Folded steel San Mai swords represent a remarkable fusion of artistry and functionality in the world of blade crafting. The term “San Mai” refers to a specific construction technique that involves layering different types of steel to create a blade that is both resilient and aesthetically pleasing. Typically, this method consists of a hard core steel sandwiched between two layers of softer steel.

This unique combination not only enhances the sword’s durability but also allows for a sharp edge that can withstand the rigors of use. The folding process, which is often associated with traditional Japanese sword-making, contributes to the blade’s strength and flexibility, making it a favored choice among martial artists and collectors alike. The beauty of San Mai swords lies not only in their performance but also in their visual appeal.

The contrasting colors and textures of the different steel layers create intricate patterns that are often highlighted through polishing and finishing techniques. Each blade tells a story, reflecting the skill and dedication of the craftsman who forged it. Understanding the intricacies of folded steel San Mai swords is essential for anyone looking to grind or maintain these exceptional blades, as it informs the techniques and precautions necessary to preserve their integrity and beauty.

Key Takeaways

- Folded steel San Mai swords are made by layering different types of steel to create a strong and durable blade with a unique pattern.

- Before grinding, it is important to wear safety gear such as goggles, gloves, and a mask to protect against sparks and metal dust.

- Setting up the workspace involves ensuring a stable and well-lit area with a sturdy workbench and proper ventilation to prevent inhalation of metal particles.

- Choosing the right grinding equipment, such as a belt grinder or angle grinder, is crucial for achieving the desired shape and edge on the sword.

- Proper handling of the sword during grinding involves securing it firmly in a vise and using steady, controlled movements to avoid accidents.

Safety Precautions Before Grinding

Before embarking on the grinding process, it is crucial to prioritize safety. The act of grinding metal can produce sparks, debris, and sharp edges, all of which pose potential hazards. Wearing appropriate personal protective equipment (PPE) is essential.

This includes safety goggles to protect the eyes from flying particles, gloves to shield the hands from sharp edges and heat, and a dust mask to prevent inhalation of metal dust. Additionally, wearing long sleeves and sturdy footwear can further minimize the risk of injury during the grinding process. Another important safety consideration is ensuring that the workspace is free from flammable materials.

The grinding process generates heat and sparks, which can ignite nearby substances if not properly managed. It is advisable to have a fire extinguisher on hand and to work in a well-ventilated area to dissipate any fumes or dust generated during grinding. By taking these precautions seriously, you can create a safer environment that allows you to focus on the task at hand without unnecessary distractions or risks.

Setting Up the Workspace

Creating an efficient workspace is vital for successful grinding, especially when working with folded steel San Mai swords. A well-organized area not only enhances productivity but also contributes to safety. Start by selecting a sturdy workbench or table that can accommodate your grinding equipment and provide ample space for maneuvering the sword.

Ensure that the surface is clean and free from clutter, as this will help prevent accidents and allow for better focus on the task. Lighting is another critical aspect of setting up your workspace. Adequate illumination will enable you to see the details of the blade clearly, ensuring precision during grinding.

Consider using adjustable task lights that can be directed toward your work area for optimal visibility. Additionally, having all necessary tools and materials within arm’s reach will streamline the process and minimize interruptions. By taking the time to set up your workspace thoughtfully, you lay the groundwork for a successful grinding experience.

Choosing the Right Grinding Equipment

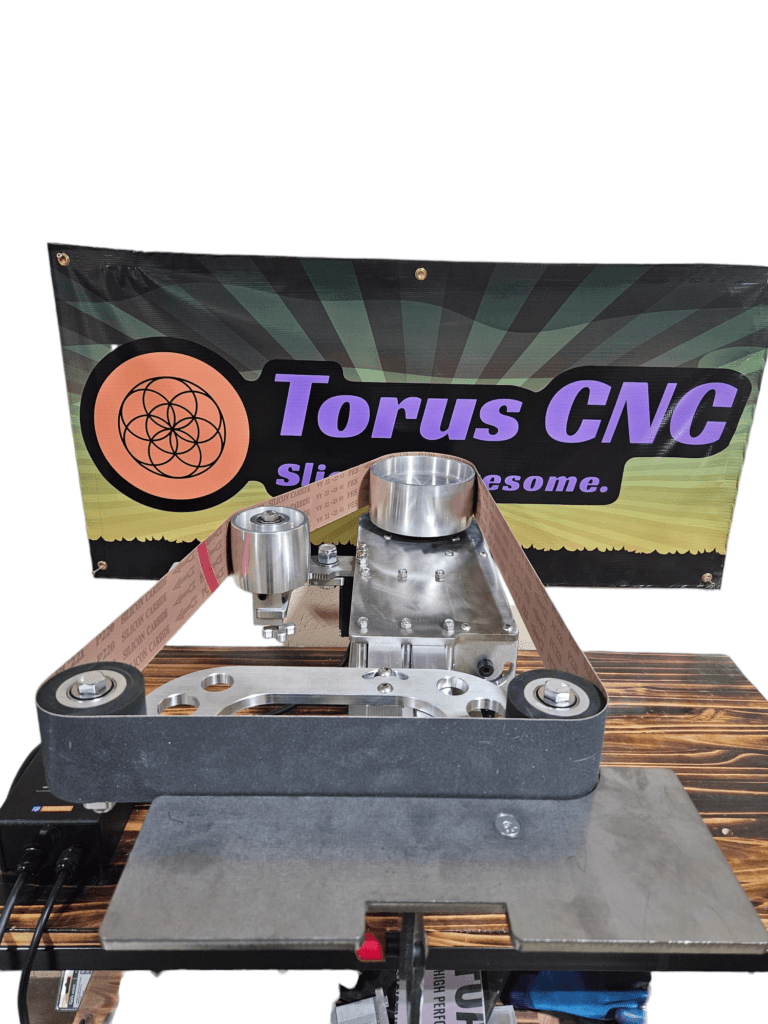

Selecting the appropriate grinding equipment is essential for achieving the desired results when working with folded steel San Mai swords. The type of grinder you choose will significantly impact the efficiency and quality of your work. Belt grinders are popular among swordsmiths due to their versatility and ability to remove material quickly while providing a smooth finish.

They come in various sizes and configurations, allowing you to select one that best suits your needs. In addition to the grinder itself, choosing the right grinding belts or wheels is equally important. Different materials and grits are available, each designed for specific tasks.

For initial material removal, coarser grits are ideal, while finer grits are better suited for finishing touches. It’s also worth considering specialized attachments or accessories that can enhance your grinding capabilities, such as contact wheels or platen attachments. By investing in quality equipment tailored to your specific requirements, you can ensure a more efficient and effective grinding process.

Proper Handling of the Sword

Proper handling of the sword during grinding is crucial for both safety and effectiveness. When gripping the blade, always use both hands to maintain control and stability. This is especially important when working with heavier San Mai swords, as improper handling can lead to accidents or uneven grinding.

Ensure that your grip is firm but not overly tight; this will allow for better maneuverability while reducing fatigue during extended periods of work. Additionally, be mindful of your body positioning while grinding. Stand with your feet shoulder-width apart for balance, and keep your elbows close to your body to maintain control over the blade’s movements.

Avoid leaning too far forward or backward, as this can compromise your stability and increase the risk of injury. By adopting proper handling techniques, you can enhance both your safety and the quality of your work.

Grinding Techniques for Folded Steel

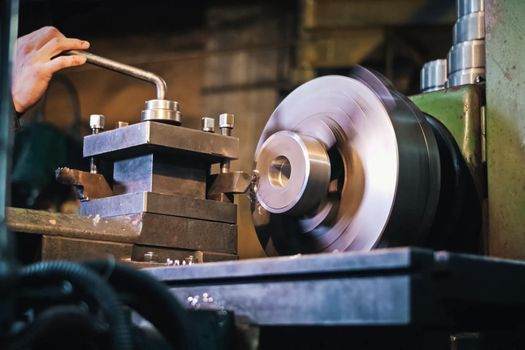

Assessing the Blade and Initial Grinding

When grinding folded steel San Mai swords, it’s crucial to start by assessing the blade’s current condition and determining which areas require more material removal or refinement. For initial grinding, use a coarser grit belt or wheel to remove any imperfections or excess material efficiently.

Achieving an Even Surface and Refining the Edge

Maintain a consistent angle while moving the blade across the grinder to ensure an even surface. As you progress to finer grits, focus on refining the edge and achieving a polished finish. This stage requires patience and attention to detail; take your time to avoid removing too much material too quickly.

Inspecting Progress and Mastering Techniques

Regularly check your progress by inspecting the blade under good lighting conditions, ensuring that you are achieving the desired shape and sharpness without compromising its structural integrity. By mastering these grinding techniques, you can enhance both the performance and aesthetic appeal of your San Mai sword.

Checking for Overheating

One of the most critical aspects of grinding folded steel is monitoring for overheating during the process. Excessive heat can adversely affect the blade’s tempering and overall quality, potentially leading to warping or brittleness. To prevent overheating, take breaks during grinding sessions to allow both the blade and grinder to cool down.

A good rule of thumb is to periodically touch the blade with your hand; if it feels too hot to hold comfortably, it’s time to pause. Additionally, using water or coolant during grinding can help dissipate heat more effectively. Some craftsmen prefer to dip the blade in water periodically or use a spray bottle to mist it while working.

This not only helps maintain an optimal temperature but also reduces friction between the blade and grinder, resulting in smoother operation. By being vigilant about overheating, you can preserve the integrity of your folded steel San Mai sword throughout the grinding process.

Cooling and Cleaning the Sword

After completing the grinding process, cooling and cleaning the sword are essential steps that should not be overlooked. Allowing the blade to cool naturally is important; avoid placing it in cold water immediately after grinding, as this can cause thermal shock and damage the steel structure. Instead, let it rest in a safe area where it can cool gradually while maintaining its shape.

Once cooled, cleaning the sword is vital for removing any metal shavings or debris that may have accumulated during grinding. Use a soft cloth or brush to gently wipe down the blade, ensuring that no particles remain lodged in crevices or along the edge. This step not only enhances appearance but also prevents corrosion or rust from forming on exposed metal surfaces.

By taking care during this cooling and cleaning phase, you set the stage for further inspection and finishing touches.

Inspecting the Sword After Grinding

After completing all grinding processes, thorough inspection of the sword is crucial before moving on to finishing touches. Carefully examine both sides of the blade for any inconsistencies or imperfections that may have arisen during grinding. Look for areas where material may have been removed unevenly or where scratches may still be present from coarser grits.

This inspection allows you to identify any additional work needed before proceeding. Pay special attention to the edge of the sword; it should be sharp and free from nicks or chips that could affect performance during use. If any issues are detected, consider returning to finer grits or utilizing hand tools for touch-ups as necessary.

A meticulous inspection ensures that you address any flaws before applying final finishes, ultimately leading to a higher-quality end product.

Final Touches and Finishing

Once satisfied with your inspection results, it’s time to apply final touches and finishing techniques to enhance both functionality and aesthetics of your folded steel San Mai sword. Start by using finer grit belts or wheels to refine any remaining rough spots on the blade’s surface. This step will help achieve a smooth finish while preparing it for polishing.

Polishing is an essential part of finishing; it not only enhances visual appeal but also protects against corrosion by creating a barrier on the metal surface. Various polishing compounds are available depending on desired results—some may provide a high-gloss finish while others offer a more subdued sheen. Apply polish using a soft cloth or buffing wheel, taking care to cover all areas evenly without leaving residue behind.

By dedicating time to these final touches, you ensure that your San Mai sword not only performs well but also stands out as a work of art.

Maintaining the Sword After Grinding

Maintaining your folded steel San Mai sword after grinding is crucial for preserving its quality over time. Regular maintenance routines should include cleaning after each use; wiping down the blade with a soft cloth helps remove moisture and debris that could lead to rust formation. Additionally, applying a light coat of oil specifically designed for blades can provide an extra layer of protection against corrosion.

Storage also plays an important role in maintaining your sword’s condition. Keep it in a dry environment away from direct sunlight or extreme temperatures that could affect its integrity over time. Consider using a protective sheath or case when storing it long-term; this will help prevent accidental damage while keeping dust at bay.

By implementing these maintenance practices consistently, you can ensure that your folded steel San Mai sword remains in excellent condition for years to come.

FAQs

What is folded steel San Mai swords?

Folded steel San Mai swords are traditional Japanese swords that are made using a technique called San Mai, which involves sandwiching a hard steel core between layers of softer steel. The process of folding the steel creates a distinctive grain pattern on the blade, and also helps to improve the overall strength and flexibility of the sword.

Why is it important to grind folded steel San Mai swords safely?

Grinding folded steel San Mai swords safely is important to ensure that the integrity of the blade is not compromised. Improper grinding techniques can lead to overheating of the steel, which can result in the loss of the blade’s temper and hardness. Additionally, grinding the sword in an unsafe manner can also lead to the risk of injury to the person performing the grinding.

What are some safety precautions to take when grinding folded steel San Mai swords?

Some safety precautions to take when grinding folded steel San Mai swords include wearing appropriate protective gear such as safety goggles, gloves, and a face mask to protect against metal particles and sparks. It is also important to work in a well-ventilated area to avoid inhaling any fumes or dust created during the grinding process. Additionally, using the correct grinding tools and techniques, and ensuring that the blade does not overheat are also important safety measures to take.

What are some common mistakes to avoid when grinding folded steel San Mai swords?

Some common mistakes to avoid when grinding folded steel San Mai swords include using the wrong type of grinding wheel, applying too much pressure while grinding, and allowing the blade to overheat. It is also important to avoid grinding the sword for too long, as this can also lead to overheating and potential damage to the blade. Additionally, not wearing the appropriate protective gear and not working in a well-ventilated area are also common mistakes to avoid.