Choosing the Right Knife Handle Material: Organic vs. Manmade, and How to Shape Them Using Your Torus 2×72 Grinder

When crafting a knife, selecting the right handle material is as important as choosing the blade steel. The handle not only affects the knife’s appearance but also its durability, grip, and overall functionality. Whether you’re making a custom blade for yourself or for a client, you’ll need to consider the pros and cons of various materials. These materials typically fall into two categories: organic and manmade. In this post, we’ll take a closer look at some popular knife handle materials—including G10, Micarta, bone, wood, stabilized wood, and mammoth tooth—and how to shape them using a Torus 2×72 grinder.

Organic vs. Manmade Knife Handle Materials

Organic Materials: These include natural substances like wood, bone, and other animal materials. Organic materials are often sought for their unique beauty and natural aesthetics. They can develop a patina over time and offer a sense of connection to the natural world.

Manmade Materials: Manmade materials like G10, Micarta, and stabilized wood are engineered for durability, strength, and uniformity. They are often chosen for their resistance to environmental factors like moisture, heat, and impact, making them great choices for performance-oriented knives.

Popular Knife Handle Materials

- G10: The Durable Workhorse

- Type: Manmade (Fiberglass and Resin Composite)

- Pros: Extremely durable, lightweight, and resistant to water and chemicals. G10 is one of the toughest materials available and can withstand harsh environments.

- Cons: Can be tough to shape without the right equipment due to its hardness.

- Micarta: The Flexible Composite

- Type: Manmade (Fabric or Paper and Resin Composite)

- Pros: Similar to G10 in terms of durability, but Micarta offers more flexibility and a smoother texture. It’s also highly resistant to environmental damage.

- Cons: Although it’s easier to shape than G10, it can still be difficult on the grinder if not properly managed.

- Bone: The Traditional Classic

- Type: Organic (Natural Animal Bone)

- Pros: Bone provides a classic, timeless look and feels warm to the touch. It’s a favorite among custom knife makers due to its organic beauty and unique patterns.

- Cons: Bone is more prone to cracking or chipping compared to synthetic materials. It also needs to be properly stabilized to avoid deterioration.

- Wood: The Versatile Favorite

- Type: Organic (Natural Wood)

- Pros: Wood is classic, aesthetic, and versatile. It offers a natural, tactile feel and can be shaped into intricate designs.

- Cons: Wood is susceptible to moisture and environmental damage, which can cause it to swell, crack, or warp over time.

- Stabilized Wood: The Best of Both Worlds

- Type: Organic (Wood that’s been impregnated with resin)

- Pros: Stabilized wood maintains the natural beauty of wood while offering the enhanced durability of synthetic materials. It resists moisture and environmental damage better than untreated wood.

- Cons: Some stabilized woods can be expensive, and the process of stabilizing wood is time-consuming.

- Mammoth Tooth: The Rare Gem

- Type: Organic (Fossilized Mammoth Ivory)

- Pros: Mammoth tooth offers a unique, ancient aesthetic and is often considered a luxury material. It’s extremely durable and resists cracking better than bone.

- Cons: It is rare and can be expensive. It also requires extra care when handling due to its fragility.

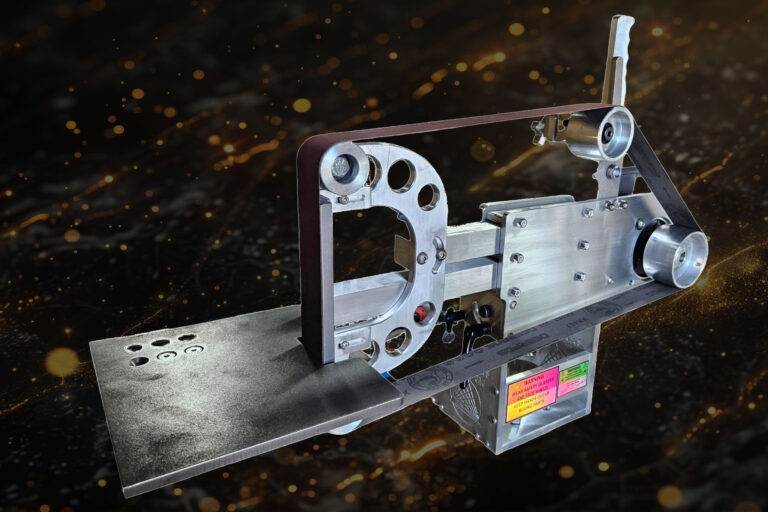

Shaping Knife Handles on the Torus 2×72 Grinder

The Torus 2×72 grinder is a great tool for shaping knife handles. Here are some general tips on how to use it effectively with different materials:

- Start with a Coarse Belt: Always start with a coarse grit belt to remove excess material. This is especially important for harder materials like G10 or Micarta. For softer materials like wood or bone, a medium grit belt may be sufficient.

- Use a Cooling Method: Some materials, like G10 and Micarta, can heat up quickly on the grinder, which can cause them to crack or discolor. Keep a bucket of water nearby to dip the handle material in to cool it down, or pause frequently to allow the material to cool.

- Work in Stages: When shaping, don’t rush. Start by shaping the rough outline of the handle, then move on to refining the contour and smoothing the surface. Using progressively finer grit belts will allow you to achieve a professional finish.

- Polishing and Finishing: After shaping, consider polishing the handle material for an extra layer of protection and a professional finish. For materials like wood and bone, a polishing compound can help bring out their natural luster.

- Dust Management: Some materials, like G10, Micarta, and stabilized wood, can produce harmful dust. Always wear a dust mask and work in a well-ventilated area or use a dust collection system to minimize inhalation.

Conclusion

Choosing the right knife handle material ultimately comes down to personal preference and intended use. Organic materials like wood and bone offer a traditional, aesthetic appeal, while manmade materials like G10 and Micarta are designed for durability and performance. No matter your choice, the Torus 2×72 grinder is an excellent tool to shape and refine your knife handle, ensuring a professional finish and a beautiful, functional result.

Keep making!