About Torus CNC

Where Craftsmanship Meets Precision

Rich Linville

A Legacy of Craftsmanship

I’ve been in the CNC machining and design industry for over 25 years, and let me tell you—I love what I do. It all started in a small garage where I was just tinkering with my first ideas for better grinders. Since then, I’ve grown Torus CNC into a full-scale operation here in Sterling, Illinois, where I still handle everything myself.

“I’m passionate about building high-quality grinders and accessories that help makers, whether you’re just starting out or you’ve been at it for years. Every product that leaves my shop is something I’m proud to put my name on, and I’m here to help you create something exceptional.“

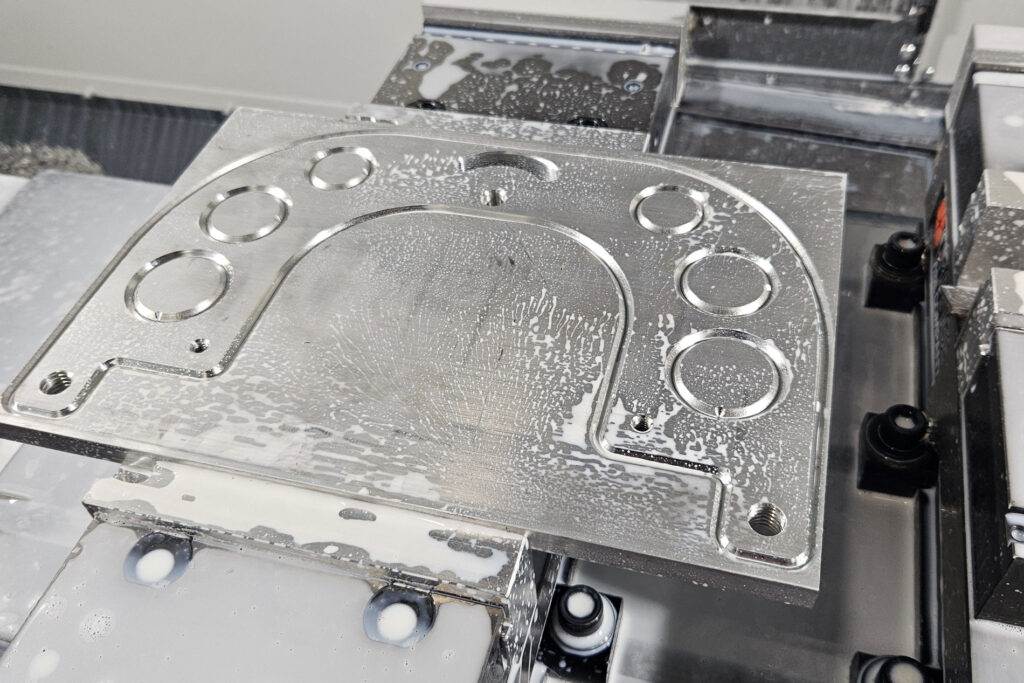

I’m a one-man show, and every grinder and accessory you see is hand-assembled by me right here in Sterling, Illinois. I take pride in using only the best materials like 6061 aluminum and 304 stainless steel and high quality hardware, because I believe in building products that last. My grinders and accessories are designed to take a beating and keep performing at the highest level—because that’s what you deserve.

My Shop in Sterling, Illinois

No big team here—it’s just me

I’m involved in every step of the process because I want to make sure that when you order from Torus CNC, you’re getting something built with care, precision, and a lot of heart.

What I Believe In: Durability, Precision, and Helping You Get the Job Done Right

When it comes to tools, I’ve got a simple philosophy: build them strong, build them right, and make sure they help you work better. That’s why everything I build is focused on durability, precision, and making your workflow smoother.

From grinders to attachments, I make sure each product is something you can rely on—whether you’re tackling a big stock removal job or dialing in the finer details on a blade. My goal is to give you tools that don’t just work—they help you work smarter.

Made in the USA

Precision Quality Comes Standard

350+

Customers

100%

Satisfaction

innovative

Product offerings

What I Build

Tools for Every Maker

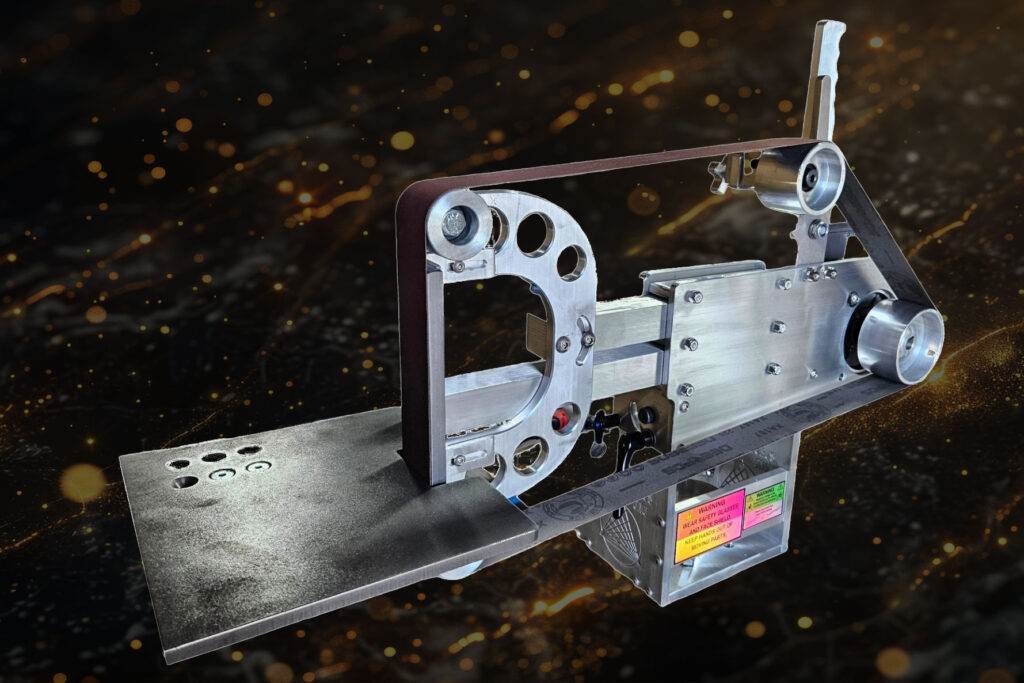

Whether you’re working on knives, metal fabrication, or just need a solid setup for general grinding, I’ve got the products to help you get it done. My signature grinder, the-Torus 2×72-AL Tilting Belt Grinder, is built for flexibility—working in both vertical and horizontal positions for any job you throw at it.

And that’s just the beginning. From small wheel attachments to flat platen accessories and ratchet tensioners, I’ve built out a whole line of accessories so you can customize your setup exactly how you need it. Whatever you’re building, I’ve got the gear to help make it happen.

My Vision

Building Tools That Work for You

The driving force behind Torus CNC has always been the same—helping other craftsmen achieve their best work. I understand that no two makers are the same, and that’s why I’ve designed my products to be flexible and customizable. I want you to have the tools that fit your unique style and help you create something exceptional.

From start to finish, I’m here to help you get the most out of your workshop. If you’re looking for grinders and accessories that are built to last and easy to work with, I’ve got you covered. Shop Torus CNC and let’s get to work!

The History

From the Garage to Precision Engineering

I’ve been in the CNC machining industry for over 25 years, and this journey all started with my first job working for my dad and his business partners here in Sterling, Illinois. Back then, I got my first taste of machining while standing at a drill press for most of the day, learning the ropes of the trade. In 1996, my Dad’s shop purchased its first HAAS CNC VF1, and I was hooked. The precision, the power—seeing what a CNC machine could do made me realize that this was something I wanted to be a part of long-term.

When my Dad eventually sold the business to a third party, I knew I had to be prepared for whatever came next, so I went back to community college to earn certificates in CNC and CAD. That decision gave me the confidence and skills to carve out my own path, just in case the new owner outsourced the work. But as fate would have it, those skills set me up for something even better—starting Torus CNC.

How Torus CNC Began

From the Garage to a Full-Scale Shop

The idea for Torus CNC was born in my garage, inspired by something as simple as wanting my own grinder for metalworking and knifemaking. I’d been watching shows like Forged in Fire, and I knew I needed a grinder—but the price tags were steep, way out of my range. So I decided to design one myself.

In 2019, I bought my first HAAS MiniMill, and that’s when things started to take shape. Self-employment had always been a dream of mine, and buying that MiniMill was the first big step toward making it happen. I set up shop, got to work, and haven’t looked back since.

Today, I run a full-scale operation out of Sterling, Illinois, and I’m still very much a one-man show. I design, build, and assemble every grinder and accessory myself because I believe that attention to detail makes all the difference. My goal? To build the kind of tools I wanted when I was getting started—reliable, high-quality grinders that deliver top-tier performance.