The pre-quench finishing process is a critical step in the heat treatment of metals, particularly in the production of high-quality knives and tools. This stage involves preparing the metal surface to ensure optimal performance during the quenching phase, which is essential for achieving the desired hardness and durability. During pre-quench finishing, the focus is on refining the surface to remove any imperfections, such as scratches or oxidation, that could adversely affect the final product.

This meticulous preparation not only enhances the aesthetic appeal of the metal but also plays a significant role in its mechanical properties. In essence, pre-quench finishing serves as a bridge between the initial shaping of the metal and its subsequent heat treatment. The process typically involves grinding, sanding, or polishing the surface to achieve a uniform finish.

The quality of this finish can significantly influence the effectiveness of the quenching process, as a smoother surface allows for more even heat distribution. Consequently, understanding the nuances of pre-quench finishing is vital for anyone involved in metalworking, particularly those focused on producing high-performance blades and tools.

Key Takeaways

- Understanding the pre-quench finishing process is essential for achieving high-quality heat-treated parts.

- Selecting the right abrasives is crucial for efficient pre-quench finishing and achieving the desired surface finish.

- Consistent pressure and speed are important factors in pre-quench finishing to ensure uniform results and prevent damage to the workpiece.

- Proper belt tension is key to achieving clean heat treat prep and preventing belt slippage during pre-quench finishing.

- Maintaining proper belt tracking on the 2×72 grinder is essential for achieving precise and consistent pre-quench finishing results.

Selecting the Right Abrasives for Efficient Pre-Quench Finishing

Choosing the appropriate abrasives is paramount for achieving efficient pre-quench finishing. The type of abrasive material used can greatly impact the quality of the finish and the overall efficiency of the process. Common options include aluminum oxide, silicon carbide, and ceramic abrasives, each offering distinct advantages depending on the specific requirements of the project.

For instance, aluminum oxide is known for its durability and versatility, making it suitable for a wide range of applications. In contrast, silicon carbide is ideal for harder materials due to its sharp cutting edges. Moreover, the grit size of the abrasive plays a crucial role in determining the final finish.

Coarser grits are effective for initial material removal, while finer grits are essential for achieving a polished surface. It is important to strike a balance between removing material quickly and maintaining a high-quality finish. By carefully selecting abrasives based on the material being worked on and the desired outcome, metalworkers can enhance their pre-quench finishing process and ensure that their products meet stringent quality standards.

The Importance of Consistent Pressure and Speed in Pre-Quench Finishing

Maintaining consistent pressure and speed during pre-quench finishing is vital for achieving uniform results. Variations in pressure can lead to uneven wear on abrasives and inconsistent finishes across the surface of the metal. For instance, applying too much pressure can cause excessive heat build-up, leading to potential warping or damage to the material.

Conversely, insufficient pressure may result in inadequate material removal, leaving behind imperfections that could compromise the integrity of the final product. Speed is another critical factor that influences the effectiveness of pre-quench finishing. Operating at an optimal speed ensures that abrasives work efficiently without overheating the material.

Different materials may require adjustments in speed to achieve the best results; therefore, understanding how to calibrate both pressure and speed is essential for any metalworker aiming to produce high-quality knives or tools. By focusing on these parameters, craftsmen can enhance their finishing processes and ultimately improve their end products.

Achieving Clean Heat Treat Prep with Proper Belt Tension

Proper belt tension is crucial for achieving clean heat treat preparation during pre-quench finishing. A well-tensioned belt ensures that abrasives maintain consistent contact with the workpiece, which is essential for effective material removal and surface refinement. If the belt is too loose, it may slip or vibrate, leading to an uneven finish and potentially damaging the workpiece.

On the other hand, excessive tension can cause premature wear on both the belt and the machine components. To achieve optimal belt tension, it is important to follow manufacturer guidelines and regularly inspect equipment for wear and tear. Adjusting belt tension should be part of routine maintenance to ensure that machines operate at peak performance.

By prioritizing proper belt tension, metalworkers can enhance their pre-quench finishing processes, resulting in cleaner surfaces that are better prepared for heat treatment.

Tips for Maintaining Proper Belt Tracking on the 2×72 Grinder

Maintaining proper belt tracking on a 2×72 grinder is essential for ensuring efficient pre-quench finishing. Misalignment can lead to uneven wear on belts and inconsistent finishes on workpieces. To prevent tracking issues, it is important to regularly check and adjust the tracking mechanism of the grinder.

This involves ensuring that both pulleys are aligned correctly and that any tracking adjustments are made gradually to avoid sudden shifts that could disrupt operation. Additionally, keeping the grinder clean and free from debris can significantly improve belt tracking performance. Dust and particles can accumulate on pulleys and rollers, leading to misalignment over time.

Regular cleaning routines should be established to maintain optimal conditions for grinding operations. By focusing on proper belt tracking techniques, metalworkers can enhance their efficiency during pre-quench finishing and achieve superior results.

Utilizing Jigs and Fixtures for Precise Pre-Quench Finishing

Eliminating Movement and Inconsistencies

Securing workpieces in place, jigs help eliminate movement that could lead to uneven finishes or inaccuracies in dimensions. This ensures that the finished product meets the required standards, reducing the need for rework and improving overall quality.

Customization for Specific Projects

Jigs can be customized to accommodate specific projects or materials, further enhancing their utility in pre-quench finishing. For instance, a jig designed for knife blades can ensure that each blade receives uniform treatment across its entire surface area.

Improved Efficiency and Quality

The use of jigs and fixtures not only improves the quality of the finish but also contributes to overall efficiency by reducing setup time and minimizing errors during production. By streamlining the pre-quench finishing process, manufacturers can increase productivity and reduce costs.

Minimizing Heat Build-up During Pre-Quench Finishing

Minimizing heat build-up during pre-quench finishing is essential for preserving the integrity of metalwork pieces. Excessive heat can alter material properties, leading to warping or other forms of damage that compromise performance. To mitigate heat generation, metalworkers should employ techniques such as using appropriate feed rates and maintaining consistent pressure during grinding or sanding operations.

Incorporating cooling methods can also be beneficial in managing heat build-up. For instance, using water or coolant during grinding can help dissipate heat effectively while prolonging the life of abrasives. Additionally, taking breaks between operations allows both the workpiece and equipment to cool down, further reducing the risk of heat-related issues.

By implementing these strategies, craftsmen can ensure that their pre-quench finishing processes yield high-quality results without compromising material integrity.

The Role of Cooling Systems in Efficient Pre-Quench Finishing

Cooling systems play a pivotal role in enhancing efficiency during pre-quench finishing processes. These systems are designed to regulate temperatures by providing a steady flow of coolant or air to dissipate heat generated during grinding or sanding operations. By maintaining optimal temperatures, cooling systems help prevent thermal damage to workpieces while also extending the lifespan of abrasives.

In addition to protecting materials from heat-related issues, cooling systems can improve overall productivity by allowing metalworkers to operate at higher speeds without fear of overheating. This increased efficiency translates into faster turnaround times and improved output quality. Investing in effective cooling solutions is therefore essential for anyone looking to optimize their pre-quench finishing processes while ensuring high standards of craftsmanship.

Troubleshooting Common Issues in Pre-Quench Finishing

Troubleshooting common issues in pre-quench finishing is an important skill for metalworkers aiming to maintain high-quality standards in their production processes. One frequent problem encountered is uneven finishes caused by inconsistent pressure or misaligned equipment. To address this issue, it is crucial to regularly inspect machinery settings and make necessary adjustments to ensure uniformity throughout operations.

Another common challenge is excessive wear on abrasives, which can lead to decreased efficiency and poor surface quality. To combat this problem, metalworkers should monitor abrasive performance closely and replace worn belts or discs promptly. Additionally, maintaining proper belt tension and tracking can help extend abrasive life while ensuring consistent results during pre-quench finishing.

Best Practices for Safety and Personal Protective Equipment during Pre-Quench Finishing

Safety should always be a top priority during pre-quench finishing operations. The use of personal protective equipment (PPE) is essential for safeguarding against potential hazards associated with grinding or sanding processes. Essential PPE includes safety goggles to protect eyes from flying debris, gloves to shield hands from sharp edges or hot surfaces, and respiratory protection if dust or fumes are generated during operations.

In addition to wearing appropriate PPE, implementing best practices such as maintaining a clean workspace and ensuring proper ventilation can further enhance safety during pre-quench finishing tasks. Regular training sessions on equipment operation and safety protocols should also be conducted to keep all personnel informed about potential risks and how to mitigate them effectively.

Maximizing Efficiency and Quality in Pre-Quench Finishing with Proper Maintenance and Cleaning Practices

Maximizing efficiency and quality in pre-quench finishing requires a commitment to proper maintenance and cleaning practices. Regularly scheduled maintenance checks help identify potential issues before they escalate into significant problems that could disrupt production timelines or compromise product quality. This includes inspecting belts for wear, checking alignment on grinders, and ensuring that all components are functioning optimally.

Cleaning practices are equally important; keeping equipment free from dust and debris not only enhances performance but also contributes to safety by reducing fire hazards associated with accumulated materials. Establishing a routine cleaning schedule ensures that machines remain in peak condition while also promoting a safe working environment. By prioritizing maintenance and cleanliness, metalworkers can achieve superior results in their pre-quench finishing processes while maximizing overall efficiency.

FAQs

What is pre-quench finishing in heat treatment?

Pre-quench finishing is the process of preparing a metal workpiece for heat treatment by refining its surface to achieve the desired finish and dimensions before the quenching process.

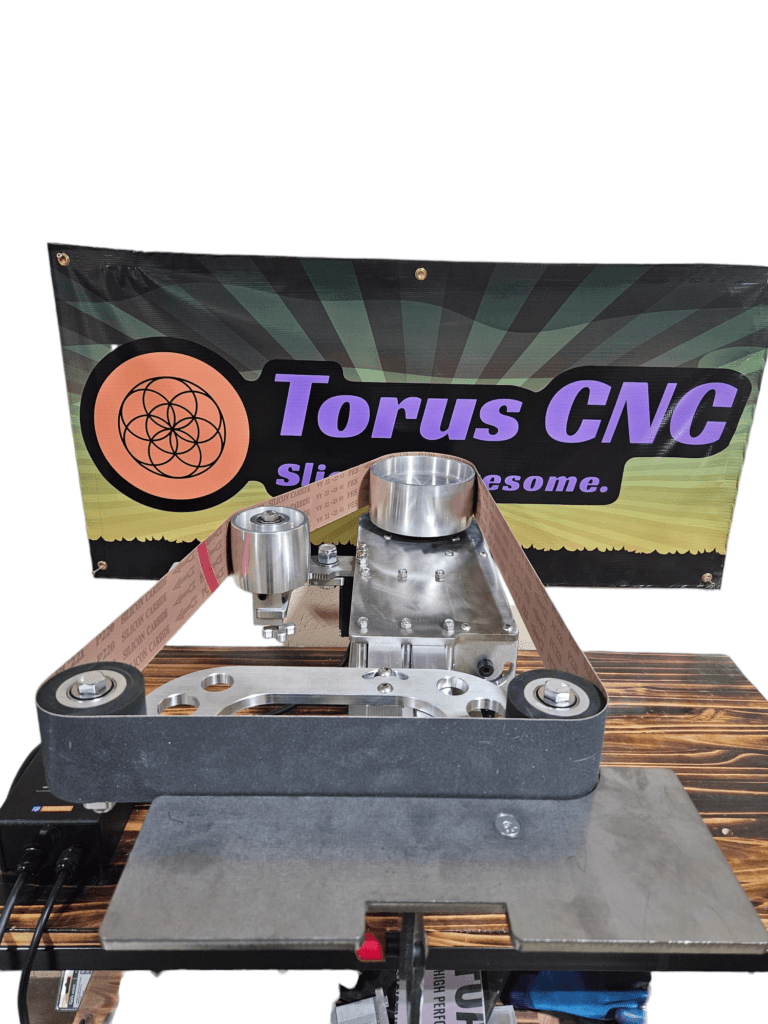

What is a 2×72 in the context of pre-quench finishing?

In the context of pre-quench finishing, a 2×72 refers to a belt grinder with a 2-inch by 72-inch belt, commonly used for shaping and finishing metal workpieces.

How does pre-quench finishing on the 2×72 reduce cleanup in heat treatment?

Pre-quench finishing on the 2×72 allows for precise shaping and smoothing of the metal workpiece, reducing the amount of post-heat treatment cleanup required and minimizing the risk of distortion or damage to the workpiece.

What are the benefits of using a 2×72 for pre-quench finishing?

Using a 2×72 for pre-quench finishing offers benefits such as increased efficiency, improved accuracy, and the ability to achieve a consistent finish on metal workpieces, ultimately leading to reduced cleanup and improved overall quality of the heat-treated parts.