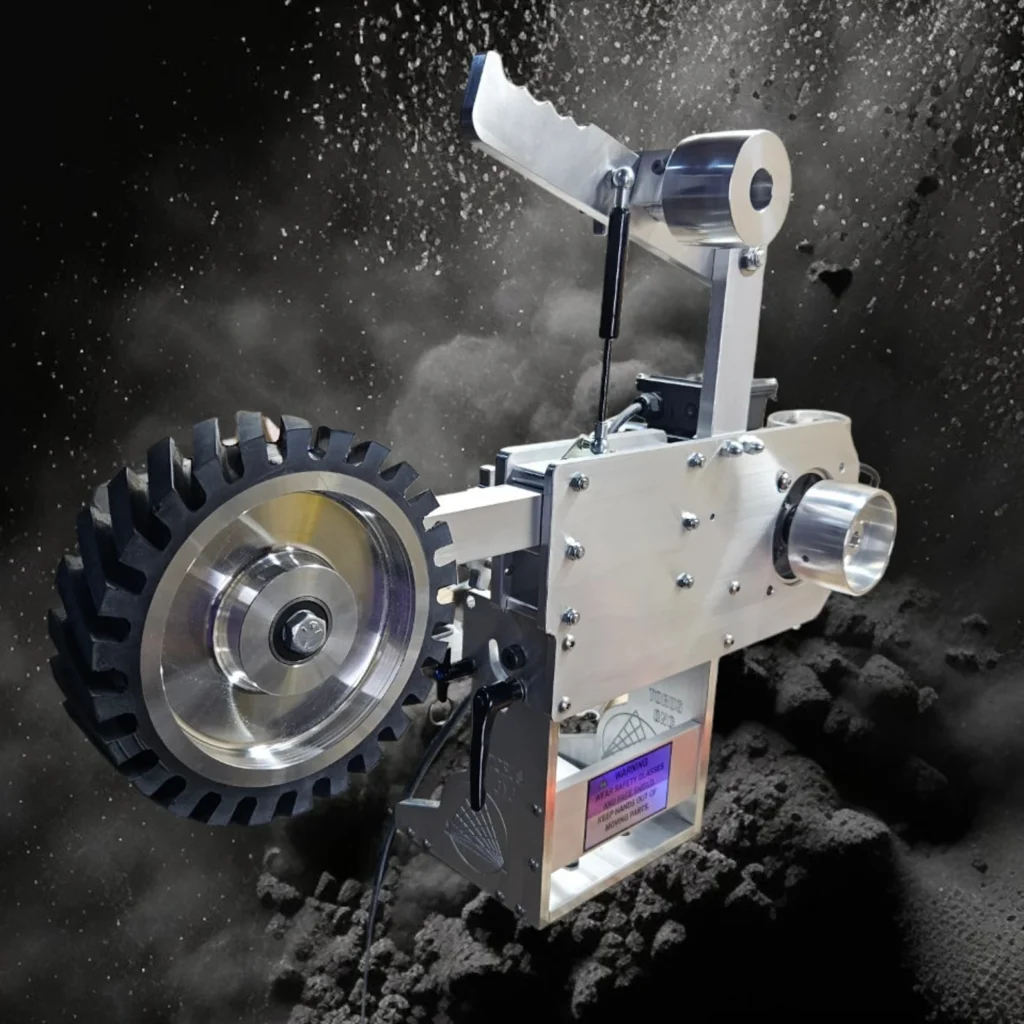

The 2×72 belt grinder is a versatile and powerful tool that has become a staple in many workshops, particularly for metalworking and woodworking applications. The designation “2×72” refers to the dimensions of the sanding belt used by the grinder, which is two inches wide and seventy-two inches long. This size is favored for its ability to provide a large surface area for grinding, shaping, and finishing materials, making it ideal for a variety of tasks, from knife making to metal fabrication.

The extended length of the belt allows for a greater contact area, which can lead to more efficient material removal and smoother finishes. One of the key features of the 2×72 belt grinder is its adaptability. Many models come with adjustable speed settings and interchangeable attachments, allowing users to customize their grinding experience based on the specific requirements of their projects.

This flexibility makes the 2×72 grinder suitable for both beginners and experienced craftsmen alike. Additionally, the design of these grinders often includes a robust frame and powerful motor, ensuring durability and reliability during prolonged use. As a result, the 2×72 belt grinder has earned a reputation as an essential tool for those who demand precision and performance in their work.

Key Takeaways

- A 2×72 belt grinder is a versatile tool used for shaping, sharpening, and polishing metal and wood.

- Other belt grinder sizes, such as 1×30 and 2×48, offer different capabilities and are suitable for specific tasks.

- The 2×72 belt grinder provides a larger grinding surface, higher belt speed, and more power, making it ideal for heavy-duty tasks.

- Smaller belt grinders are more affordable and take up less space, but may lack the power and versatility of a 2×72 grinder.

- When choosing a belt grinder, consider your specific needs, budget, and the availability of different sizes and models.

Exploring Other Belt Grinder Sizes

While the 2×72 belt grinder is widely recognized for its capabilities, other sizes of belt grinders also exist, each with its own unique advantages and applications. Common alternatives include 1×30, 1×42, and 4×36 belt grinders. The 1×30 grinder, for instance, is compact and often more affordable, making it an attractive option for hobbyists or those with limited workspace.

Its smaller size allows for easier maneuverability, but it may not provide the same level of efficiency or versatility as the larger models. On the other hand, the 4×36 belt grinder offers a broader surface area, which can be beneficial for larger projects or when working with bigger pieces of material. However, this size may be less practical for intricate work that requires precision.

Each size of belt grinder serves a specific purpose and caters to different user needs. Understanding these variations can help potential buyers make informed decisions based on their individual requirements and the types of projects they plan to undertake.

Evaluating the Benefits of a 2×72 Belt Grinder

The benefits of using a 2×72 belt grinder are numerous and significant. One of the primary advantages is its efficiency in material removal. The combination of a wide belt and a long length allows users to cover more surface area quickly, making it ideal for tasks that require rapid shaping or finishing.

This efficiency can save valuable time in both professional and hobbyist settings, allowing users to focus on other aspects of their projects. Another notable benefit is the versatility that comes with a 2×72 belt grinder. With various attachments available, users can switch between grinding, sanding, polishing, and even buffing with relative ease.

This adaptability means that one machine can handle multiple tasks, reducing the need for additional equipment and saving space in the workshop. Furthermore, many models are designed to accommodate different types of belts, allowing users to select the appropriate grit for their specific needs. This level of customization enhances the overall user experience and contributes to achieving high-quality results.

Comparing the Pros and Cons of Other Belt Grinder Sizes

| Size | Pros | Cons |

|---|---|---|

| 2×72 | Versatile, widely available accessories | Large and heavy, takes up space |

| 2×48 | Good compromise between size and power | Limited availability of accessories |

| 1×30 | Compact and portable | Less powerful, limited for heavy-duty tasks |

When considering other belt grinder sizes, it is essential to weigh their pros and cons against those of the 2×72 model. For instance, while smaller grinders like the 1×30 are more affordable and easier to store, they may lack the power and efficiency needed for larger projects or more demanding tasks. Users may find themselves limited in their capabilities when working with tougher materials or when attempting to achieve finer finishes.

Conversely, larger grinders such as the 4×36 can handle bigger jobs but may not be as nimble or precise as their smaller counterparts. The bulkiness of these machines can make them cumbersome in tight spaces or when working on intricate designs. Additionally, larger grinders often come with a higher price tag and may require more substantial investment in terms of both space and budget.

Ultimately, understanding these trade-offs is crucial for anyone looking to invest in a belt grinder that best suits their needs.

Determining the Best Belt Grinder for Your Needs

Choosing the best belt grinder involves careful consideration of several factors, including project requirements, available space, and budget constraints. For those who frequently work on larger projects or require high levels of precision, investing in a 2×72 belt grinder may be the most beneficial option. Its efficiency and versatility make it suitable for a wide range of applications, from crafting custom knives to shaping metal components.

On the other hand, if space is limited or if the user primarily engages in smaller projects, a compact model like the 1×30 might be more appropriate. This size offers sufficient functionality for hobbyists without overwhelming their workspace or budget. Ultimately, assessing individual needs and preferences will guide users toward selecting the right belt grinder that aligns with their specific goals and working style.

Cost is often a significant factor when deciding between different sizes of belt grinders. The 2×72 models tend to be priced higher than smaller grinders due to their advanced features and capabilities. However, many users find that the investment pays off in terms of performance and longevity.

The availability of replacement belts and accessories for 2×72 grinders is also generally better than for smaller models, ensuring that users can maintain their equipment without difficulty. In contrast, smaller grinders like the 1×30 are typically more budget-friendly but may require users to compromise on certain features or capabilities. While they can be excellent choices for beginners or those with limited needs, users should consider whether they might outgrow these machines as their skills develop or project demands increase.

Ultimately, weighing cost against functionality will help potential buyers make informed decisions about which size best fits their financial situation while meeting their operational needs.

Exploring Different Brands and Models of Belt Grinders

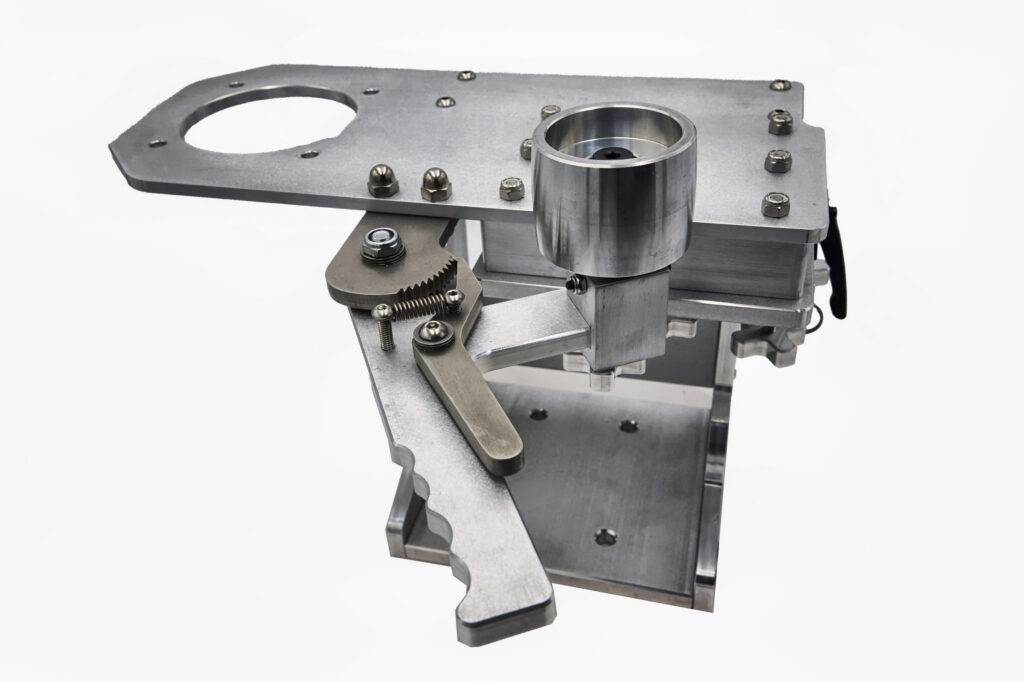

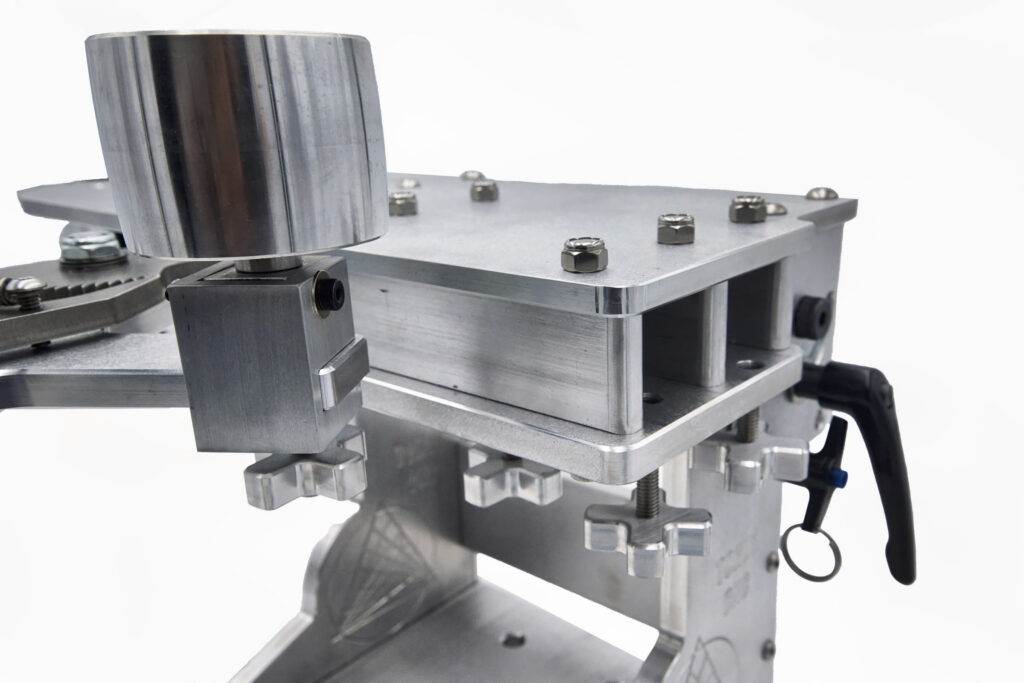

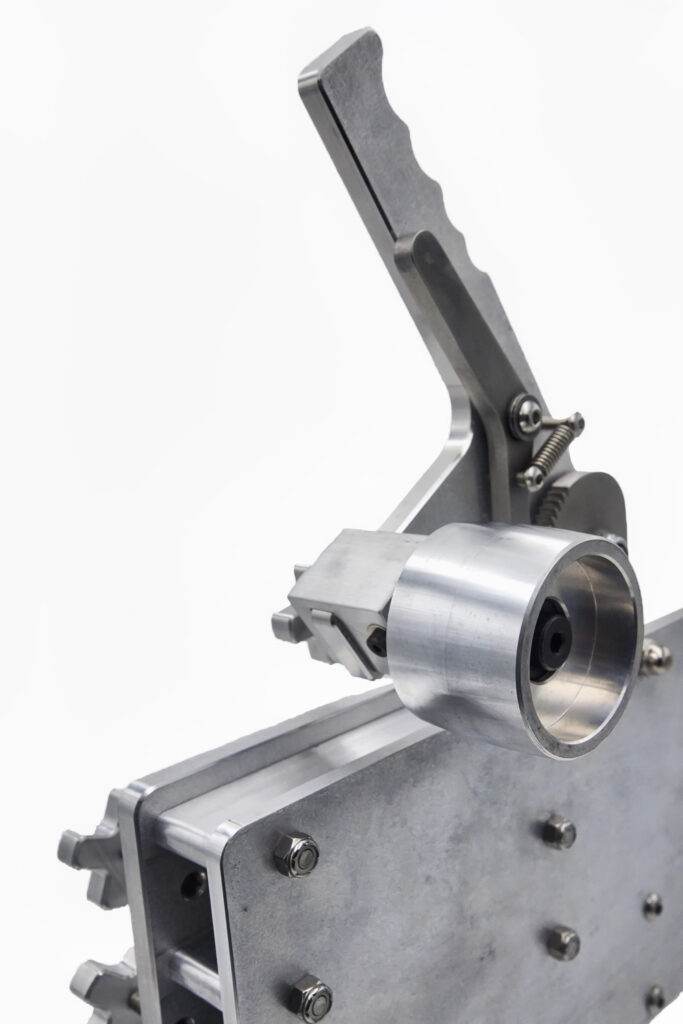

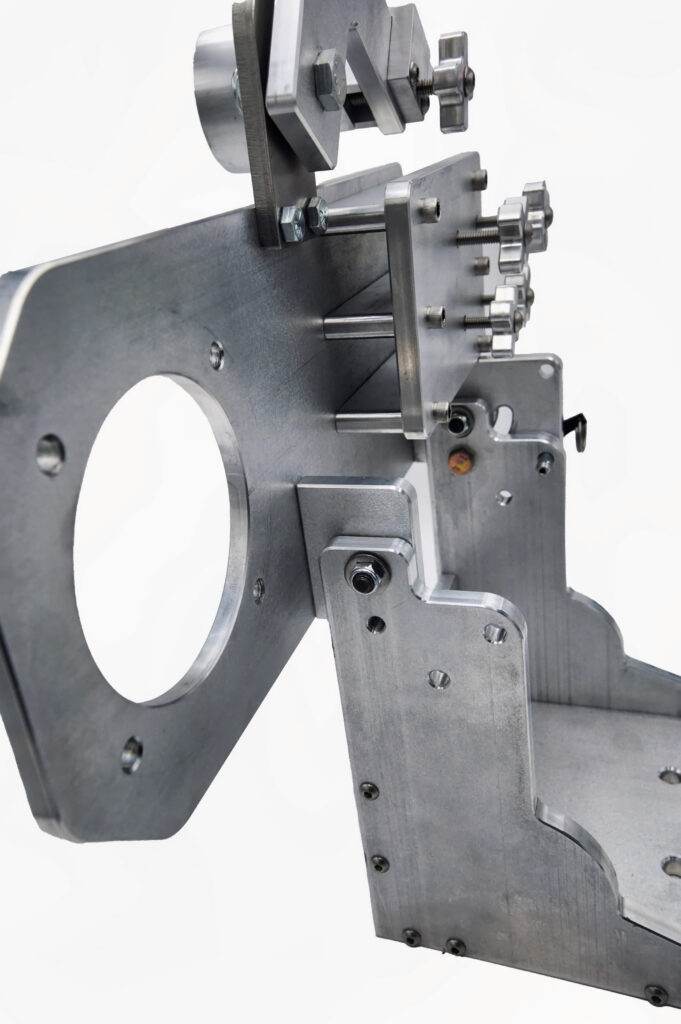

When it comes to selecting a belt grinder, various brands offer models that cater to different user preferences and requirements. TorusCNC is one such brand known for its high-quality 2×72 grinders that combine durability with advanced features tailored for both professionals and hobbyists alike. Their machines are designed with user-friendliness in mind while maintaining robust performance standards.

In addition to TorusCNC, other brands also provide reliable options across various sizes of belt grinders. Each brand typically has its unique selling points—some may focus on affordability while others emphasize advanced technology or specialized attachments. Researching different brands and models allows users to compare specifications, read reviews from other craftsmen, and ultimately choose a machine that aligns with their specific needs and expectations.

Tips for Maintaining and Using Your Belt Grinder

Proper maintenance is crucial for ensuring the longevity and performance of any belt grinder. Regularly checking the tension of the sanding belt is essential; a properly tensioned belt will operate more efficiently and reduce wear on both the belt and the machine itself. Additionally, keeping the work area clean helps prevent debris from interfering with the grinding process and can enhance safety by reducing hazards.

When using a belt grinder, it’s important to adopt safe practices to protect both the user and the equipment. Wearing appropriate personal protective equipment (PPE), such as safety glasses and gloves, is vital when operating any grinding machinery. Furthermore, understanding how to adjust speed settings based on material type can lead to better results while minimizing damage to both the workpiece and the grinding belt itself.

By following these tips for maintenance and safe operation, users can maximize their investment in a belt grinder while achieving high-quality results in their projects.

FAQs

What are the advantages of a 2×72 grinder compared to other belt grinder sizes?

A 2×72 grinder offers a larger grinding surface, which allows for more versatility in terms of the types of projects it can handle. It also typically has more horsepower and speed options, providing greater control and efficiency.

What are the disadvantages of a 2×72 grinder compared to other belt grinder sizes?

One potential disadvantage of a 2×72 grinder is its larger size, which may not be suitable for smaller workspaces. Additionally, the cost of a 2×72 grinder may be higher compared to smaller belt grinder sizes.

What are the common uses for a 2×72 grinder?

A 2×72 grinder is commonly used for metalworking, knife making, and general fabrication. Its larger size and power make it suitable for heavy-duty grinding and shaping tasks.

What are the common uses for other belt grinder sizes?

Smaller belt grinder sizes, such as 1×30 or 2×48, are often used for more precise and detailed work, such as sharpening tools, shaping small metal pieces, and hobbyist projects.

How do I determine which belt grinder size is right for me?

Consider the types of projects you will be working on, the available workspace, and your budget. If you need a larger grinding surface and more power, a 2×72 grinder may be the best choice. For smaller, more detailed work, a smaller belt grinder size may be more suitable.